Device for fixing at least battery module at the bottom of a housing of a battery housing

A battery module and battery housing technology, applied in electric power devices, battery pack components, batteries, etc., can solve problems such as reducing rigidity, and achieve the effects of less deformation, less cost, and high aging resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

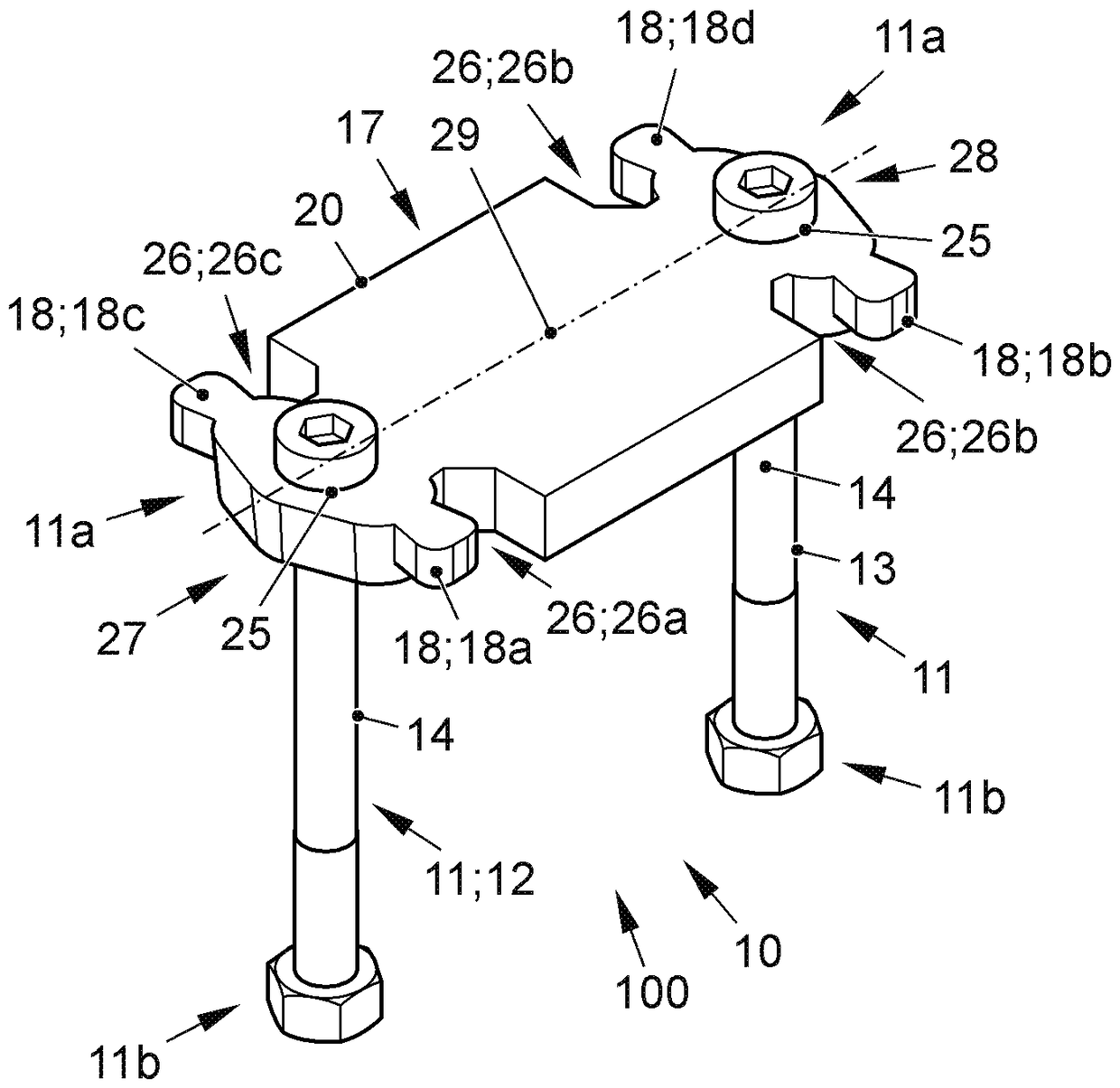

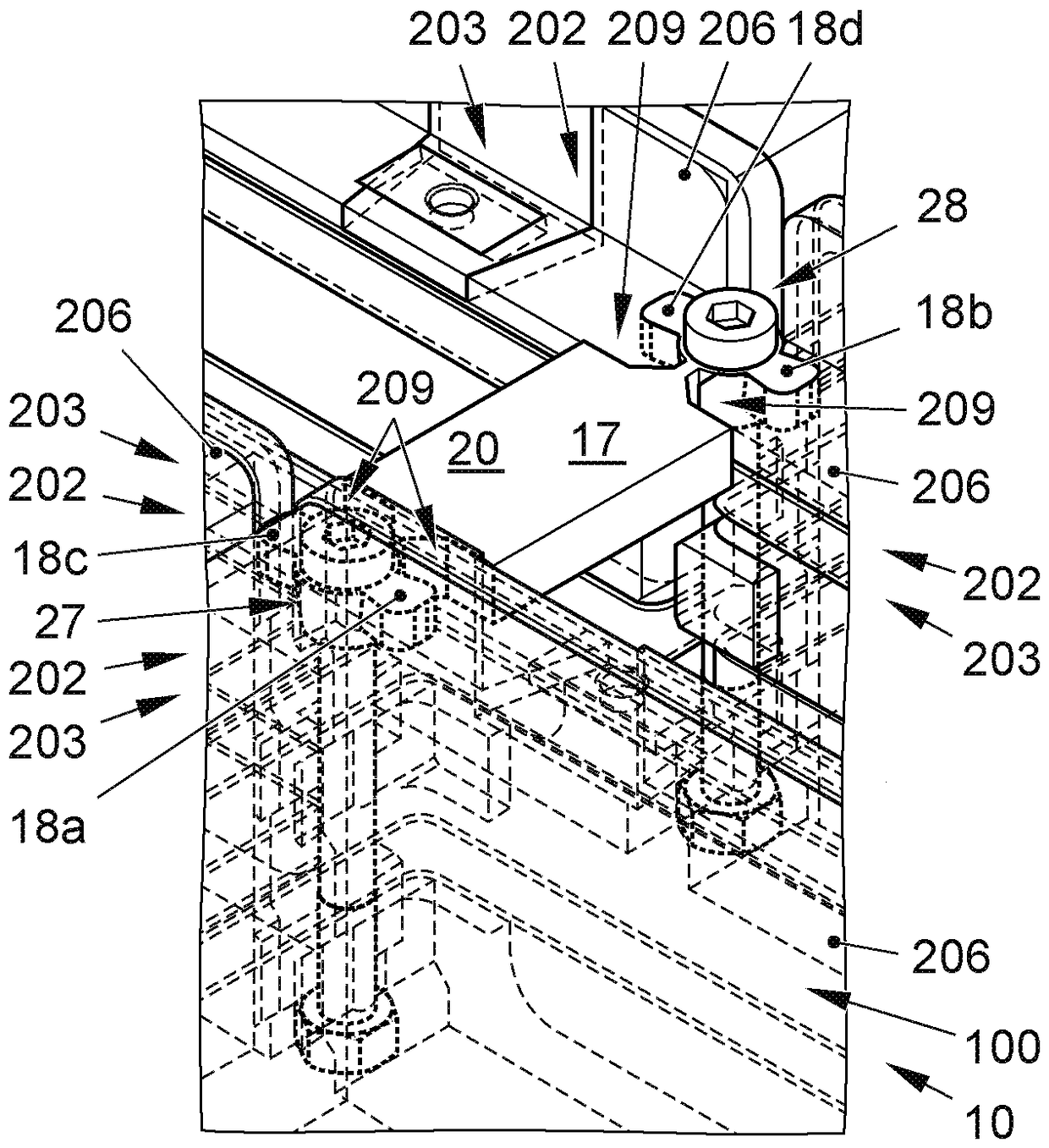

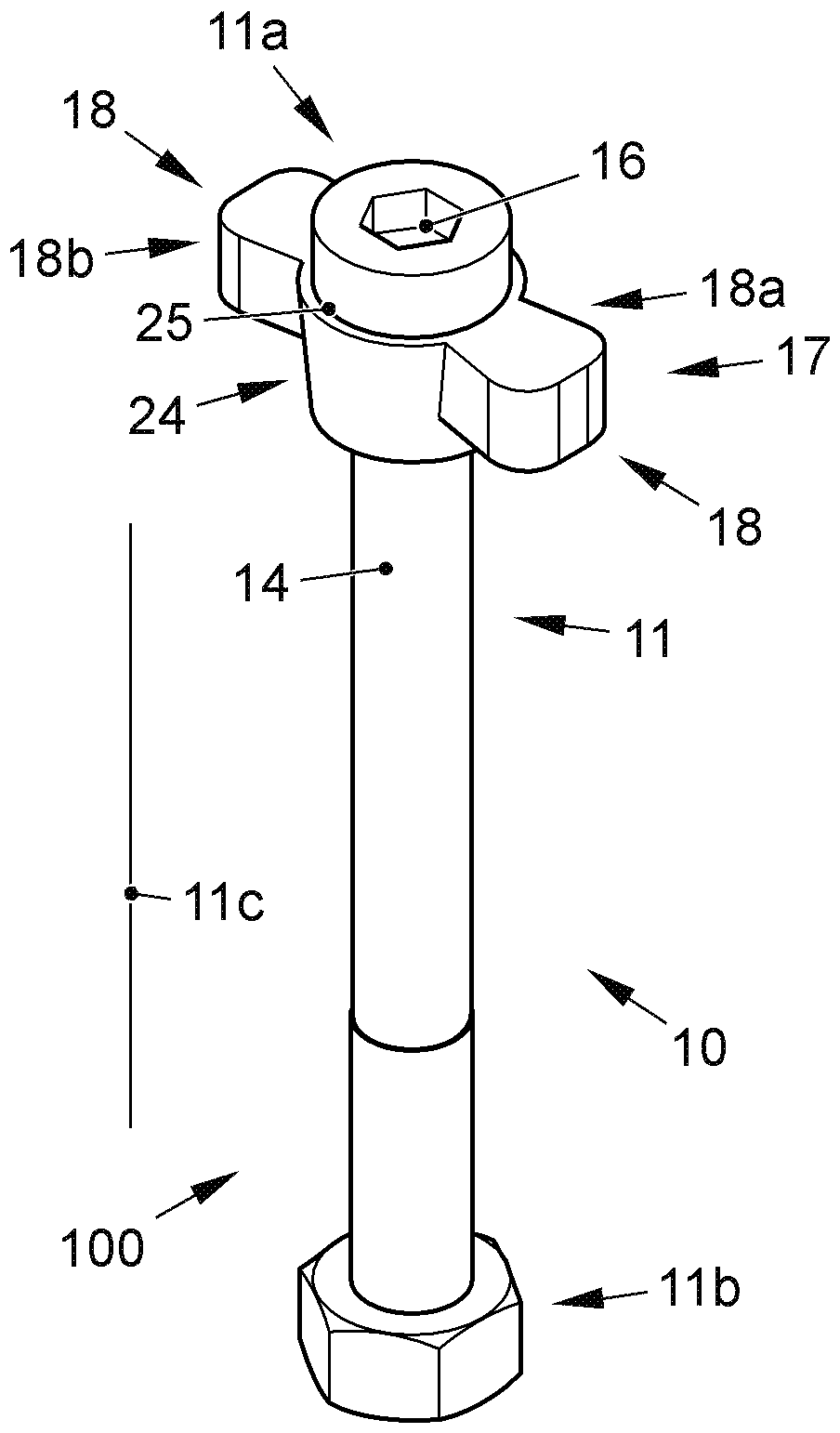

[0095] figure 1 A device (100) for fastening at least one battery module (202) on a housing bottom (201) of a battery housing (200) is shown. The fixing element (10) comprises a holding element (17) which has a bore (25). Furthermore, the fastening element (10) has a threaded fastener (11), which is guided through a bore (25) of the holding element (17). The holding element (17) has a projection (18) which extends in the lateral direction of the holding element (17) of the fixing element (10). The retaining element ( 17 ) extends eyelet-shaped or annular around the shank ( 14 ) of the threaded fastener ( 11 ), that is to say over the entire circumference. In other words, the retaining element (17) comprises a ring (24) from which the protrusion (18) protrudes.

[0096]The threaded fastener (11) has a first end region (11a) and a second end region (11b) and a longitudinal direction (11c). With regard to threaded fasteners, the protrusions extend into the radial direction. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com