Chemical liquid supplying device and method for venting air

一种化学液体、设备的技术,应用在化学液体供应设备领域,能够解决化学液体分配量不稳定、分配精度下降等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Hereinafter, embodiments of the present invention will be described in detail based on the accompanying drawings.

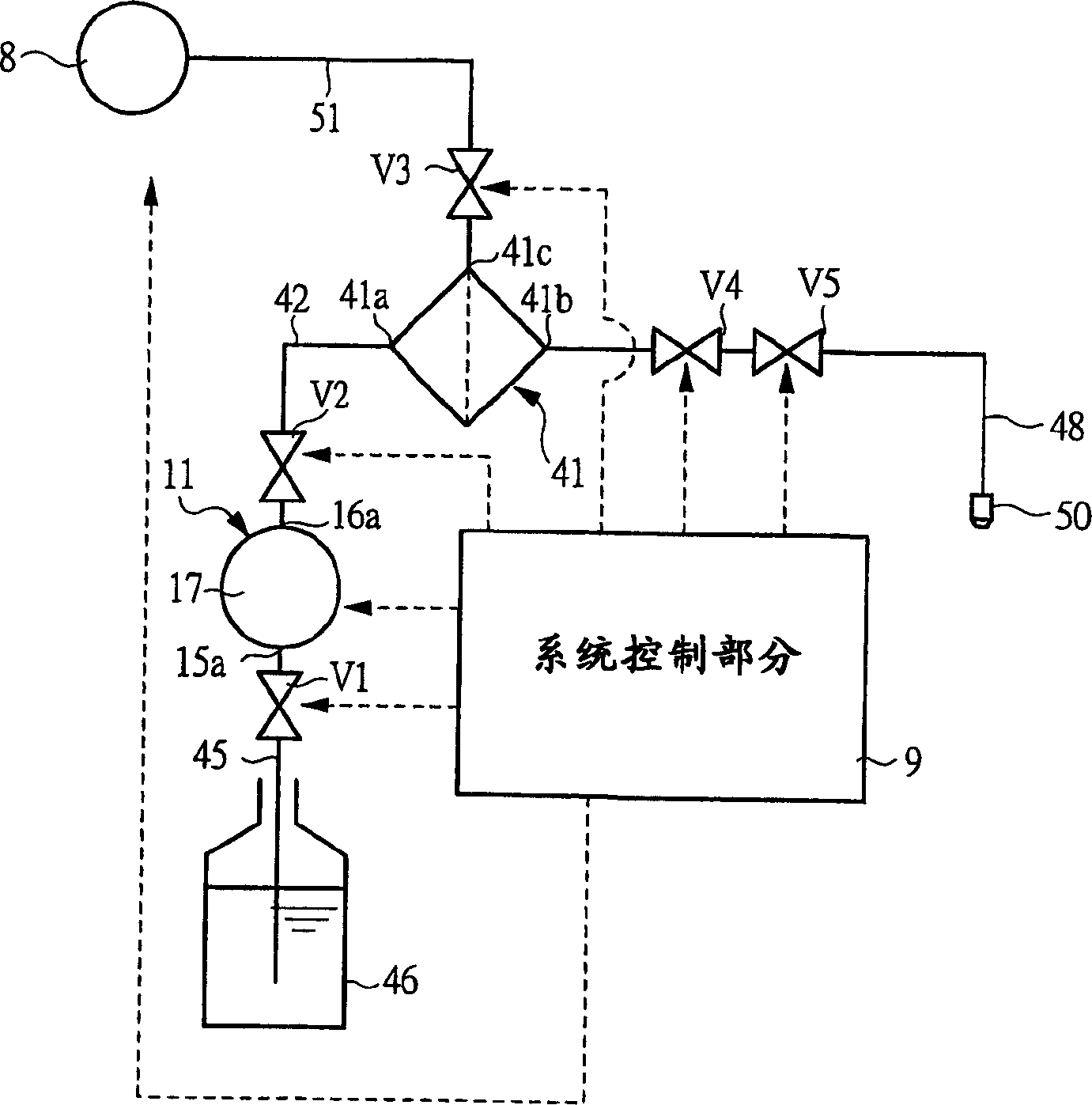

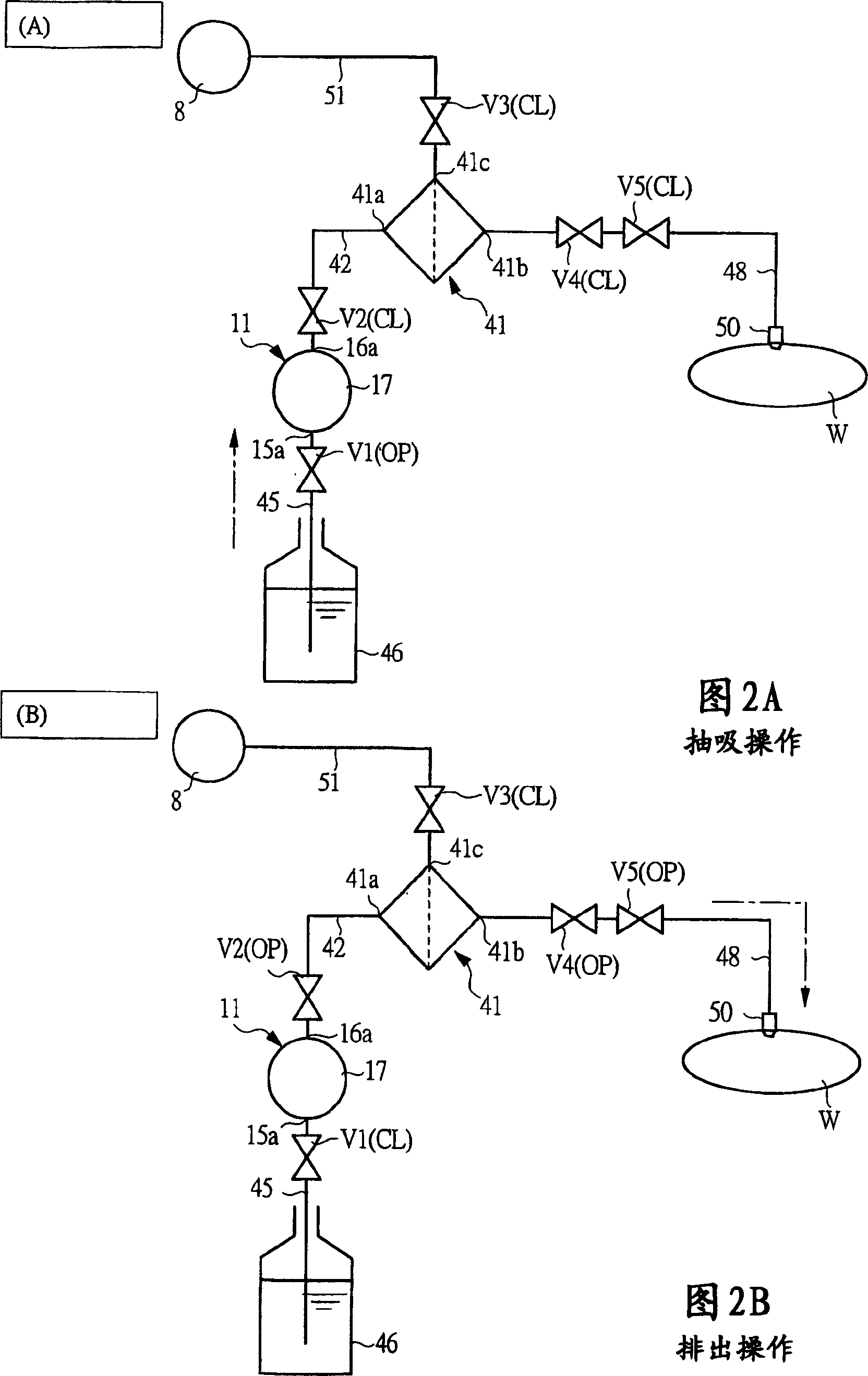

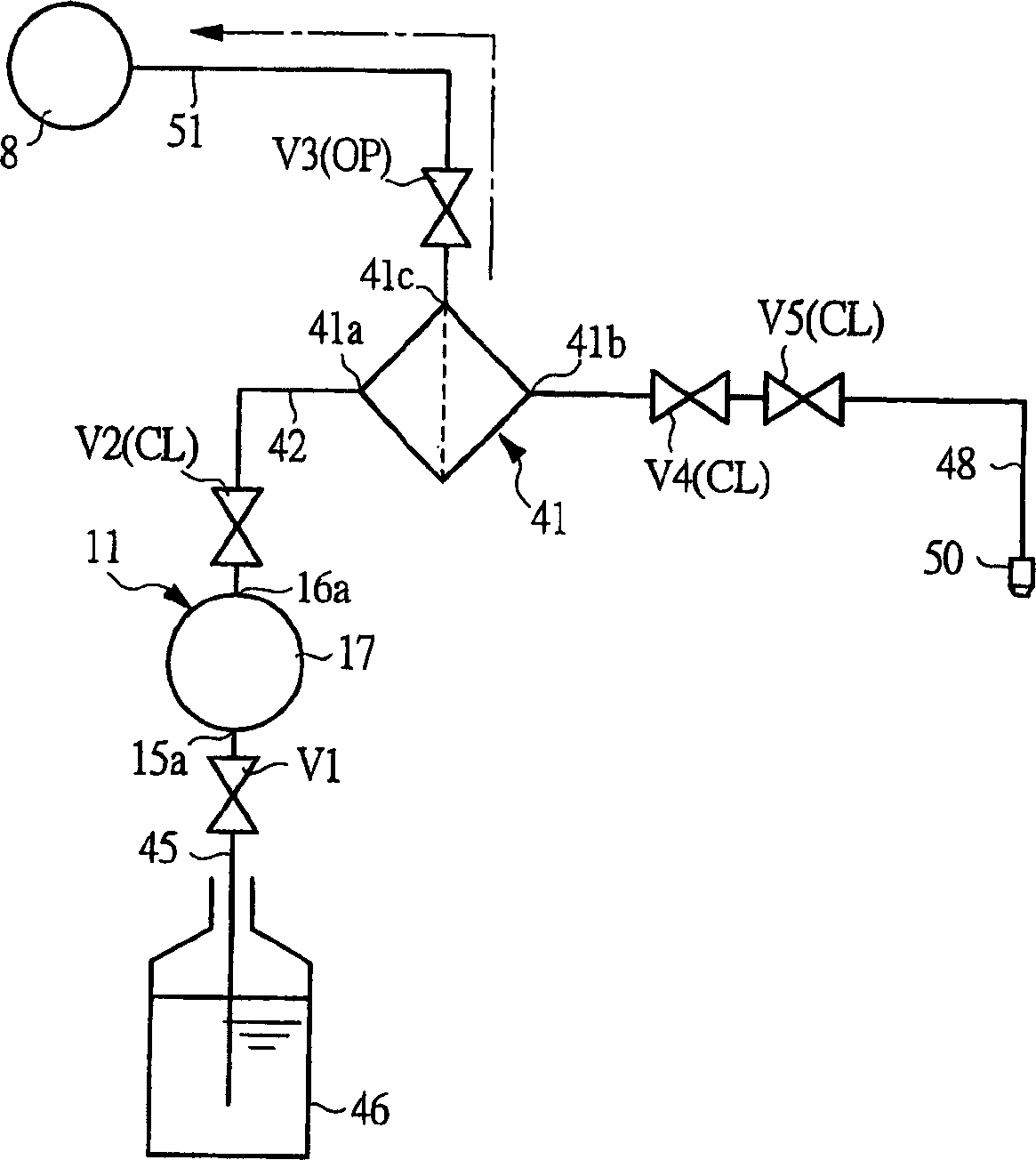

[0027] figure 1 is a liquid circuit diagram schematically showing a chemical liquid supply device according to an embodiment of the present invention. Such as figure 1 As shown, the chemical liquid supply equipment includes: a pump 11 for discharging liquid contained in a liquid tank 46; a filter 41 connected to the pump 11 through a pump outlet flow path 42, wherein the pump outlet flow path is set There is a pump discharge side valve V2 for opening / closing the flow path; a dispensing nozzle (liquid discharge portion) 50 connected to the filter 41 through a liquid discharge flow path 48 provided for opening / closing The discharge valve V4 of the flow path; the vacuum source 8 communicated with the filter 41 through the exhaust flow path 51, wherein the exhaust flow path is provided with a degassing valve V3 for opening / closing the flow path. The structu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com