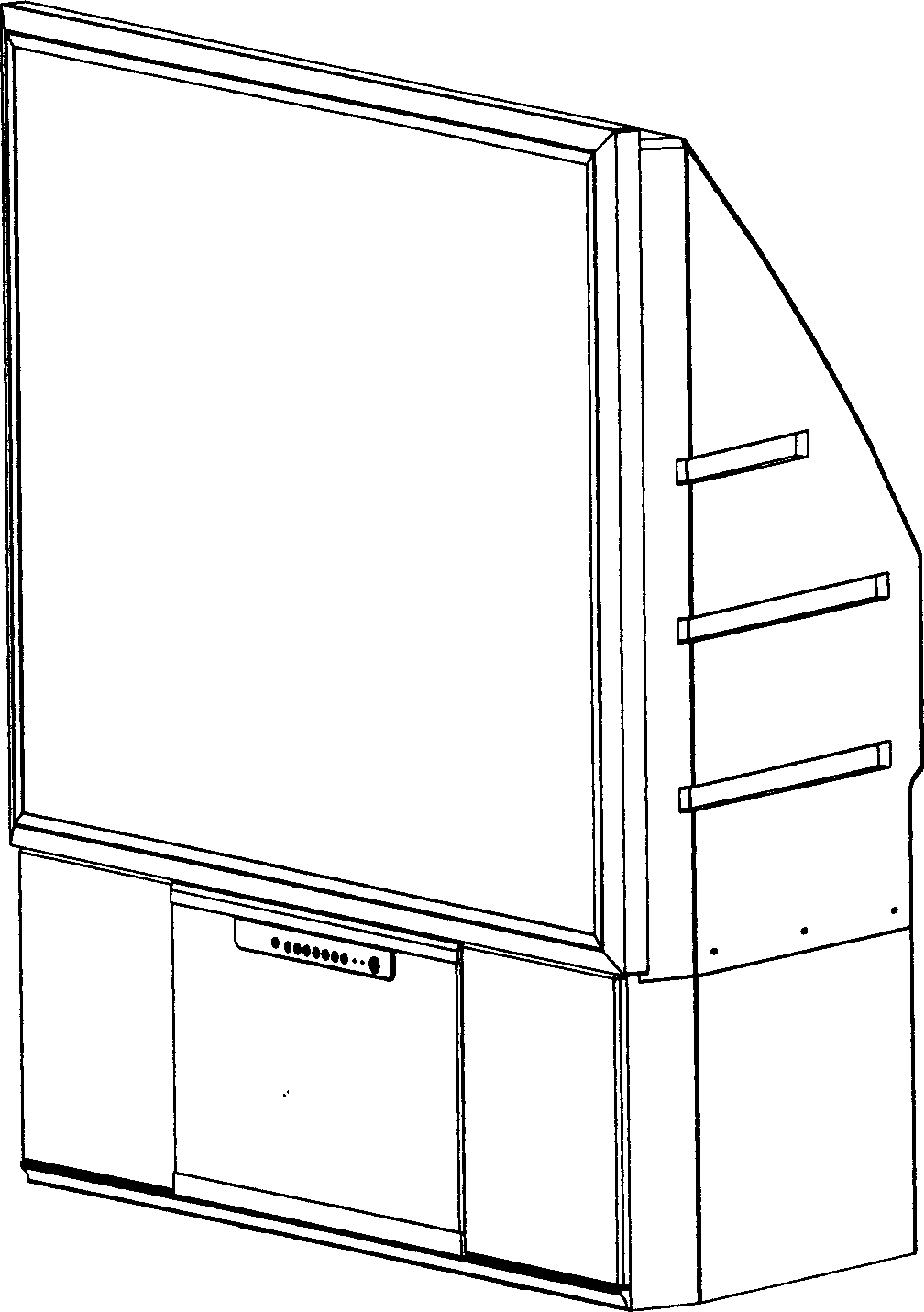

Digital light display rear projector and its face frame producing method

A manufacturing method and digital light technology, applied in the field of digital optical display rear projection, can solve the problems of high cost of digital optical display rear projection, and achieve the effect of shortening development cycle, short manufacturing cycle, and reducing development and manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

