Nozzle device and substrate processing device with nozzle device

A technology of a substrate processing device and a nozzle device, which is applied in the direction of spraying devices, spraying devices, and devices for coating liquid on surfaces, etc., and can solve problems such as the inability to form a processing liquid film, the inability to coat the processing liquid, and the thickness of the processing liquid.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

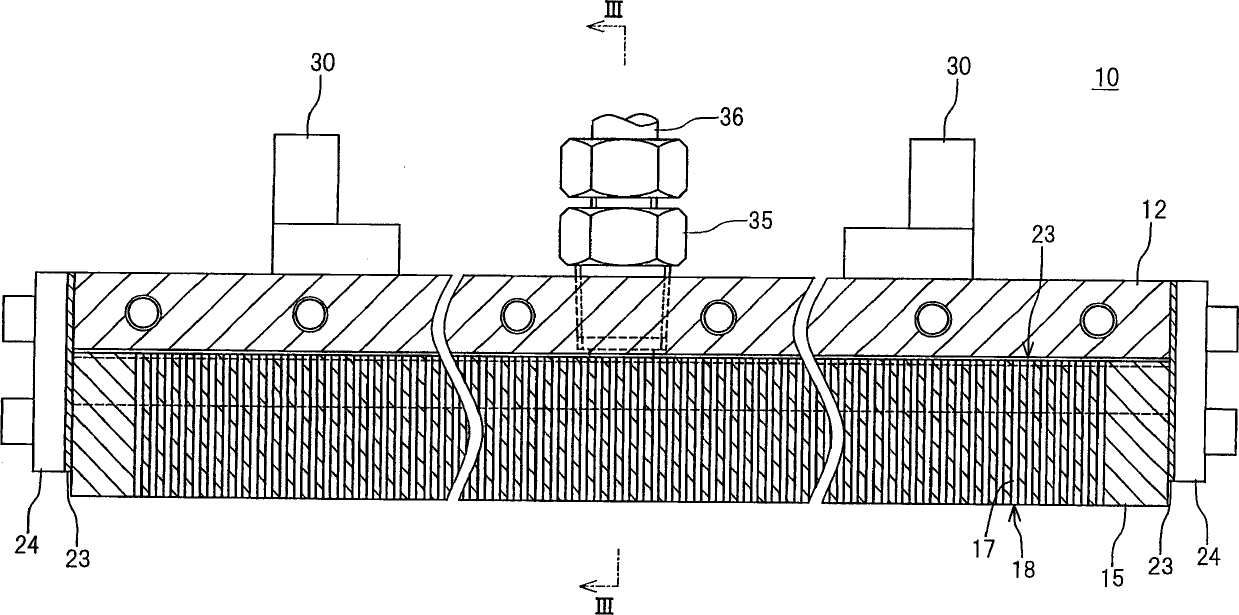

[0053] Hereinafter, in order to describe this invention in more detail, it demonstrates based on drawing.

