Built-electrode sensor for water level in steam drum

A technology with built-in electrodes and steam drum water level, which is applied to the liquid level indicator for physical variable measurement, etc. It can solve problems such as easy leakage, uncertain density, and unreliable electrode sealing installation method, so as to improve the degree of insulation and high temperature and high pressure resistance. extent, the effect of measuring accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

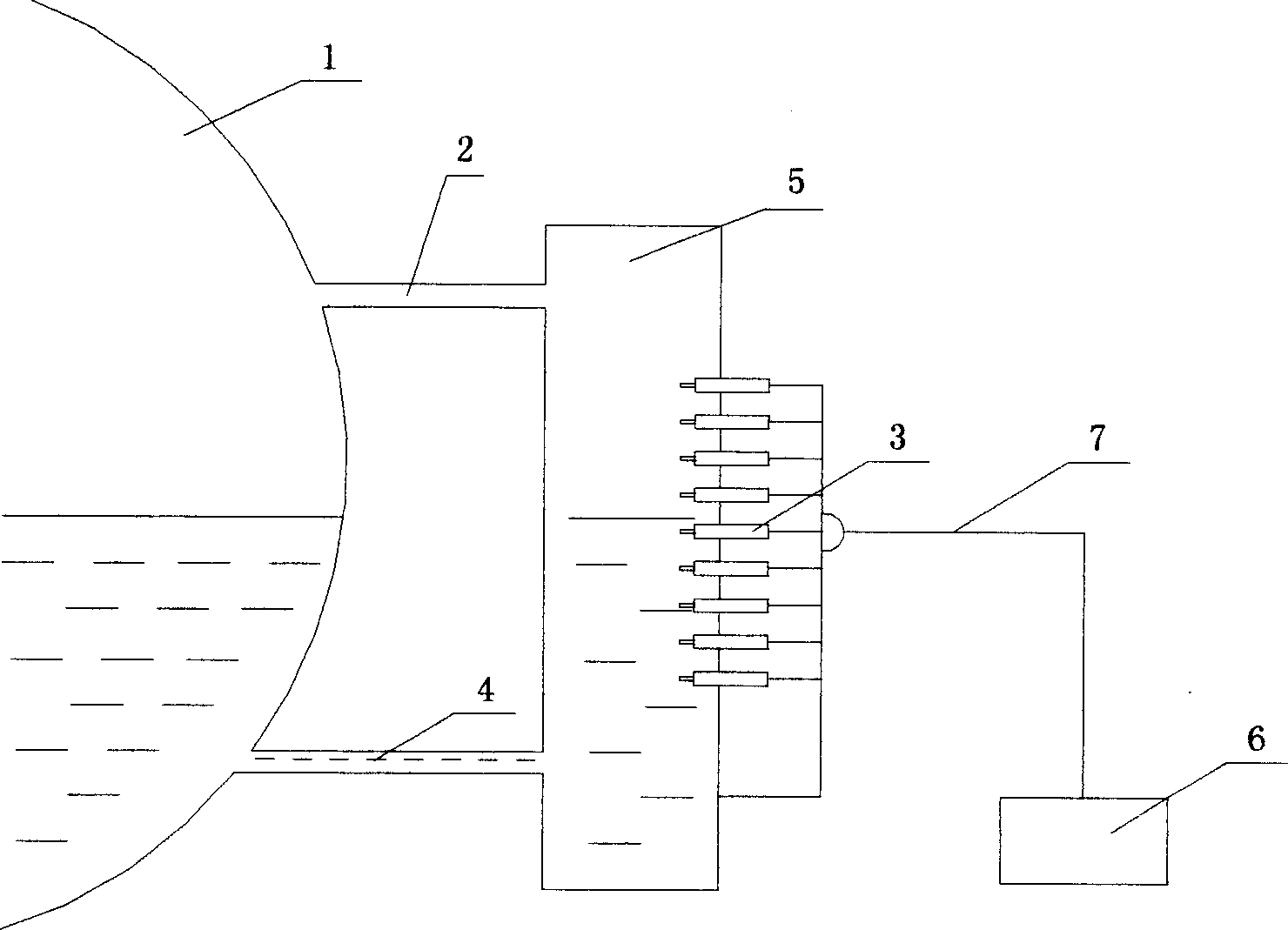

