Connector with floating structure

A technology of connector and structure, which is applied to the installation of connecting parts, devices to prevent wrong connection, protective clothing, etc., can solve the problems of deformation or twisting of flexible cable 19, inability to fully absorb the cone surface, and inability to contact the cone surface, etc. To achieve the effect of preventing breakage or poor connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

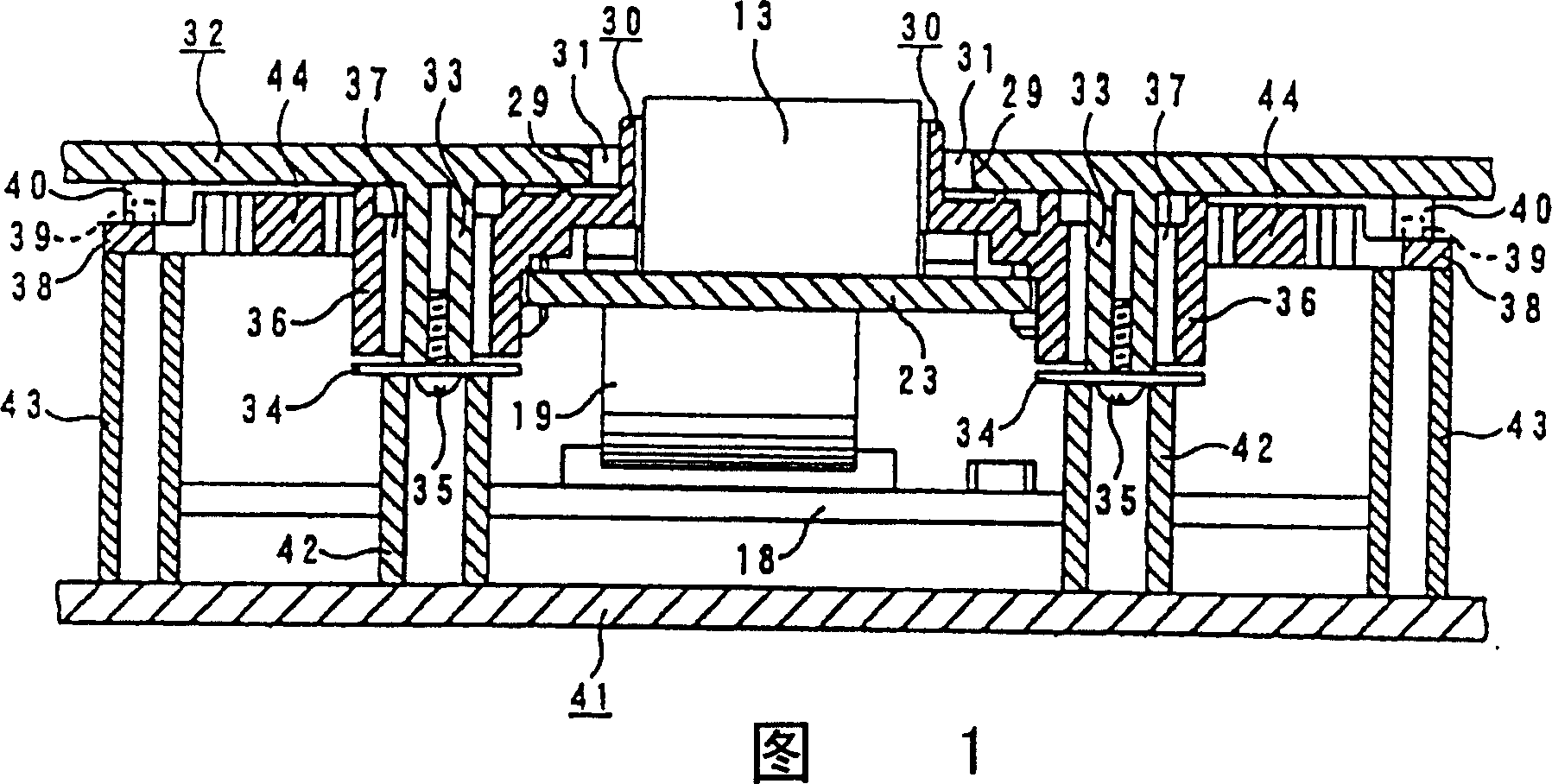

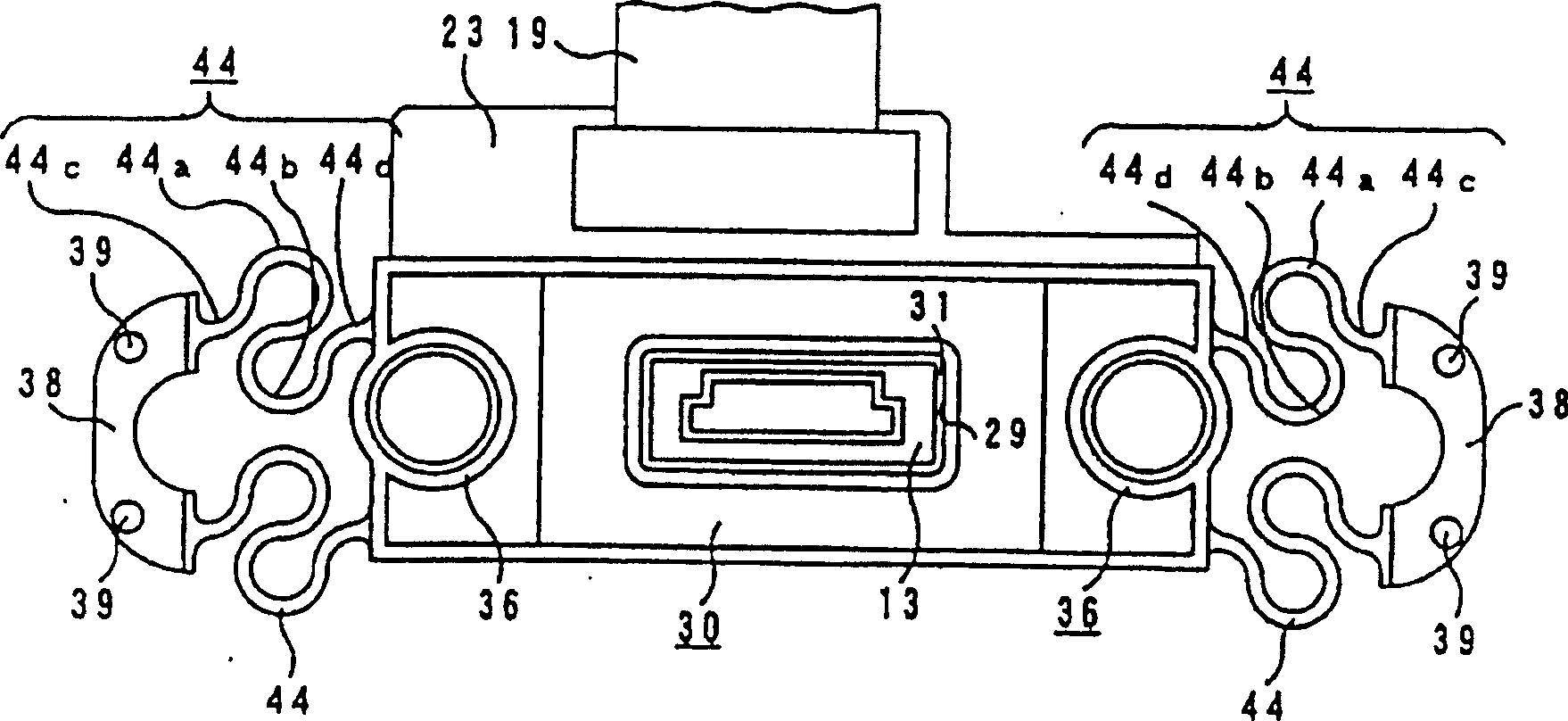

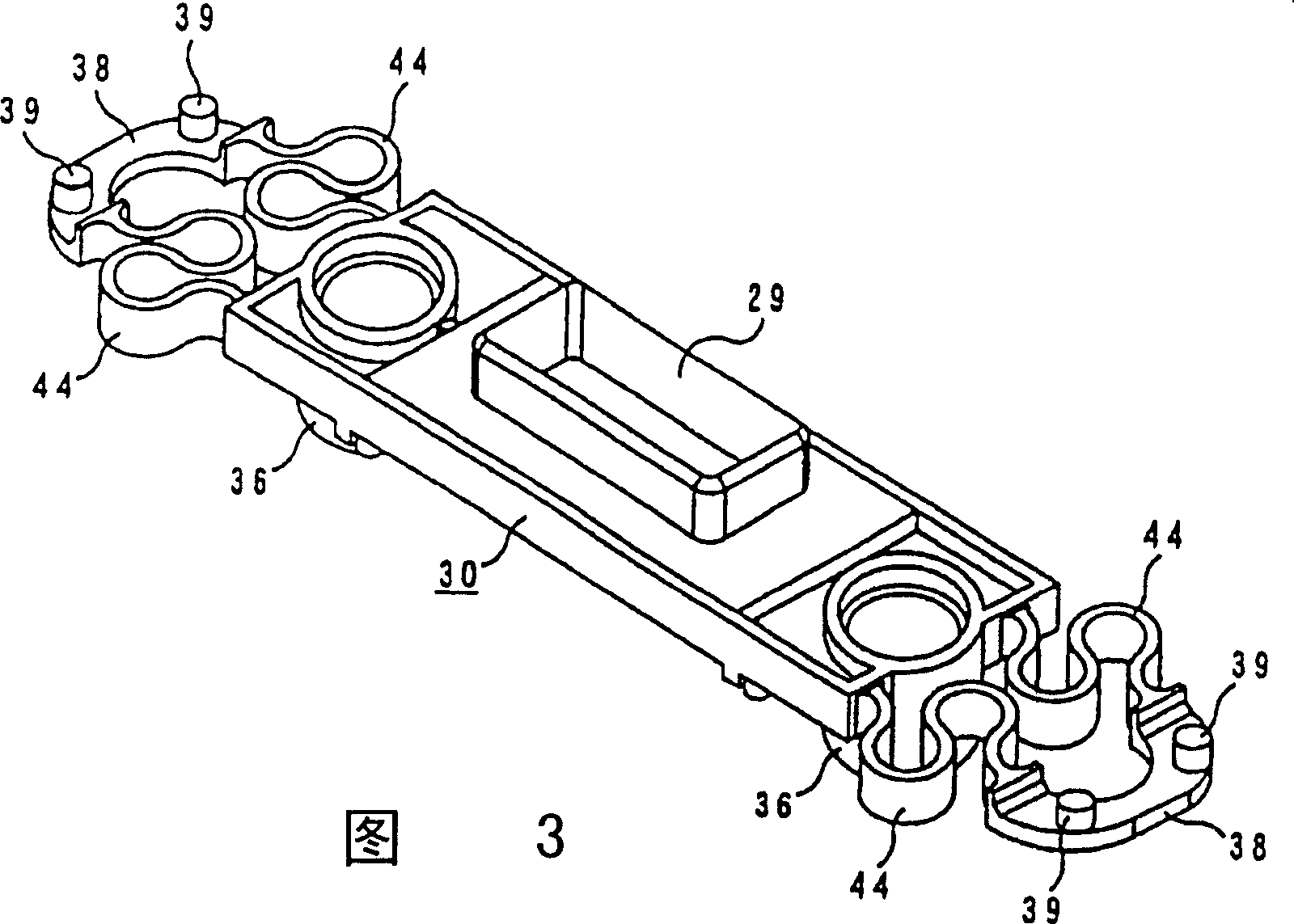

[0028] A first embodiment of the present invention will be described below with reference to FIGS. 1 to 3 .

[0029] In Fig. 1, on the housing 32 on the bracket 11, a connector setting window 29 is provided at the protruding part of the connector 13, and a window 29 is provided on