Pipe nut supporting structure

A support structure and nut technology, applied in the directions of the upper structure, the lower structure, the upper structure sub-assembly, etc., can solve the problems such as the vibration of the pipe nut, and achieve the effect of suppressing the vibration and improving the assembly.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Next, a preferred embodiment of the support structure for implementing the tube nut according to the present invention will be described.

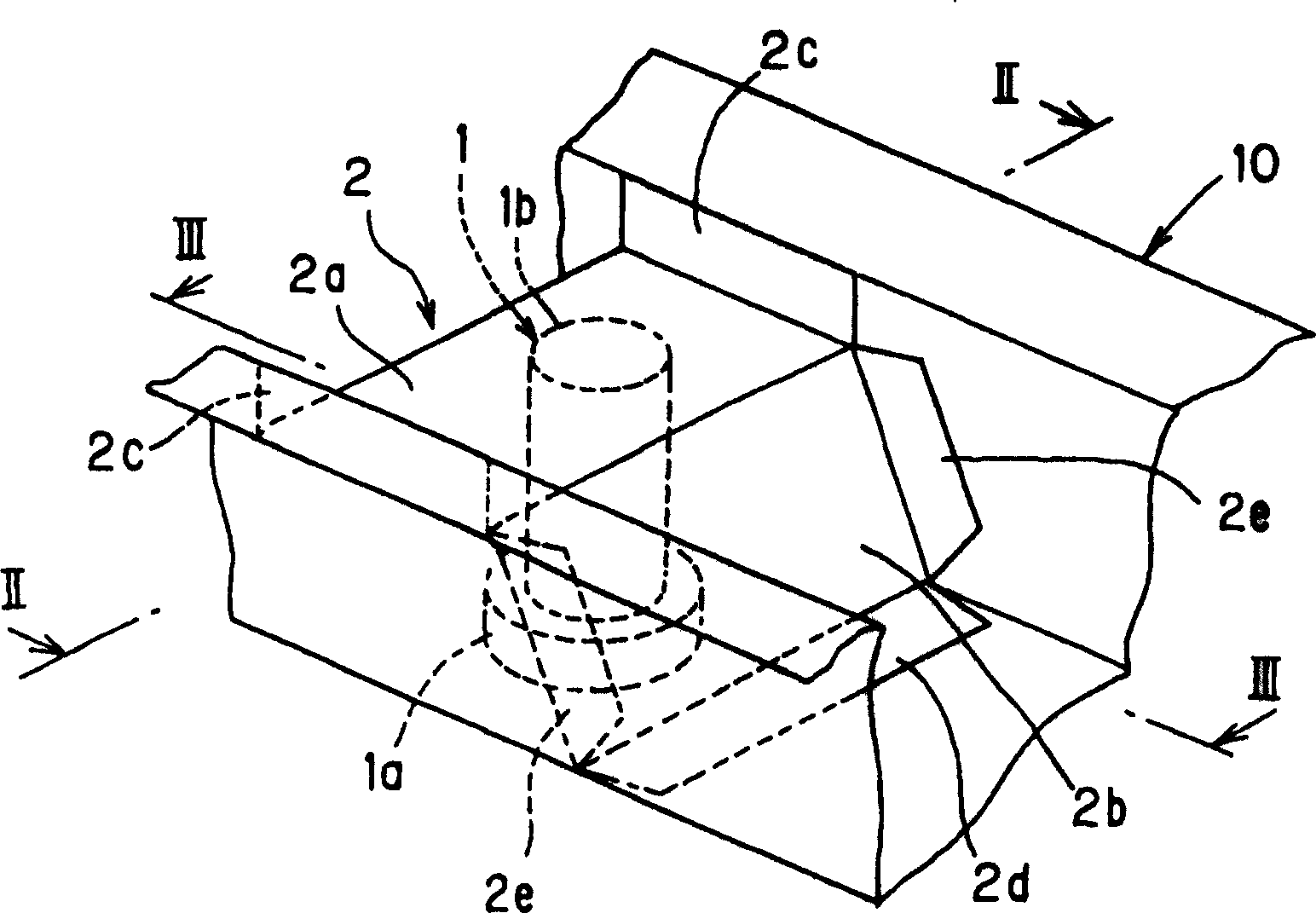

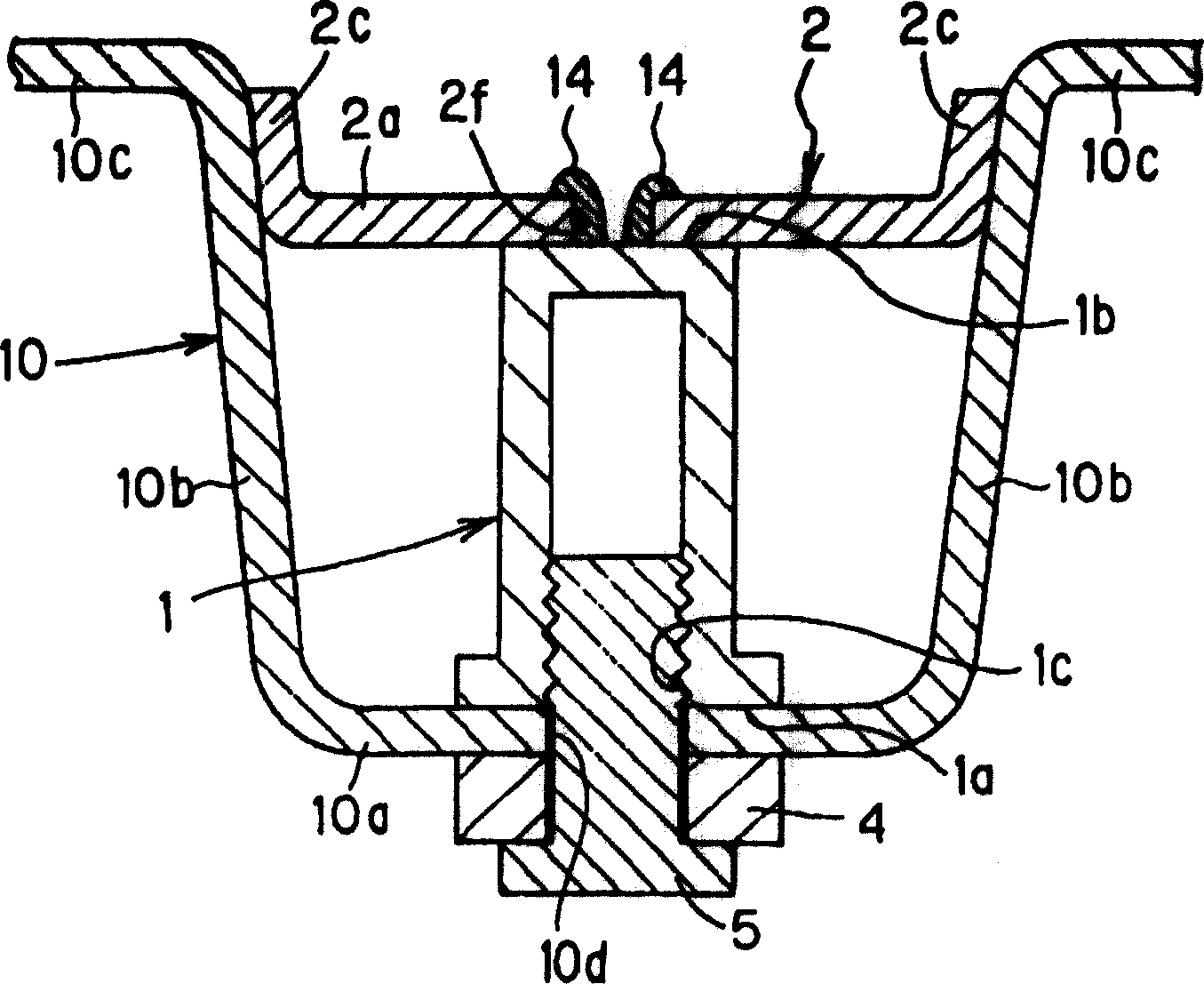

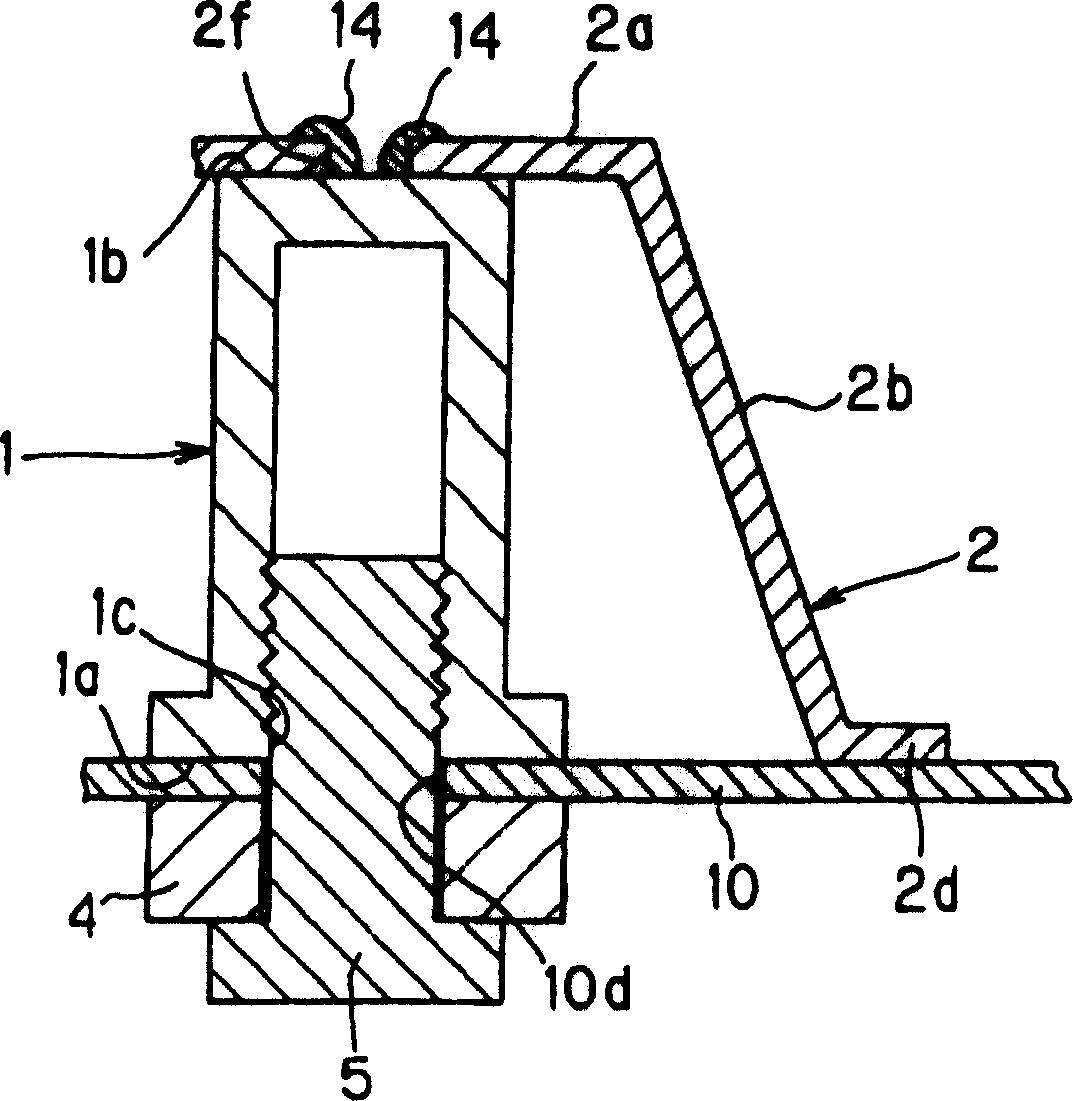

[0031] figure 1 is a perspective view of a tube nut support structure according to an embodiment of the present invention; figure 2 is along figure 1 The section view taken along line II-II in ; image 3 is along figure 1 Sectional view taken along line III-III in ; Figure 4 is a perspective view of a reinforcement member used in a tube nut support structure according to an embodiment of the present invention; Figure 5 It is an explanatory drawing of the tube nut support structure according to one embodiment of the present invention, (A) shows the state before the force F is applied thereto, and (B) shows the state after the force F is applied thereto.

[0032] In the tube nut support structure according to an embodiment of the present invention, such as Figure 1 to Figure 4 As shown, one end 1a of the tube nut 1 is ove...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com