Patents

Literature

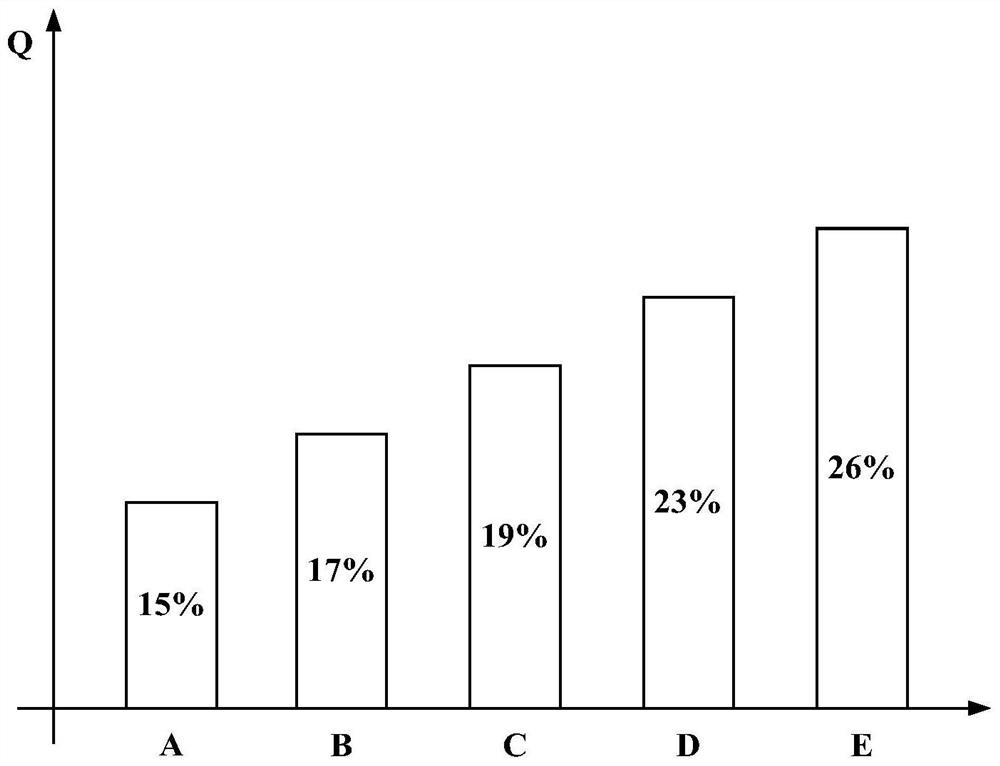

39results about How to "Reasonable weight distribution" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method and device for evaluating fighting capability of air defense and antimissile system

InactiveCN108805430AReasonable weight distributionImprove comprehensivenessResourcesEvaluation resultEngineering

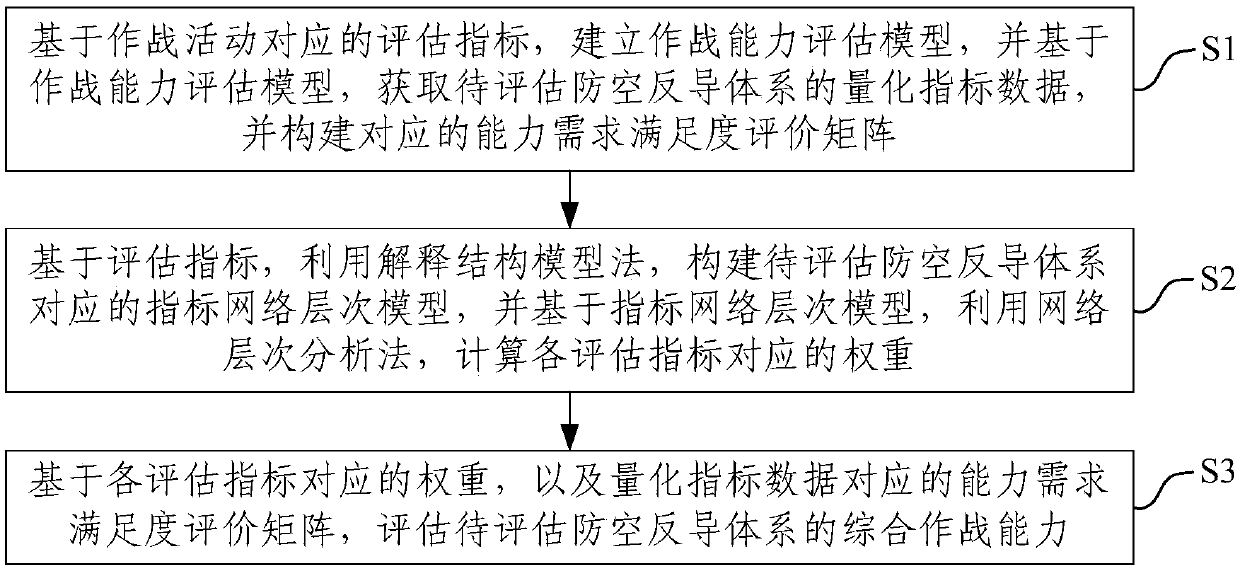

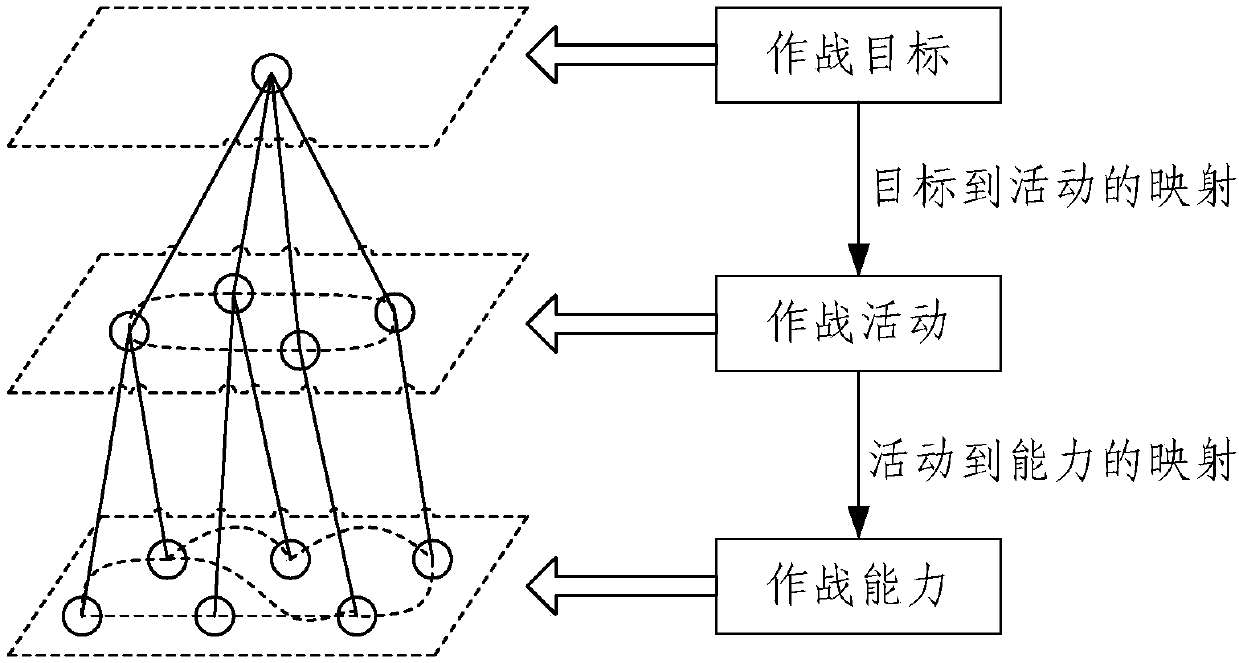

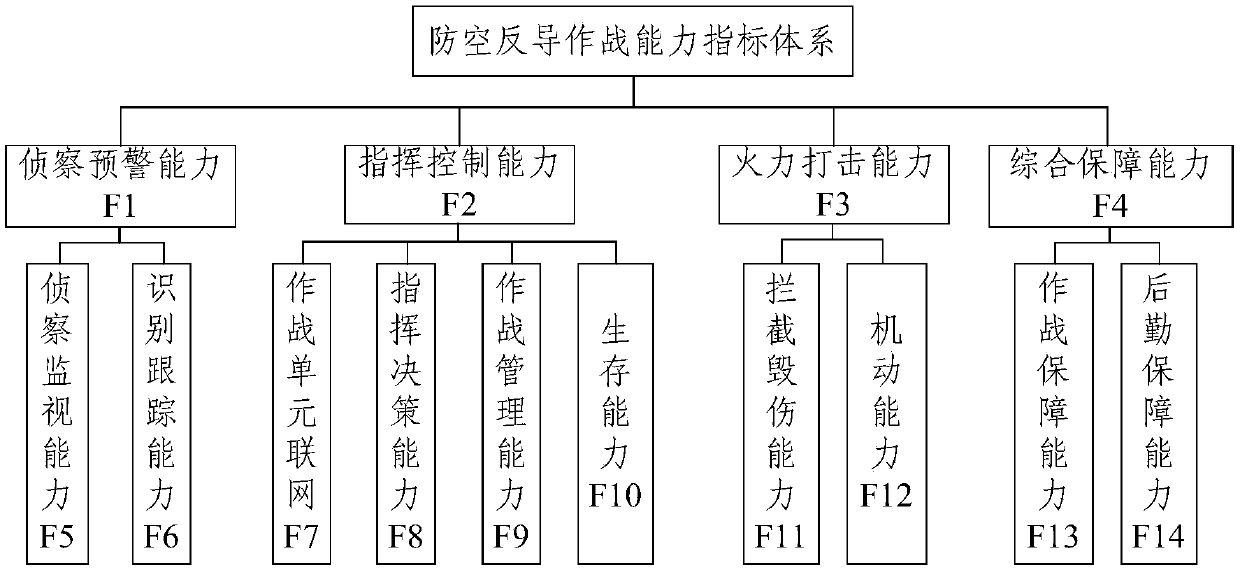

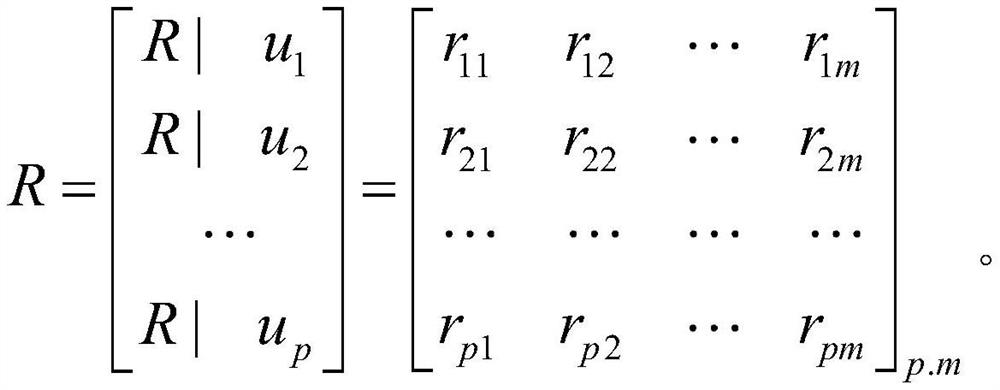

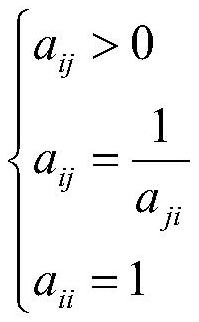

The invention provides a method and a device for evaluating fighting capability of an air defense and antimissile system. The method comprises the following steps: establishing a fighting capability evaluation model based on an evaluation index corresponding to a fighting activity, obtaining quantitative indicator data of a to-be-evaluated air defense and antimissile system based on the model, andbuilding a corresponding capability requirement satisfaction degree evaluation matrix; based on the evaluation index, using an interpretative structural modeling method to construct an index networkhierarchical model corresponding to the to-be-evaluated air defense and antimissile system; based on the index network hierarchical model, using a network hierarchical analytic method to calculate theweight corresponding to each evaluation index; and evaluating the comprehensive fighting capability of the to-be-evaluated air defense and antimissile system based on the weight corresponding to eachevaluation index and the capability requirement satisfaction degree evaluation matrix corresponding to the quantitative index data. The method and the device for evaluating fighting capability of theair defense and antimissile system in the invention can deeply analyze and directly reflect the internal logical relationship of the air defense and antimissile indicator system, so that the weight distribution between the indicators is more reasonable, thereby effectively improving the comprehensiveness, effectiveness and credibility of the evaluation results.

