A Floatability Test Model

A characteristic test and model technology, applied in the direction of aircraft component testing, etc., can solve the problems of excessive model weight, backward design technology, poor strength, etc., and achieve the effect of large internal space, reasonable weight distribution, and good strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] A classification principle of the present invention is as follows:

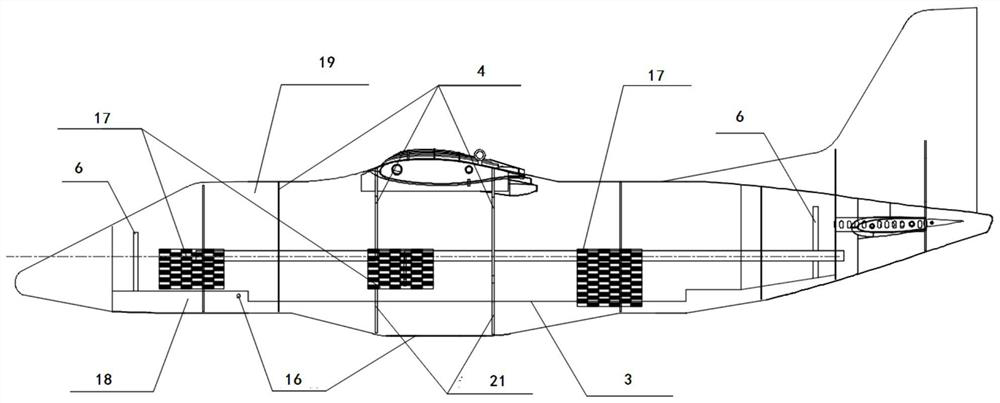

[0023] The model design adopts a modular design, which is different from the parting surface of the actual machine. Based on the principle of easy assembly, the model is divided on a plane parallel to the longitudinal section, and the model is divided into several large parts that are directly connected by connectors.

[0024] B model structure design of the present invention is as follows:

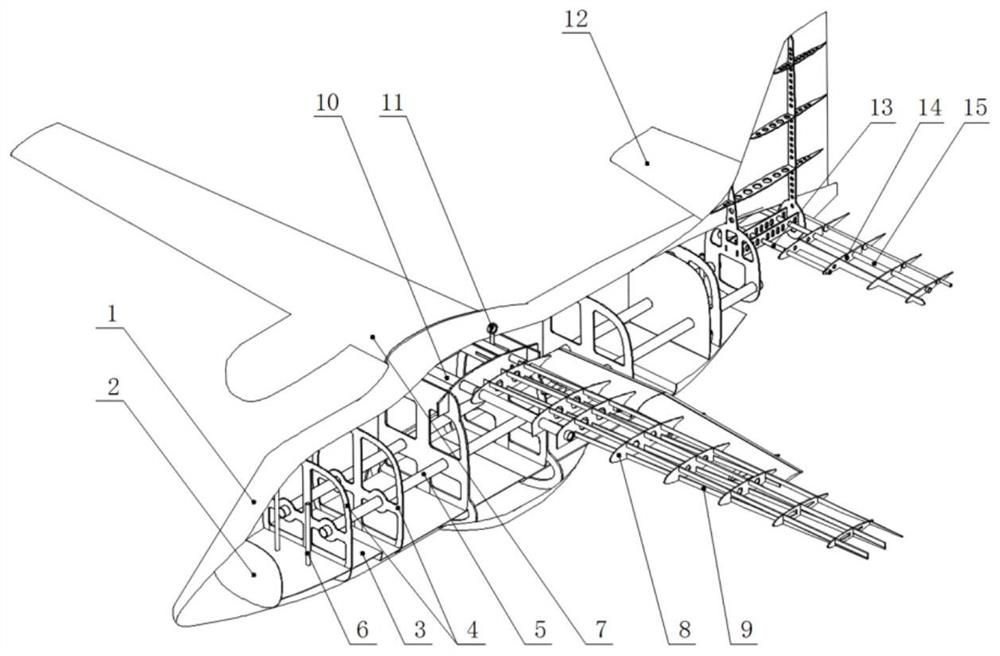

[0025] The present invention consists of a fuselage skin 1, a fuselage subdivision panel 2, a fuselage floor 3, a fuselage frame 4, a fuselage bearing beam 5, an air pipe 6, a wing skin 7, a wing frame 8, The wing stringer girder 9, the wing fuselage docking beam 10, the lifting adjustment system 11, the horizontal tail skin 12, the horizontal tail fuselage docking beam 13, the horizontal tail bulkhead 14, and the horizontal tail beam 15 are composed.

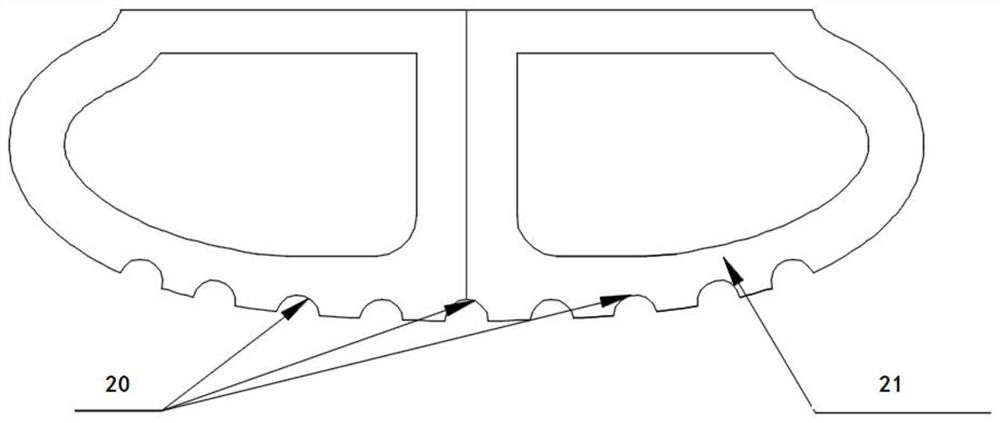

[0026] The fuselage subdivision plate 2 and the fuselage flo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com