Platelike body transporting device

A technology for conveying tools and objects, applied in the field of multi-layer glass conveying tools, can solve the problems of difficult insertion and removal of fingers, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

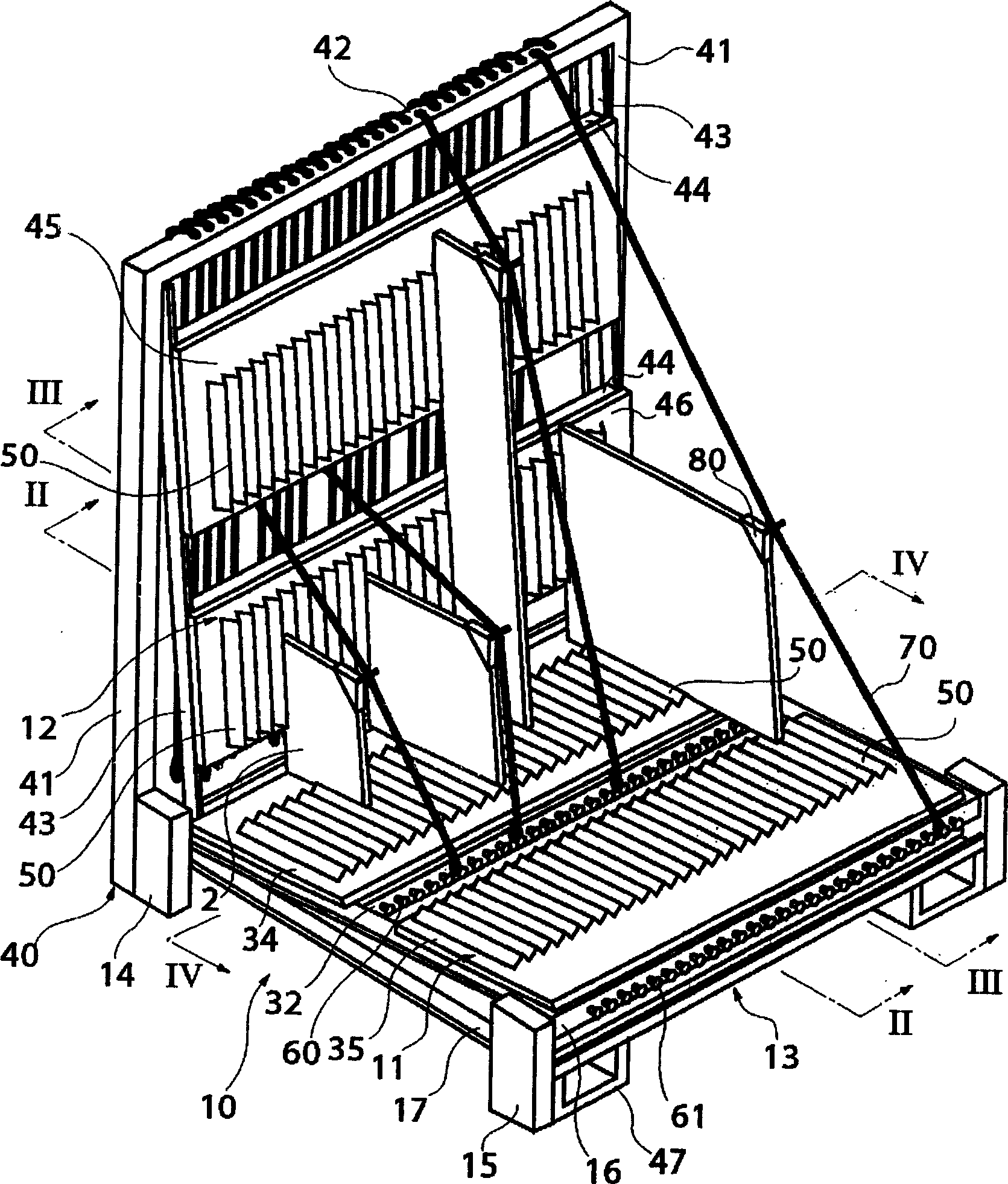

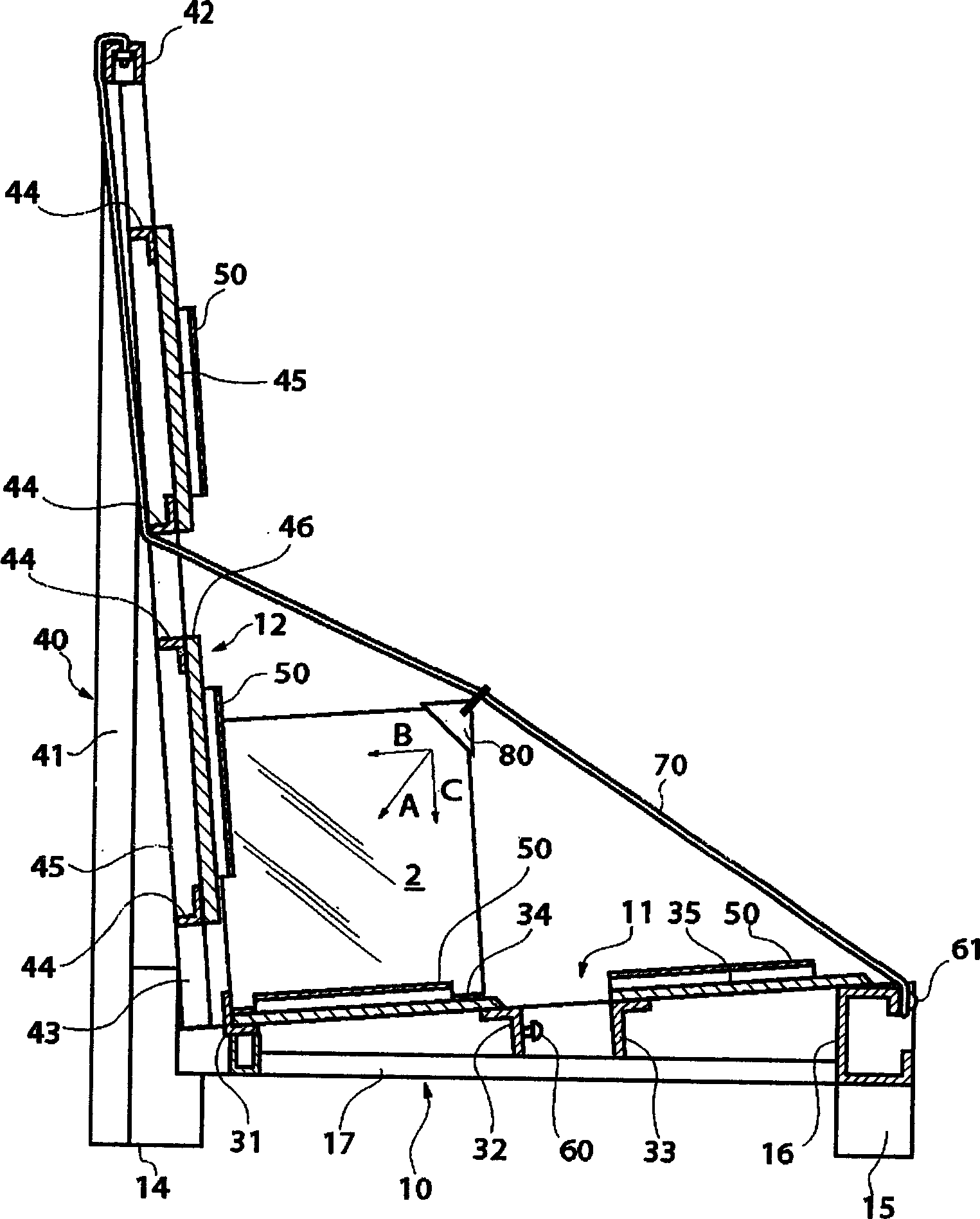

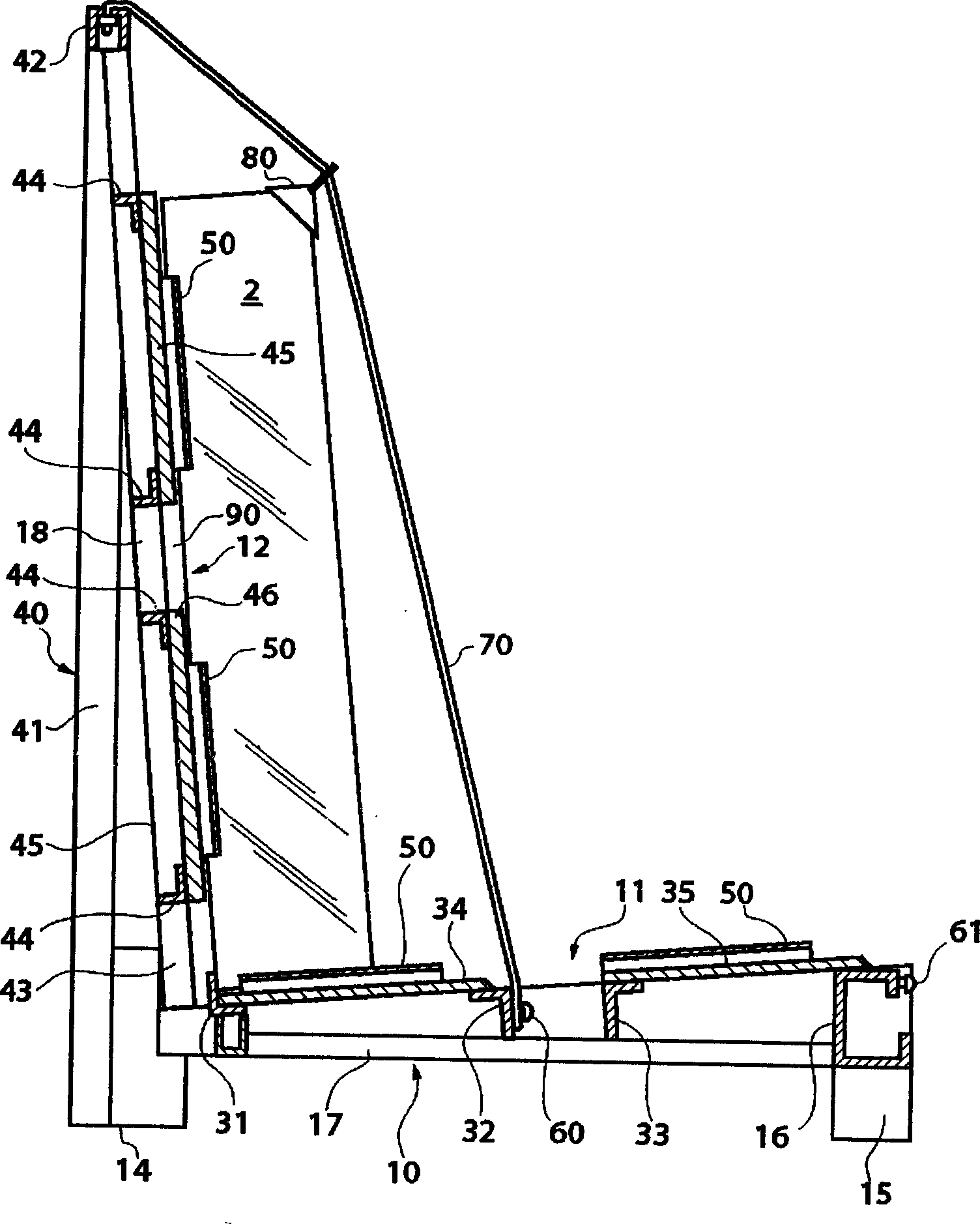

[0046] Next, a plate-shaped object transport tool according to an embodiment of the present invention will be described with reference to the drawings.

[0047] figure 1 is a perspective view of a plate-shaped object transport tool according to the first embodiment of the present invention, figure 2 is along figure 1 The profile of the II-II line, image 3 is along figure 1 Sectional view of line III-III.

[0048] exist figure 1 Among them, the conveying stand 10 as the plate-shaped object conveying tool of the first embodiment is composed of a bottom plate portion 11 and a back portion 12 vertically erected from the rear end of the bottom plate portion 11 .

[0049]The bottom plate portion 11 is composed of a rectangular horizontal frame 13 , a pair of legs 14 provided at the rear corners of the frame 13 , and a pair of legs 15 provided at the front corners of the frame 13 . The frame 13 is composed of a horizontal cross member 16 connecting the pair of legs 15 , a hor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com