Owner:BEIHANG UNIV

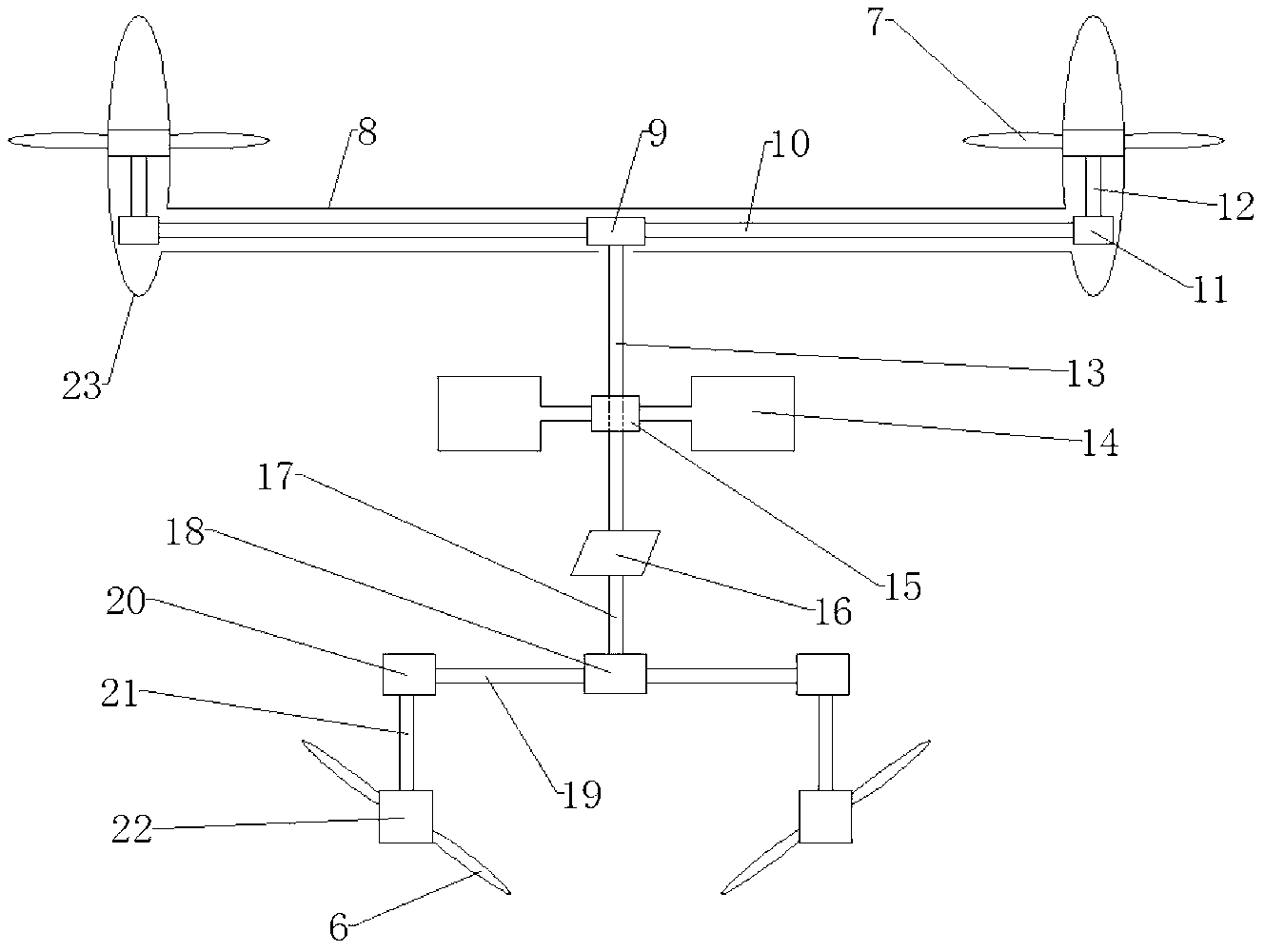

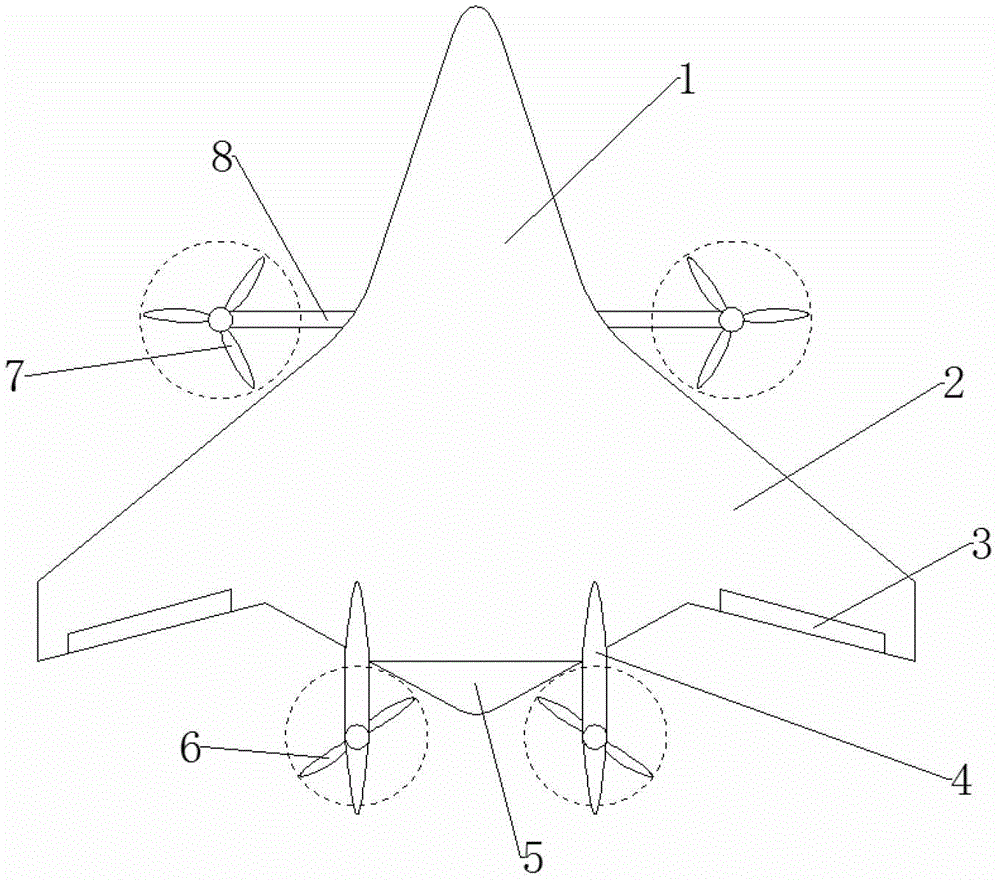

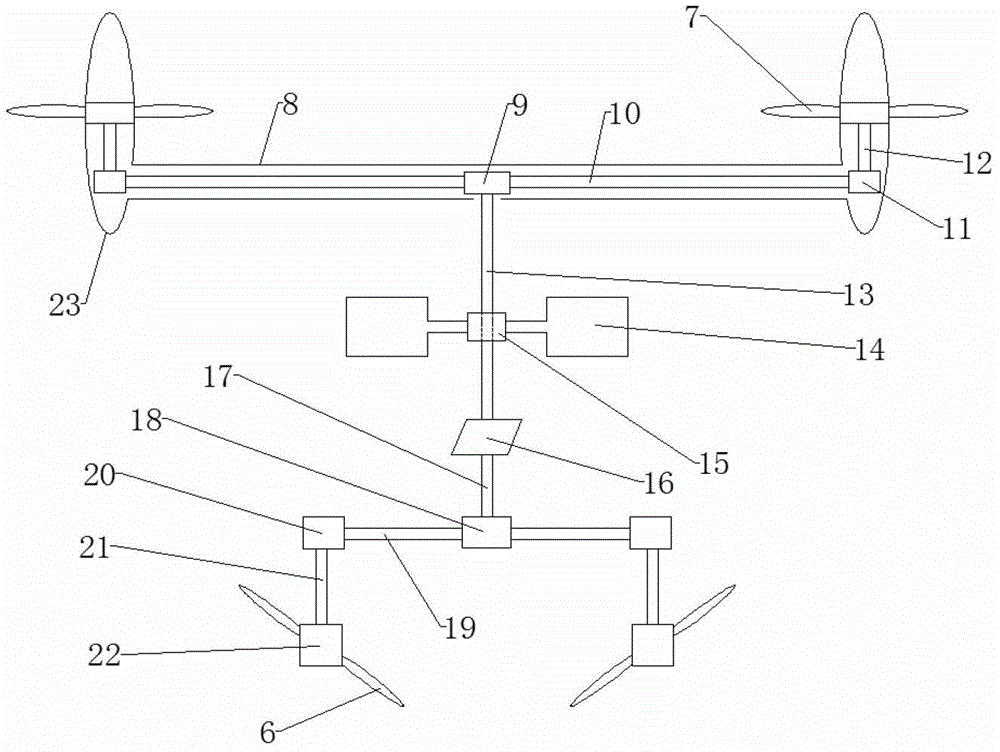

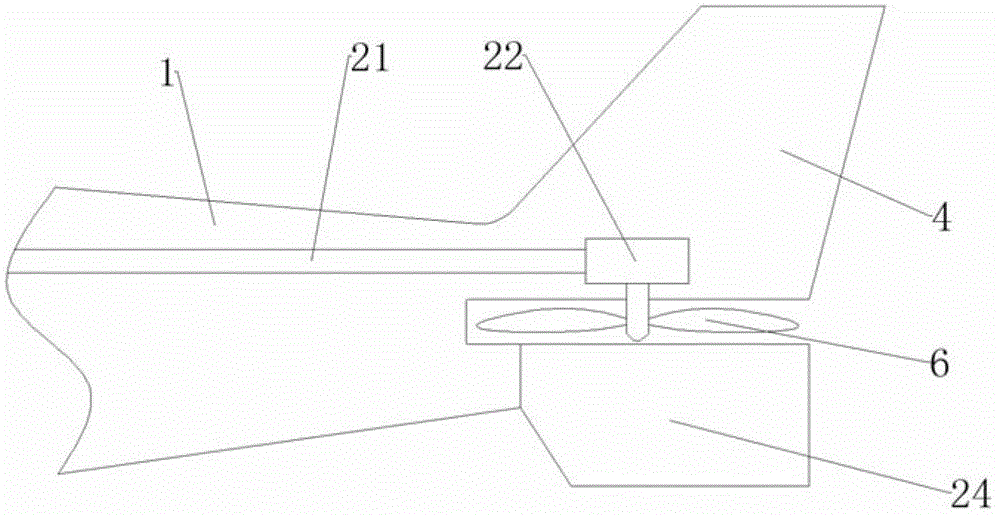

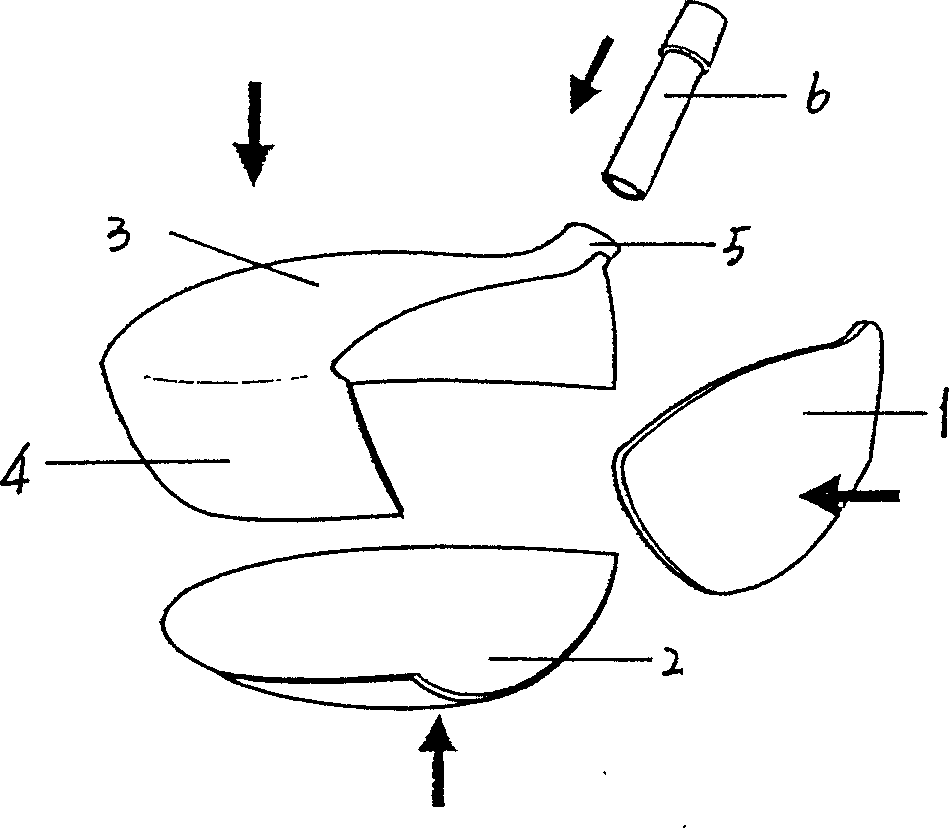

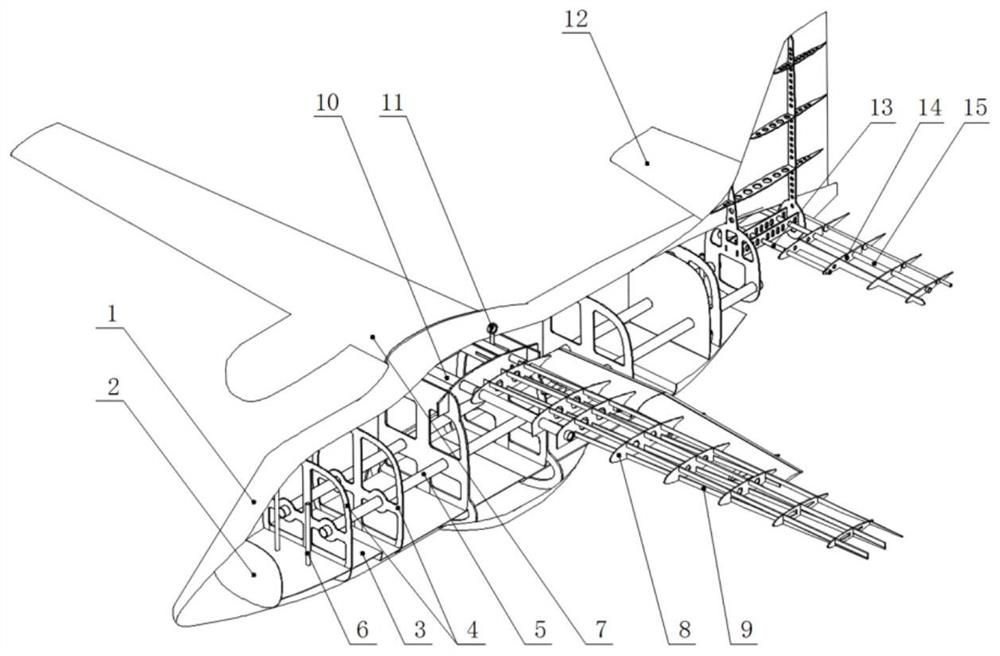

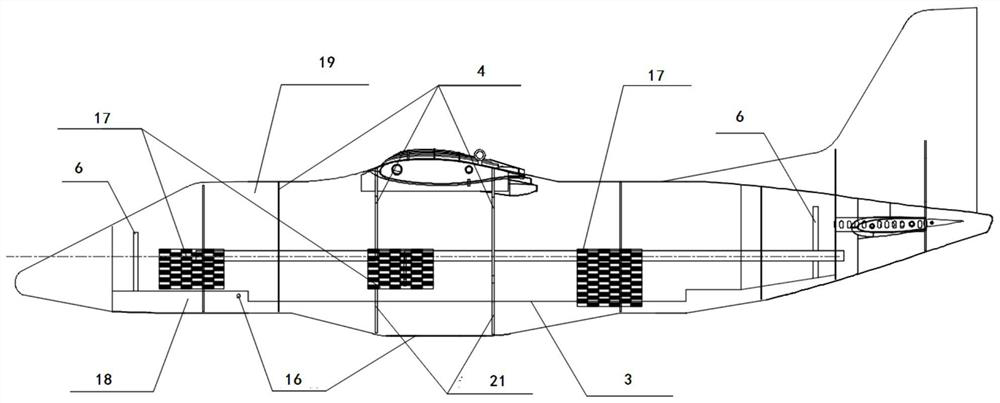

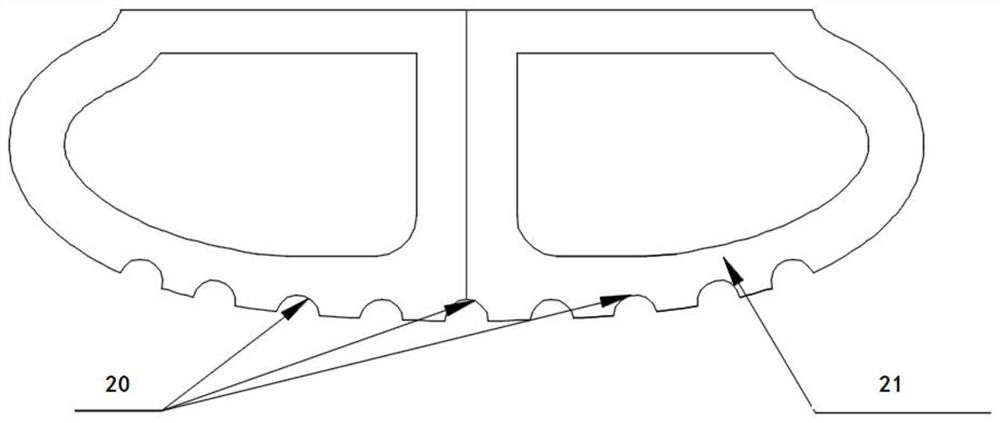

Vertical/short take-off and landing flying wing layout aircraft

InactiveCN103192990ALarge internal spaceReasonable weight distributionDepending on number of propellersRotocraftFlight directionLevel flight

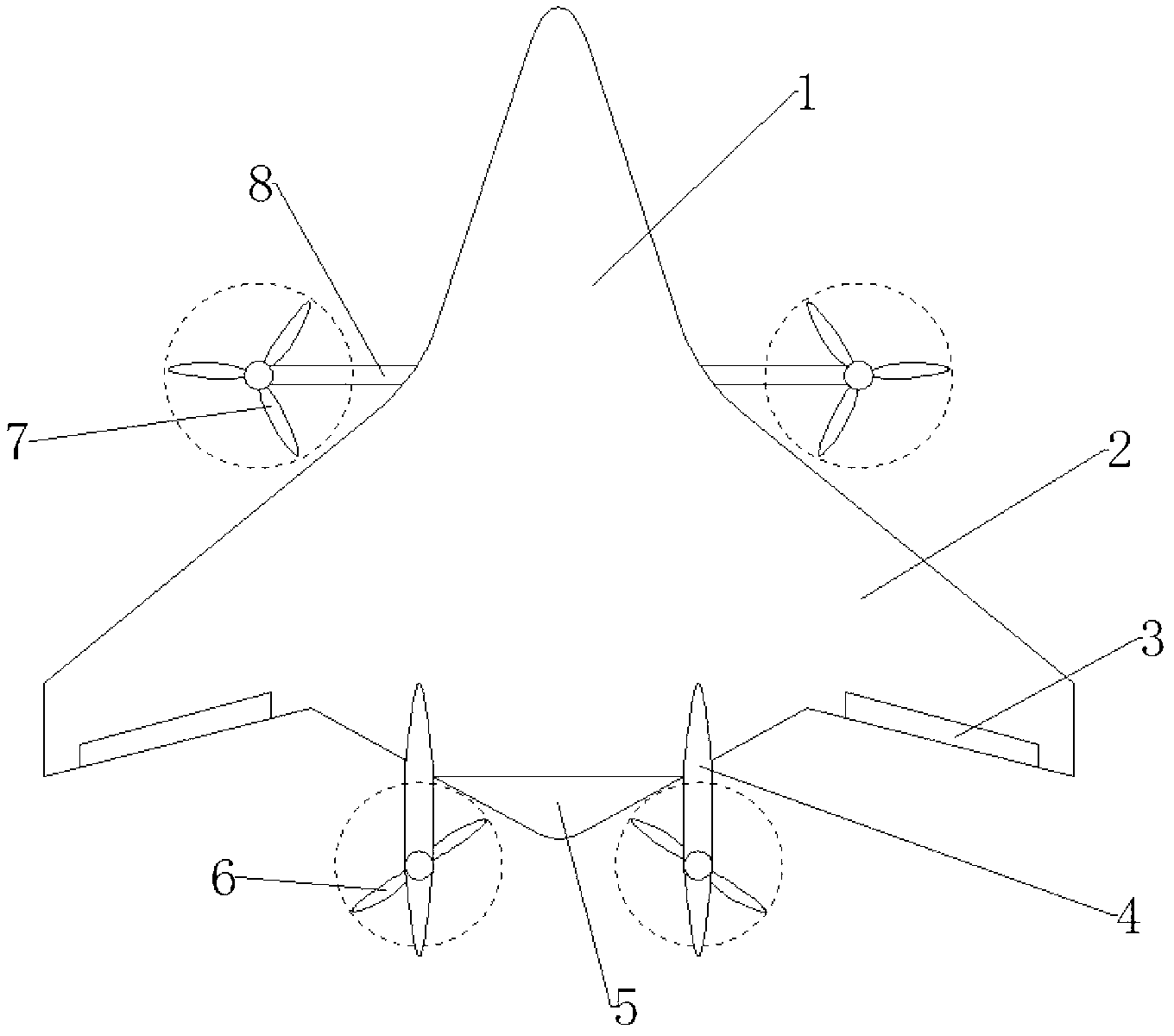

The invention provides a flying wing layout aircraft which comprises an aircraft body (1), aircraft wings (2), ailerons, an elevator (5) and double vertical fins (4), wherein the aircraft body (1) and the aircraft wings (2) are integrated; the ailerons (3) are positioned on the outer sections of the aircraft wings (2), and are used for rolling control in level flight; the elevator (5) is positioned at the rearmost part of the aircraft body (1), and is used for pitching control in level flight; and the dual vertical fins (4) are positioned at the rear part of the aircraft body (1), and are used for enhancing the flight direction safety in level flight. The flying wing layout aircraft provided by the invention has the advantages that the aircraft body integration technique inherits the excellent pneumatic property of the flying wings, and larger internal space is provided; the weight distribution is more reasonable, and the structure is lighter, so that the load and the voyage are increased; front air screws which are arranged in an engine and tilt and rear air screws which are fixed and can be accommodated in the vertical fins achieve the capability of vertical / short take-off and landing, and the interference to the whole pneumatic appearance of the aircraft is lowered greatly; and the connection shaft design among engines greatly improves the reliability of a dynamic system, avoids the dangerous situation of invalidity after taking off, and guarantees the flight safety in vertical / short take-off and landing.

Owner:BEIHANG UNIV

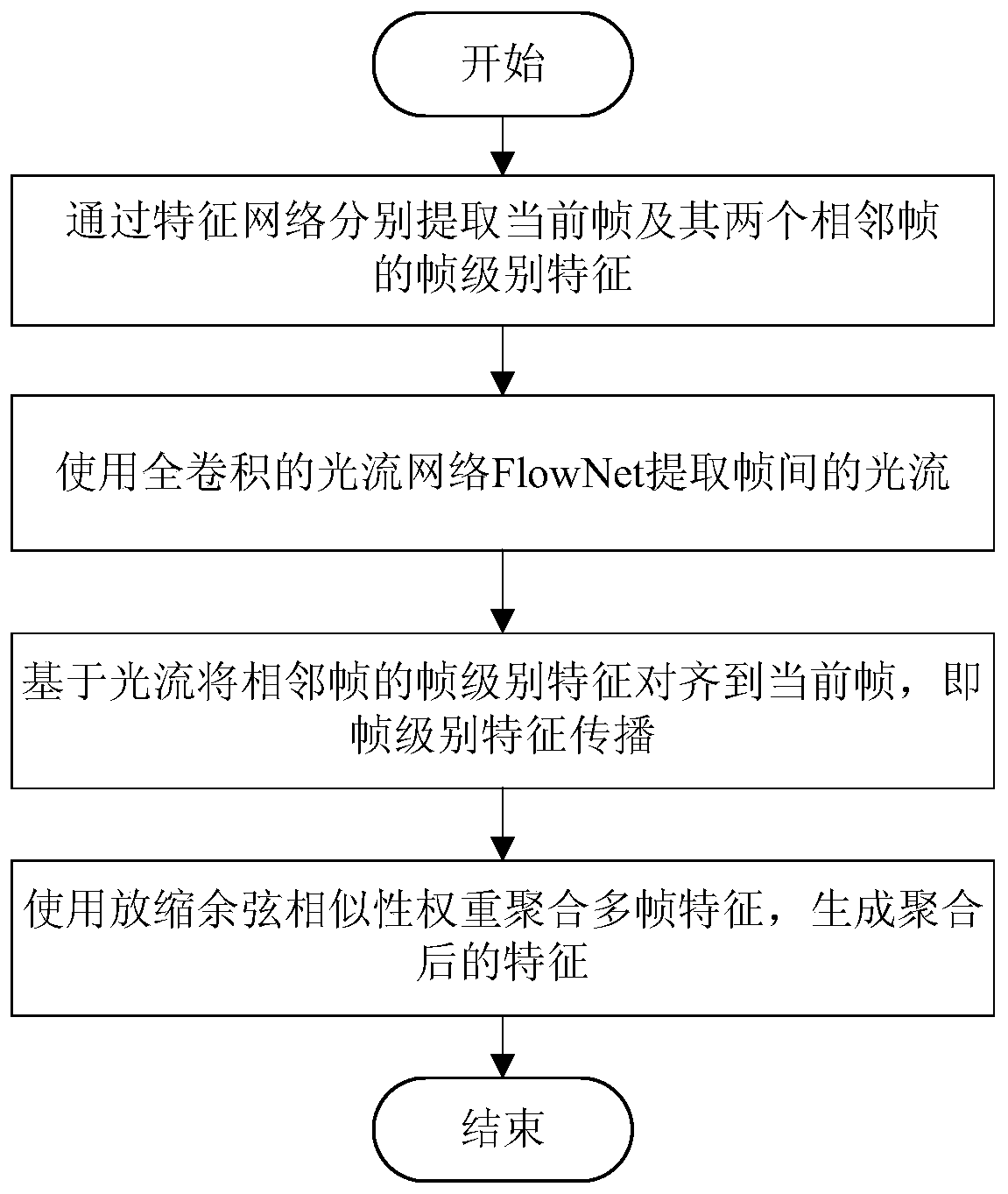

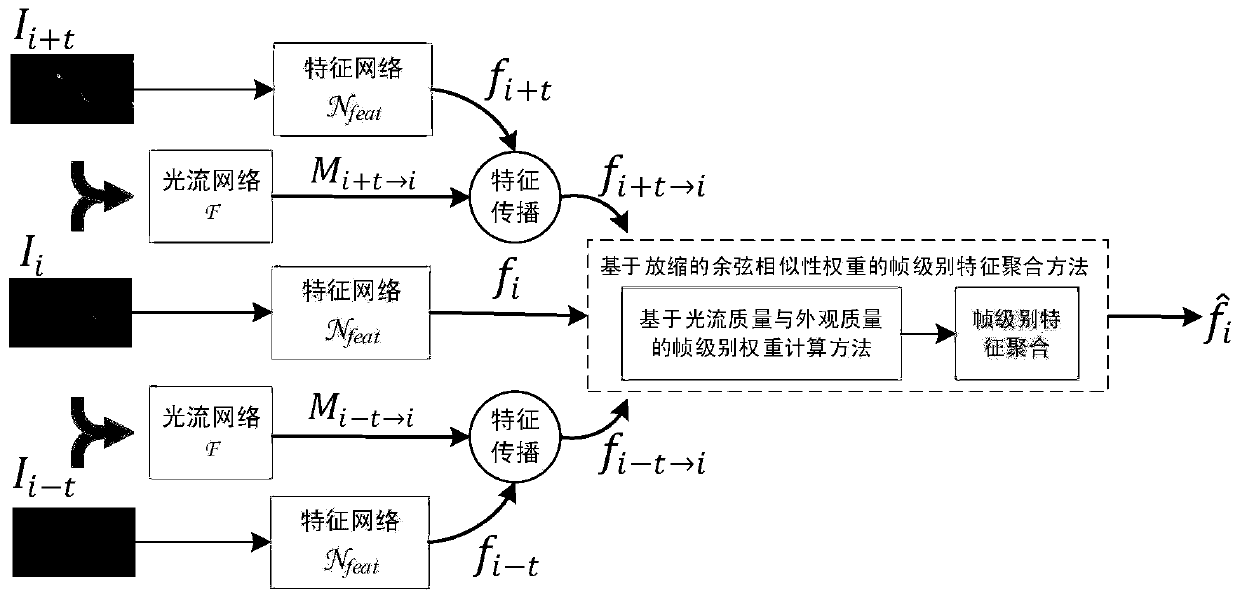

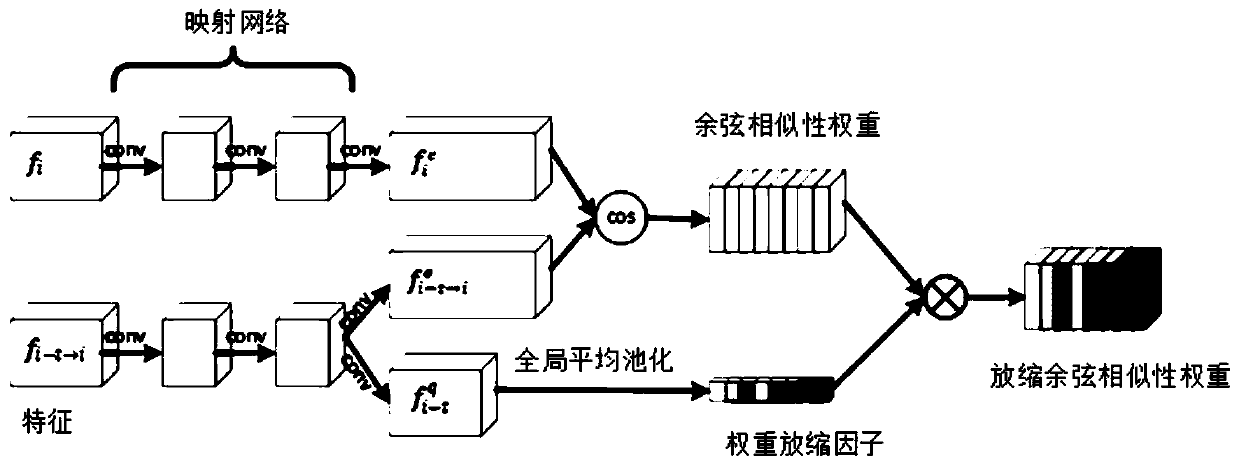

Frame level feature aggregation method for video target detection

ActiveCN109993095AEasy to detectReasonable weight distributionCharacter and pattern recognitionNeural learning methodsCosine similarityFrame based

The invention provides a frame level feature aggregation method for video target detection, and relates to the technical field of computer vision. The invention provides a frame-level feature aggregation method for video target detection. The method comprises the following steps: firstly, extracting deep features from a single-frame image through a feature network; extracting an inter-frame optical flow by using an optical flow network FlowNet; aligning the frame-level features of the adjacent frames to the current frame based on the optical flow to realize frame-level feature propagation; finally, calculating the scaling cosine similarity weight through the mapping network and the weight scaling network, and using the scaling cosine similarity weight to aggregate the multi-frame featuresto generate the aggregated features. According to the frame-level feature aggregation method for video target detection provided by the invention, the weight distribution is more reasonable, and the aggregated features are input into the video target detection network, so that video detection in complex scenes such as motion blur, low pixels, lens zooming and shielding can have a better detectioneffect and robustness.

