Polishing main machine installing structure with stable structure

A technology with a stable structure and an installation structure, which is applied in the direction of grinding racks, grinding drive devices, and machine tools suitable for grinding workpiece planes. Achieve structural balance, reasonable weight distribution, and reduce production difficulty and cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] In order to further explain the technical solution of the present invention, the present invention will be described in detail below through specific examples.

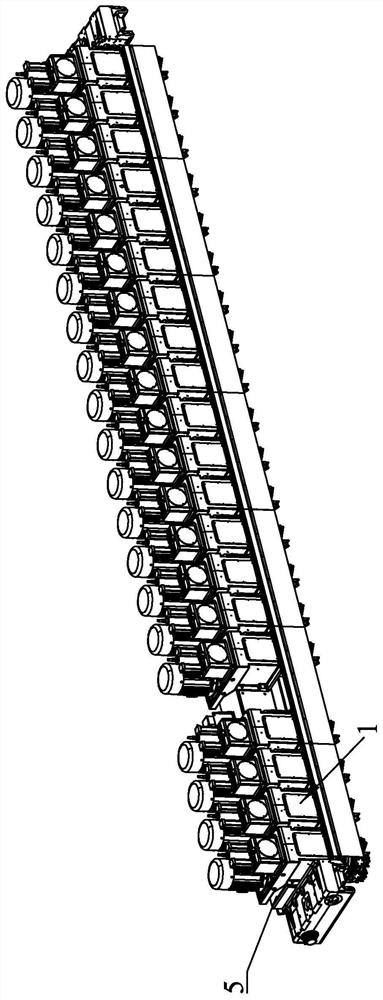

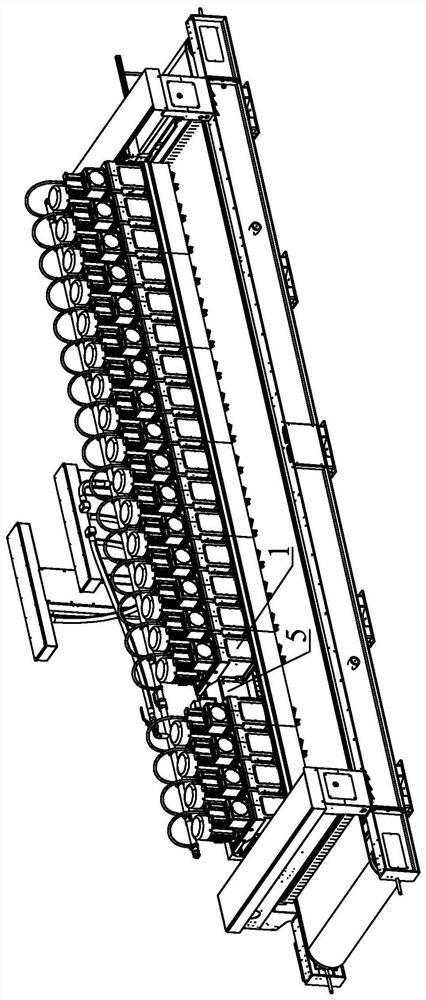

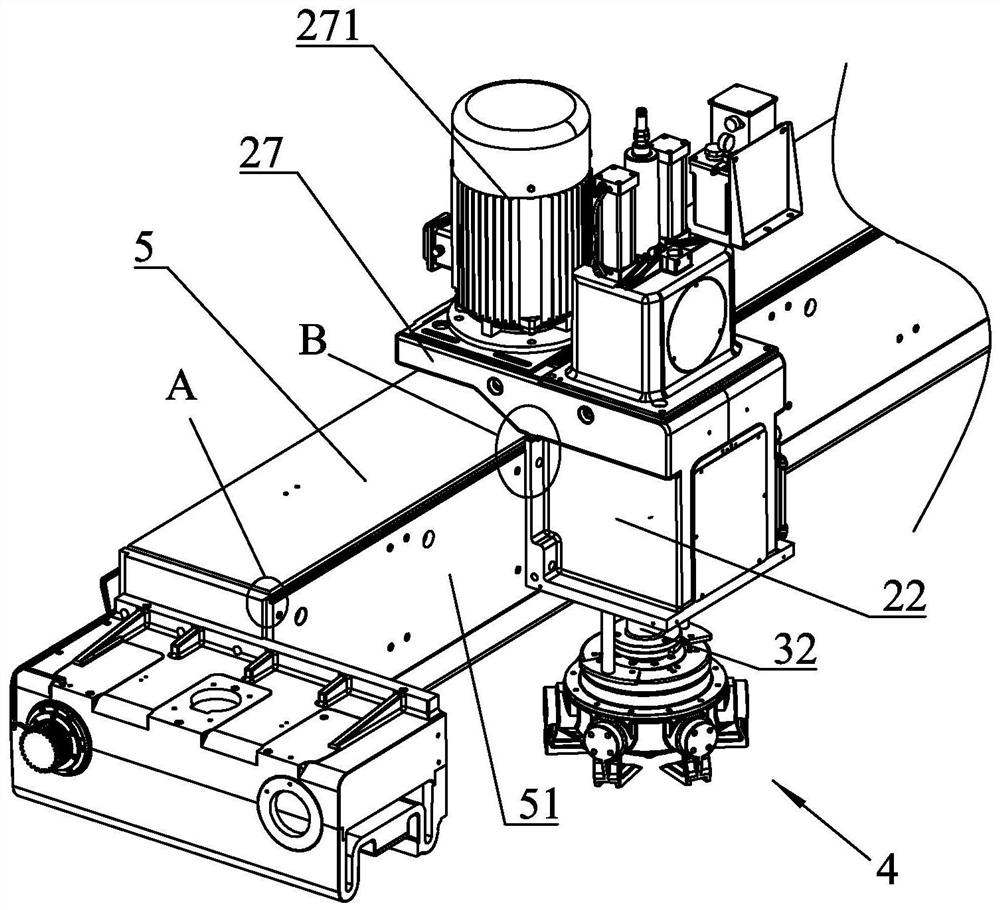

[0037] Such as Figure 1 to Figure 11 As shown, it is a structurally stable grinding host 1 installation structure related to the present invention, including a swing beam 5 and at least one grinding host 1 installed on the swing beam 5; the grinding host 1 includes a base 21, a main shaft 3 , Grinding head 4 and drive motor 271; Described seat body 21 comprises support frame 22 and motor mounting base 27, and described motor mounting base 27 is connected on described support frame 22 upper end and cantilever outside described support frame 22; The main shaft 3 is rotatably mounted on the support frame 22, the driving motor 271 is fixedly mounted on the motor mount 27 to drive the main shaft 3 to rotate, and the grinding head 4 is installed at the lower end of the main shaft 3; A first mounting fitting surface...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com