Hot rolling case steel coil coreless transferring apparatus and method

The technology of a transfer device and a hot coil box, which is applied to the device for transferring objects and the field of transferring objects by using the device, can solve the problems of excessive temperature drop of the inner ring of steel coils, etc., and improve the quality of finished products, reduce losses, and facilitate rolling. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

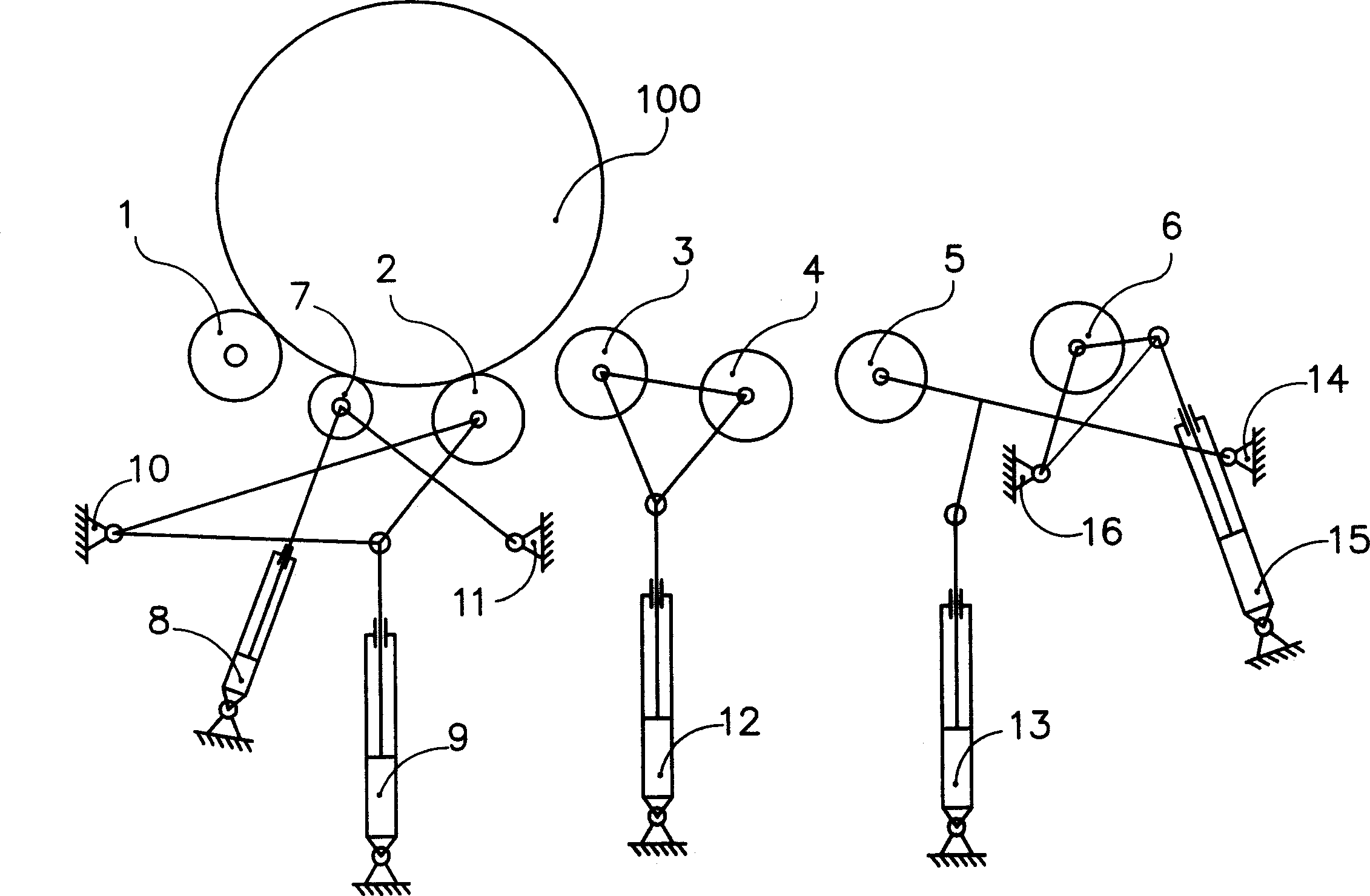

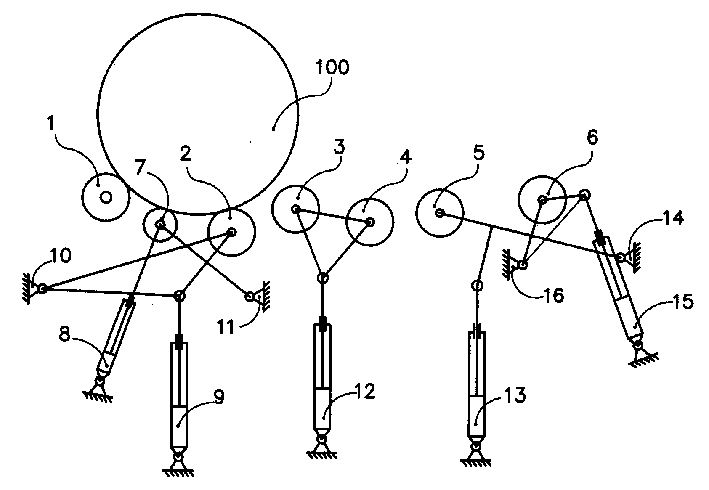

[0015] Such as figure 1 As shown, the coreless transfer device for hot coil box steel coils includes an idler roller 1 and a floating idler roller 2. There is a hydraulic cylinder 9 below the floating idler roller 2. The idler roller 2 and its hinge support seat 10 are connected to the The hydraulic cylinder 9 constitutes a swing mechanism.

[0016] Also be provided with push roll roller 7 between idler roller 1, floating idler roller 2, there is hydraulic cylinder 8 below push roll roller 7, push roll roller 7 and its hinge support seat 11 and hydraulic cylinder 8 constitute swing mechanism.

[0017] Floating idler rollers 3, 4 are arranged behind the floating idler roller 2, and a hydraulic cylinder 11 is arranged below, and the hydraulic pump 11 below the floating idler rollers 3, 4 and their below constitutes a swing mechanism.

[0018] The floating idler 5 is arranged behind the floating idler 4, and a hydraulic cylinder 13 is arranged below it, and the floating idler 5 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com