Owner:NORTHEASTERN UNIV

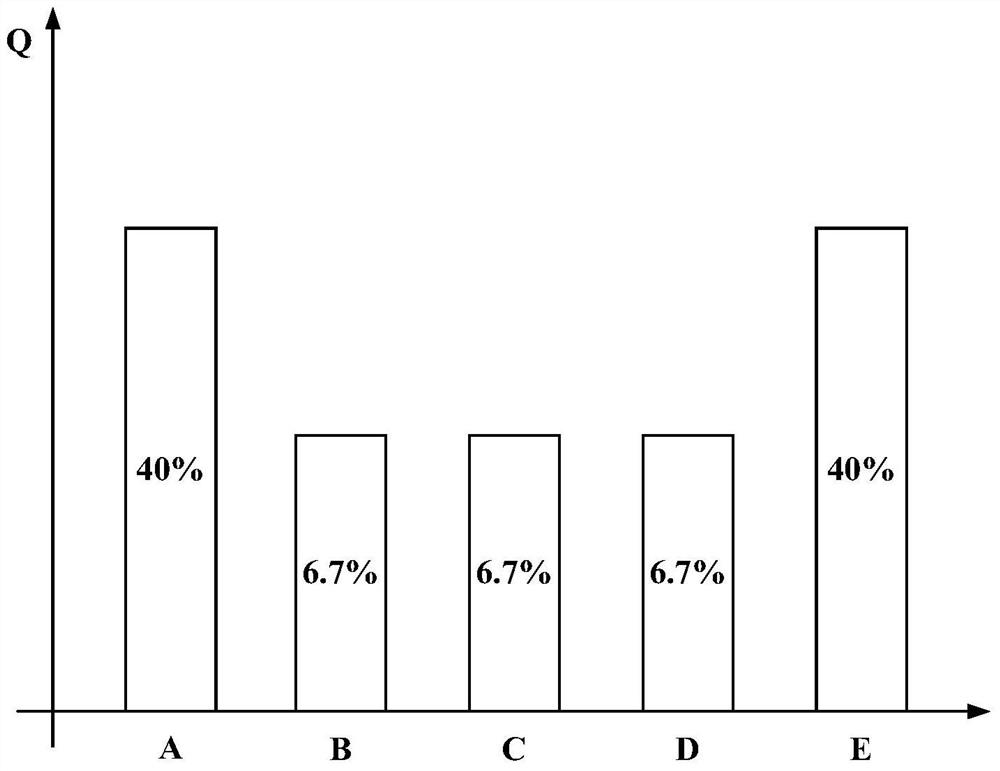

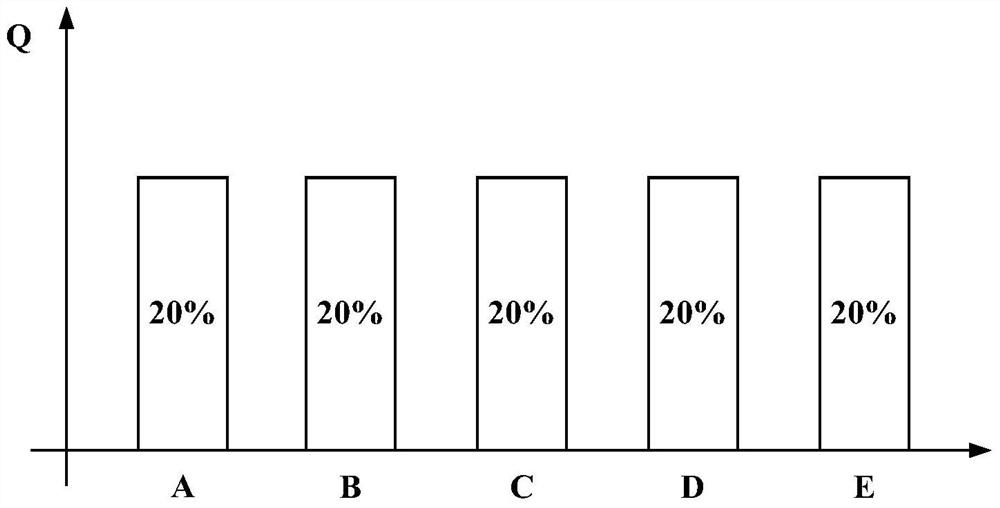

Attribution method and device of information putting effects

The invention discloses an attribution method and device of information putting effects. The method comprises steps of after counting information conversion frequency and information reaching frequency brought by each channel combination consisting of a single channel combination put by an information putting party within a set period, determining the information conversion rate of each channel combination according to the information conversion frequency and the information reaching frequency brought by each channel combination; determining the weight of each single channel in each channel combination according to the information conversion rate of each channel combination; and based on the weight of each single channel in each channel combination, determining the information conversion frequency brought by each signal channel. Compared with the current attribution method of information putting effects, the provided method is characterized in that effects caused by different channel cooperation are fully considered, so it can be ensured that the distribution weight corresponding to each signal channel is quite precise and proper, and problems of improper and inaccurate attributionin the current attribution method of information putting effects are solved.

Owner:ALIBABA GRP HLDG LTD

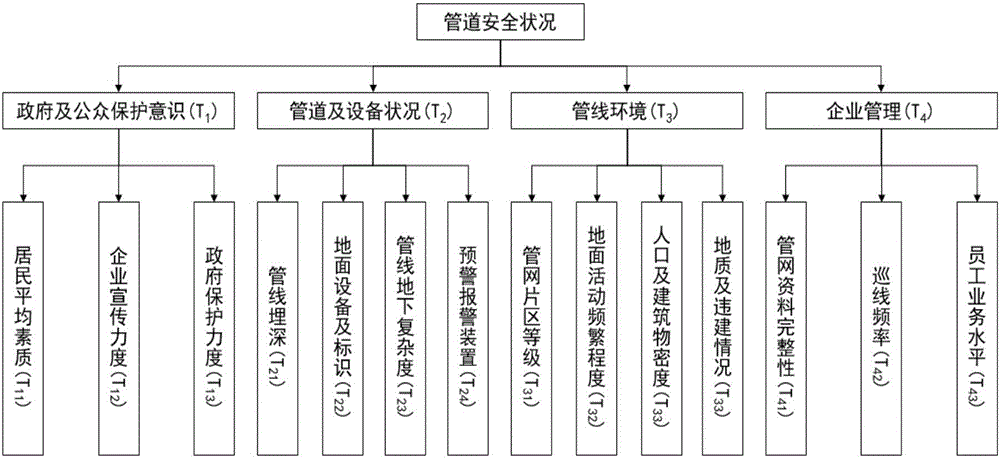

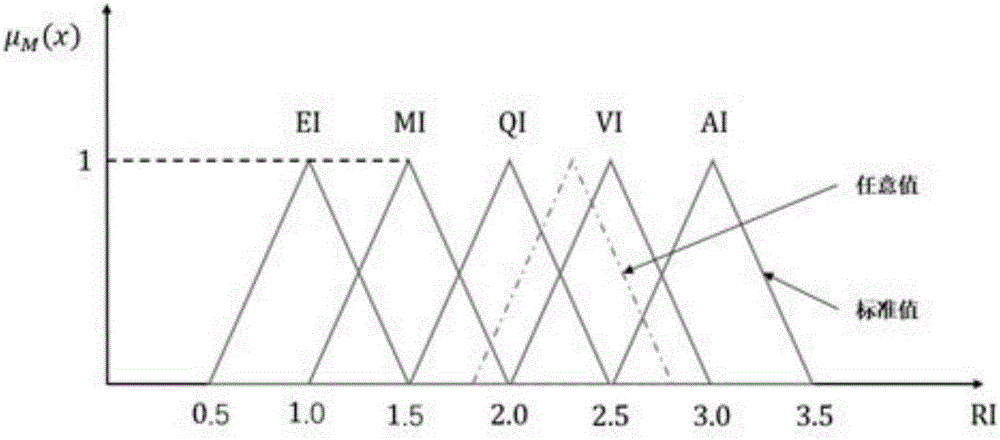

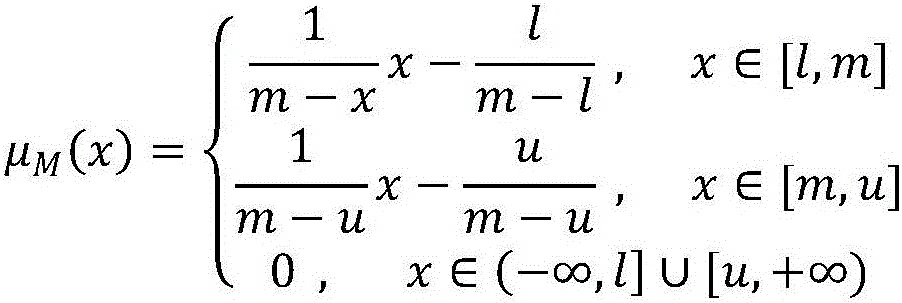

Fuzzy mathematics-based gas pipeline third-party damage risk assessment method

InactiveCN106779320AComprehensive Potential Risk FactorsObjective potential risk factorsResourcesThree levelEngineering

The invention discloses a fuzzy mathematics-based gas pipeline third-party damage risk assessment method, which can realize quantitative assessment of gas pipeline third-party damage risk. According to the technical scheme, various possible conditions of a gas pipeline third-party damage accident are systematically analyzed by adopting an analytical hierarchy process and an MMESE system theory for characteristics of diversity, complexity, uncertainty and the like of the gas pipeline third-party damage accident, a three-level hierarchical structure model is built, and a triangular fuzzy number is introduced according to a fuzziness characteristic, so that a relative importance degree among factors is quantitatively represented, the limitation of the analytical hierarchy process is overcome, human subjective influence in a conventional assessment method is reduced, and weight allocation is more accurate, objective and reasonable. The method has the advantages that the limitation of the analytical hierarchy process is overcome, and the subjective influence of the human factors in the conventional assessment method is reduced; and the weight allocation is reasonable, and an assessment result is objective and accurate.

Owner:CHENGDU QIANJIA TECH CO LTD

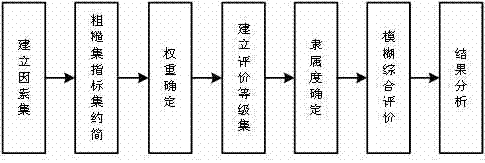

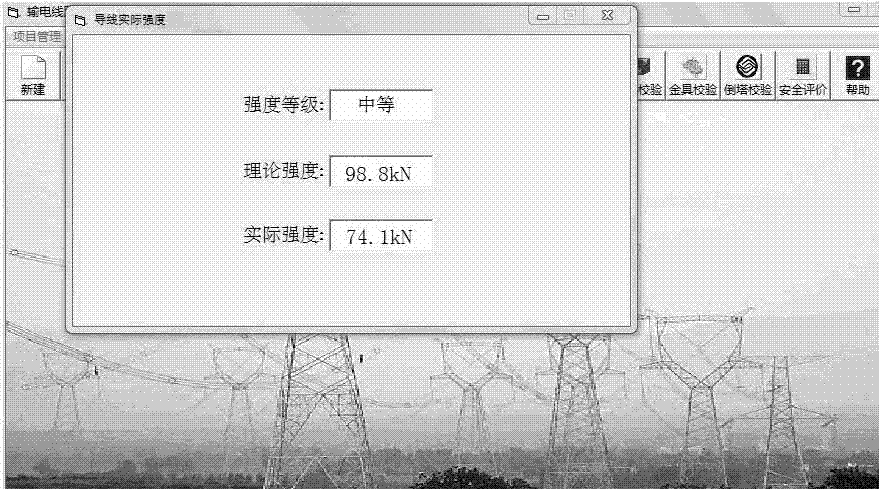

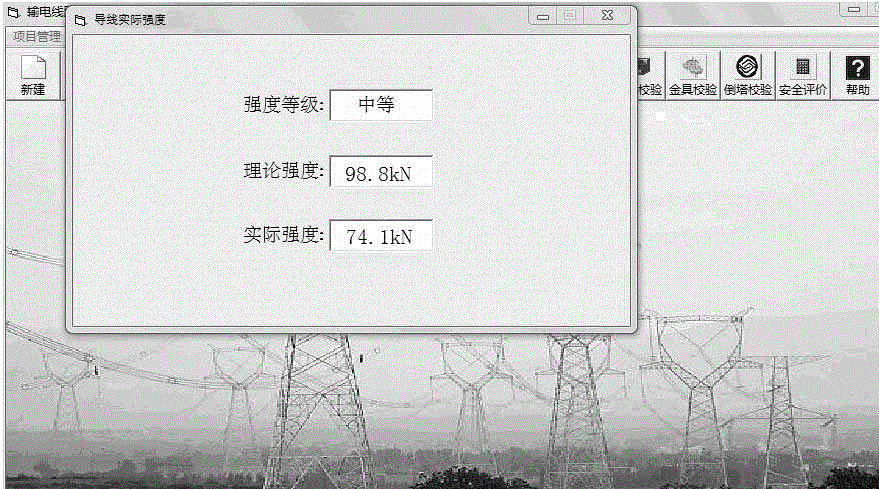

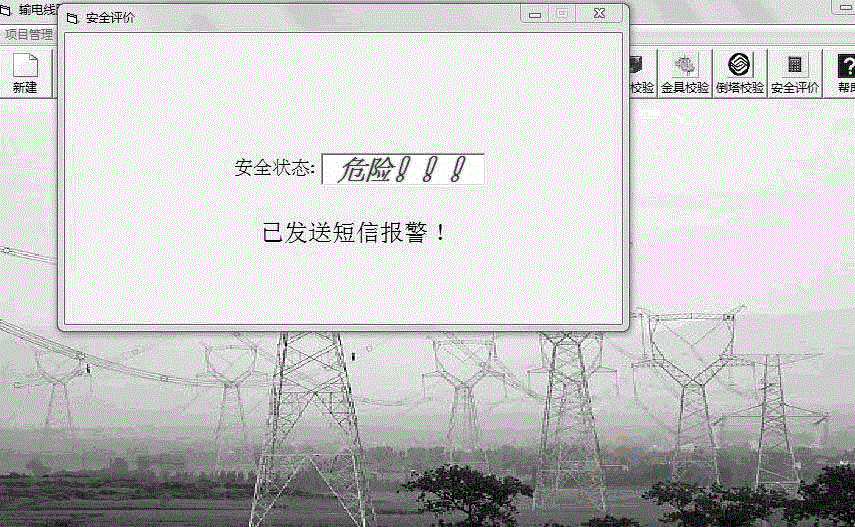

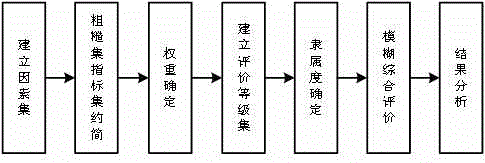

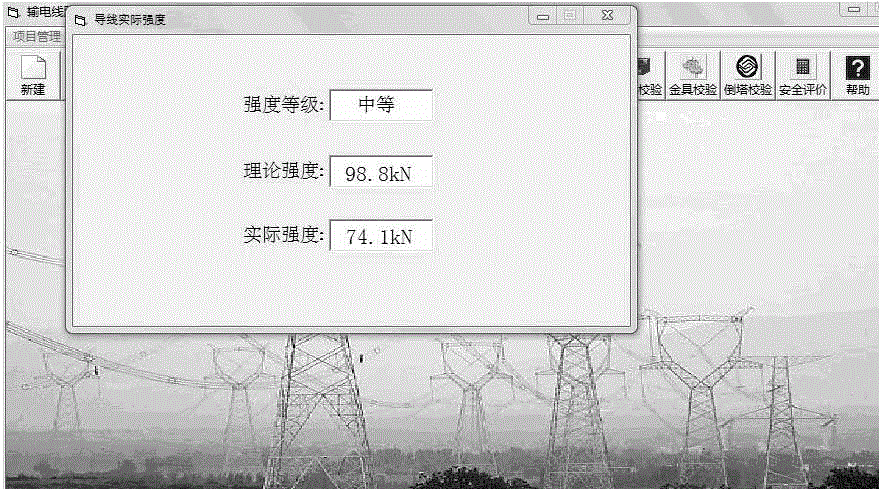

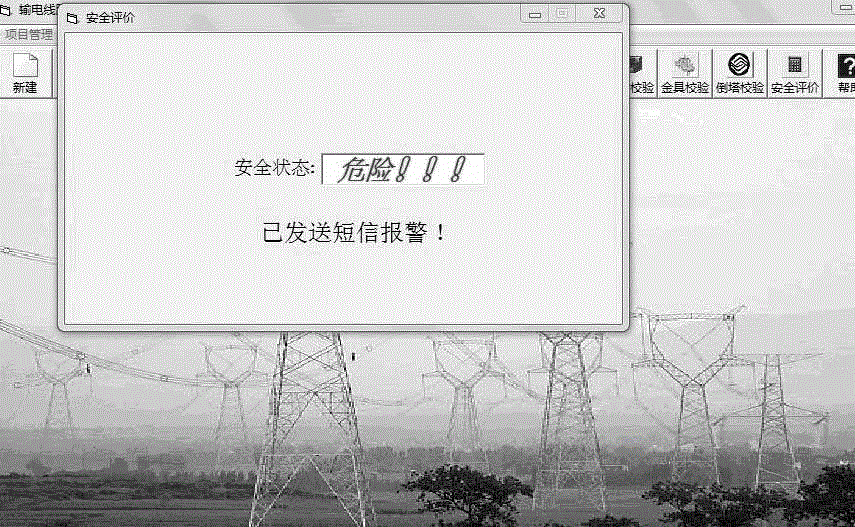

Method for estimating and calculating strength of power transmission pole tower material on basis of rough-fuzzy set

InactiveCN104281773AImprove discriminationEffectively reflectSpecial data processing applicationsTowerControl theory

The invention discloses a method for estimating and calculating the strength of a power transmission pole tower material on the basis of a rough-fuzzy set. The method comprises the following steps of performing reduction on an index set by using a rough set theory; determining evaluation index weight by a method that subjective weight and objective weight are combined; according to an established evaluation order set, comprehensively evaluating and calculating the actual strength of the tower material by using a fuzzy mathematical method. The typical uncertain problem that the factorial validity affecting the strength of the tower material is not clear in an evolutionary process can be solved. The method can provide an important scientific criterion to the safety evaluation of an iron tower structure.

Owner:STATE GRID CORP OF CHINA +2

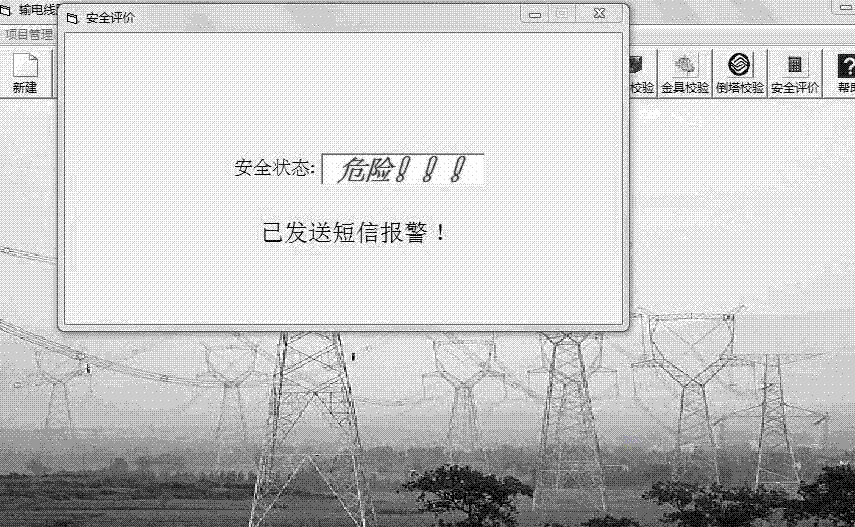

Segmented tree disparity map acquisition method based on improved matching cost

InactiveCN110211168AReasonable weight distributionEnhanced Cost QuantityImage enhancementImage analysisParallaxCost aggregation

The invention discloses a segmented tree disparity map acquisition method based on improved matching cost. The method comprises the following steps: carrying out pixel point acquisition on a left image and a right image; establishing a matrix; performing cost calculation; converting the undirected connected graph; converting the minimum spanning tree; calculating the weight between adjacent pixelpoints; cost aggregation; acquiring left and right disparity maps wherein left and right pixels are consistent; introducing depth information and color information; performing cost aggregation again;obtaining a final disparity map. For the defect that ambiguity matching is easily generated in a weak texture region, color and gradient multi-dimensional information components are introduced, so that the weight distribution of a window is more reasonable, and the cost amount of pixel points in the weak texture region is enhanced; a novel grouping strategy is provided, and pixel points conformingto parallax consistency are divided to the same spanning tree; and a more accurate matching result can be generated while the time efficiency is kept.

Owner:CHANGCHUN UNIV OF SCI & TECH

Tower material strength evaluation and calculation method for solving factors influencing tower material strength

InactiveCN105069280AImprove discriminationEffectively reflectSpecial data processing applicationsTowerOrder set

The invention discloses a method for estimating and calculating the strength of a power transmission pole tower material on the basis of a rough-fuzzy set. The method comprises the following steps of performing reduction on an index set by using a rough set theory; determining evaluation index weight by a method that subjective weight and objective weight are combined; according to an established evaluation order set, comprehensively evaluating and calculating the actual strength of the tower material by using a fuzzy mathematical method. The typical uncertain problem that the factorial validity affecting the strength of the tower material is not clear in an evolutionary process can be solved. The method can provide an important scientific criterion to the safety evaluation of an iron tower structure.