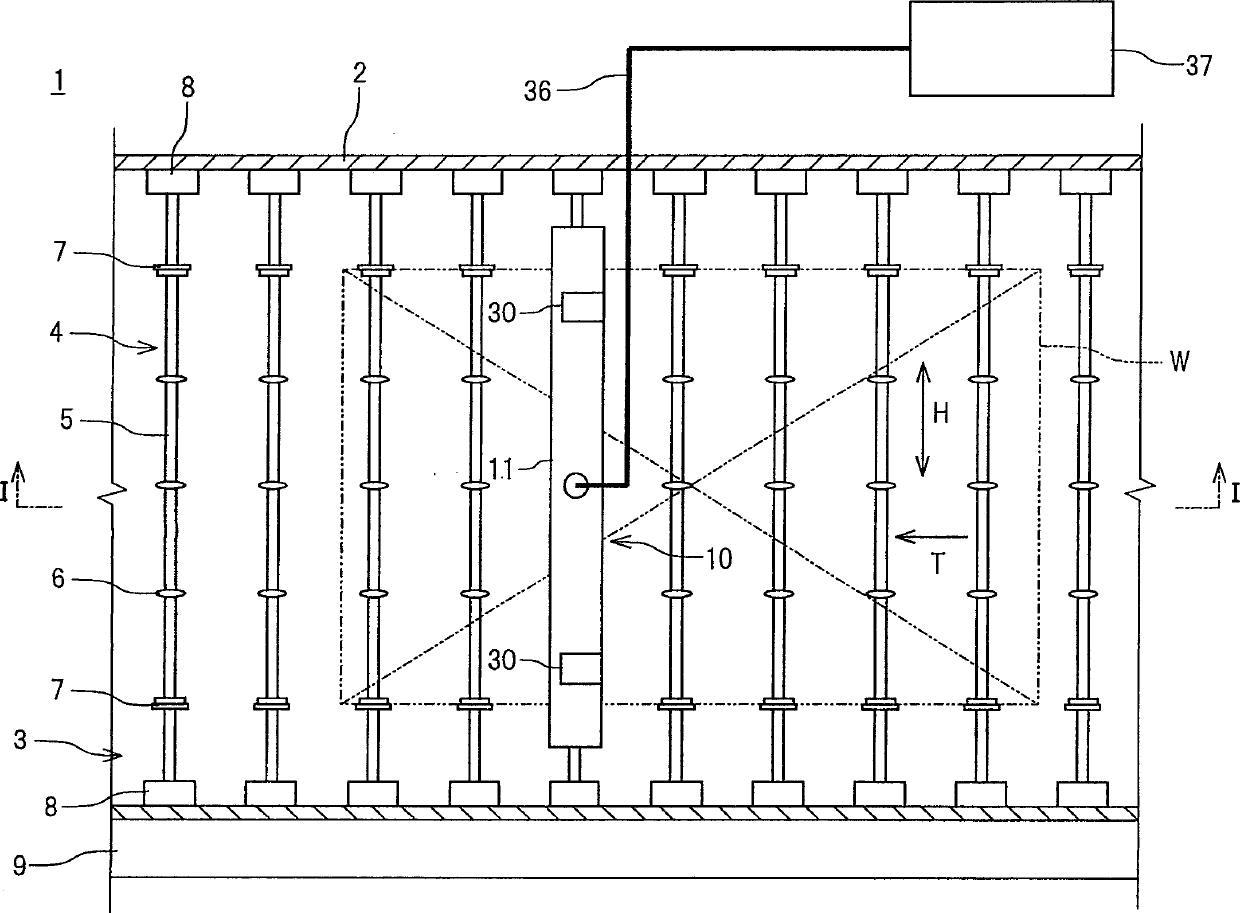

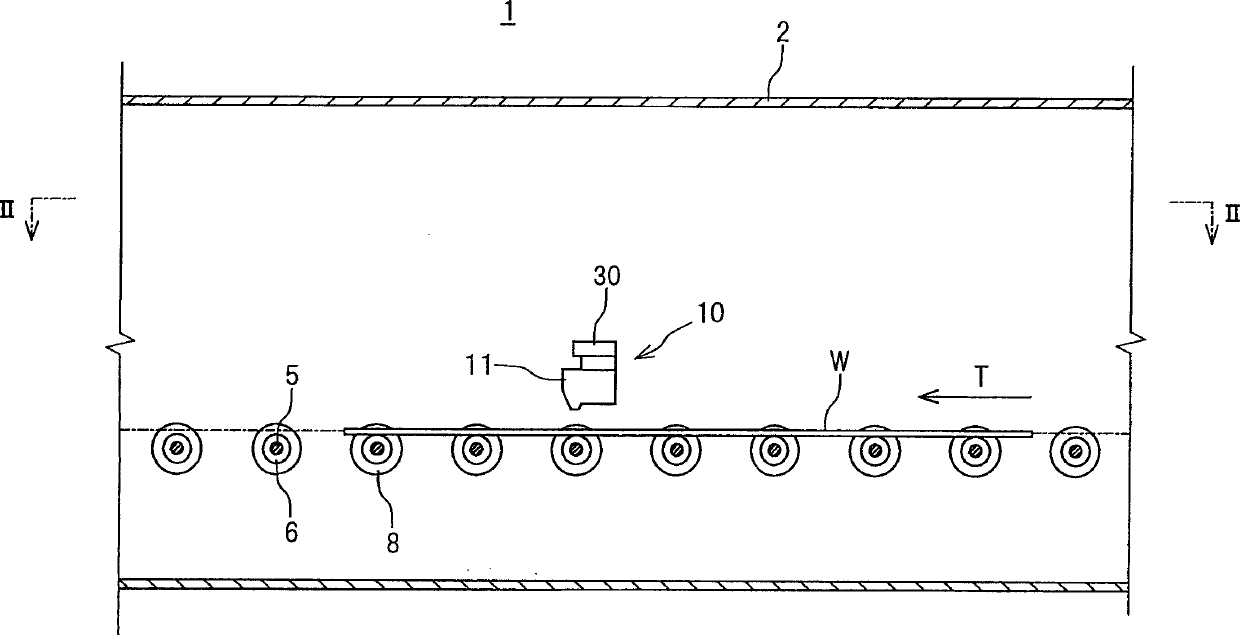

[0054] As shown in FIGS. 1 and 2 , a substrate processing apparatus 1 in the present invention includes a cover 2 forming a closed space, and a plurality of transfer rollers 4 installed at predetermined intervals in the closed space. It also includes a conveying device 3 that supports and conveys the substrate W as the processing object through the conveying roller 4; a nozzle device 10 that is installed above a series of conveying rollers 4 and applies a processing liquid on the substrate W; The nozzle device 10 supplies a processing liquid supply device 37 and the like of a pressurized processing liquid.

[0055] In addition to the above-mentioned multiple conveying rollers 4 , the conveying device 3 also includes a bearing 8 capable of rotatably supporting the conveying rollers 4 and a driving mechanism 9 capable of driving each conveying roller 4 . The conveying rol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com