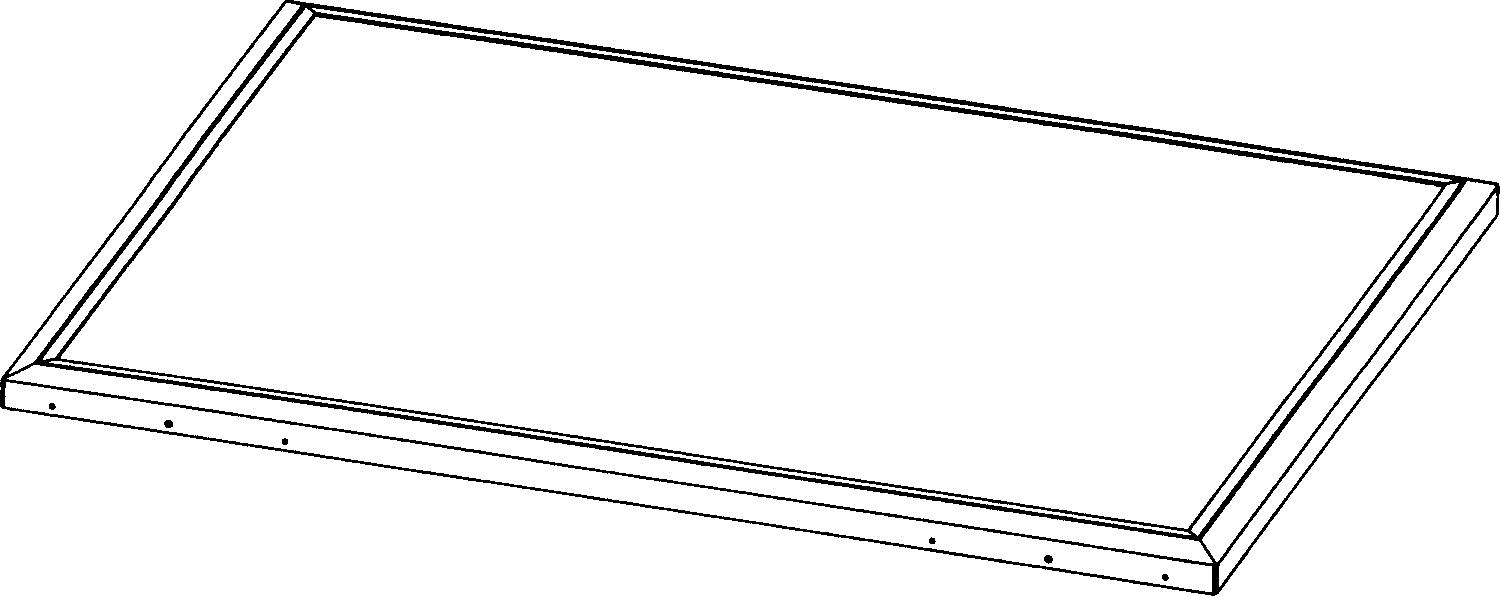

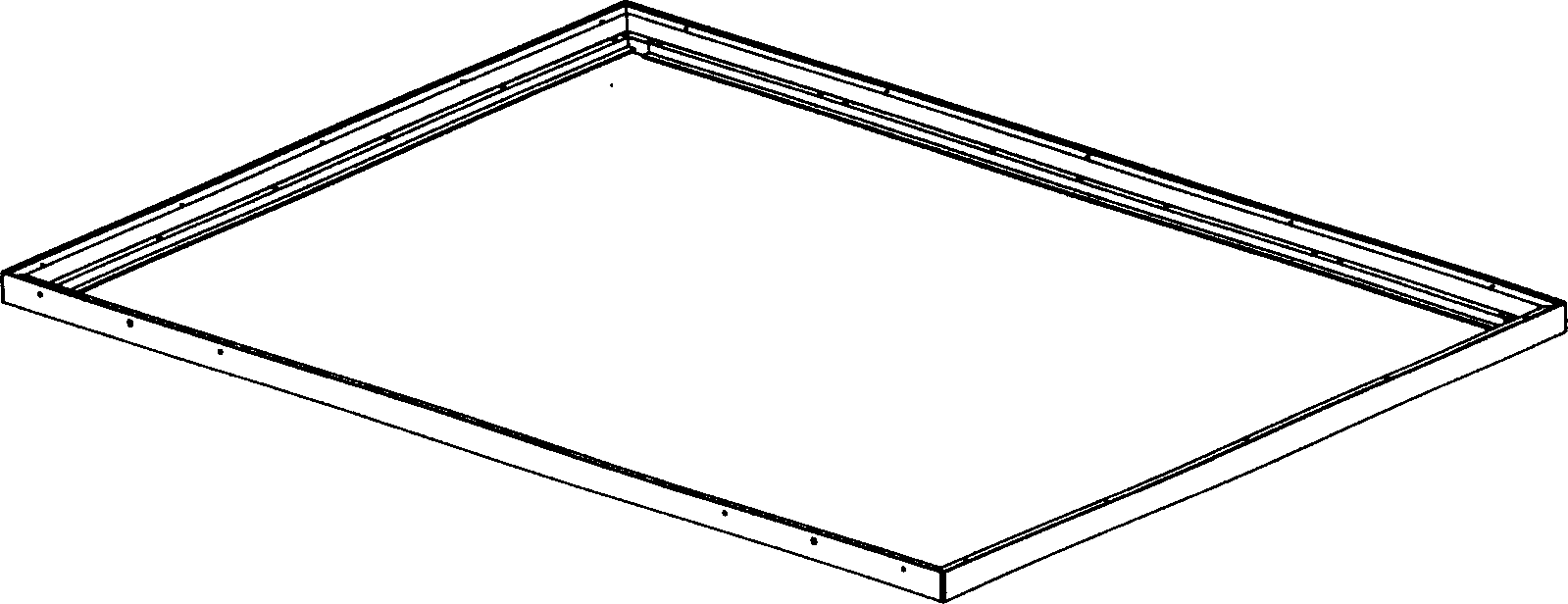

[0021] Such as Figure 4 Shown is a best embodiment of the present invention, the flow process of making the aluminum profile surface frame is: first carry out the aluminum profile cross-section design, and then extrude the heated molten aluminum from the die cross-section by extrusion, according to the Cut off the required length, and then process some required holes for locking screws to fix other parts on it, and then process the splicing end faces so that four matching aluminum profiles can form a quadrilateral frame, such as figure 2 , 3 shown. Because it is impossible to directly form columns on aluminum profiles, they can only be installed after processing, or a certain shape of section is designed, and then holes are drilled on the surface specially designed for screw holes. If the cross-sections of two adjacent aluminum profiles are different, the method of processing the splicing end faces is as follows: process the end faces of two adjacent aluminum profiles into...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com