Owner:STATE GRID CORP OF CHINA +2

Transmission tower material strength estimation and calculation method for simplifying index set

InactiveCN105005698AImprove discriminationEffectively reflectSpecial data processing applicationsTransmission towerComputing Methodologies

The invention discloses a method for estimating and calculating the strength of a power transmission pole tower material on the basis of a rough-fuzzy set. The method comprises the following steps of performing reduction on an index set by using a rough set theory; determining evaluation index weight by a method that subjective weight and objective weight are combined; according to an established evaluation order set, comprehensively evaluating and calculating the actual strength of the tower material by using a fuzzy mathematical method. The typical uncertain problem that the factorial validity affecting the strength of the tower material is not clear in an evolutionary process can be solved. The method can provide an important scientific criterion to the safety evaluation of an iron tower structure.

Owner:STATE GRID CORP OF CHINA +2

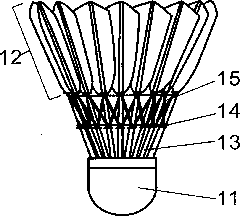

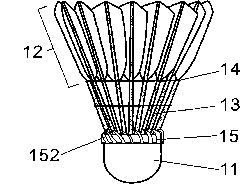

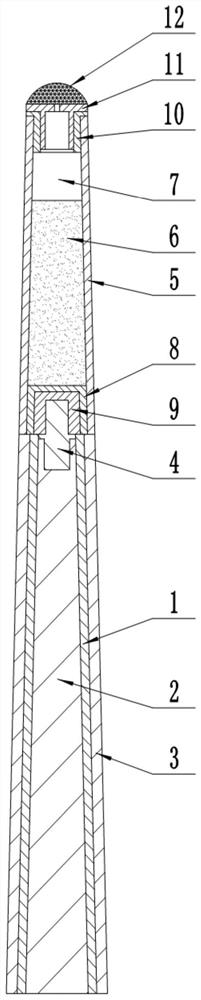

Badminton and badminton body containing rotating component

InactiveCN102188806AGuaranteed performanceReasonable weight distributionSport apparatusWeight distributionGravitation

The invention relates to a novel badminton. The badminton contains an independent rotating component (15) which is not adhered to a badminton skirt (12), and the rotating component (15) has various kinds of structures, wherein, optimally the rotating component comprises a plurality of rotating wind resistance fins (152) or rotating wind resistance wall surfaces (153); and optimally the rotating wind resistance fins (152) or the rotating wind resistance wall surfaces (153) and the cross section of the badminton form an inclined angle (B) along an axis direction. The independent rotating component (15) has higher efficiency so as to more conveniently control weight, center-of-gravity position and weight distribution of the badminton; and the rotating component (15) and the badminton skirt (12) of the badminton can be respectively made into an independently molded fitting so as to enhance overall performance and facilitate production. The invention further relates to a badminton body containing the rotating component (15).

Owner:张文广

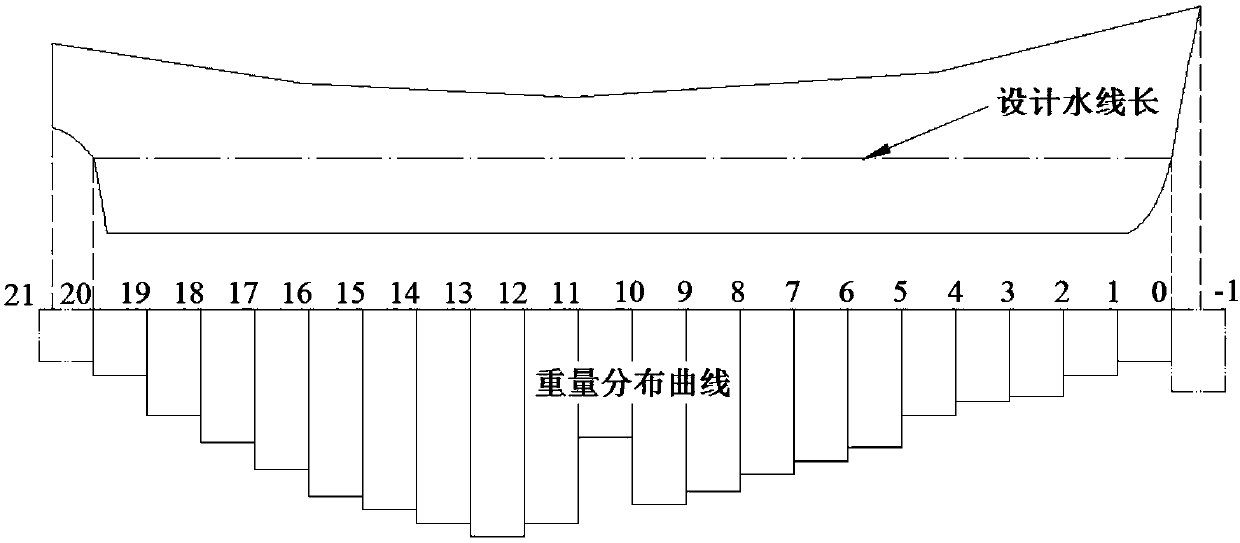

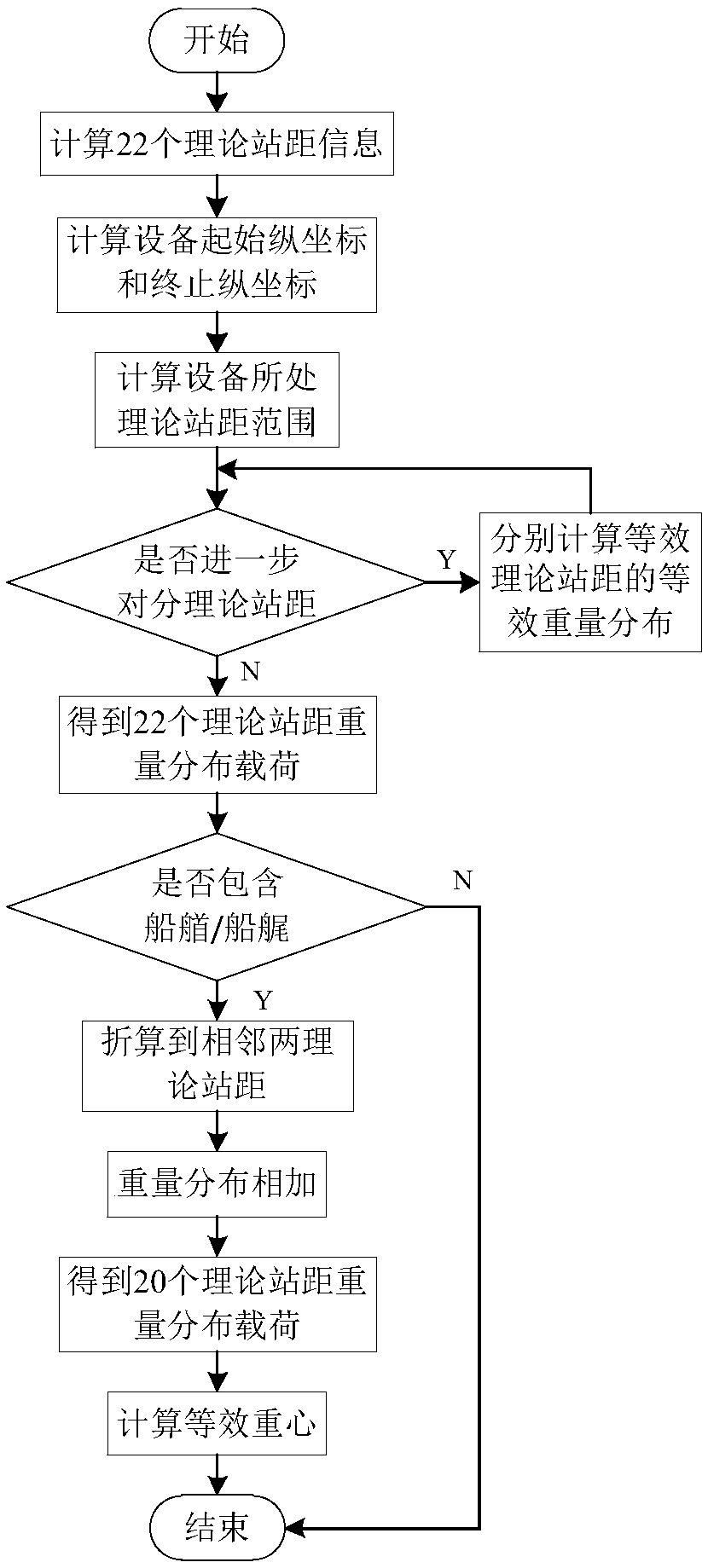

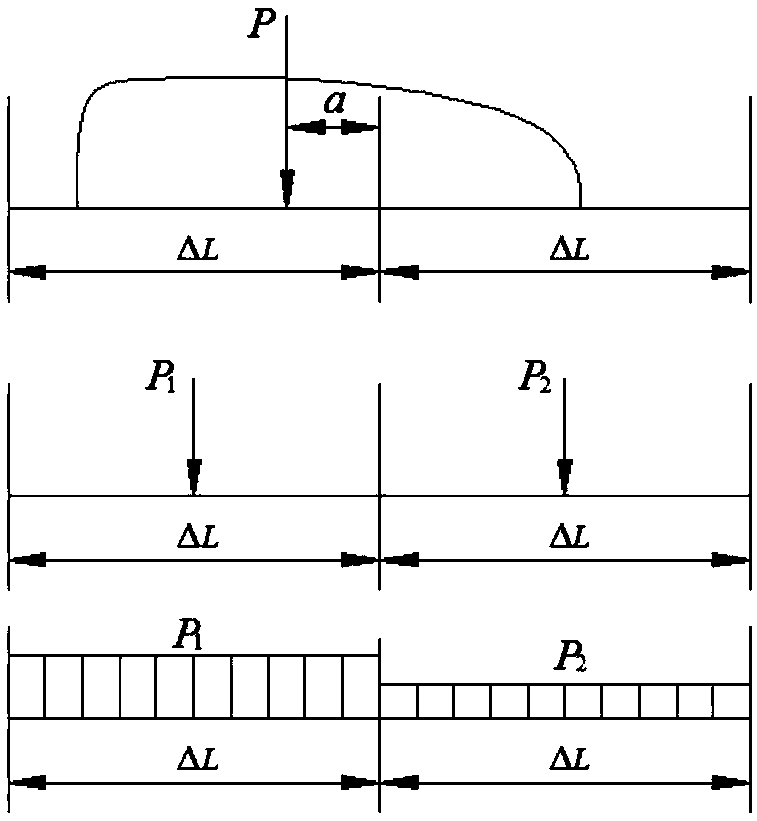

Method for calculating ship weight longitudinally distributed load density

ActiveCN107933822AWeight distributiongood loadEnsure weight distributionVessel partsDistortionStatic force

The invention discloses a method for calculating a ship weight longitudinally distributed load density. By adopting the method, the situation that partial weight losses or distortion of equipment at aship bow / stern can be avoided, so that weight distributed load density is more reasonable and accurate. According to the method for calculating the ship weight longitudinally distributed load density, the ship bow and the stern can serve as complete standard theoretical station distances correspondingly, 20 standard theoretical station distances in a traditional method are expanded to be 22 standard theoretical station distances, and then weight of each equipment or goods on a ship is equivalently distributed on the standard theoretical station distances in theoretical station distance ranges where the equipment or the goods are located according to a static force equivalence principle; and the weight distributed in the ship bow standard theoretical station distance and the stern standard theoretical station distance is converted into two standard theoretical station distances adjacent to the ship bow standard theoretical station distance and the stern standard theoretical station distance, and finally weight distribution of the 20 standard theoretical station distances of a hull, namely, the ship weight longitudinally distributed load density, is obtained. Partial weight lossesor distortion of the equipment at the ship bow / stern is avoided, and weight distributed load density is more accurate.

Owner:CHINA SHIP DEV & DESIGN CENT +1

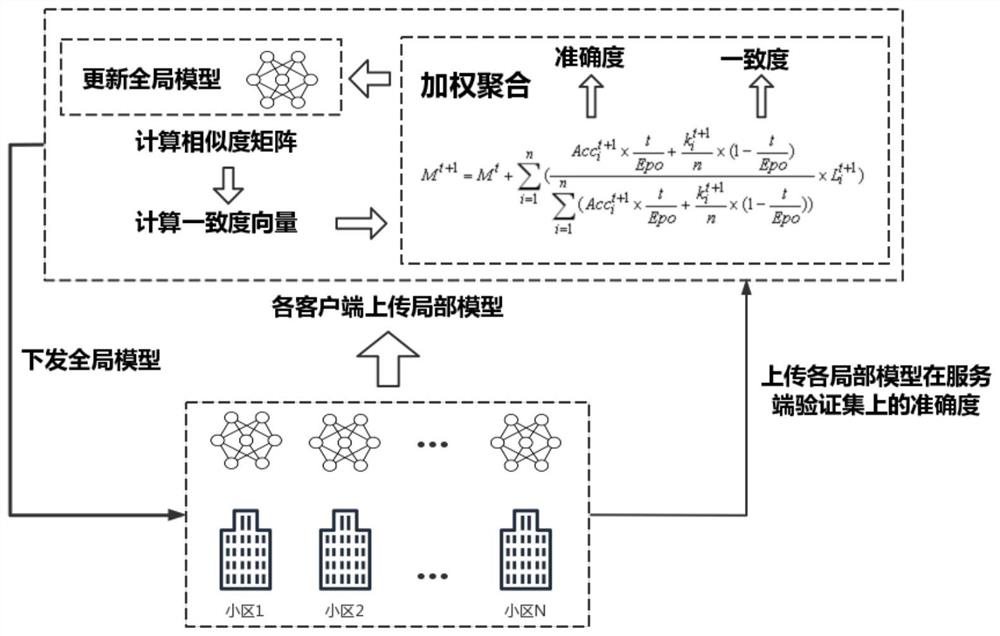

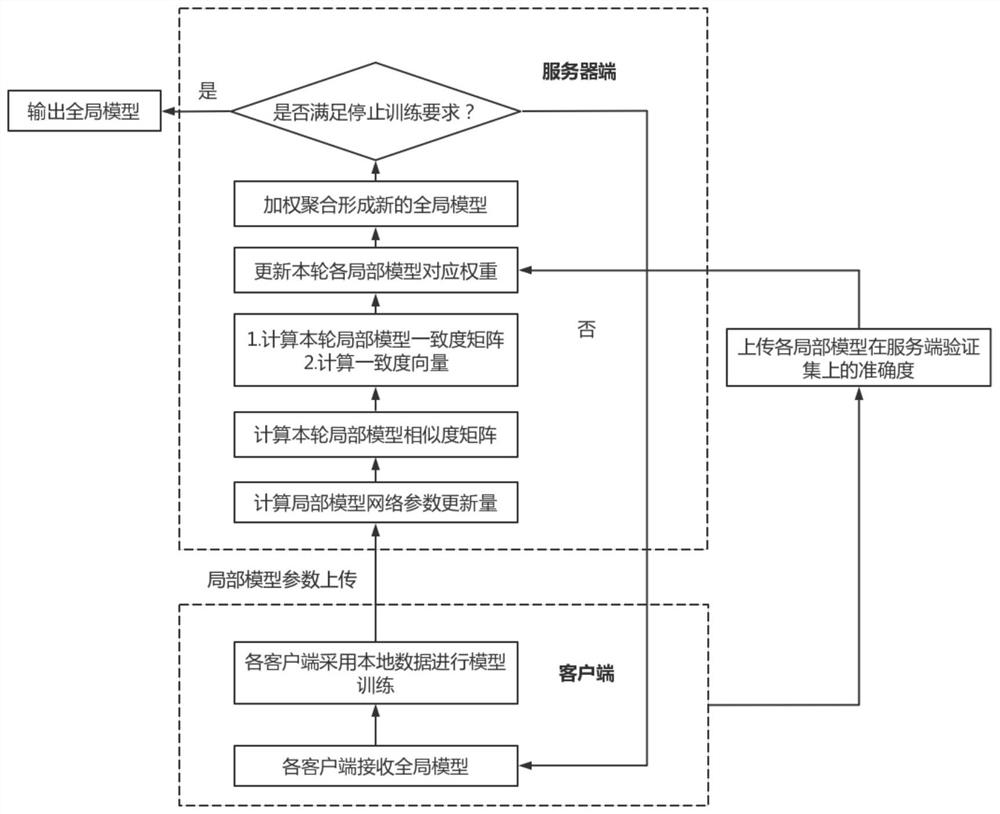

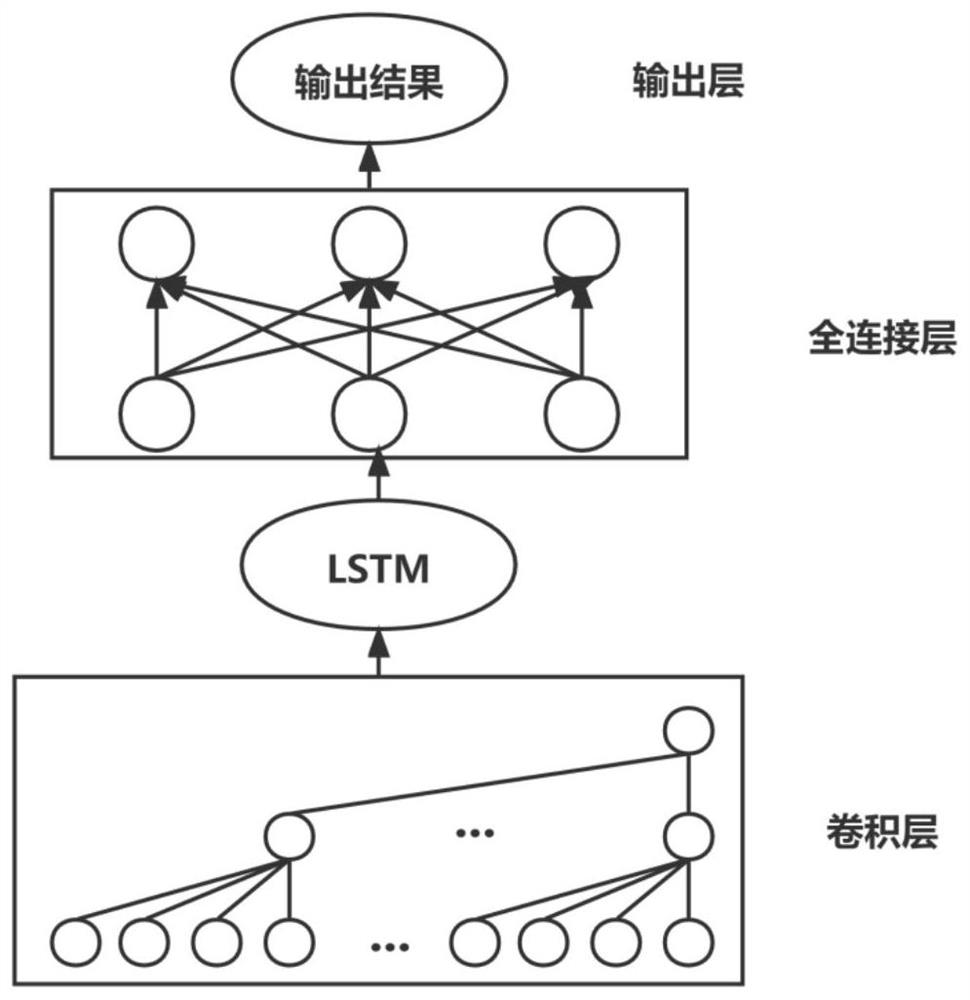

Federal learning load prediction method based on dynamic weighted aggregation

PendingCN114707765APrivacy protectionImprove accuracyEnsemble learningForecastingEngineeringMachine learning

The invention relates to a short-term load prediction technology of a power system, and aims to provide a federated learning load prediction method based on dynamic weighted aggregation. According to the method, an edge computing device adopts local data to carry out neural network training, network parameter change vectors are obtained and uploaded to a cloud server to carry out pairwise similarity calculation to generate a similarity matrix, and a consistency vector between local models in the current round of training is calculated. And then weighting network parameter changes of different local models based on the consistency between the accuracy of each round of local model for the server verification set and the local models to realize a local model cleaning effect, issuing the updated global model to the edge computing device by the cloud server, and repeating the above steps to realize the cleaning effect of the local models. And the server reaches the preset training round number. The problem that a dirty model possibly trained by a local model and data isomerism in federal learning cannot be effectively avoided in the prior art is solved, and convergence of global model training is accelerated.