the lower side of the housing 32 on both sides of the above-mentioned connector setting window 29. There is a cylindrical hub 33. A connector case 30 for protecting the connector 13 is fitted inside the connector installation window 29 , and a gap 31 is provided between the connector installation window 29 and the connector installation window 29 . The above-mentioned connector 13 is connected to a movable substrate 23 mounted on the lower side of the connector housing 30 . In addition, in the connector housing 30 , the cylindrical portion 36 having an inner diameter larger than the outer diameter of the hub 33 has a gap 37 for movably fitting the hub 33 , and the height of the cylindrical portion 36 ...

Embodiment 2

[0033] based on the following Figure 4 A second embodiment of the present invention will be described.

[0034] In the above-mentioned embodiment, the elastic S-shaped elastic portion 44 is integrally formed on the connector housing 30 as a floating structure capable of moving in all directions to return the connector 13 to the center, but the present invention is not limited to this structure. Figure 4 Shown is the structure shown in the second embodiment of the present invention, and the elastic member extending along the plugging direction of the connector is integrally formed on the connector housing 45 or the supporting housing 49 to replace the S-shaped elastic part 44, without adding The number of parts is such that the connector 13 is returned to the center.

[0035] Figure 4 Among them, on the housing 47 on the bracket, a connector setting window 48 is provided at the protruding part of the connector 13, and the connector housing 45 for protecting the connector ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com