Fruit and vegetable transport device with transport and spray function

A conveying device and spraying device technology, which is applied in application, food processing, food science, etc., can solve the problems of low work efficiency, low degree of mechanization, damage of fruits and vegetables, etc., and achieve the effect of avoiding pollution and improving the cleanliness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

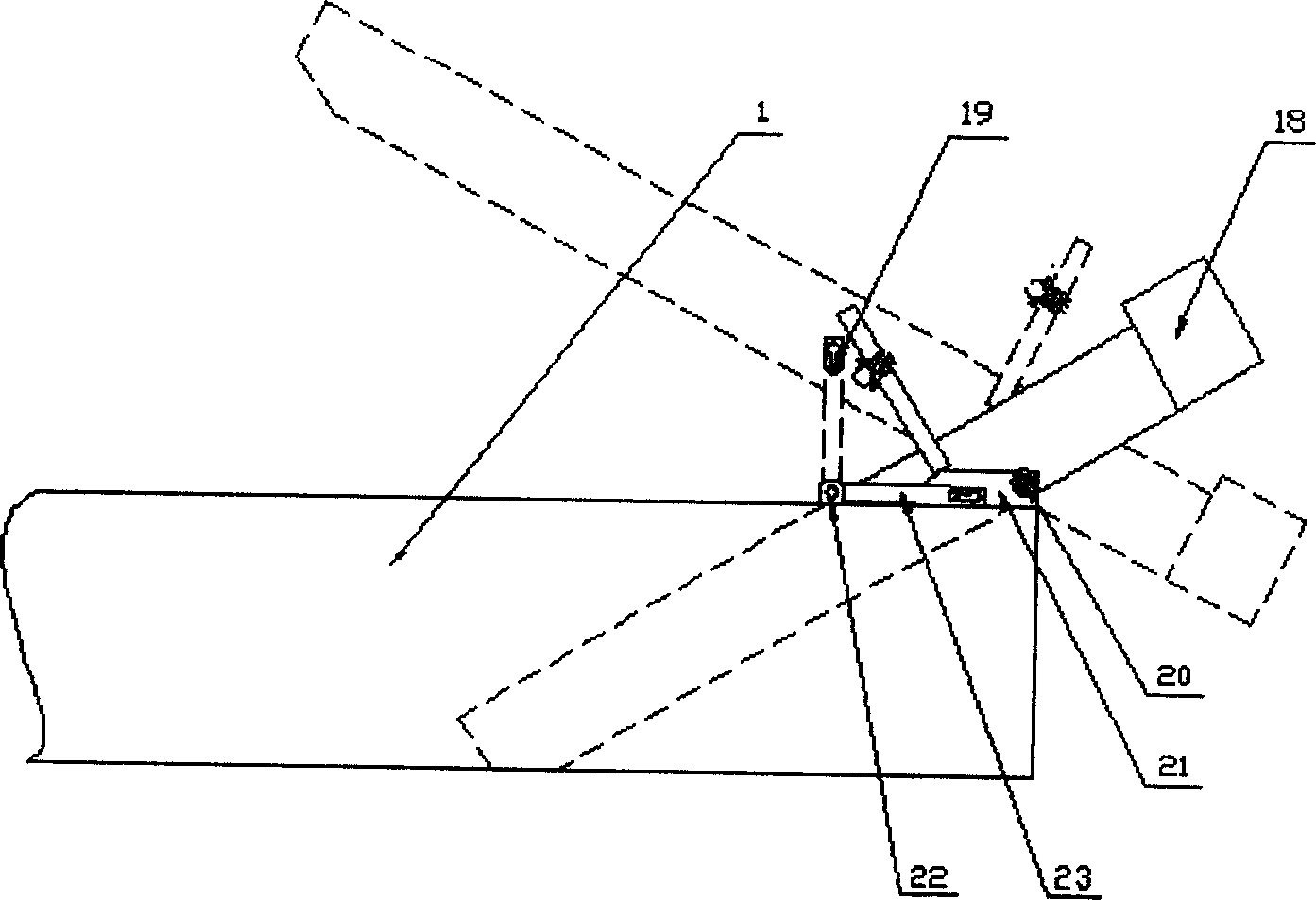

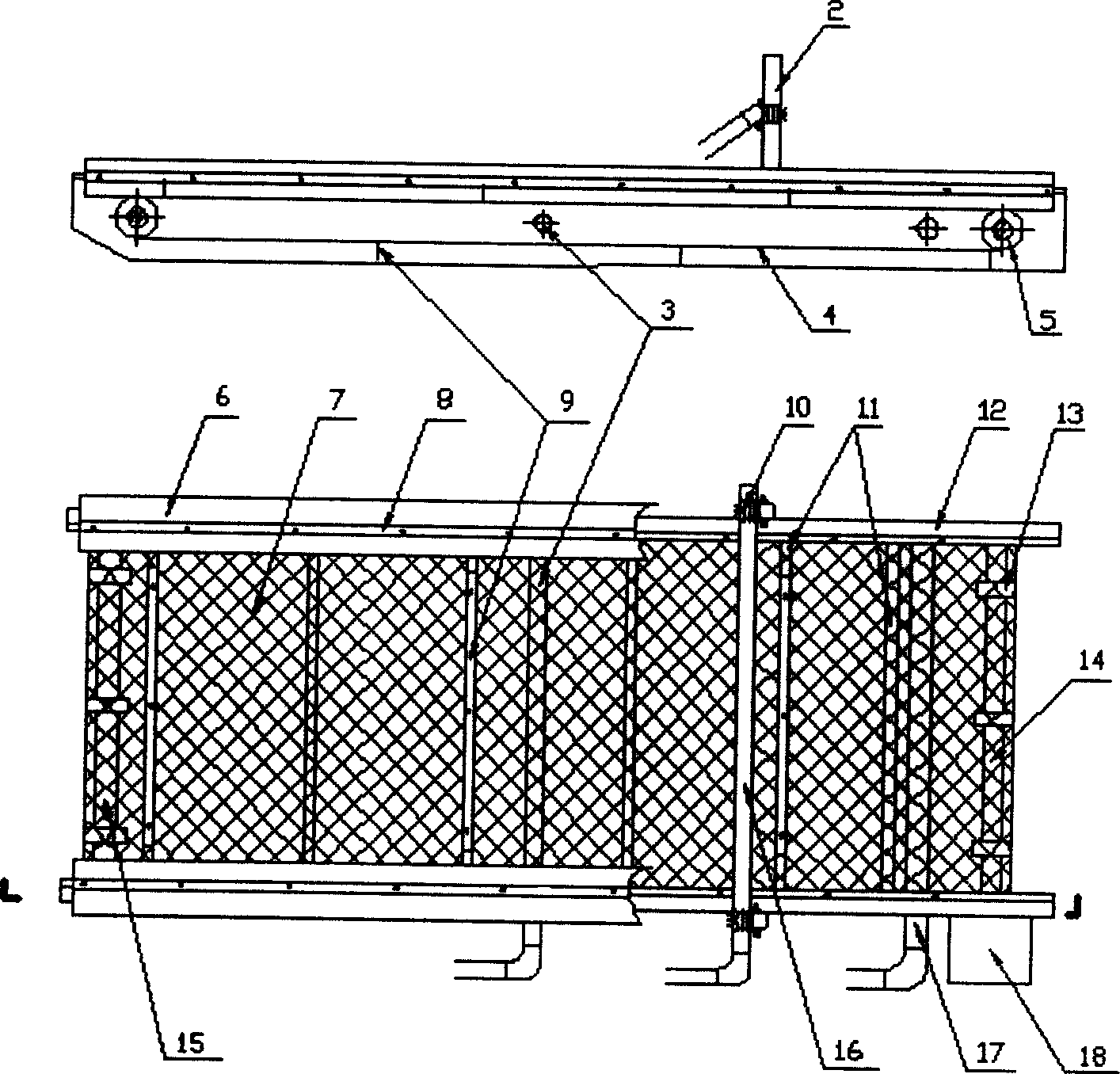

[0012] The conveying device with conveying and spraying functions has a cleaning tank 1, and the cleaning tank 1 is equipped with a conveying device, a spraying device and a sundry separation device. One end of the conveying device leans against the bottom of the cleaning tank, and the other end leans against the edge of the cleaning tank; Both sides of conveyer belt respectively have a turning bolt 20, screw on the conveyer frame side plate 12 after passing through the circular hole of reverse support 21, said conveying device has two conveyer frame side plates 12, two conveyer frame side plates 12 is connected with the rotating shaft 15 through the transmission shaft 14, the sprockets 5 are fixed at both ends of the transmission shaft 14 and the rotating shaft 15, three ferrules 13 are set on the two shafts, and the rotating chain 4 is meshed on the sprocket 5 After steel bar 11 passes through a row of holes of filter screen 7, its two ends are respectively fixed on two rotat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com