Owner:ZHEJIANG UNIV +2

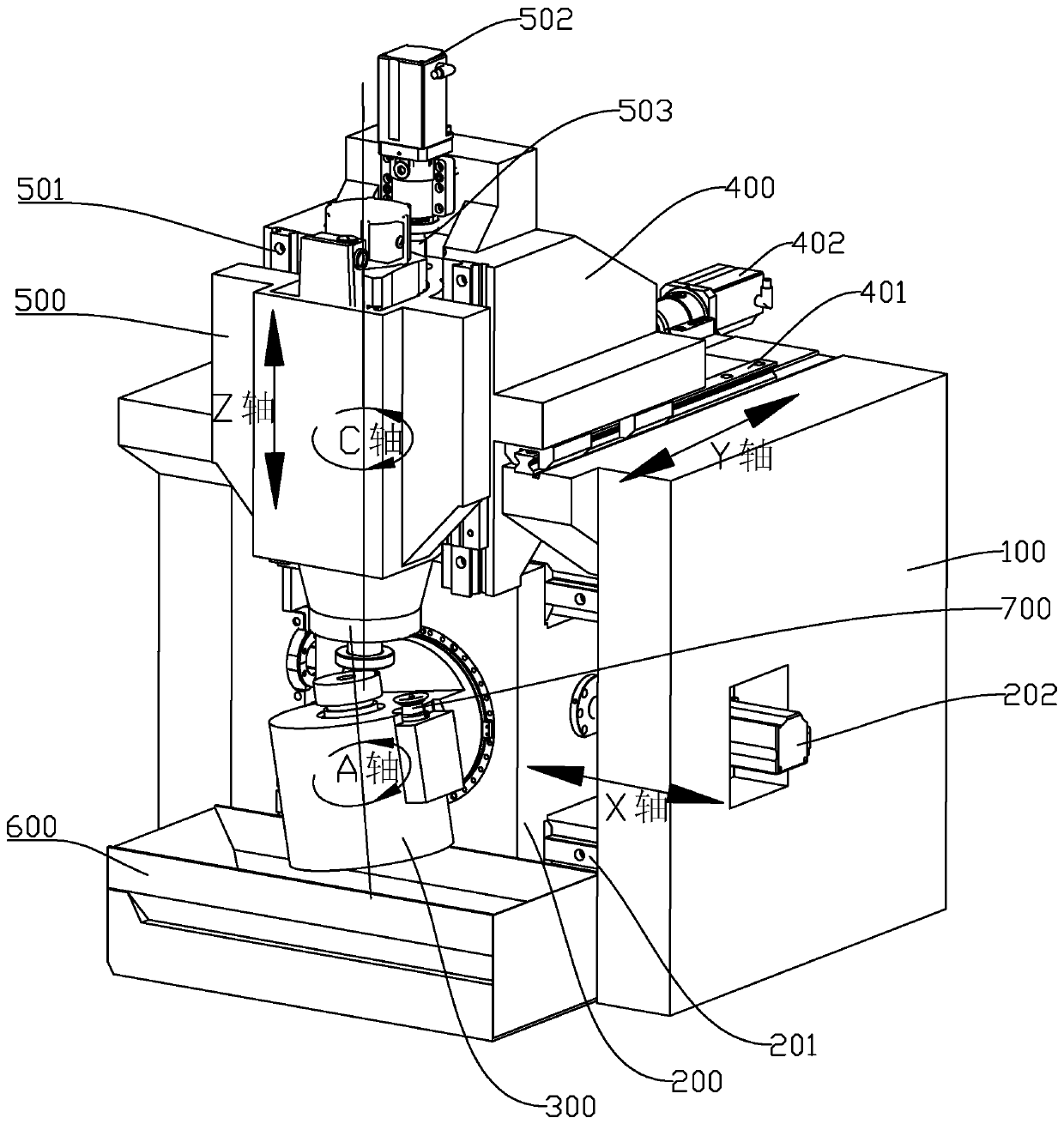

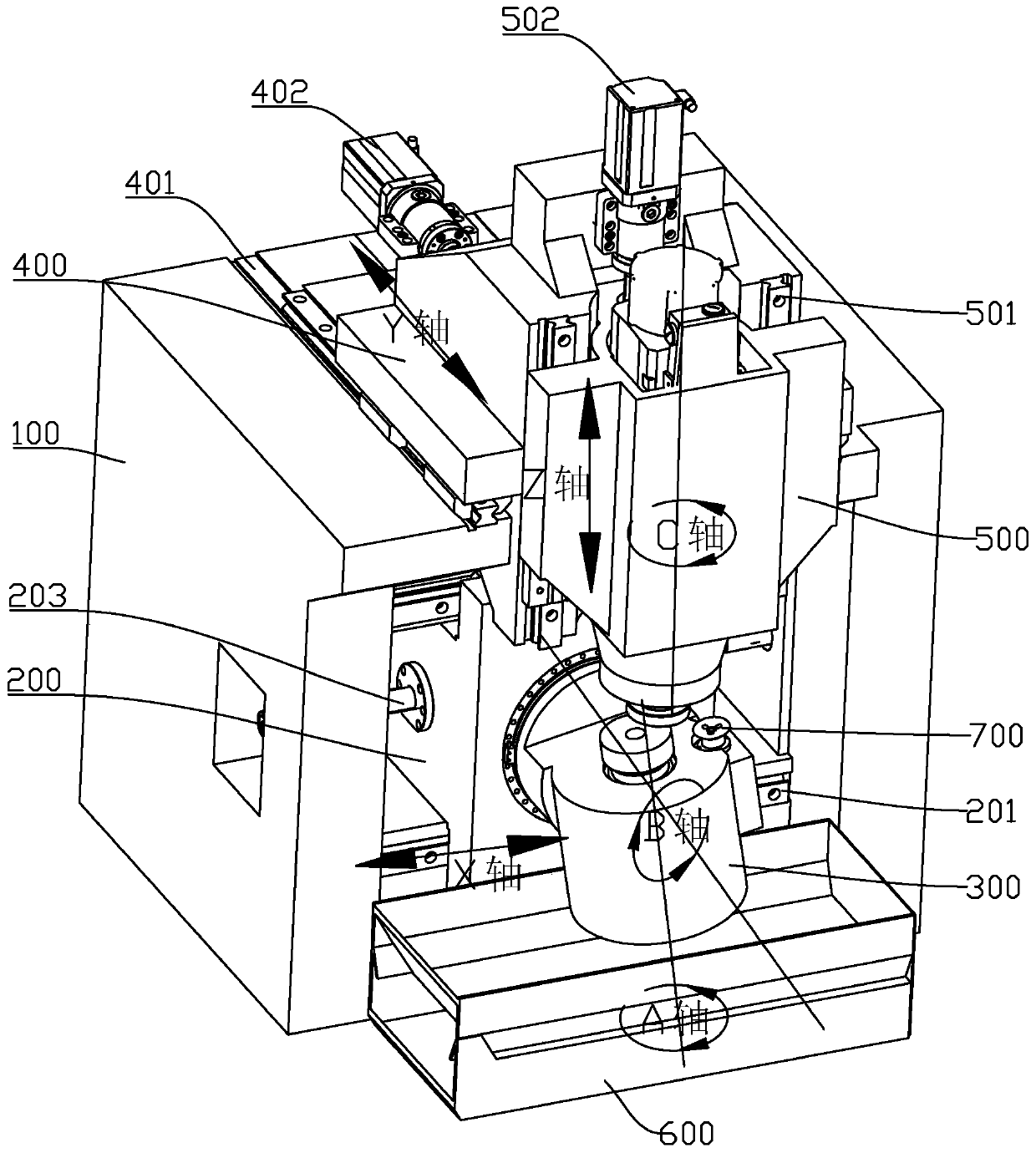

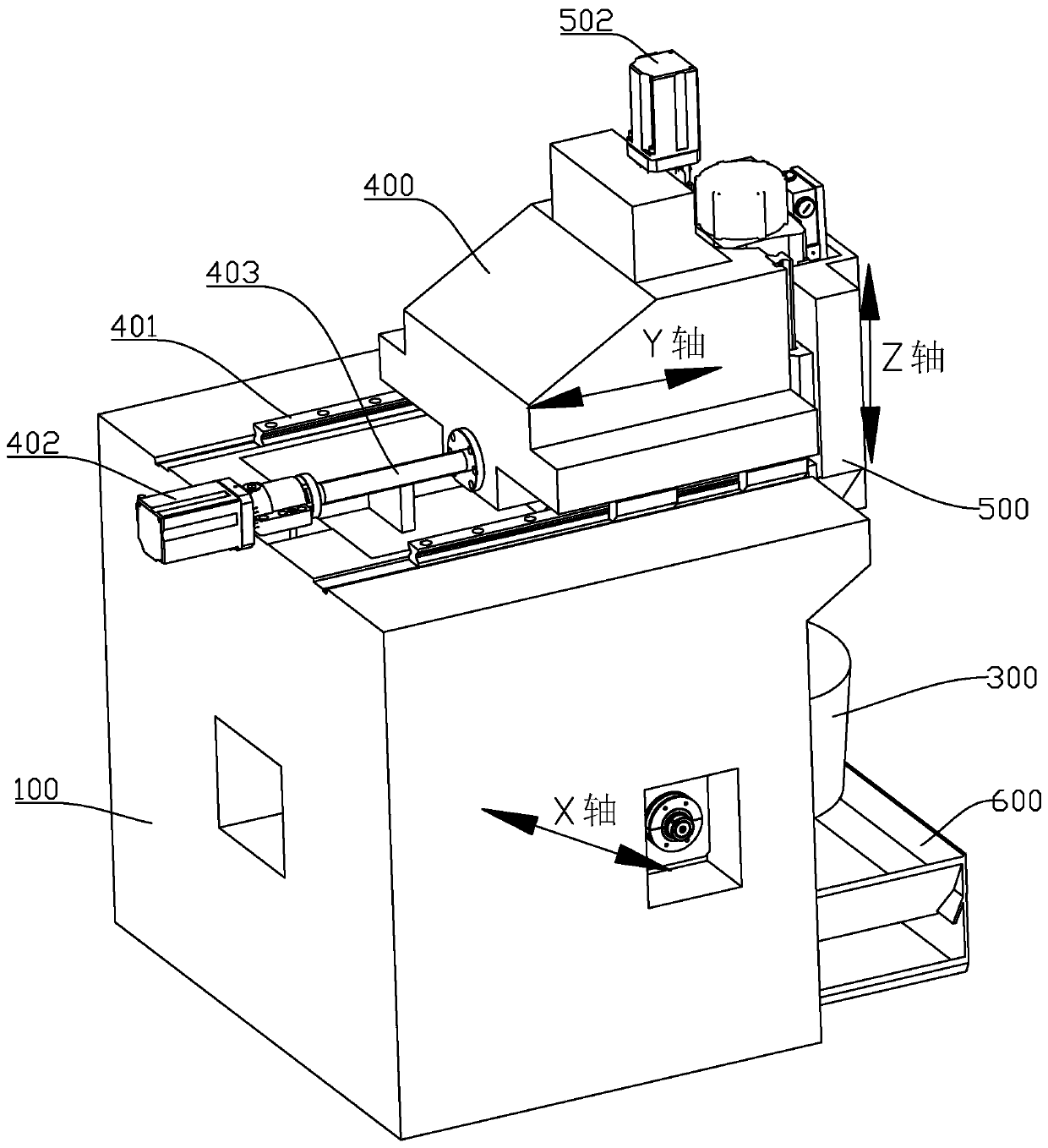

Gear grinding machine

PendingCN110340449AEasy to assemble and disassembleIncrease productivityGear-cutting machinesGear teethGear grindingFuel tank

The invention discloses a gear grinding machine comprising a machine body, a second rotating shaft box body, a sliding table and a cooling oil tank; the side wall of the machine body is provided withan X-axis guide rail; the second rotating shaft box body is slidably installed on the X-axis guide rail, and internally provided with a rotating shaft B; the tail end of the rotating shaft B is provided with a first rotating shaft box body which is internally provided with a workpiece spindle A, and the end of the workpiece spindle A is provided with a workpiece; the sliding table is movably installed on the machine body, and located above the second rotating shaft box body; the sliding table is provided with a third rotating shaft box body which is internally provided with a grinding wheel spindle C of which the lower end is provided with a grinding wheel; and the cooling oil tank is arranged below the first rotating shaft box body in the X-axis direction. Compared with a traditional structure, the gear grinding machine has the advantages that the three movable shafts are not stacked, and accordingly the removal and installation are simple and convenient; not only can the production efficiency be improved, but also the maintenance is convenient; the weight distribution is more reasonable, and the situation that the gear grinding machine is not top-heavy is avoided, so that the counterweight of the machine body can be further reduced; and the size of the machine is reduced.

Owner:HUNAN ZDCY (ZHONGDA CHUANG YUAN) CNC EQUIP CO LTD

Flying wing layout aircraft capable of short takeoff/vertical takeoff and landing

InactiveCN103192990BLarge internal spaceReasonable weight distributionDepending on number of propellersRotocraftFlight directionLevel flight

The invention provides a flying wing layout aircraft which comprises an aircraft body (1), aircraft wings (2), ailerons, an elevator (5) and double vertical fins (4), wherein the aircraft body (1) and the aircraft wings (2) are integrated; the ailerons (3) are positioned on the outer sections of the aircraft wings (2), and are used for rolling control in level flight; the elevator (5) is positioned at the rearmost part of the aircraft body (1), and is used for pitching control in level flight; and the dual vertical fins (4) are positioned at the rear part of the aircraft body (1), and are used for enhancing the flight direction safety in level flight. The flying wing layout aircraft provided by the invention has the advantages that the aircraft body integration technique inherits the excellent pneumatic property of the flying wings, and larger internal space is provided; the weight distribution is more reasonable, and the structure is lighter, so that the load and the voyage are increased; front air screws which are arranged in an engine and tilt and rear air screws which are fixed and can be accommodated in the vertical fins achieve the capability of vertical / short take-off and landing, and the interference to the whole pneumatic appearance of the aircraft is lowered greatly; and the connection shaft design among engines greatly improves the reliability of a dynamic system, avoids the dangerous situation of invalidity after taking off, and guarantees the flight safety in vertical / short take-off and landing.

Owner:BEIHANG UNIV

Golf putter head

InactiveCN1669603AReasonable weight distributionLower center of gravityGolf clubsRacket sportsEngineeringGolf Ball

A kind of golf bulb, comprises knock face, ball bottom, ball cover, pipe and bulb latus. The knock face is connected to the other parts by welding material. The ball cover and the bulb latus are connected as one body. The ball bottom is connected to the bulb by welding material. The invention's structure is good to lower the height of the gravity. As the ball bottom is a single spare part, we can change the thickness freely to adjust the bulb's gravity. The throat is formed by the one time tension, so the correlation is good, and the shape is nearer to the design request.

Owner:世元高尔夫器材制造(上海)有限公司

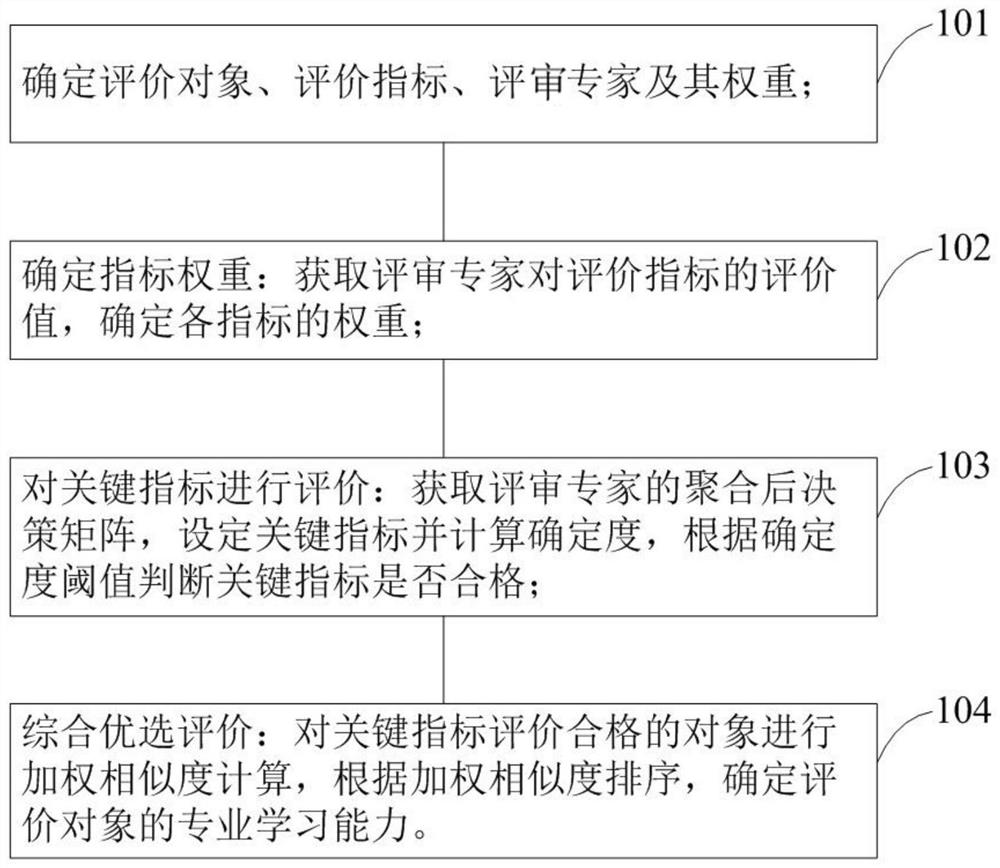

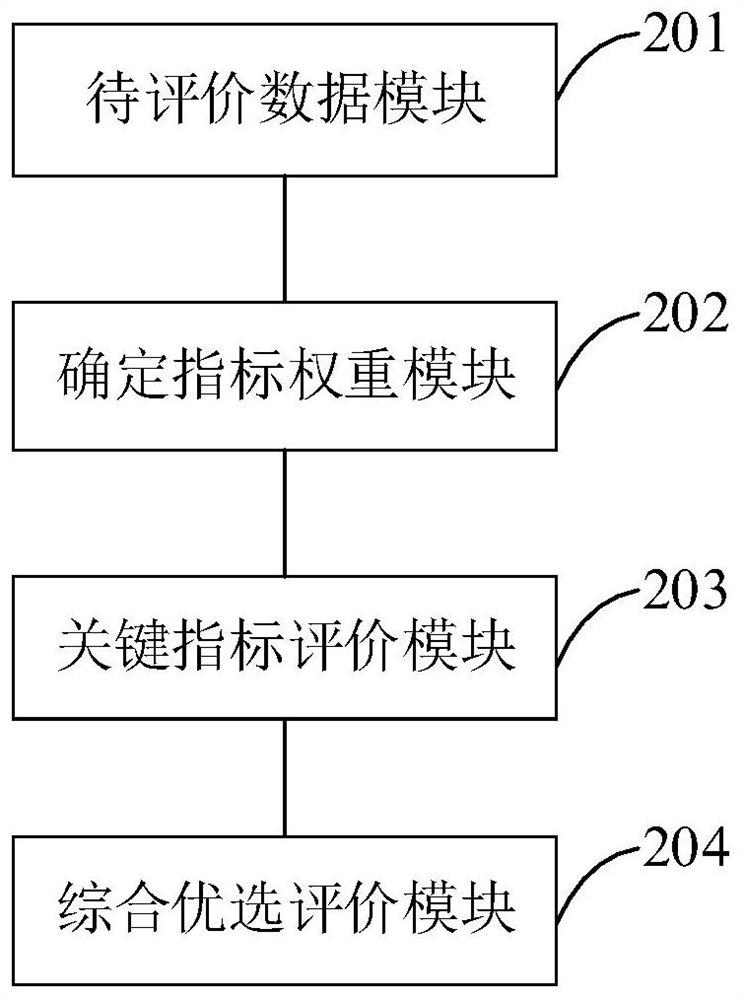

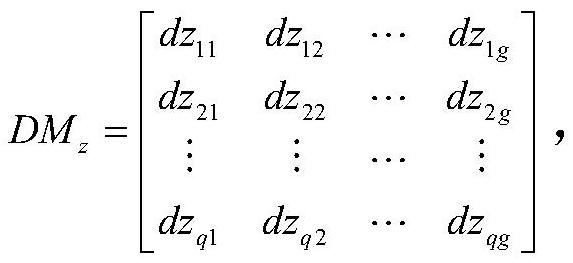

Professional learning ability evaluation method and system based on interval neutrosophy theory

The invention provides a professional learning ability evaluation method based on an interval neutrosophy theory. The method comprises the following steps: determining an evaluation object, an evaluation index, an evaluation expert and a weight thereof; determining index weights: obtaining evaluation values of evaluation experts on the evaluation indexes, and determining weights of the indexes; evaluating a key index: obtaining an aggregated decision matrix of the review expert, setting the key index and calculating the certainty degree, and judging whether the key index is qualified or not according to a certainty degree threshold value; and comprehensive optimization evaluation: carrying out weighted similarity calculation on the objects with qualified key index evaluation, and determining the professional learning ability of the evaluation objects according to weighted similarity sorting. The invention further provides a professional learning ability evaluation system based on the interval neutrosophy theory. According to the method and system, the interval neutrosophy theory is introduced into the professional learning ability evaluation process of the students, so that the accuracy and effectiveness of decision making can be effectively improved; and weight distribution is more reasonable.