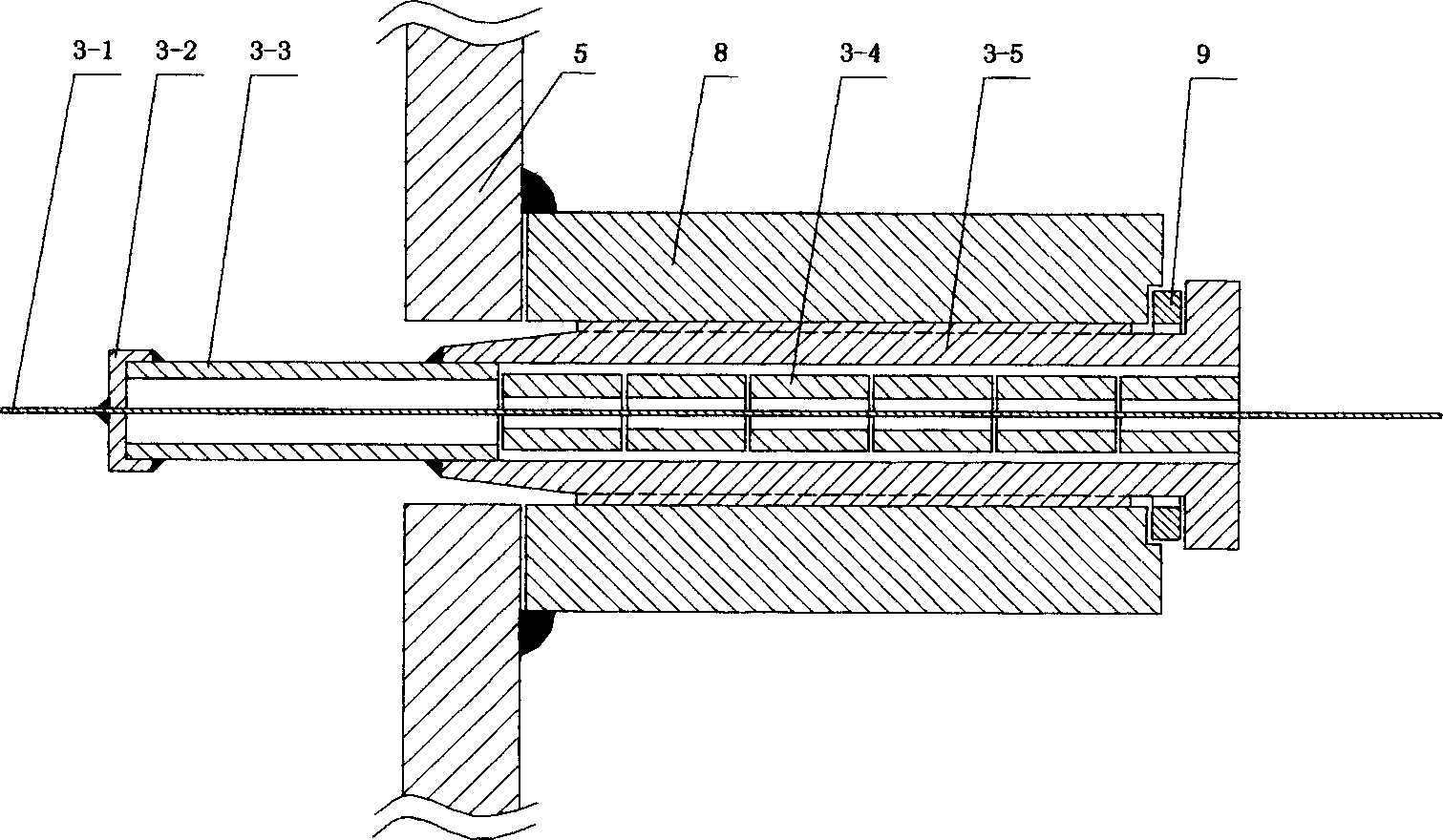

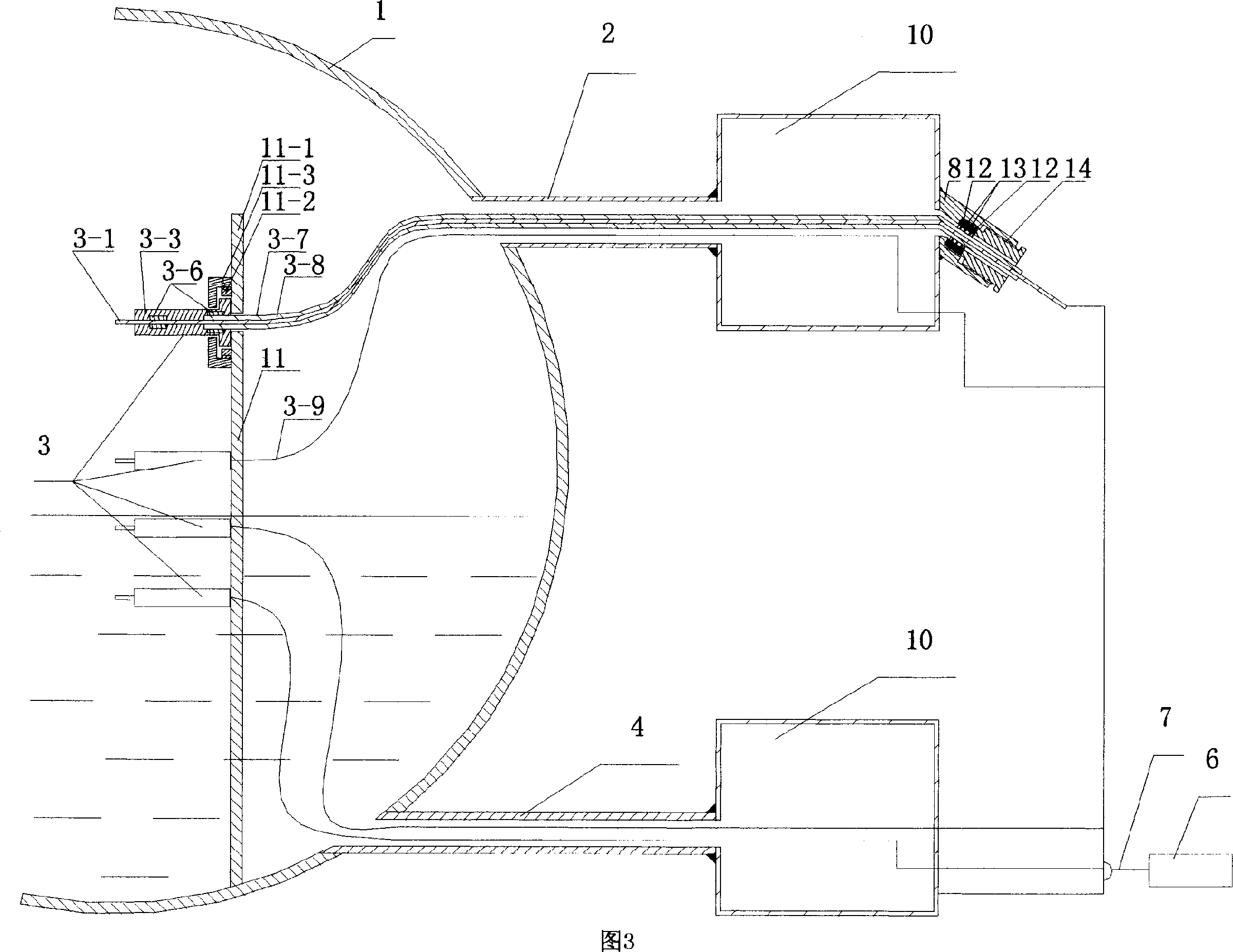

[0016] As shown in Figure 3, due to the different conductivity of steam and water in the steam drum (1), when the water level in the steam drum (1) reaches the height of a certain electrode (3), the electrode core ( 3-1) Through the cable (7), a conduction loop is formed with the steam drum (1), the water in the steam drum (1), the lead box (10) and the secondary instrument (6). Displays that the water level in the current steam drum (1) is higher than the height of the electrode (3), when the water level in the steam drum (1) is lower than the electrode (3), the electrode core (3-1) of the electrode (3) ) The circuit formed by the cable (7) is disconnected from the steam drum (1), the water in the steam drum (1), the outlet box (10) and the secondary instrument (6), and the secondary instrument (6) displays the current steam The water level in the bag (1) is lower than the height of the electrode (3), and by installing a plurality of electrodes, the water level at this time c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com