Turbine blade of turine and its puller

一种涡轮叶片、拔卸工具的技术,应用在叶片的支承元件、制造工具、金属加工等方向,能够解决加重、涡轮叶片损伤等问题,达到倾斜的危险减小、导入简化的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

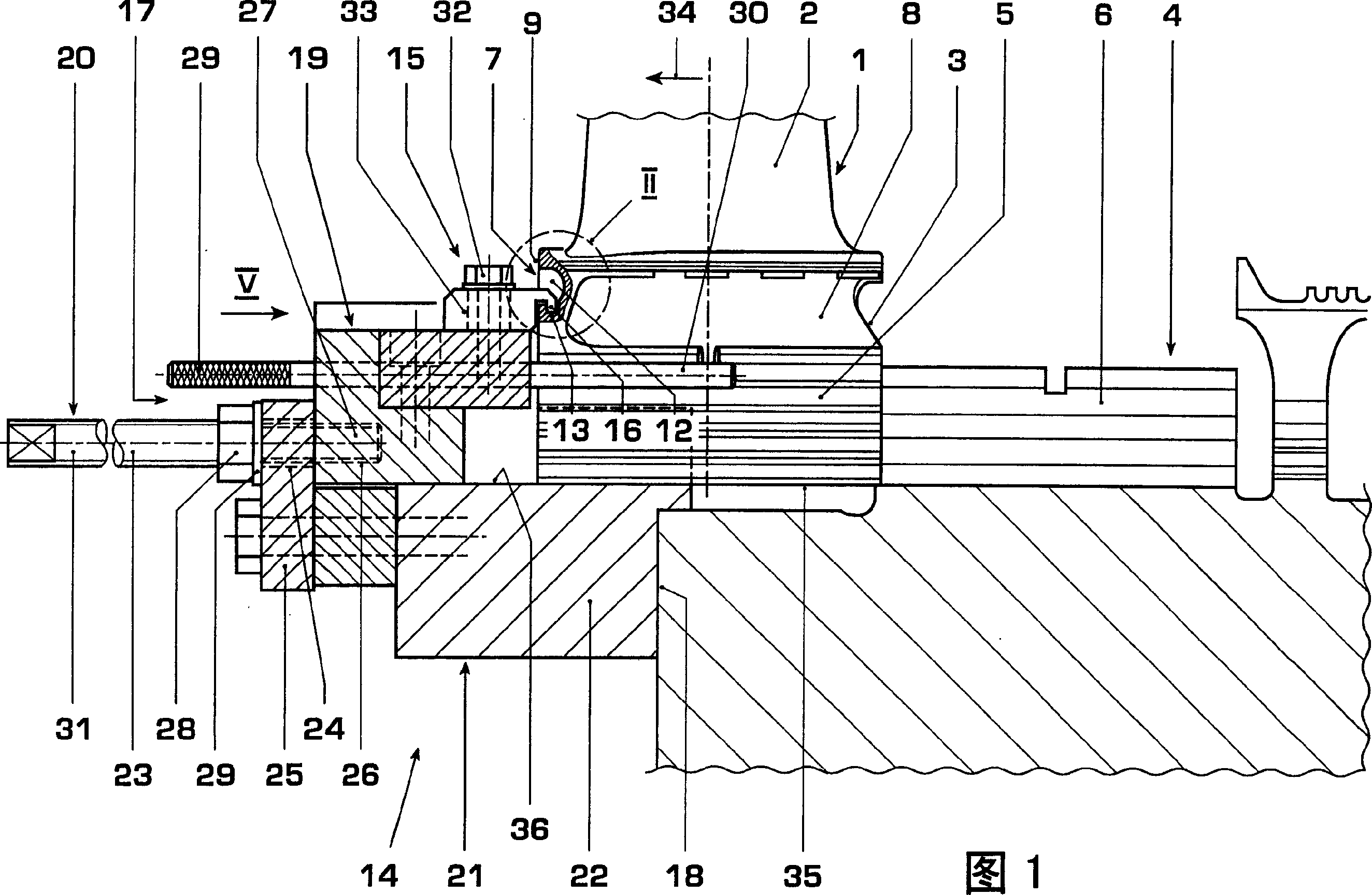

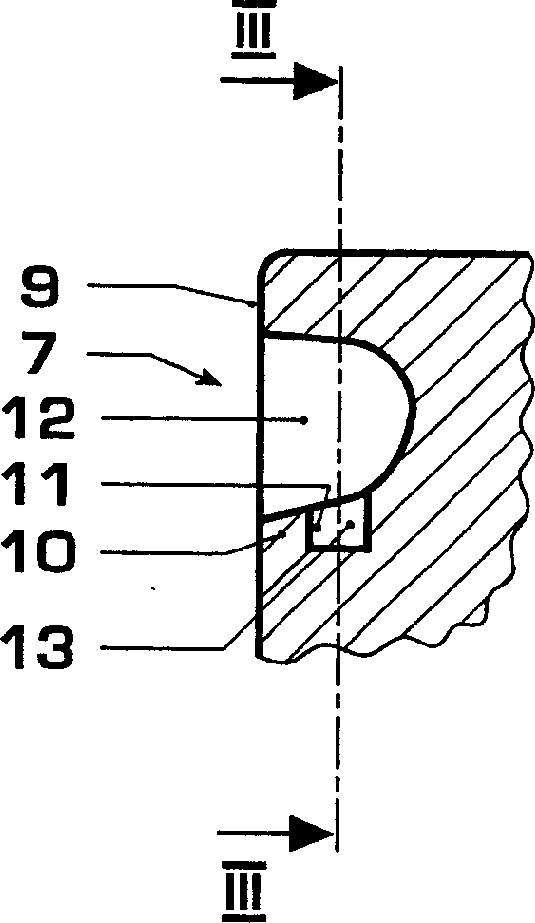

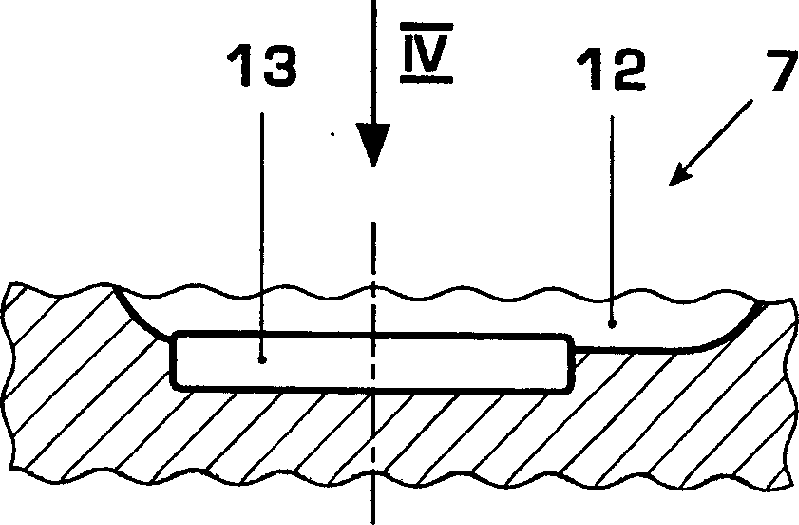

[0025] According to FIG. 1, the turbine blade 1 according to the invention has in the usual manner an aerodynamically shaped blade 2, which is used to guide the flow of air, and has a base 3, by which the turbine blade 1 can be fixed to a turbomachine, such as a gas turbine or a compressor. on rotor 4 of the machine. According to FIGS. 1 and 5 , on the base 3 on the side facing away from the blade 2 , for fastening purposes, an anchoring section 5 is formed, each having a Seed tooth portions, wherein these tooth portions converge in the direction of the axis of rotation of the rotor 4 . The profile of such a tooth portion may also be referred to as a "Christmas tree tooth".

[0026] According to FIG. 1 , the rotor 4 has, for each turbine blade 1 , an anchoring groove 6 extending axially, ie parallel to the axis of rotation of the rotor 4 , which is formed complementary to the anchoring section 5 of the turbine blade 1 . Correspondingly, the anchoring grooves 6 here also have...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com