Pipe repair system and device

A technology for pipelines and sealing devices, applied in the direction of pipe components, pipes/pipe joints/fittings, connections with fluid pressure for packing seals, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

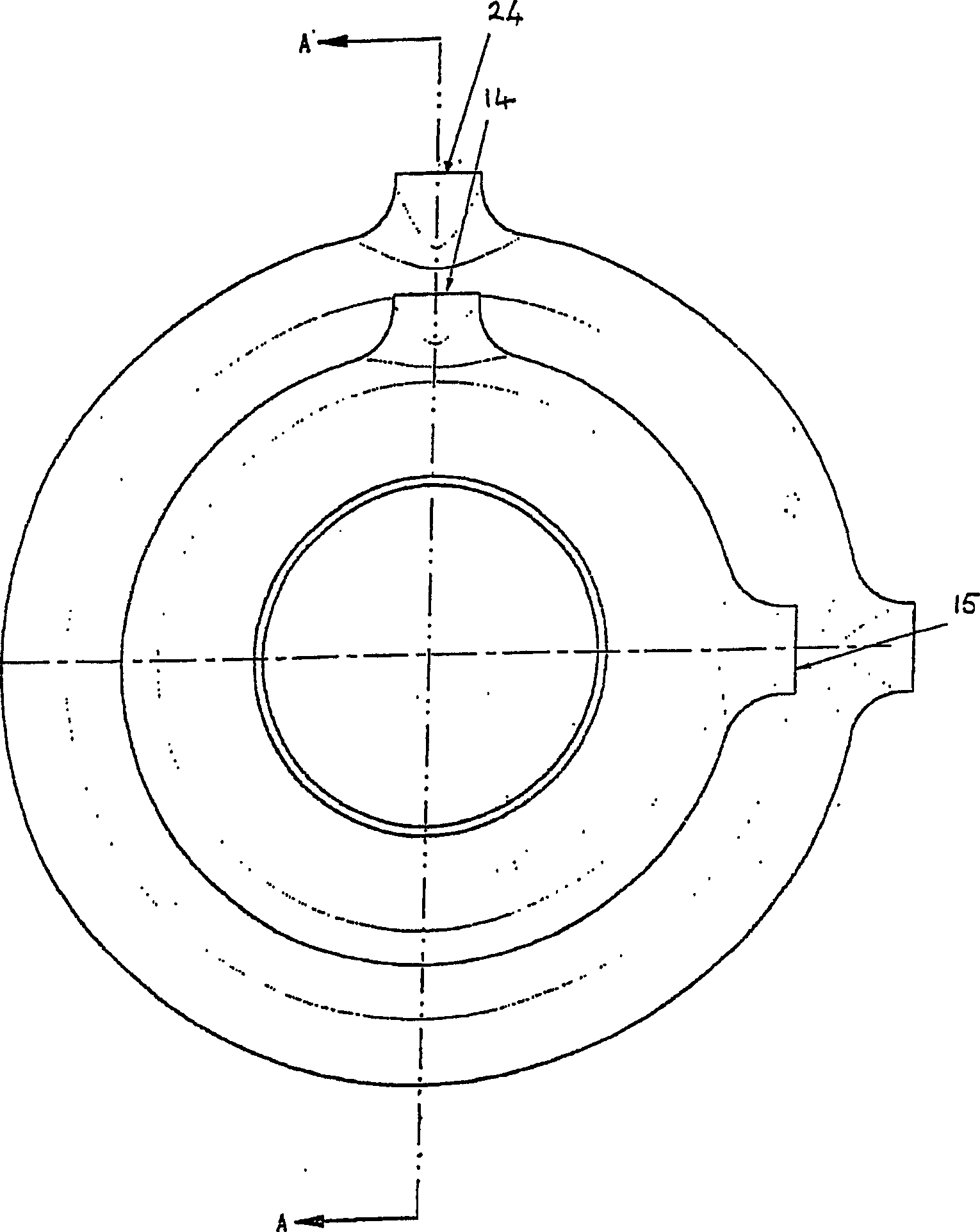

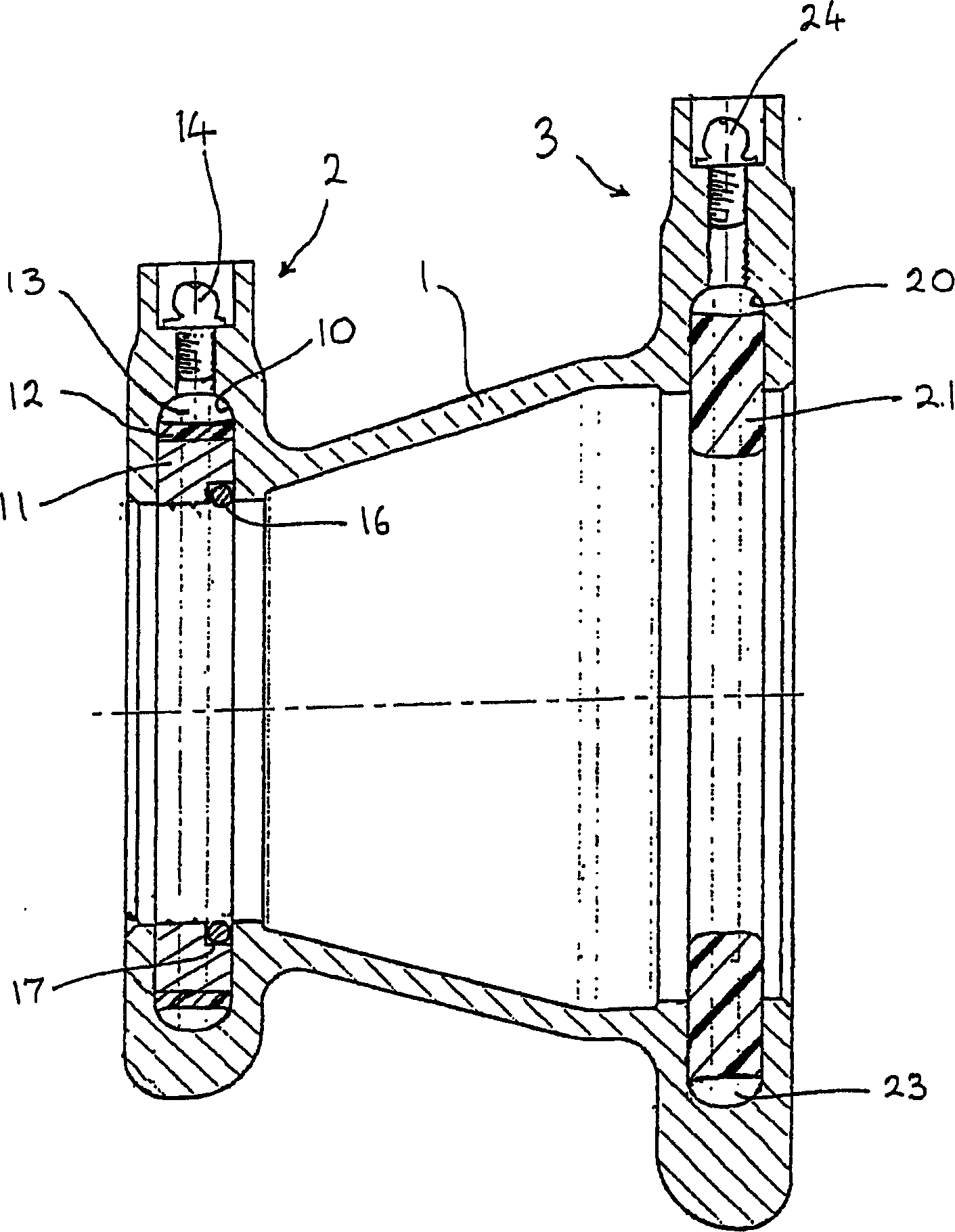

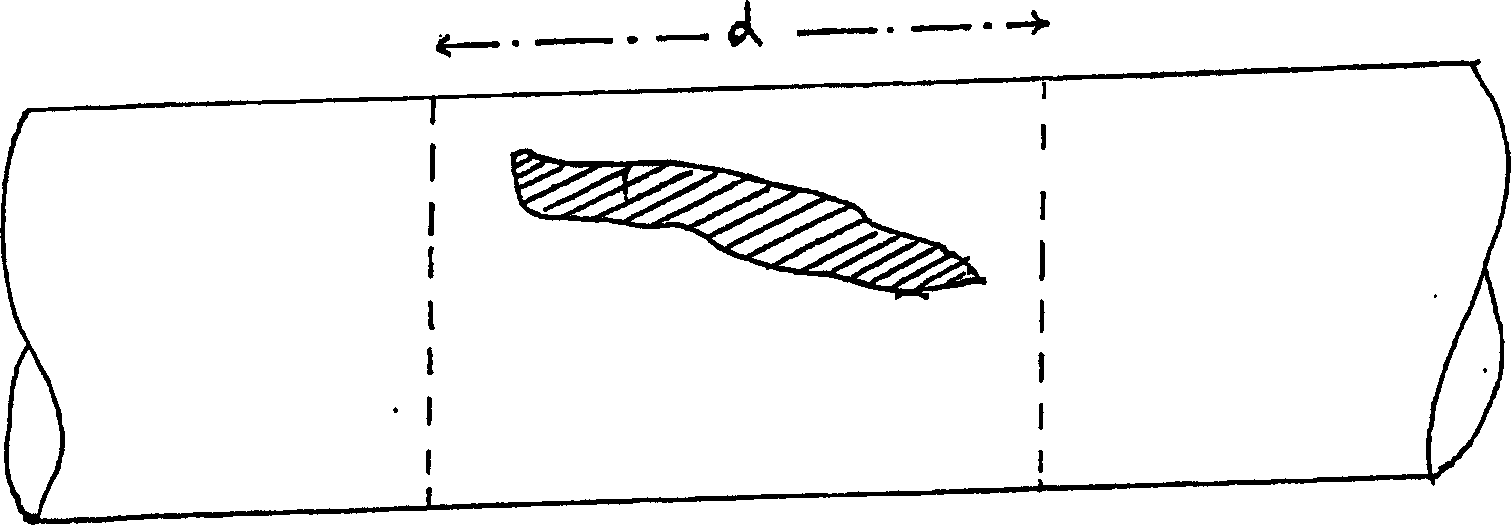

[0020] figure 1 and 2 The pipe joint comprises a generally frusto-conical sleeve portion 1 extending from a first journal 2 to a second journal 3 . As described in European patent EP-B-727026, during use, this first journal 2 is intended to surround a new pipe section. Formed on the inner surface of the journal 2 is an annular groove 10 which accommodates a circular row of arcuate pipe clips 11 surrounded by a seal 12 . A hydraulic chamber 13 is formed between the sealing member 12 and the inner peripheral surface of the ring groove 10 , and high-pressure grease can be applied through a grease nipple 14 for pressurization. It is necessary that the drain valve 15 is offset by 90° from the grease nipple 14 so that the pressure can be released from the hydraulic chamber 13 . A row of arcuate gaskets (not shown) is arranged between the seal 12 and the arcuate pipe clamp 11, and each spacer overlaps the gap between adjacent arcuate pipe clamps, thereby preventing the seal 12 fro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com