Owner:SHAOXING UNIVERSITY

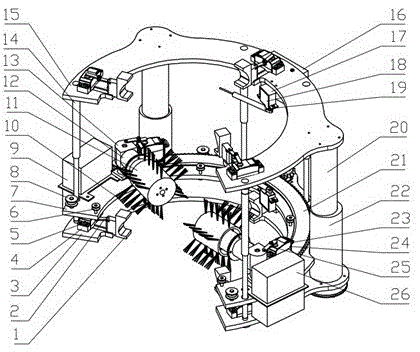

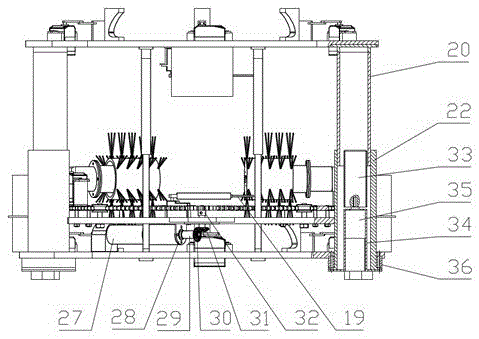

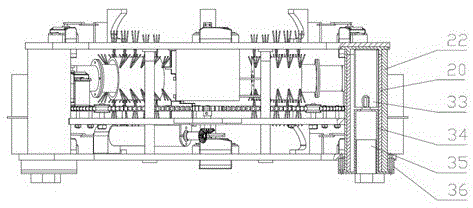

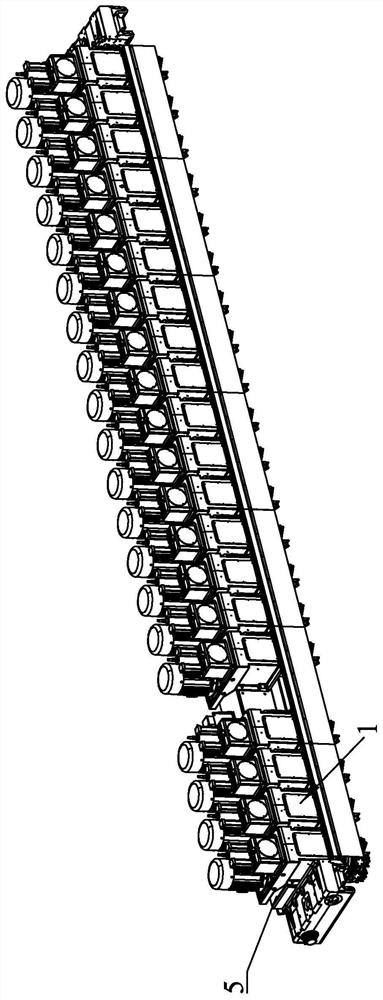

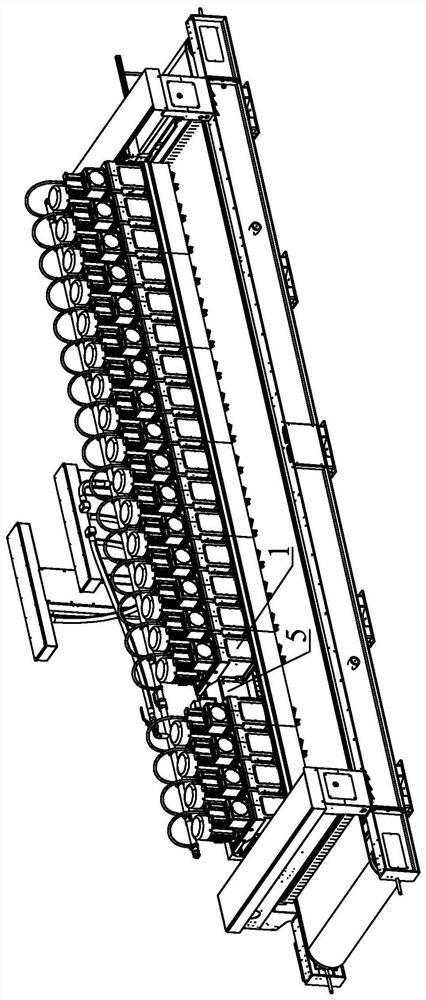

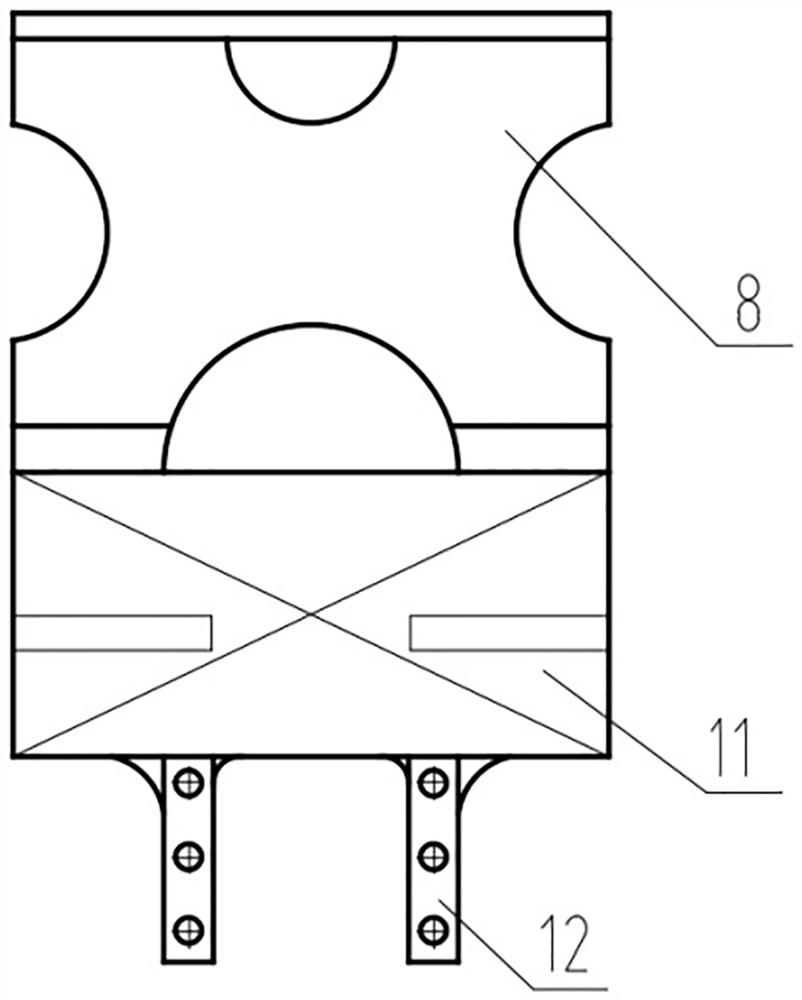

A high-voltage line insulator detection and cleaning robot

ActiveCN104128320BImprove practicalityImprove motion stabilityElectrical testingCleaning using toolsHigh pressureHigh voltage

The invention relates to a high-voltage line insulator detection and cleaning robot, which includes a three-layer bracket, several clamping mechanisms, a climbing telescopic mechanism, an insulator live detection device, and an insulator cleaning mechanism. The clamping mechanism, the insulator live detection device and the insulator cleaning mechanism are all arranged on the bracket, and the bracket is connected through a climbing telescopic mechanism. The invention can climb along the insulator string and automatically clean and detect the insulators. The invention has compact structure, comprehensive functions, stable crawling, simple stringing operation, can short-circuit up to three insulators, and is suitable for live cleaning and detection of horizontal and suspended insulator strings.

Owner:WUHAN UNIV

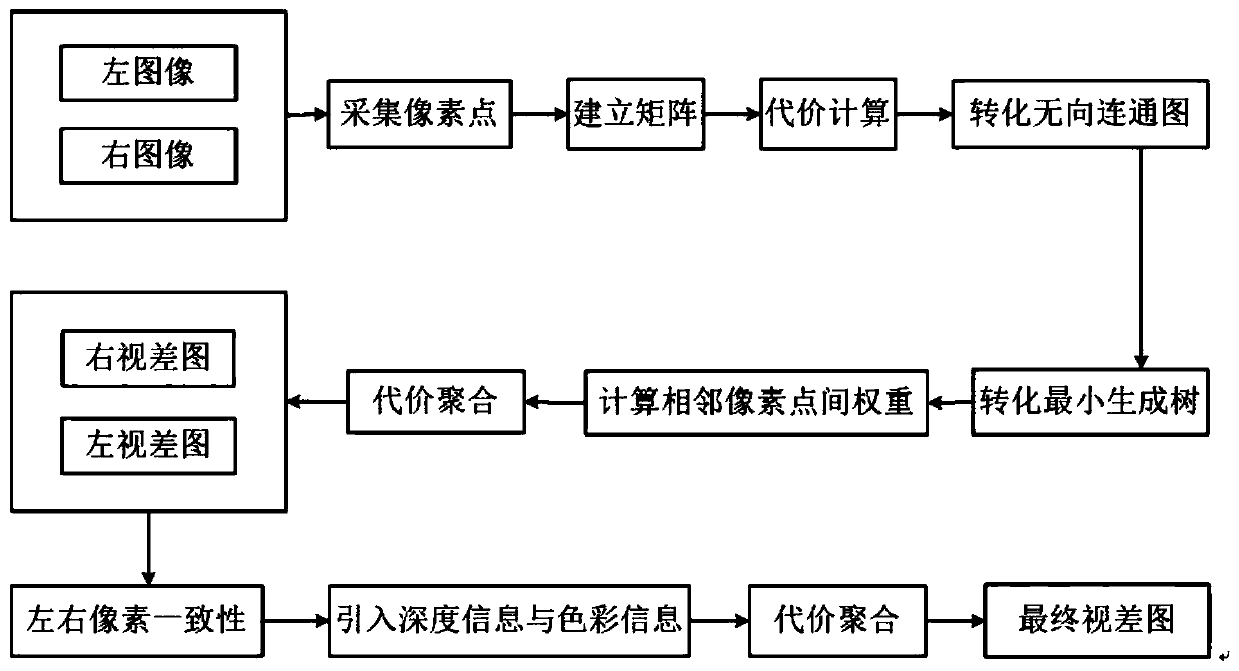

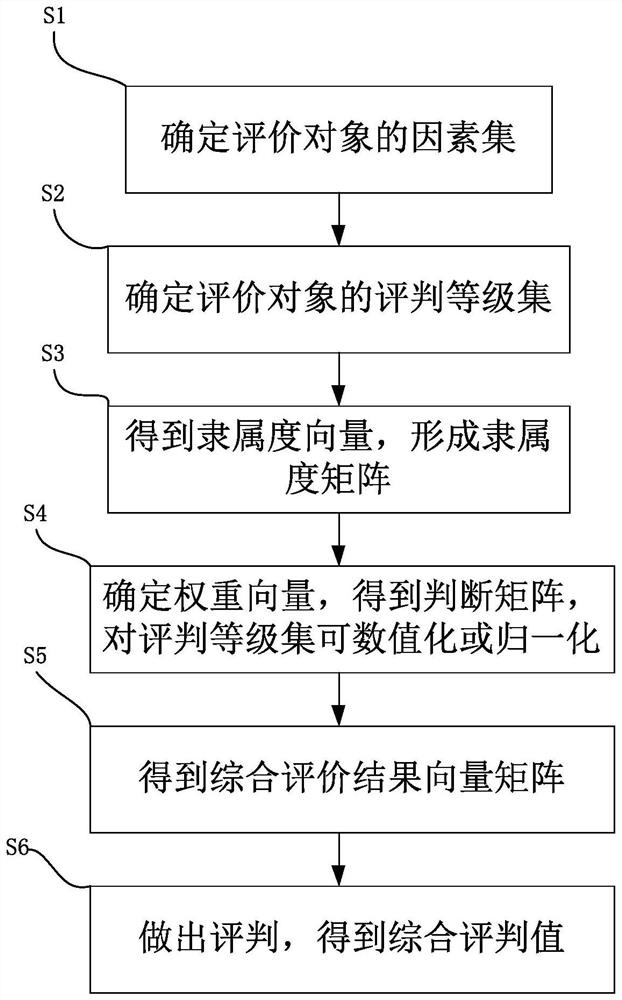

Hydraulic engineering safety evaluation method based on improved fuzzy analytic hierarchy process

PendingCN113780763AReasonable weight distributionFuzzy logic based systemsResourcesEvaluation resultFuzzy analytic hierarchy process

The invention discloses a hydraulic engineering safety evaluation method based on the improved fuzzy analytic hierarchy process, and mainly solves the problem that the evaluation result of an existing water conservancy project safety evaluation method is inaccurate. The method comprises the following steps: (S1) determining a factor set of an evaluation object; (S2) determining an evaluation grade set of the evaluation object; (S3) performing single-factor evaluation on the evaluation object to form a membership matrix; (S4) determining a factor weight vector of the evaluation object to obtain a judgment matrix, and carrying out numeralization or normalization on the evaluation grade set; (S5) obtaining a comprehensive evaluation result vector matrix; and (S6) performing judgment according to a membership degree maximum principle, or solving a membership degree grade by using weighted average to obtain a comprehensive judgment value. According to the method, an improved fuzzy comprehensive evaluation method based on natural index e0 / 4-e8 / 4 scales is adopted, safety evaluation is carried out on the water conservancy project, subjective weights and objective weights of bottom layer evaluation indexes are optimized, the subjective weights are corrected, and weight distribution of the indexes is more reasonable.

Owner:四川省都江堰东风渠管理处 +2

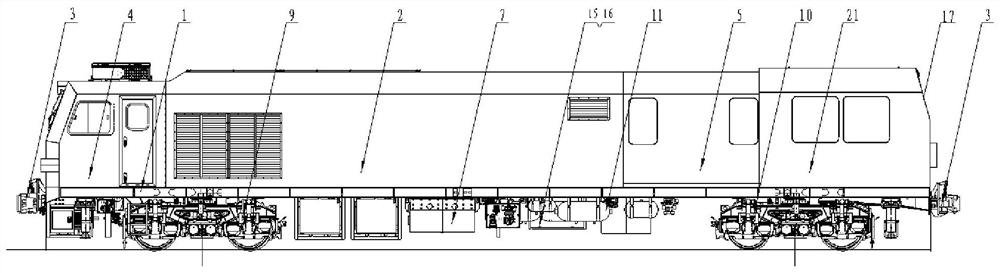

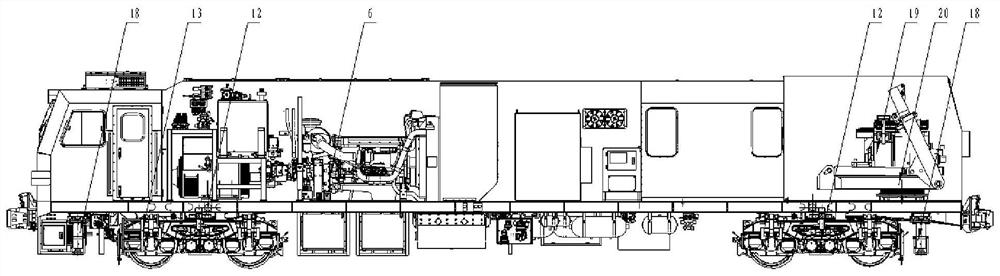

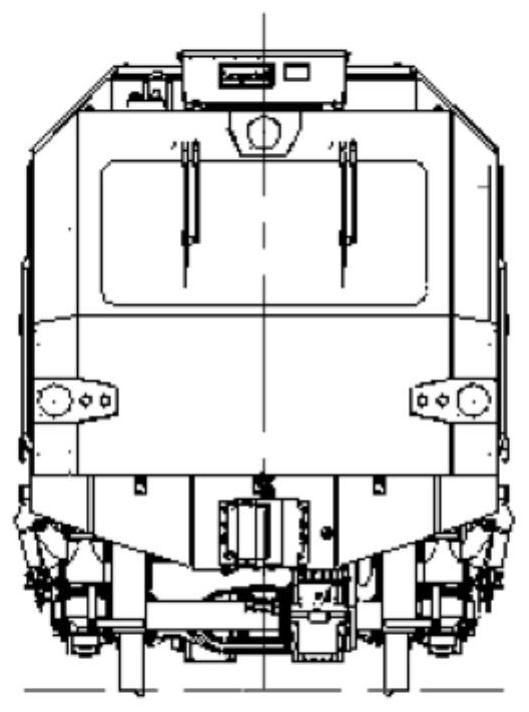

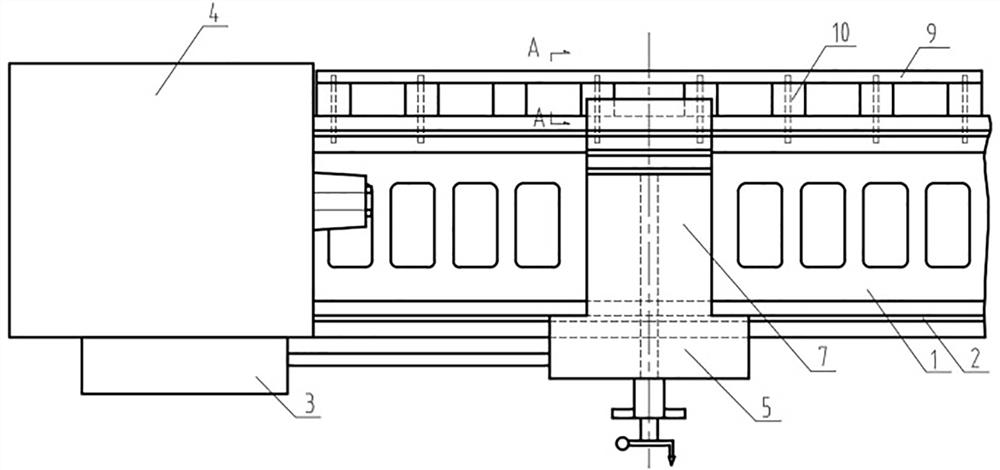

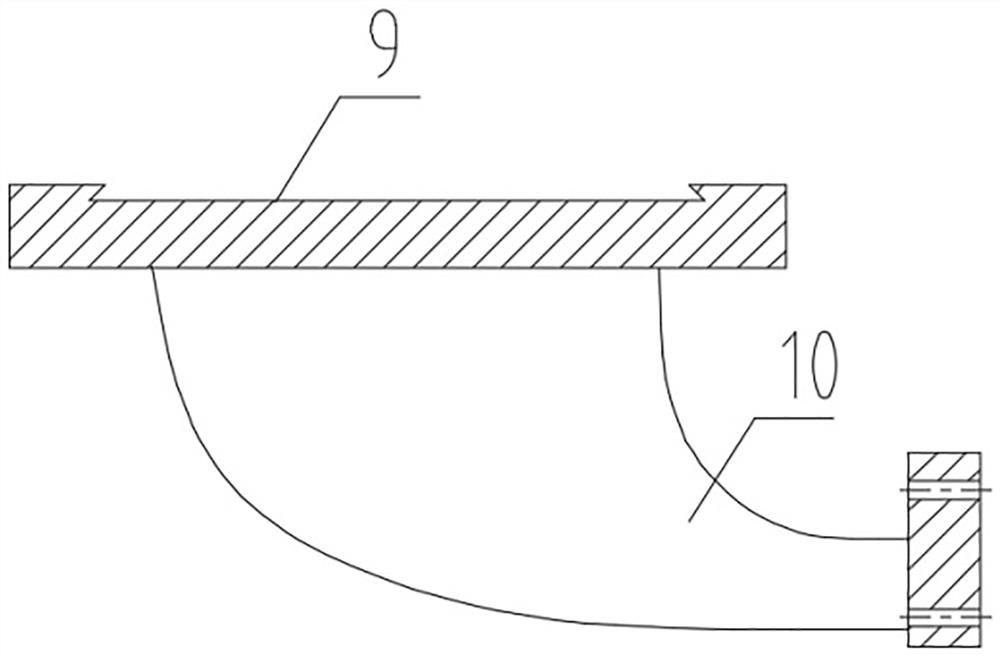

Intelligent subway rail welding vehicle and rail welding method

PendingCN111945498AWith wide temperature performanceAnti-shockTrack superstructureRailway track constructionBogieVehicle frame

An intelligent subway rail welding vehicle comprises a frame (1), a cab (4), a functional room (2), an operation room (5) and a welding machine room (21) are arranged above the frame (1), a power transmission system (6) and a hydraulic oil tank (14) are arranged in the functional room (2), an office area and an operation area are arranged in the operation room (5), a welding machine (19) and a welding machine take-up and pay-off device (20) is arranged in the welding room (21). A front driving bogie (9), a diesel tank (7) and a rear driving bogie (10) are arranged below the frame (1); escalators (13) are arranged on the two sides of the front drive bogie (9); and an overturn door (17) is arranged at the end of the welding machine room (21). The intelligent subway rail welding vehicle can automatically run to a rail welding site to conduct online welding, offline welding and base welding, and if extreme derailment occurs, the vehicle can be rapidly lifted and restored; all operations inthe operation process are designed mechanically and automatically.

Owner:CRCC HIGH TECH EQUIP CORP LTD

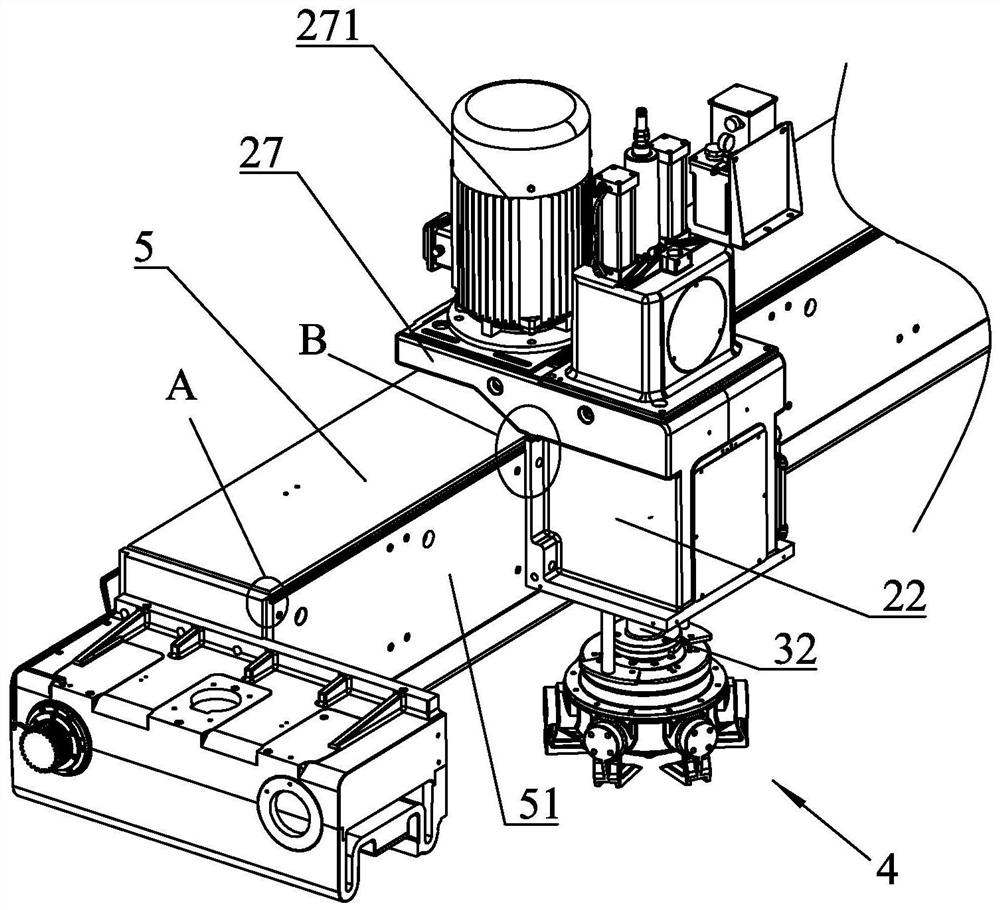

Polishing main machine installing structure with stable structure

ActiveCN112222988AStructural balanceReasonable weight distributionGrinding carriagesGrinding drivesPhysicsElectric machinery

The invention discloses a polishing main machine installing structure with a stable structure. The polishing main machine installing structure comprises a swing beam and at least one polishing main machine installed on the swing beam, wherein the grinding main machine comprises a base, a main shaft, a grinding head and a driving motor, the main shaft is rotationally installed on the supporting frame, the driving motor is fixedly installed on the motor installation base to drive the main shaft to rotate, the grinding head is installed at the lower end of the main shaft, a first installing fitting surface is formed on the outer side wall of the supporting frame below the motor installing base, a first supporting clamping groove is formed in the upper end of the first installing fitting surface, a second installing fitting surface is arranged on the outer side wall of the swing beam, and a second supporting clamping groove is formed in the upper end of the second installing fitting surface. Compared with the prior art, the mode that the base body of the polishing main machine is installed on the side portion of the swing beam is adopted, so that the weight distribution of the whole structure is more reasonable, and meanwhile the polishing main machine can be conveniently installed and uninstalled from the swing beam, the structure of the swing beam is simplified, and the production difficulty and cost of the main beam are reduced.

