Wood pulp crushing machine

A pulverizer and pulverization mechanism technology, applied in pulp beating/refining methods, textiles and papermaking, raw material separation, etc., can solve problems such as inability to pulverize hard pulp, inability to adapt to scale and demand, and difficulty in meeting quality requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

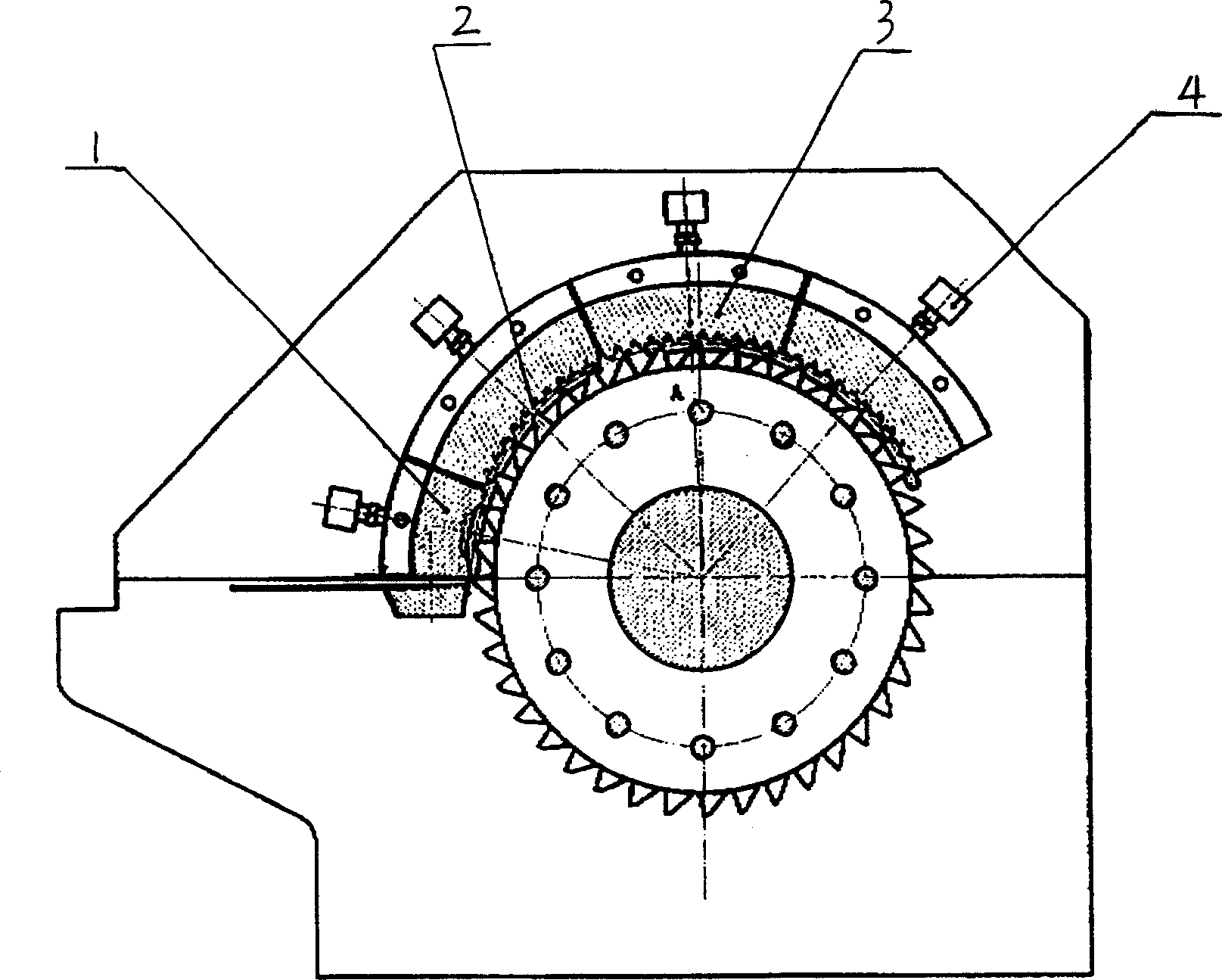

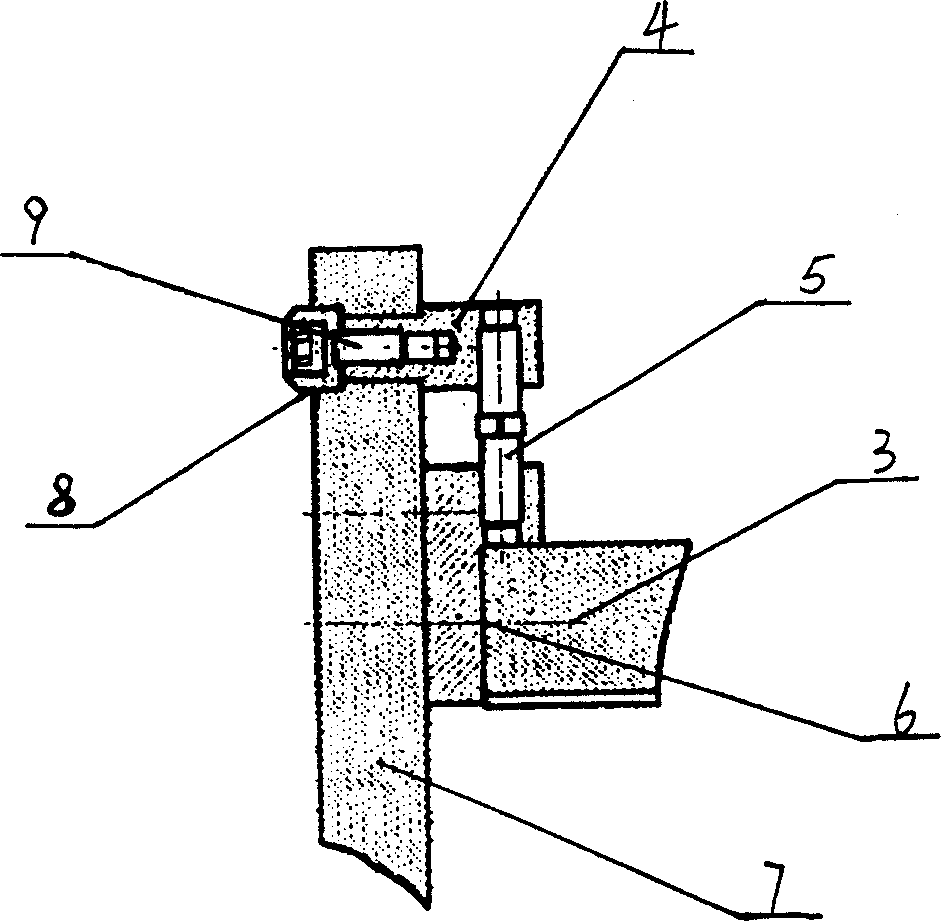

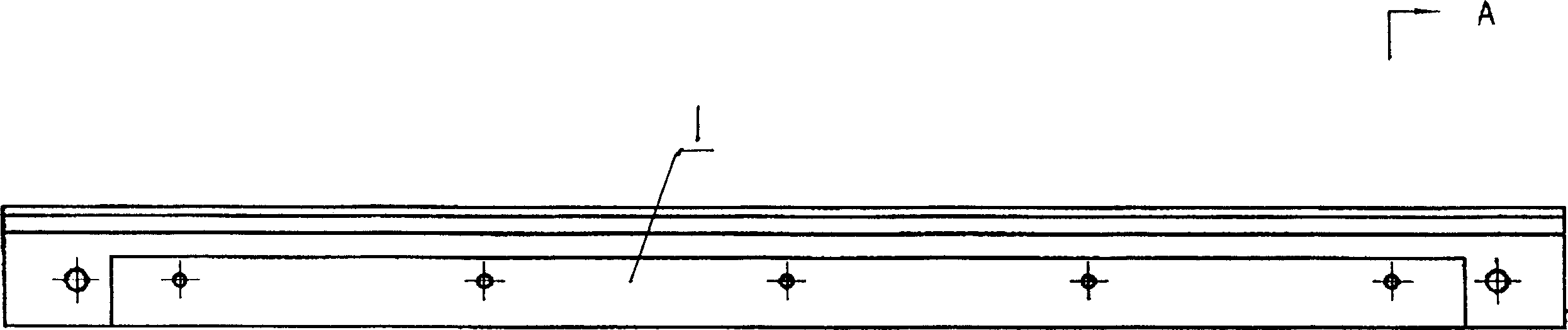

[0023] A wood pulp pulverizer includes a frame, a motor, a conveying mechanism, a material guide mechanism, and a pulverizing mechanism. The pulverizing mechanism includes a toothed roller 2 composed of a tooth piece and a main shaft, and also includes a two-blade tooth jaw plate 1 and a multi-blade tooth jaw plate 3.

[0024] See figure 1 , image 3 , the number of gears on gear roller 2 is 20, and each gear is staggered clockwise by 6 degrees; the diameter of the gear is 310 mm, and the thickness of the gear is 4 mm; the front angle of the gear is negative, and the negative angle is 10 degrees, the interdental angle is 75 degrees.

[0025] The diameter of the tooth piece increases, and the machine increases the line speed at the same speed, and its line speed is 600 m / min; the thickness of the tooth piece increases, which increases the width of the cutting edge of the tooth, increases the torn surface of the material, and reduces the product loss. Over-crushing and genera...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com