Partition wall installing base

A technology of mounting seat and mounting groove, applied in the field of support device and shock absorption, can solve the problems of passenger fatigue and increase the discomfort of the journey, and achieve the effect of enhancing comfort and reducing noise.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

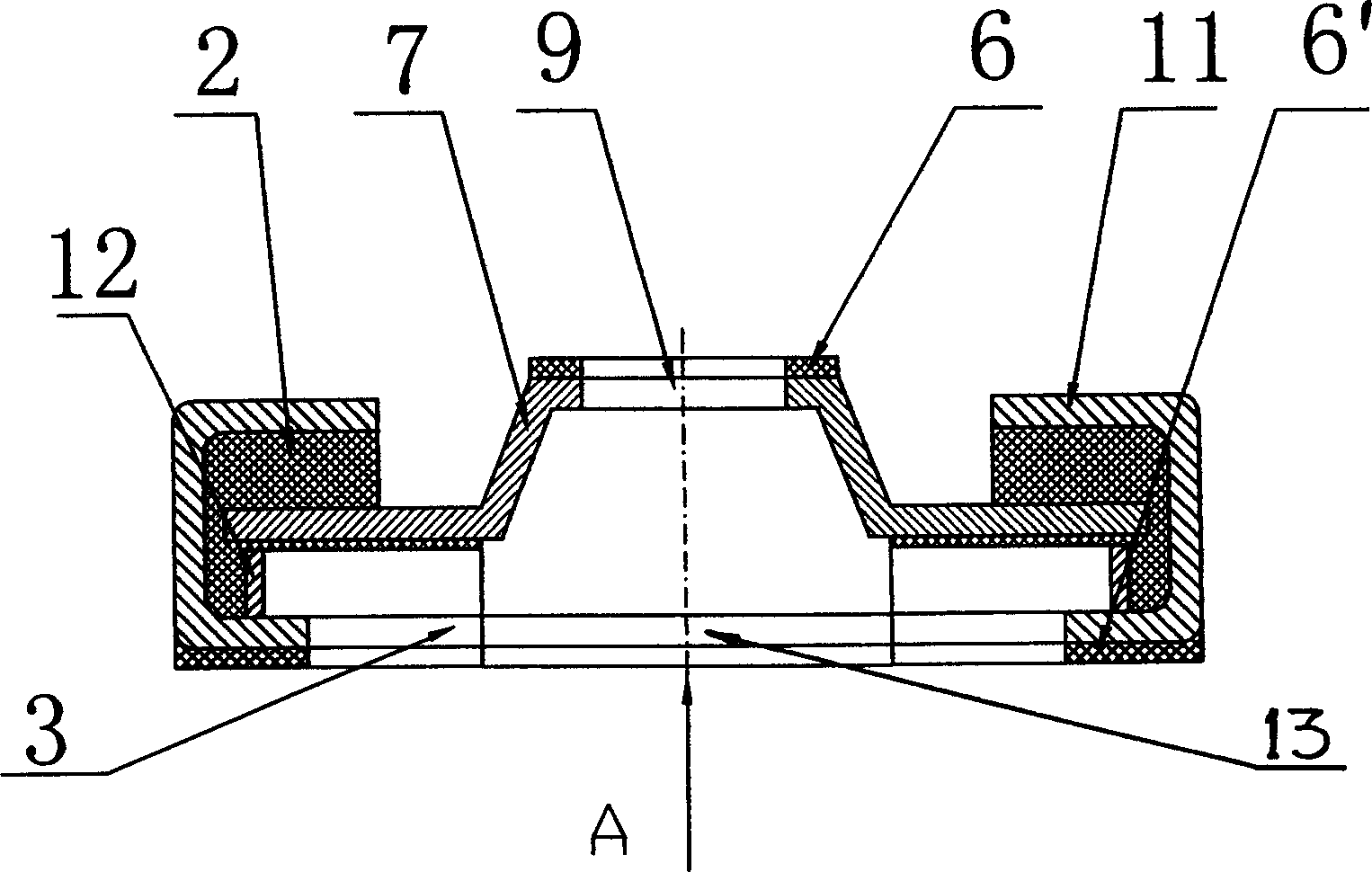

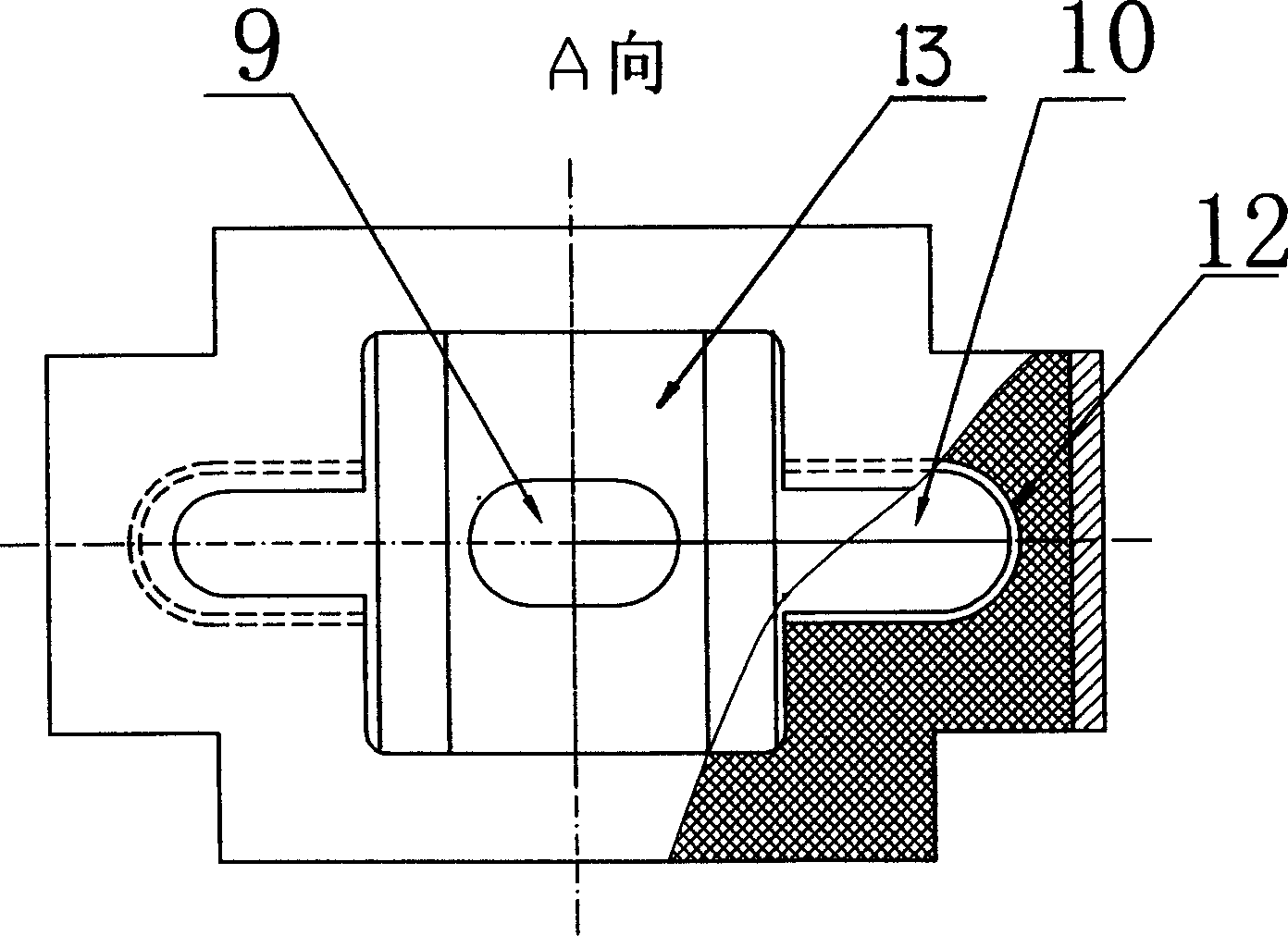

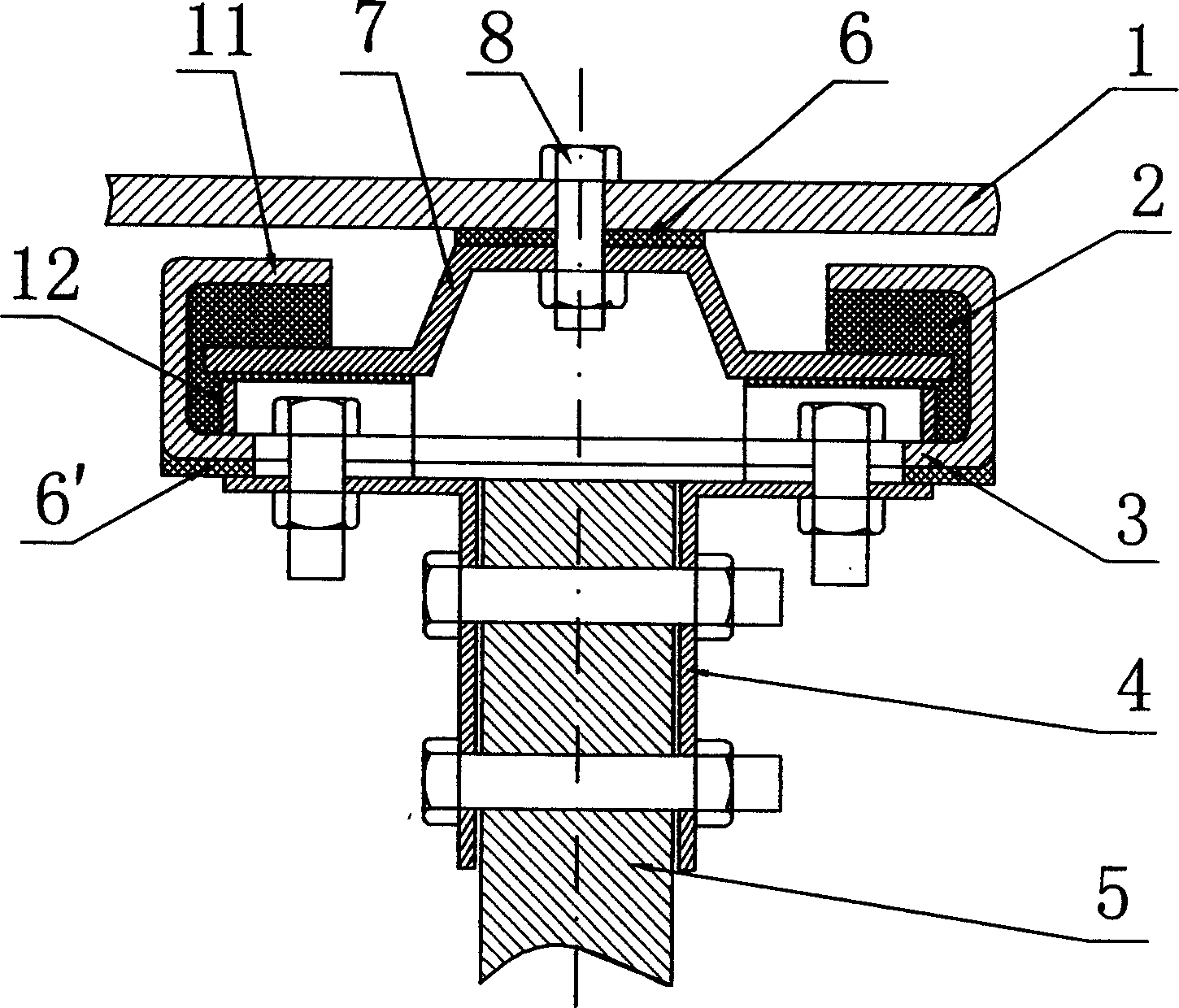

[0015] As shown in the figure, the partition wall installation seat is composed of an inner support frame 7, a front support plate 11 and a rear support plate 3, etc. The front support plate 11 and the rear support plate 3 are connected as one, which is called an outer support frame. Between the support plate 11 and the rear support plate 3, between the inner support frame 7 and the front support plate 11 and between the inner support frame 7 and the rear support plate 3, a rubber pad 2 is arranged, and the rubber pad 2 is connected to the front support plate 11, the rear Support plate 3, inner support frame 7 are connected as a whole; The front surface of inner support frame 7 is provided with shock absorber 6, and the rear surface of back support plate 3 is provided with shock absorber 6 '; The center of inner support frame is provided with a mounting Hole 9, rear support plate 3 is provided with an operation window 13 extending to installation hole 9, is respectively provide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com