Owner:QUANZHOU HAIENDE ELECTROMECHANICAL TECH DEV

A Floatability Test Model

ActiveCN109436370BEasy to transportEasy to fixAircraft components testingClassical mechanicsStructural engineering

The invention belongs to the field of aircraft ditching test, and in particular relates to a floating characteristic test model. In the case of strict weight requirements, the general model has low strength and is easily damaged. The present invention proposes a floating characteristic test model, including a fuselage, wings and empennage, wherein the fuselage is divided into an upper fuselage compartment and a lower fuselage compartment by a fuselage floor, and a lifting device is installed above the middle of the upper fuselage compartment. Adjustment system, the lifting lugs can adjust the position front and rear in the waist hole of the lifting adjustment system; a vent pipe connecting the upper compartment and the lower compartment of the fuselage is arranged on the height of the fuselage floor; the lower compartment of the fuselage has There are seepage holes, and the bottom of the lower fuselage frame has overflow holes connecting adjacent compartments; black and white waterline scales are painted on the outside of the fuselage skin. It can meet the requirements of harsh test conditions.

Owner:CHINA SPECIAL TYPE FLIER RES INST

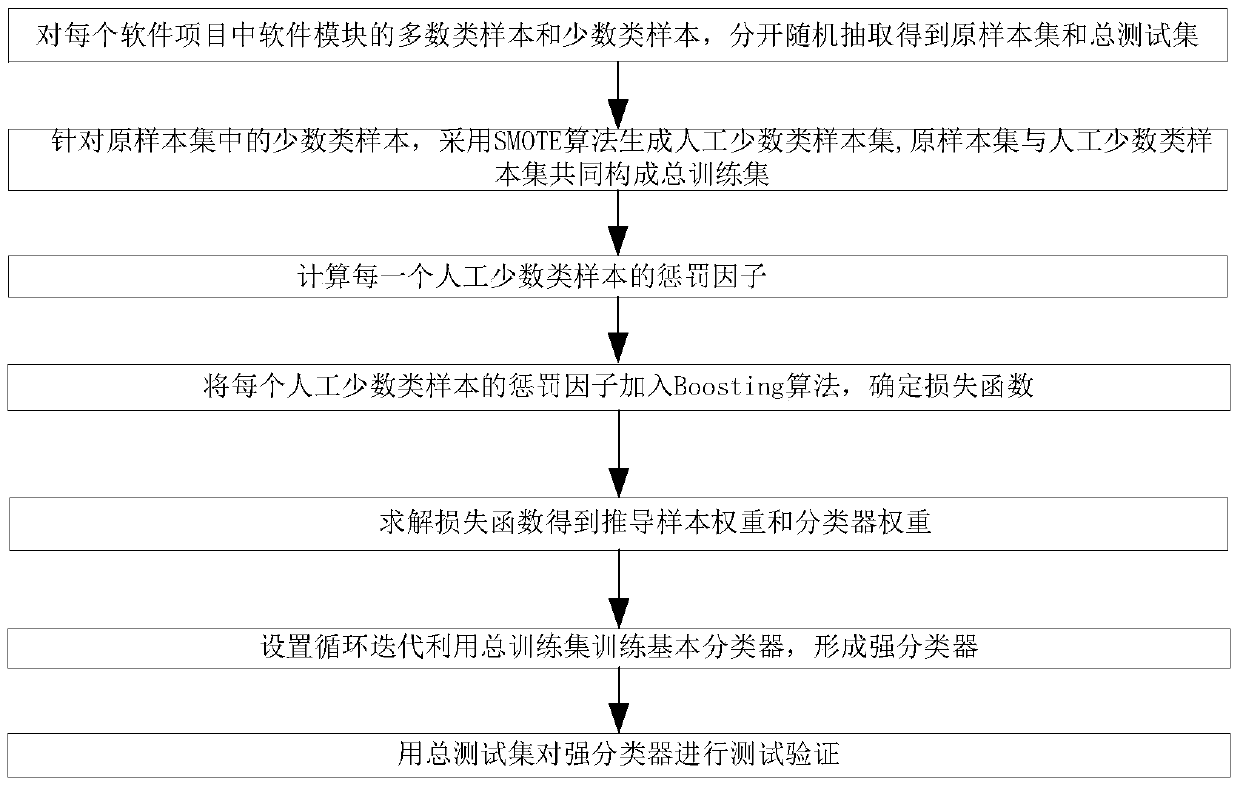

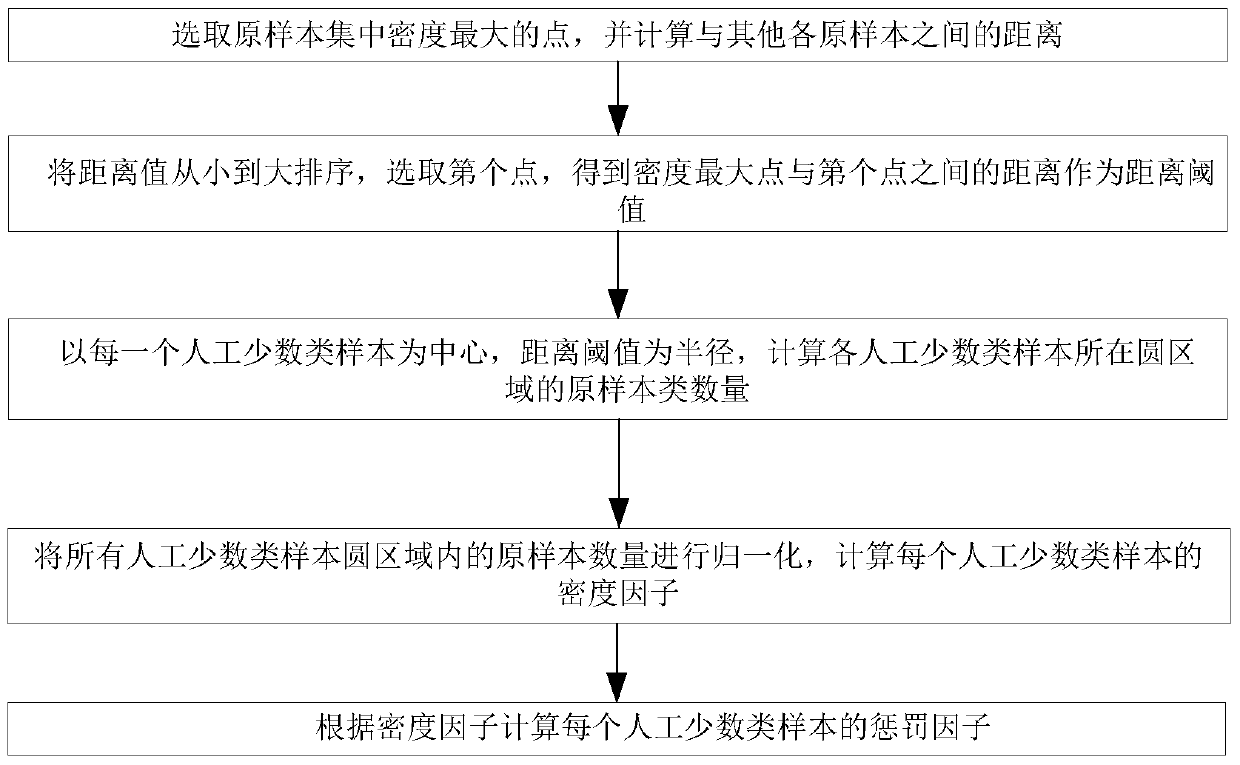

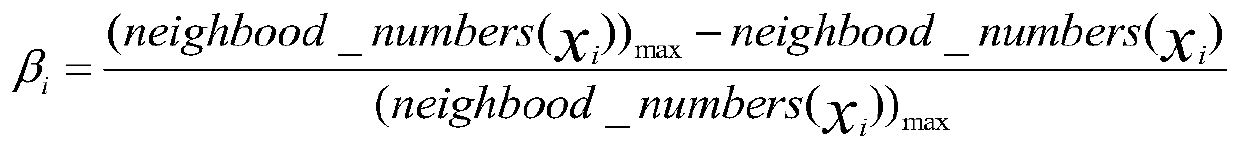

A software defect tendency prediction method based on smote+boosting algorithm

ActiveCN105589806BReasonable weight distributionAvoid subjectivitySoftware testing/debuggingMajority classAlgorithm

The invention discloses a SMOTE+Boosting algorithm based software defect tendency prediction method. The method comprises the steps of for the non-equilibrium problem of software defect data, firstly synthesizing artificial minority class samples by using an SMOTE algorithm and enabling the minority class samples and majority class samples to be balanced in quantity; secondly, calculating a penalty factor of each artificial minority class sample according to density information of original sample distribution to adjust a weight of the artificial sample so as to enable a basic classifier to distinguish the learning of an original sample and the artificial minority class sample and put more emphasis on the learning of the original sample and the artificial sample with relatively high credibility; continuing to use an original loss function for the original sample, adding a penalty factor for the loss function of the artificial minority class sample to penalize the artificial sample with low credibility, and determining a new loss function; and finally, forming a new Boosting algorithm. According to the method, the classification precision of a minority class and a majority class is improved and the problem of low classification precision of a classification model to the minority class caused by data non-equilibrium in the field of prediction and classification is solved to a certain extent.

Owner:BEIHANG UNIV

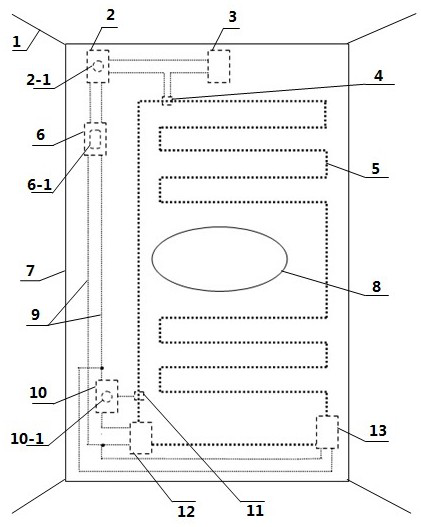

Green constant-temperature clothes

PendingCN114073346AAchieve constantSimple structureGarment special featuresBatteries circuit arrangementsEngineeringMechanical engineering

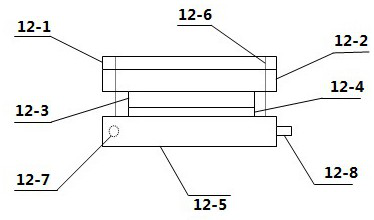

The invention discloses clothes which can keep a constant temperature, can control the constant temperature speed and does not need to be charged. The invention belongs to household articles for daily use. The green constant-temperature clothes overcome the technical defects that the constant-temperature speed of the constant-temperature clothes in the prior art cannot be controlled so that the temperature of the clothes is suddenly high or low, heating or cooling is frequently started, and charging is needed. The clothes mainly comprise a power supply device (3), a heating and refrigerating speed regulator (2), a reversing switch (6), a mechanical temperature controller (10), a temperature changing box (12), a pump (13), a rubber hose (5), a component bearing medium (7), a lead (9), a liquid (which is not marked in the rubber hose (5) and a water tank (12-5)) and the like. According to the green constant-temperature clothes, the liquid is cooled or heated according to the refrigerating and heating principle of the semiconductor cooling piece (12-4), and then the liquid is circulated in cycles through the pump (13) and the rubber hose (5). And the constant-temperature comfort is successfully kept for people.

Owner:李绪章

A single-layer image classification method based on delay mechanism

ActiveCN113408613BIncrease engagementImprove distributionCharacter and pattern recognitionNeural architecturesImaging processingFeature extraction

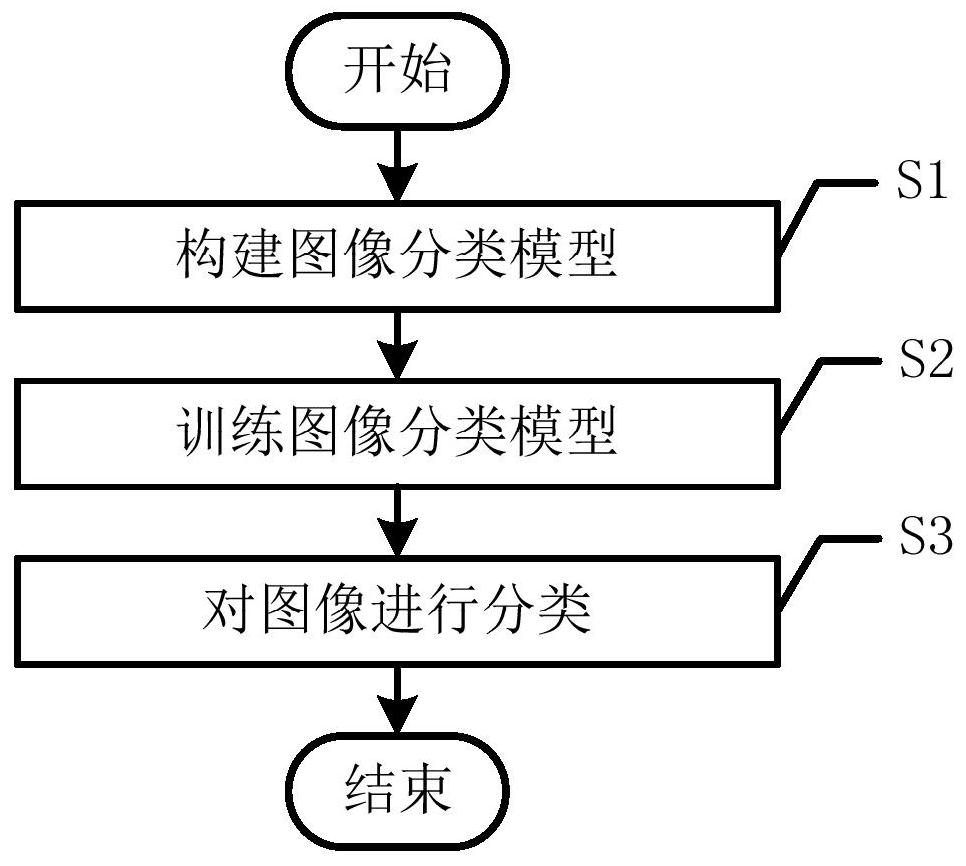

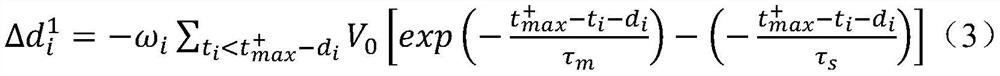

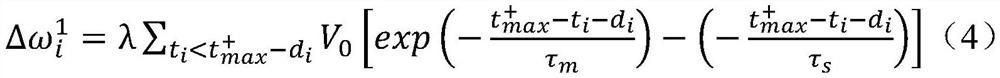

The invention discloses a single-layer image classification method based on a delay mechanism, belonging to the technical field of image processing. The method comprises the following steps: S1, constructing an image classification model; S2, using an image set to train the image classification model, and obtaining a trained image Image classification model; S3. Use the image classification model completed by training to classify the image to obtain the category of the image; the image classification model includes a feature extraction unit, a pulse delay coding unit and a single-layer classifier connected in sequence; the present invention solves the problem of Tempotron learning Algorithms only rely on adjusting synaptic weights, which leads to the problem that the learning effect is highly susceptible to interference.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

Combined type series horizontal numerically controlled lathe

InactiveCN111993088ANo loss of geometric precisionDoes not destroy rigidityFeeding apparatusOther manufacturing equipments/toolsEngineeringStructural engineering

The invention relates to the field of horizontal lathes, and particularly relates to a combined type series horizontal numerically controlled lathe. The combined type series horizontal numerically controlled lathe comprises a lathe body, guide rails, a feeding box, a headstock, a slide carriage box and a tailstock. The combined type series horizontal numerically controlled lathe is characterized in that at least one horizontal outer guide rail parallel to the guide rails is arranged on the outer side of the lathe body, wherein a plurality of connecting bodies are arranged between the horizontal outer guide rails and the lathe body, and the connecting bodies are connected with the lathe body through bolts; the lower surface of a large slide carriage is provided with a matching surface matched with the two guide rails and the horizontal outer guide rails, the upper surface of the large slide carriage is provided with a middle slide carriage, the middle slide carriage is provided with a combined equipment installation area, the combined equipment installation area is provided with a platform and an installation support extending outwards, and the combined equipment installation area is provided with functional combined equipment. Compared with the prior art, the combined type series horizontal numerically controlled lathe has the advantages that the combined type series horizontalnumerically controlled lathe can be combined with an outer circle grinding head, an inner circle grinding head, an end face grinding head, a curve grinding head, a threaded grinding head, a rail roller grinding head, a bearing grinding head and various milling heads, the combined type series horizontal numerically controlled lathe has multiple functions, and the worldwide problem of offshore maintenance of large offshore ships is solved particularly.

Owner:徐绍波

Method and device for attributing information delivery effect

The invention discloses an attribution method and device of information putting effects. The method comprises steps of after counting information conversion frequency and information reaching frequency brought by each channel combination consisting of a single channel combination put by an information putting party within a set period, determining the information conversion rate of each channel combination according to the information conversion frequency and the information reaching frequency brought by each channel combination; determining the weight of each single channel in each channel combination according to the information conversion rate of each channel combination; and based on the weight of each single channel in each channel combination, determining the information conversion frequency brought by each signal channel. Compared with the current attribution method of information putting effects, the provided method is characterized in that effects caused by different channel cooperation are fully considered, so it can be ensured that the distribution weight corresponding to each signal channel is quite precise and proper, and problems of improper and inaccurate attributionin the current attribution method of information putting effects are solved.

