Conveyor belt for precision feed of components

A precise, carrier-based technology used in conveyors, household components, transportation and packaging to solve problems such as sorting of small parts that cannot be sorted

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

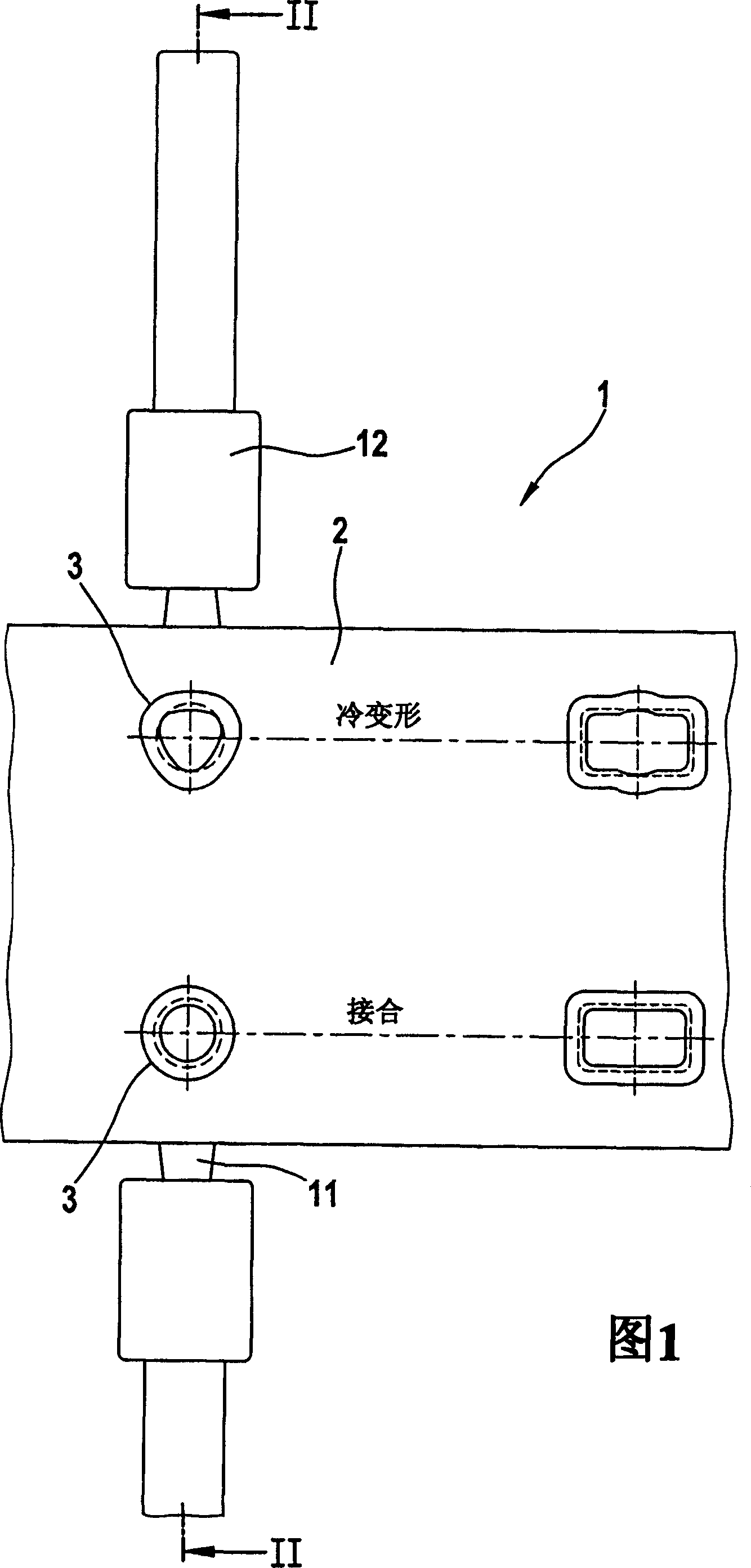

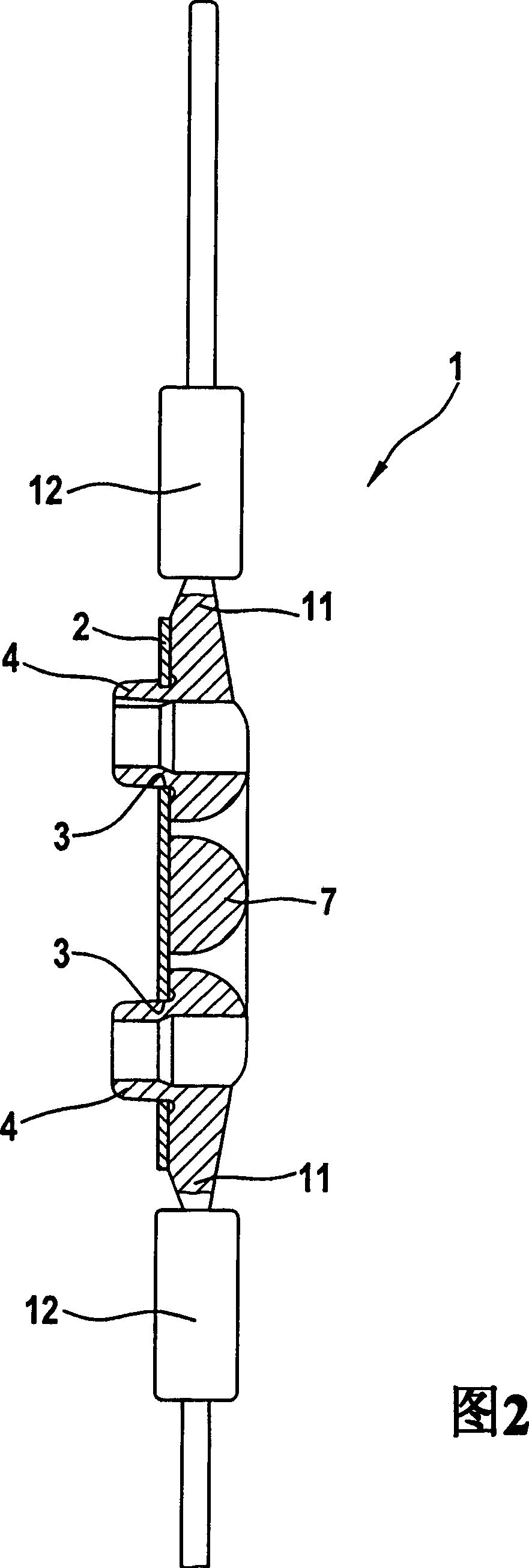

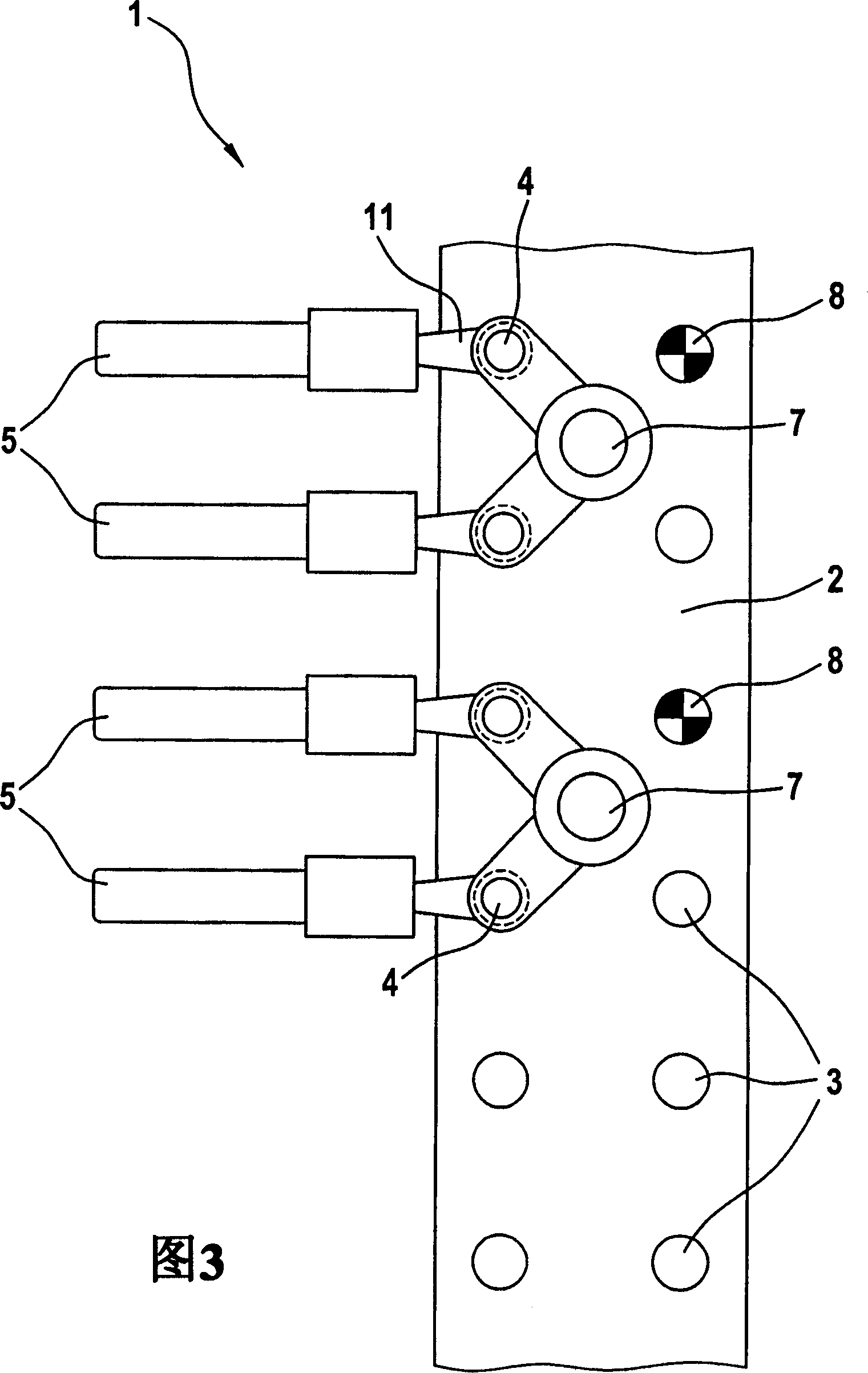

[0023] FIG. 1 shows a schematic plan view of a first advantageous embodiment and a second advantageous embodiment of a transport carrier 1 according to the invention in the upper half and the lower half, respectively.

[0024] The transport carrier 1 in the figure has a conveyor belt 2 with a matrix, that is to say with a 3-hole pattern of receiving and fixing holes. The conveyor belt 2 is formed as an essentially flat rectangular long belt. The conveyor belt 2 is made in this exemplary embodiment from a flexible metal or plastic material that complies with food regulations. Furthermore, the conveyor belt 2 has a reinforcing material, for example a special fiber mat or the like, in order to give the transport carrier 1 sufficient strength.

[0025] In this respect, the matrix of receiving and fixing holes 3 is formed by punched holes punched in pairs on the conveyor belt 2 in a regular sequence in the longitudinal direction. In this respect, the receiving and fixing hole 3 s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com