Golf putter head

A golf head and ball head technology, which is applied to golf balls, golf clubs, rackets, etc., can solve problems such as poor consistency, excessive welding weight, and influence on the weight distribution of the ball head, and achieve reasonable weight distribution and correlation Good results

Inactive Publication Date: 2005-09-21

世元高尔夫器材制造(上海)有限公司

View PDF0 Cites 2 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

At the same time, the overall welding weight is as much as 22 grams, which affects the weight distribution of the ball head

The ball bottom and the side of the ball head are integrated, and both are relatively thick. Due to the limitation of the structure, it is impossible to adjust the weight of the bottom and the center of gravity of the ball head by only changing the thickness of the ball bottom.

The connection between the ball head and the club is formed by grinding after surfacing, which has poor consistency and incorrect shape

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

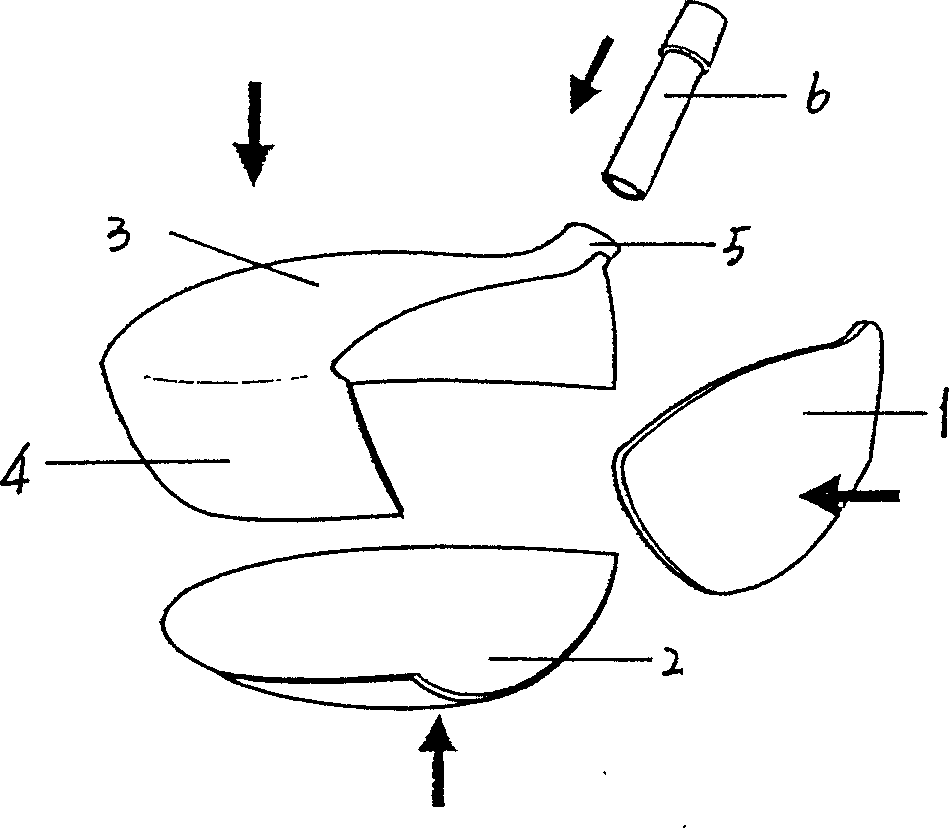

[0009] According to the drawings, while the ball cap 3 of the golf head is integrally formed with the ball head side portion 4, the portion where the ball cap 3 and the tube portion 6 are extended, that is, the throat portion 5 is also stretched and formed at the same time, and then combined with the ball sole 2, The striking surface 1 and the pipe part 6 are welded as a whole, and the final surface treatment becomes a product.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

A kind of golf bulb, comprises knock face, ball bottom, ball cover, pipe and bulb latus. The knock face is connected to the other parts by welding material. The ball cover and the bulb latus are connected as one body. The ball bottom is connected to the bulb by welding material. The invention's structure is good to lower the height of the gravity. As the ball bottom is a single spare part, we can change the thickness freely to adjust the bulb's gravity. The throat is formed by the one time tension, so the correlation is good, and the shape is nearer to the design request.

Description

technical field [0001] The invention relates to a golf equipment, in particular to a golf head for hitting a golf ball. Background technique [0002] A golf head includes several parts such as a hitting surface, a ball sole, a pipe, a side of the ball head, and a ball cover. The traditional structure is that the side of the ball head is integrated with the ball bottom, and then welded with the hitting surface and the ball cover, and the center of gravity of the ball head is high. Since the side of the ball head and the ball cover need to be welded together, the welding penetration is about 8 grams, which raises the center of gravity of the ball head. At the same time, the overall welding weight is as much as 22 grams, which affects the weight distribution of the ball head. The ball bottom and the side of the ball head are integrated, and both are relatively thick. Due to the limitation of the structure, it is impossible to adjust the weight ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): A63B53/04A63B102/32

Inventor 宋元麟

Owner 世元高尔夫器材制造(上海)有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com