Owner:ALIBABA GRP HLDG LTD

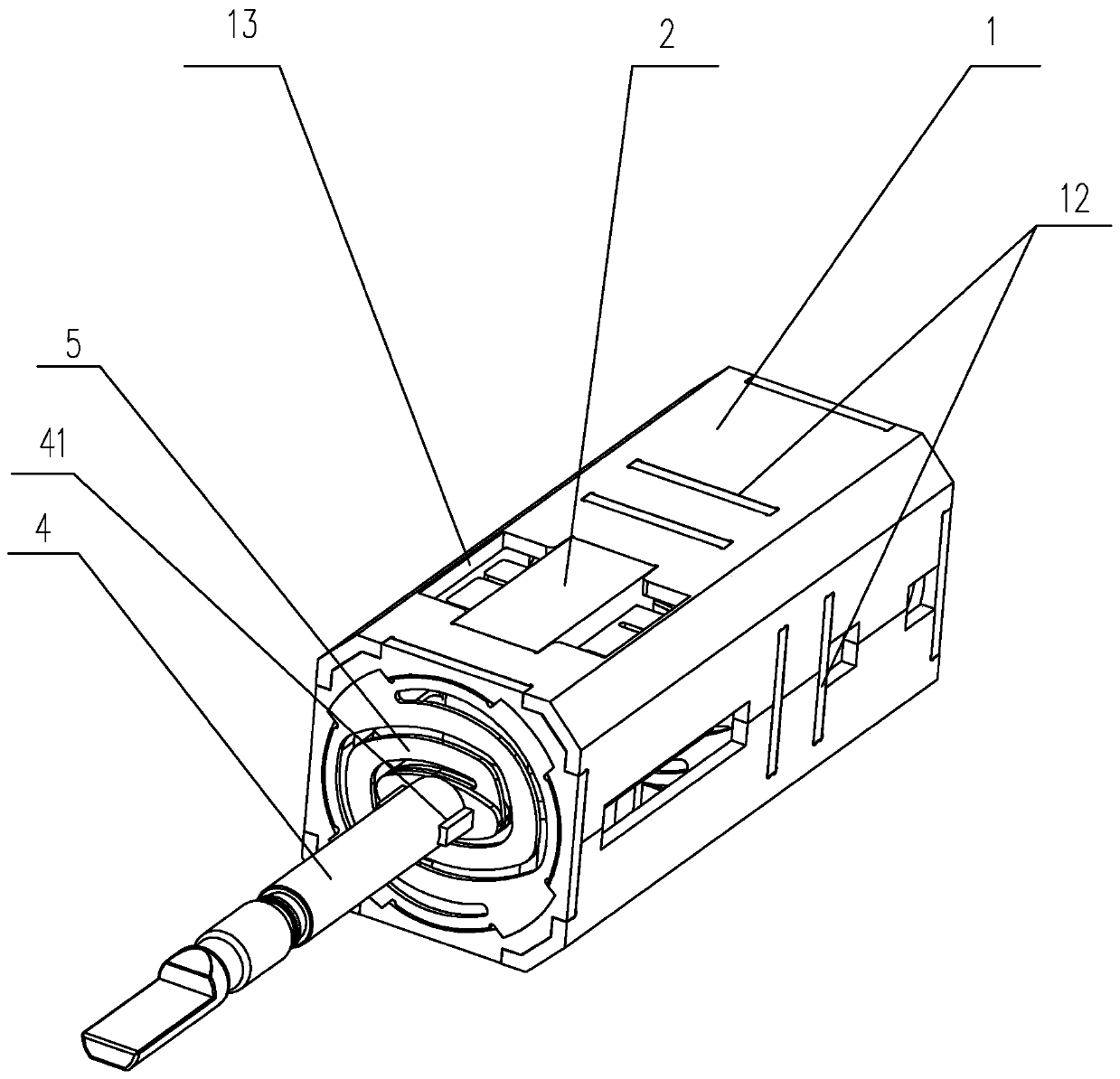

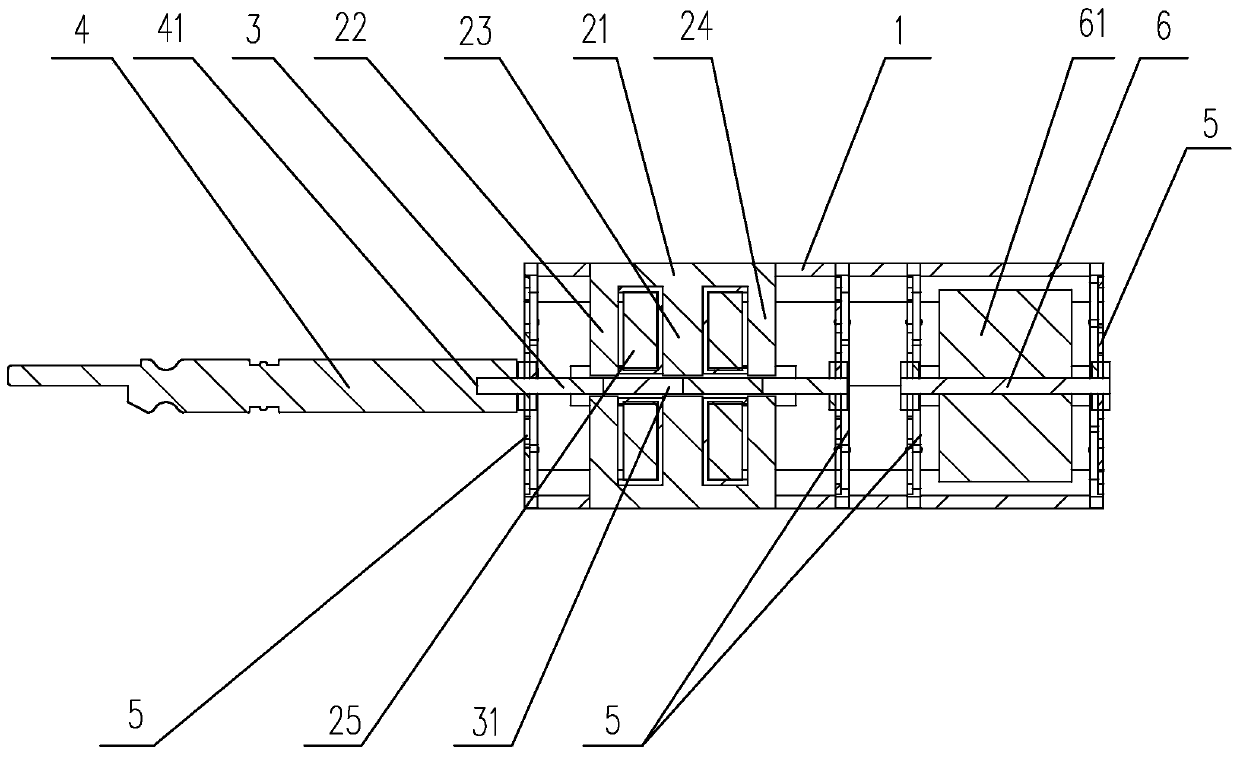

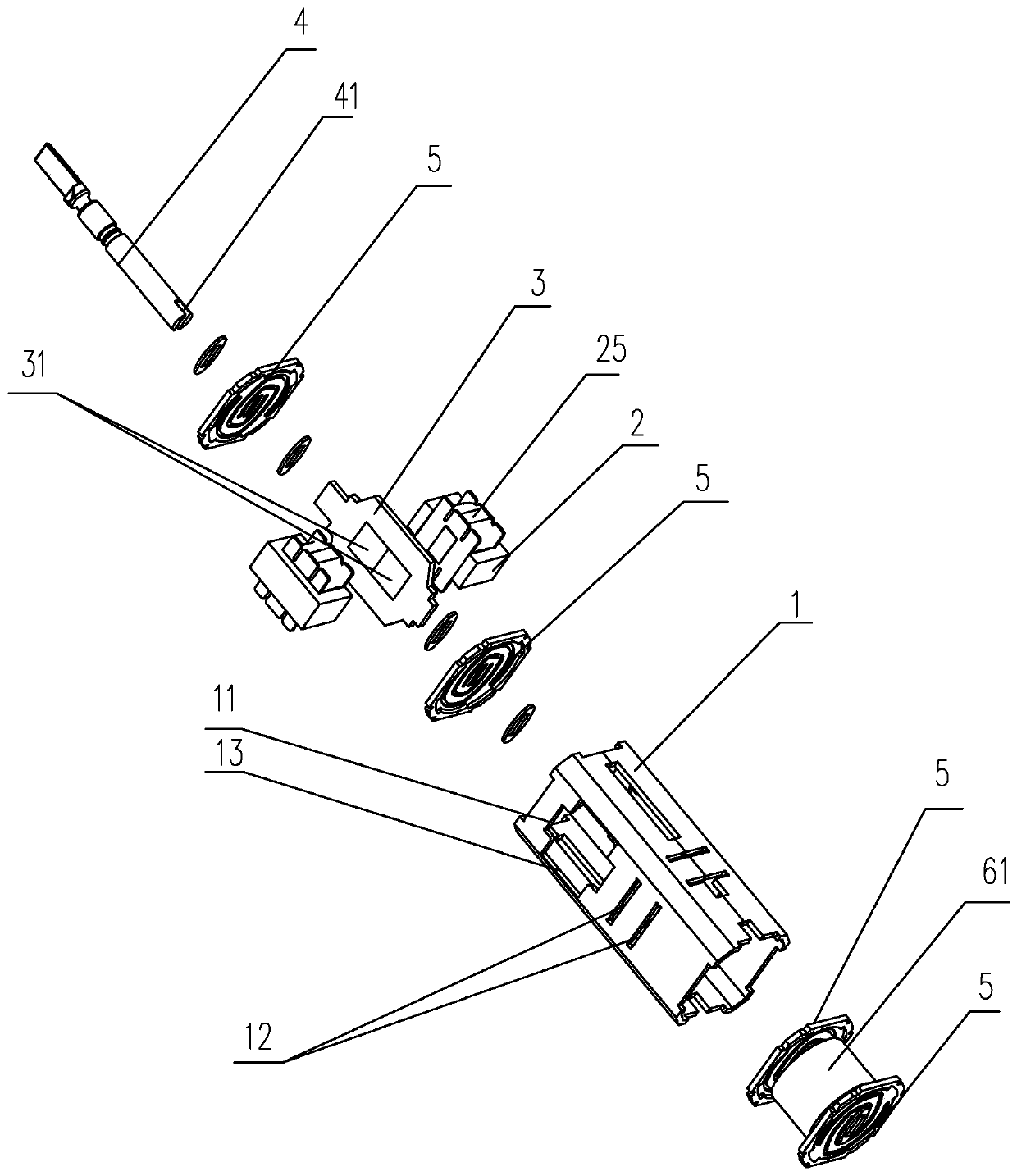

Linear oscillation motor

PendingCN110957885AAvoid mutual interferenceAvoid forceSupports/enclosures/casingsElectric machineEngineering

The invention discloses a linear oscillation motor. The linear oscillation motor comprises a shell, a linear vibration module and a reverse vibration module are arranged in the shell, the linear vibration module and the reverse vibration module are coupled through the shell; the linear vibration module comprises a sliding piece and at least one iron core set; the sliding piece is arranged in the shell in a sliding mode in the axial direction; the sliding piece extends out of the shell to form an output shaft; magnetic steel is arranged on the sliding piece, plate springs are arranged at the two ends of the sliding piece, the sliding piece is connected with the shell through the plate springs, the iron core set comprises two E-shaped iron cores arranged on the two sides of the sliding piecerespectively, windings are arranged on the E-shaped iron cores, and the reverse vibration module is arranged in the shell and is far away from the output shaft. The structure is simple, implementation is facilitated, a center shaft can move in the axial direction to be output, output is more stable, and the using effect of the whole structure is improved.

Owner:ZHEJIANG BAOLONG M&E CO LTD

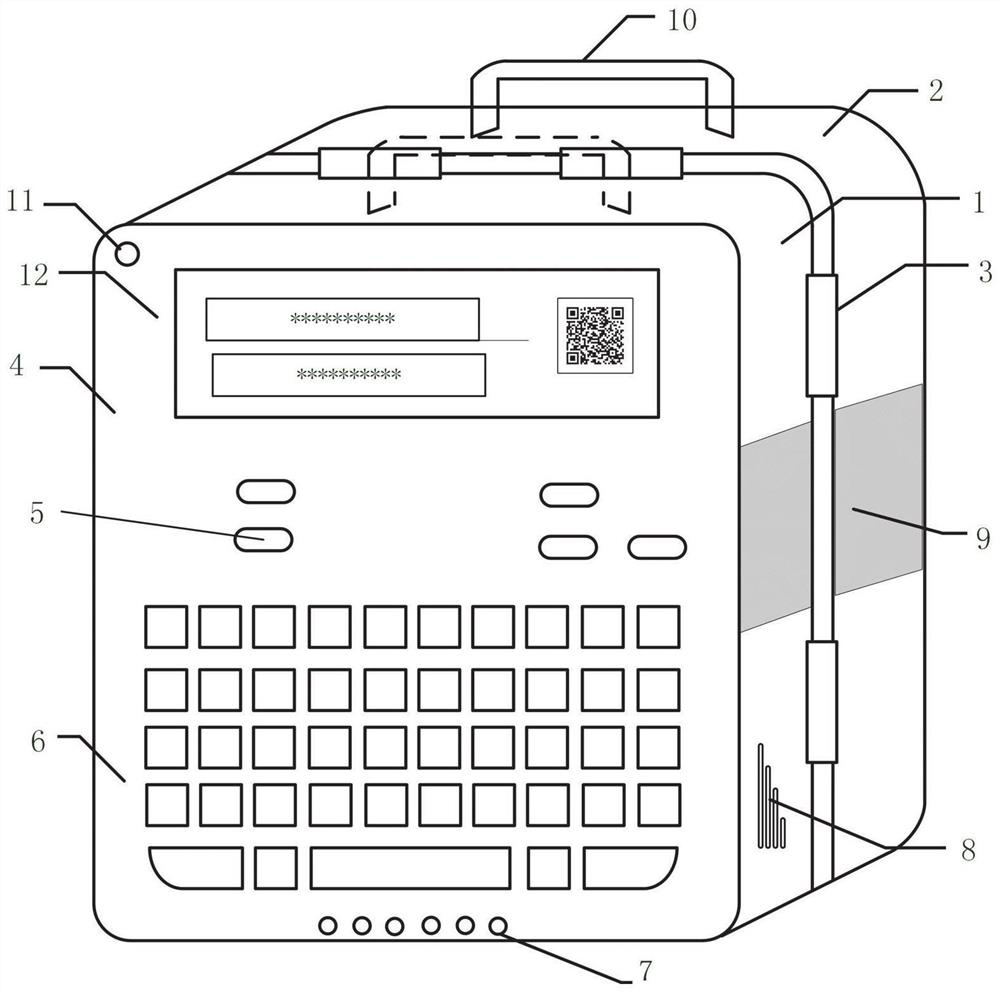

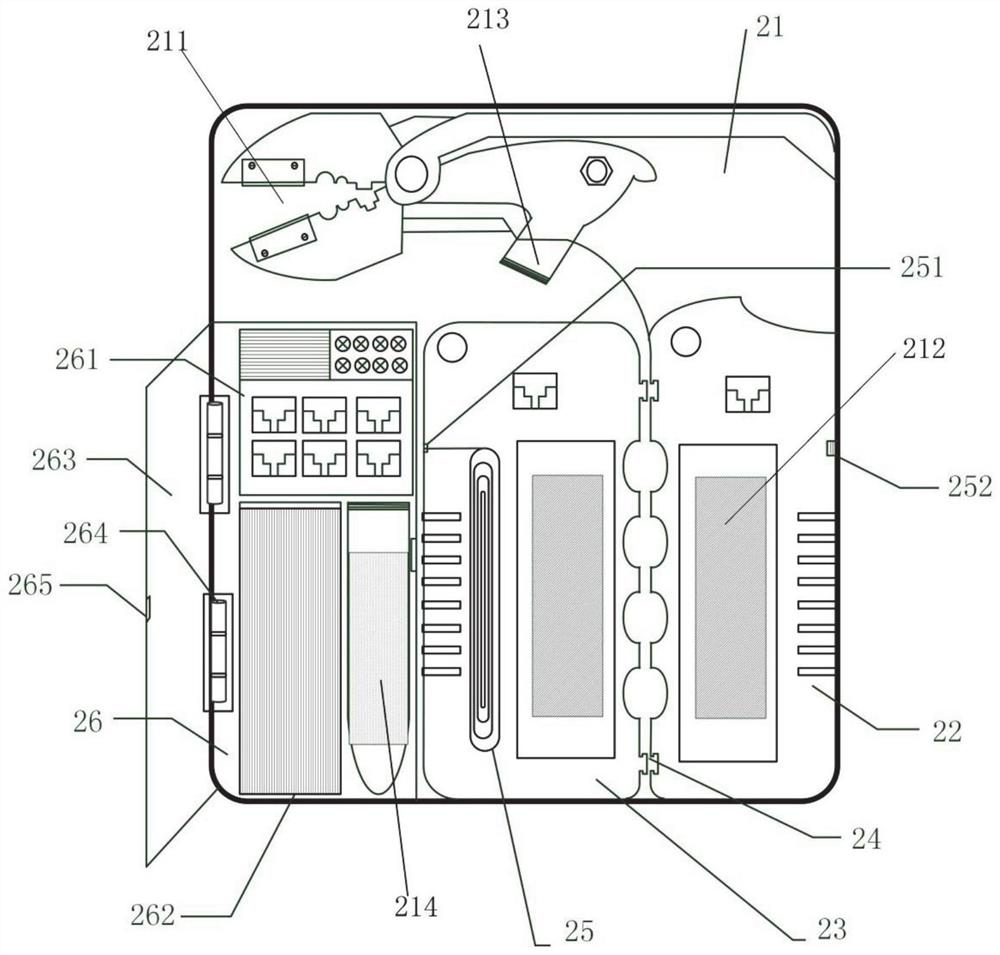

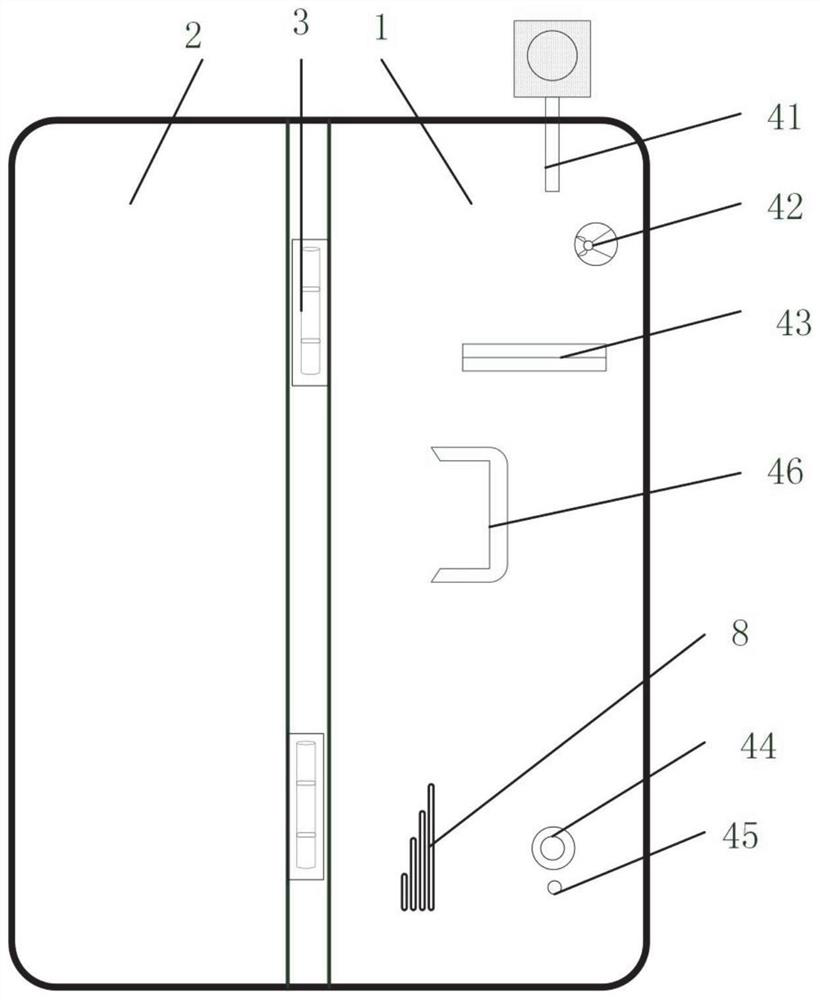

Portable network equipment maintenance device

PendingCN114161377AImprove portabilityReduce space consumptionWork tools storageEmbedded systemElectrical and Electronics engineering

The portable network equipment maintenance device comprises a front cover and a rear cover which are detachably connected, a labeling machine is arranged in the space in the front cover, a network cable clamp is arranged at the top of the space in the rear cover, and a cable tester and a tool box are arranged at the bottom of the space in the rear cover in parallel; the cable measuring instrument comprises a fixed cable measuring instrument and a movable cable measuring instrument which are detachably connected, and the fixed cable measuring instrument is connected with the network cable clamp to form a fixed handle of the network cable clamp. A labeling machine, a network cable clamp, a cable tester and common consumables in the operation and maintenance process of network equipment are integrated in a compact space formed by the front cover and the rear cover, so that the portability of the operation and maintenance tool is improved.

Owner:STATE GRID SHANDONG ELECTRIC POWER +1

Composite billiard cue

The invention discloses a composite billiard cue, which comprises a rear handle and a front branch arranged at the front end of the rear handle; the rear handle comprises a first carbon fiber tube, a solid wood core rod arranged in the first carbon fiber tube and a wood decoration layer arranged outside the first carbon fiber tube. The front branch comprises a second carbon fiber tube and a foaming filler arranged in the second carbon fiber tube. The weight of the rear handle is reduced in a mode of using a first carbon fiber pipe wood structure, and the weight of the front branch is reduced in a mode of putting the foaming filler into the second carbon fiber tube, so that the overall weight is lighter than that of an existing billiard cue; the overall density of the rear handle is greater than that of the front handle, so that the gravity center is more rear than that of an existing billiard cue, weight distribution is more reasonable, ball hitting accuracy is effectively improved, and offset is reduced; the rear handle and the front branch are both made of carbon fiber tubes, the supporting performance is higher, the hardness is correspondingly improved, and the billiard cue is not prone to deformation; particularly, the front branch is the carbon fiber tube, so that the striking force characteristic and the striking force absorption characteristic can be improved.

Owner:裴燃

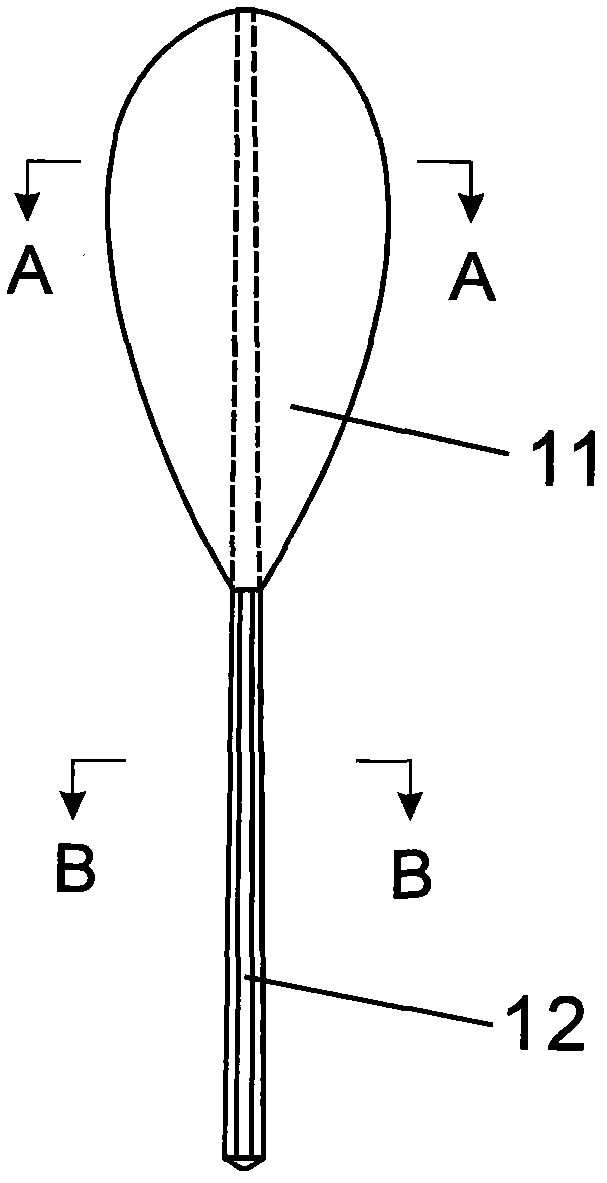

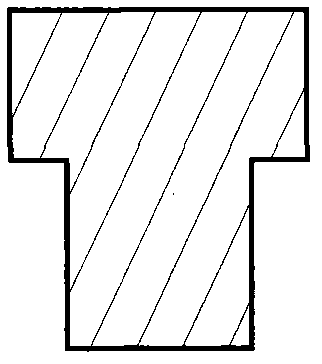

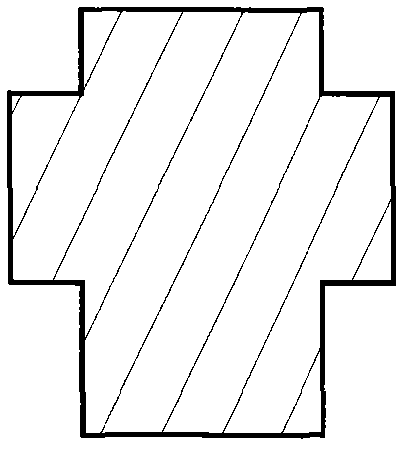

Special artificial feather for badminton and badminton

The invention relates to special artificial feather for a badminton. The special artificial feather comprises feather (11) and a feather stalk (12), and is characterized in that the transverse cross section of the feather stalk (12) is in a T shape. The special artificial feather has the optimal scheme that the upper transverse cross section of the feather stalk (12) is in the T shape, and the lower half part of the feather stalk (12) is changed into a cross shape through transition. The invention also relates to the badminton manufactured by the special artificial feather.

Owner:溧阳百事达体育用品制造有限公司 +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com