Full automatic hard gelatin capsule liquid and soft-body filler

A technology for hard capsules and filling machines, which is applied in the directions of capsule transportation, liquid materials, packaging, etc., can solve the problems of contamination of filling machines, leakage, and difficulty in cleaning the support of capsule parts, and achieves low quality stability and high production efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

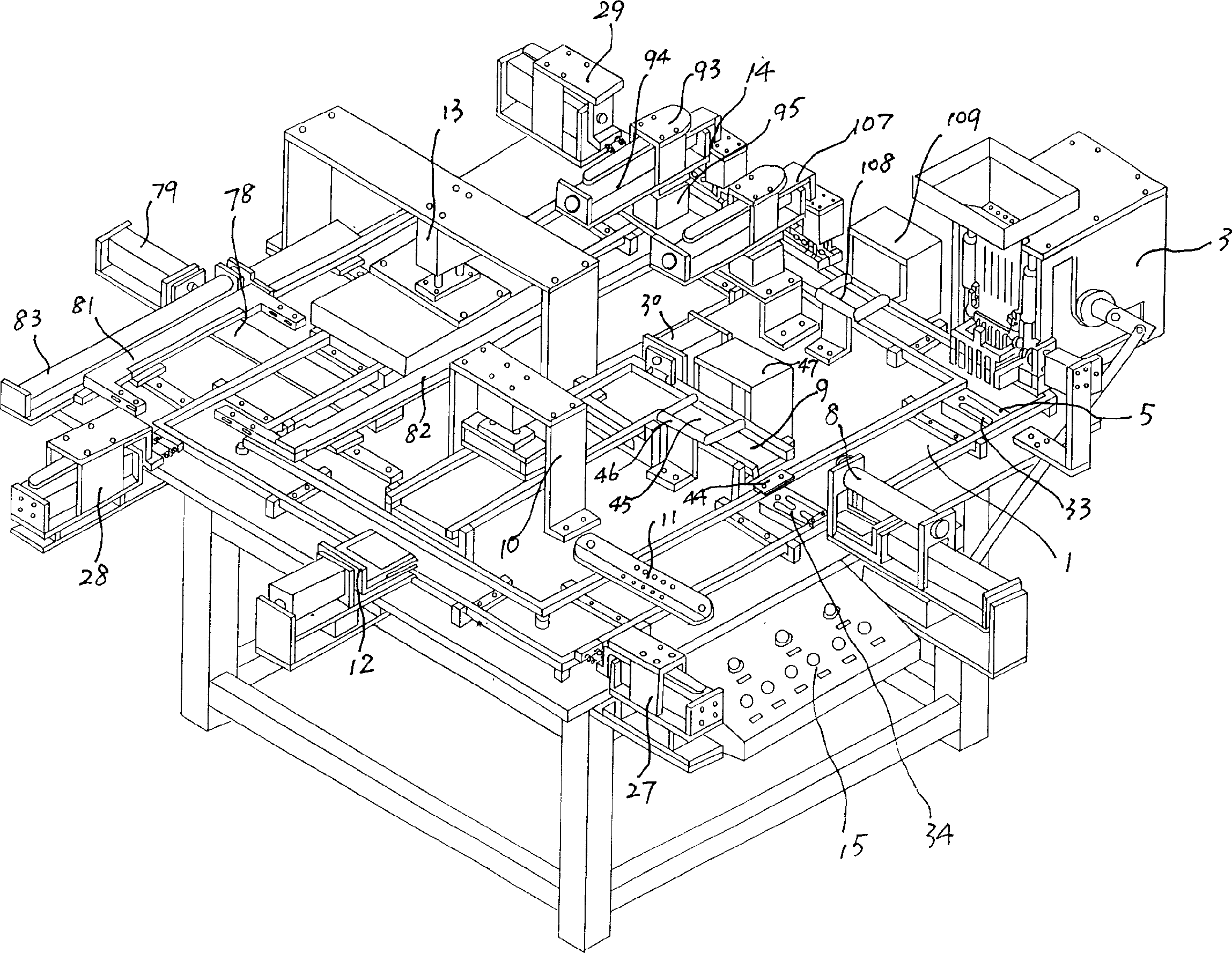

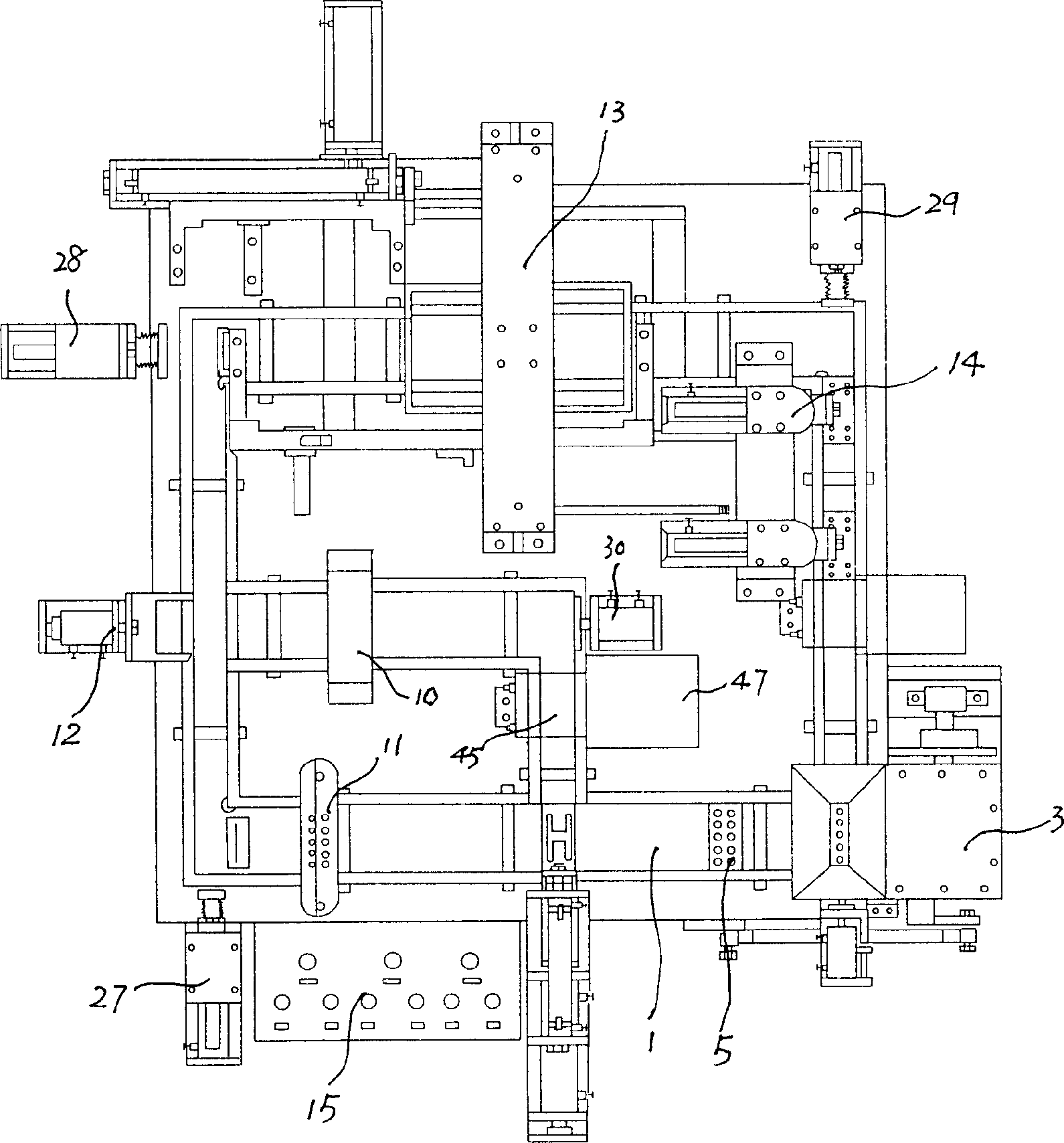

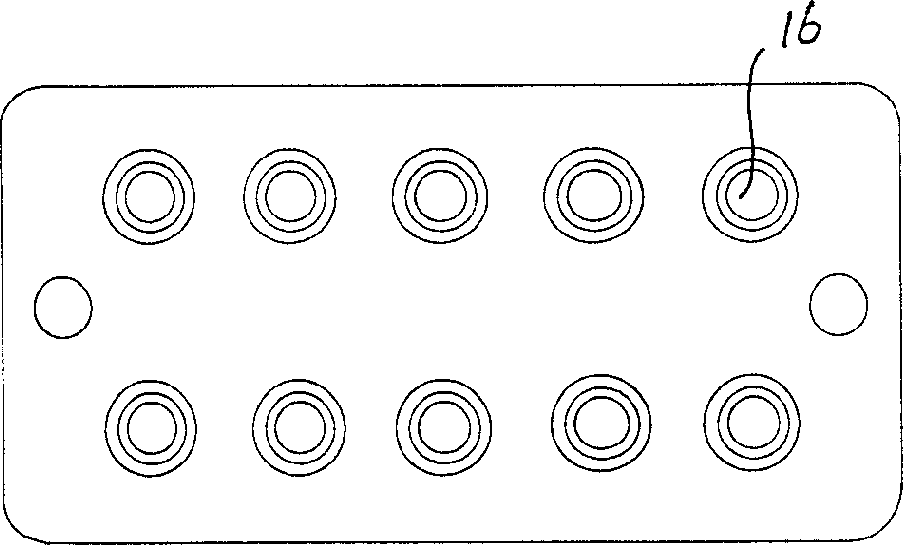

[0034] figure 1 and figure 2 A filling machine according to one embodiment of the invention is shown. In the filling machine, the first track 1 is a square or rectangular circular slide rail connected end to end, and the lower modules 2 (not shown in the figure) run in the first track 1 in a neat arrangement. After the capsule feeding device 3 sends the empty capsules into the overlapping module where the upper module 4 and the lower module 2 are in a superimposed state, the first vacuum suction device 5 separates the capsule into a capsule cap 6 and a capsule body 7, which are respectively located in the upper module 4 and the lower module 2, then the module separation device 8 lifts the upper module 4 and sends it into the second track 9 to run, and the glue coating device 10 applies the sealing glue on the inner wall of the capsule cap 6, and the lower module 2 continues on the first track 1 and the filling device 11 fills the capsule body 7 with materials, then the modu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com