Tubular composond air pocket

An airbag and tube-type technology, which is applied in vehicle safety arrangement, pedestrian/passenger safety arrangement, transportation and packaging, etc., can solve problems such as human injury and chest injury of drivers and passengers, and achieve the effect of reducing injury and improving protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

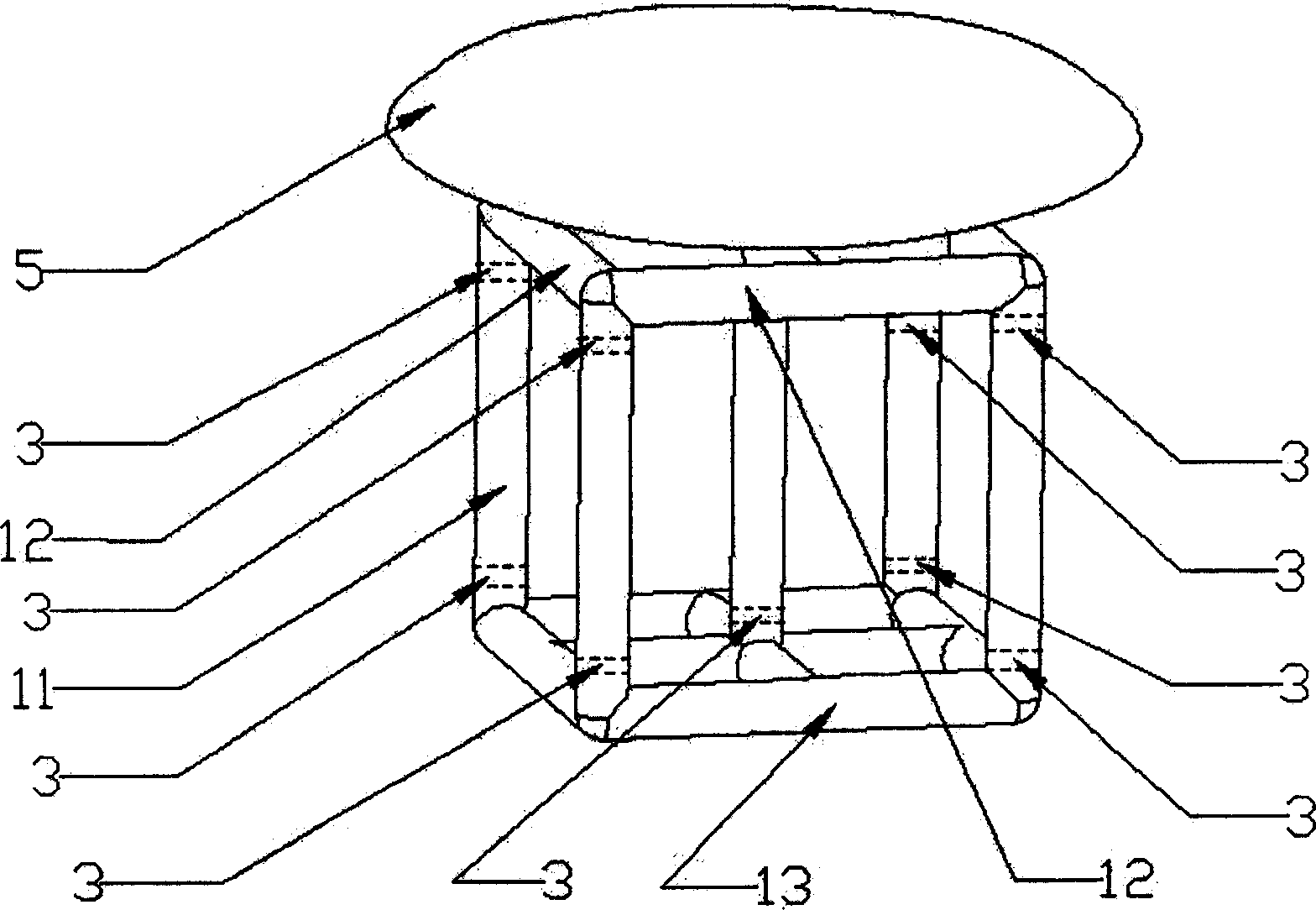

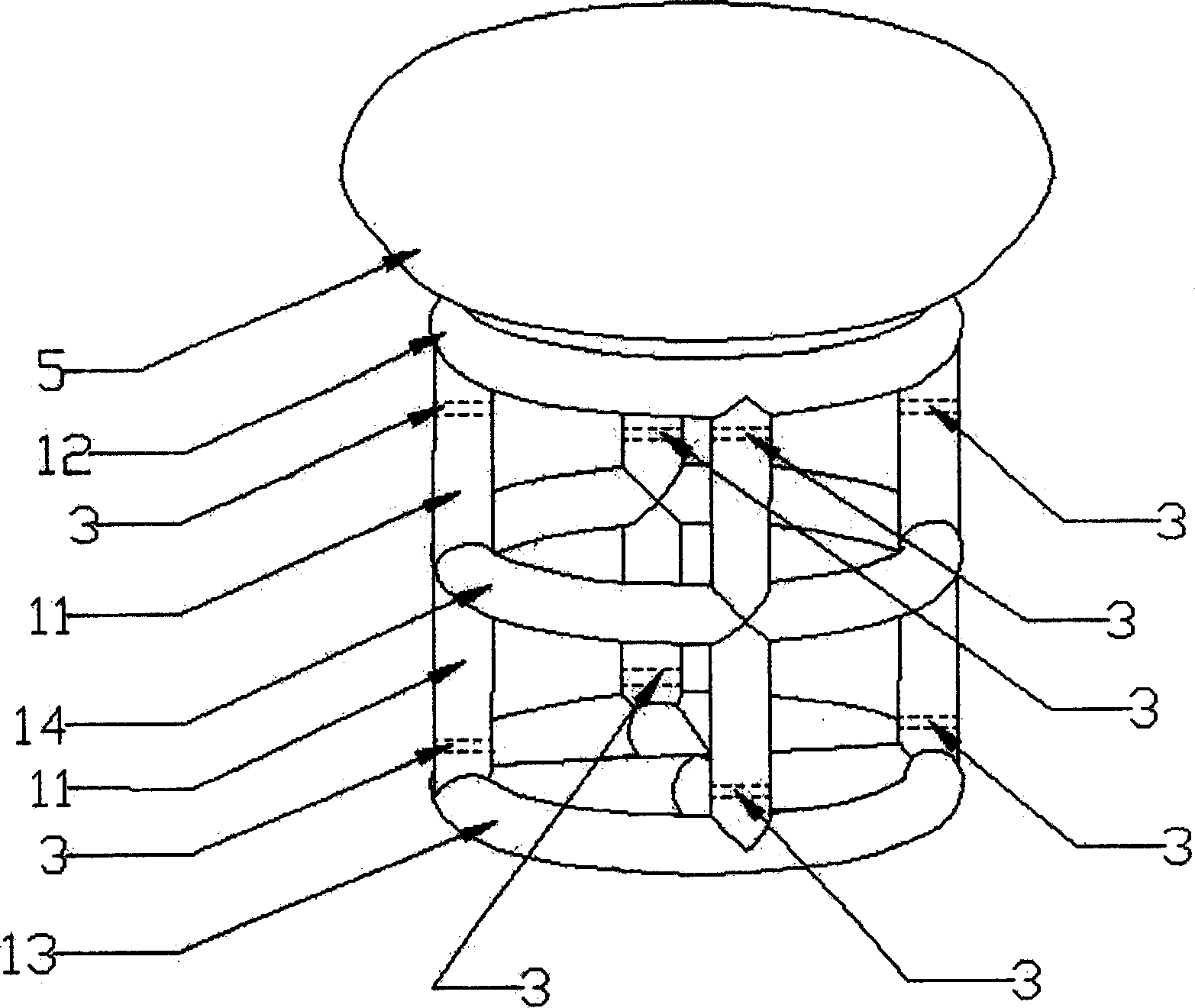

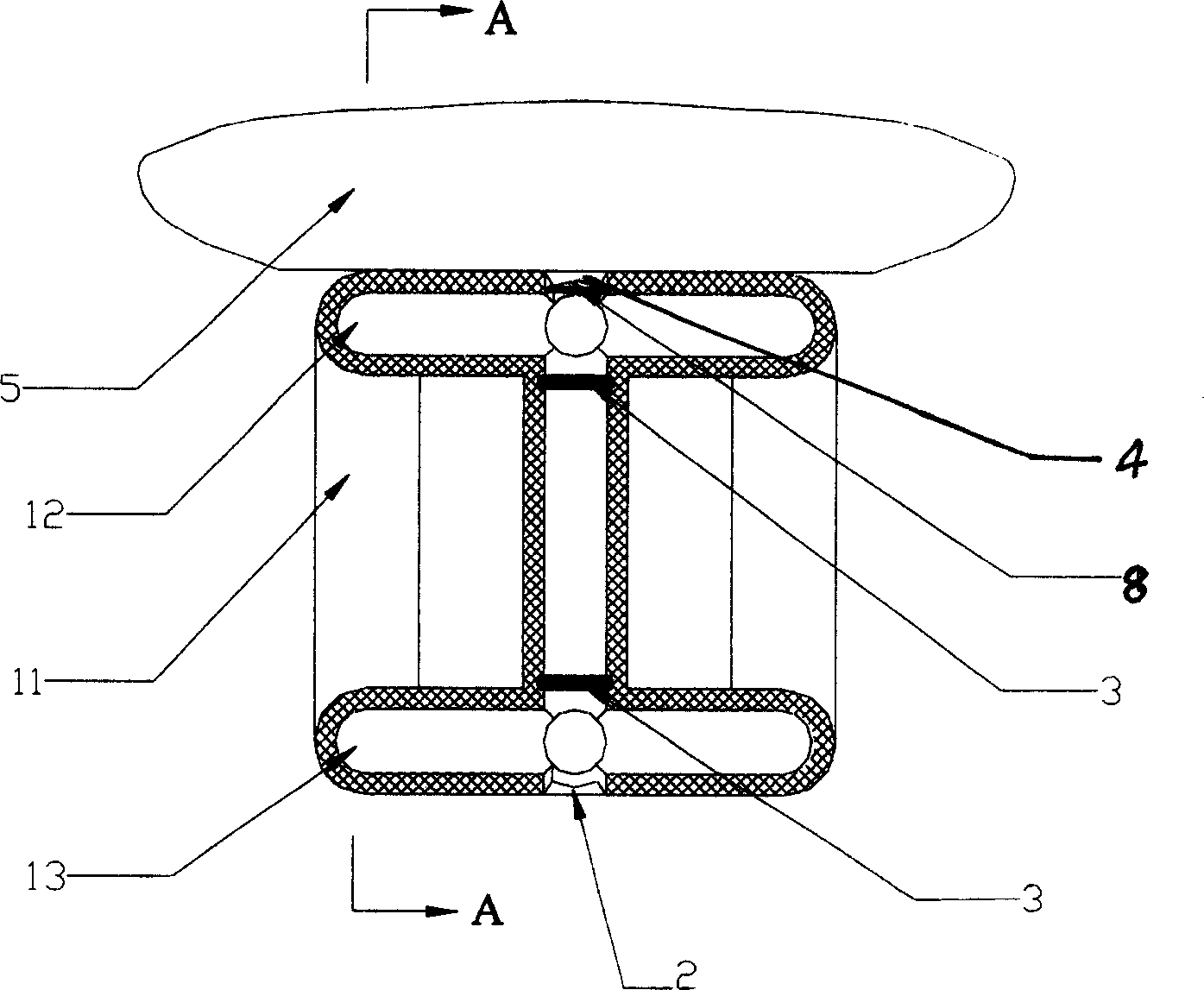

[0025] like Figure 1-8 As shown, the tubular composite airbag of the present invention comprises a truss 1 connected by a hollow trachea and a buffer airbag 5 arranged above the truss 1, and one or more than one inflation ports 2 are arranged at the bottom of the truss. An air pressure diaphragm 3 is provided at the junction of each layer of longitudinal air pipes and transverse air pipes of the truss, which can withstand different degrees of gas pressure and control the inflation direction of the truss 1 . The top of the truss 1 is provided with an air outlet 4 that communicates with the buffer airbag 5. In the trachea on the top of the truss 1, an air pressure diaphragm 8 is provided at the interface with the air outlet 4. The inflation gas breaks through the air pressure diaphragm 8 and passes through the air outlet 4 to buffer The air bag 5 is inflated to jointly form a high-low pressure composite air bag. A fixed disk 6 is arranged between the truss 1 and the buffer air...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com