Intelligent subway rail welding vehicle and rail welding method

A technology for welding rail cars and subways, which is used in tracks, track laying, track maintenance, etc. It can solve the problems of intelligence and the degree of mechanization need to be improved, and achieve easy failure analysis and maintenance, stable and reliable running process, and reduced labor intensity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 11

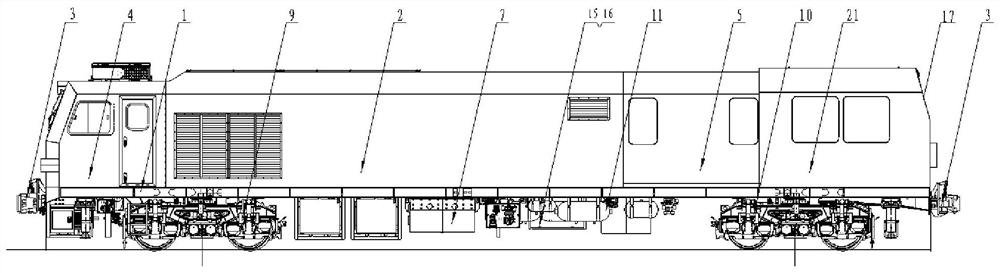

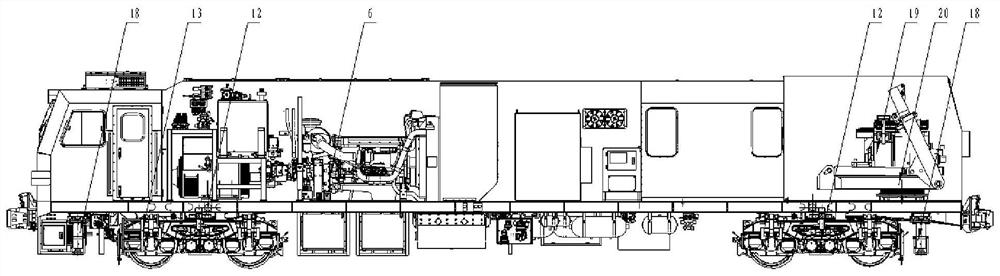

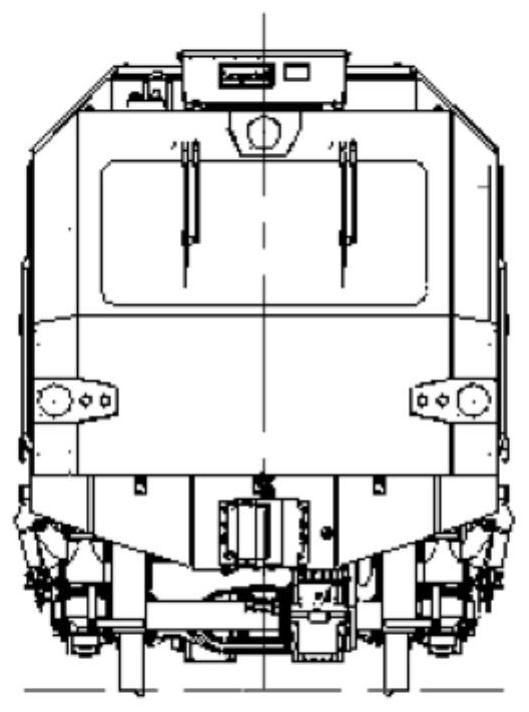

[0053] Embodiment 1.1: a kind of intelligent subway rail welding car, such as Figure 1-Figure 3 As shown, it includes a vehicle frame 1, and the top of the vehicle frame 1 is sequentially arranged with a driver's cab 4, a functional room 2, an operation room 5, and a welding machine room 21, and a power transmission system 6, a hydraulic pressure The fuel tank 14 and the operation room 5 are provided with an office area and a work operation area. A welding machine 19 and a welding machine retractable device 20 are arranged inside the welding machine room 21 . A flip door 17 is arranged at the end of the welding machine room 21 . A front drive bogie 9, a diesel tank 7, and a rear drive bogie 10 are arranged sequentially from front to rear under the vehicle frame 1. Escalators 13 are arranged on both sides of the front drive bogie 9 . The front drive bogie 9 and the rear drive bogie 10 are respectively arranged with foundation brakes 12 . The front and rear of the vehicle fra...

Embodiment 21

[0083] Embodiment 2.1: a kind of intelligent subway rail welding method comprises:

[0084] Step A: The subway rail welding car travels at high speed to the place to be welded and stops;

[0085] Step B: Operate the control switch of the reversing door, and the reversing door will automatically open to a position with an angle of 80°-90° with the original state and lock itself;

[0086] Step C: Operate the control switch of the sliding mechanism of the welding room, and slide the welding room to the working state, so that the welding machine system is completely exposed;

[0087] Step E: Put the welding machine down to the center of the track through the retractable device of the welding machine and rotate it left and right, align the rails to be welded at the center of the track, turn on the welding machine, and start the welding operation at the place where the rails are to be welded to realize offline welding;

[0088] Step I: retract the welding machine within the limit t...

Embodiment 22

[0094] Embodiment 2.2 An intelligent subway rail welding method, comprising:

[0095] Step A: The subway rail welding car travels at high speed to the place to be welded and stops;

[0096] Step B: Operate the control switch of the reversing door, and the reversing door will automatically open to a position with an angle of 80°-90° with the original state and lock itself;

[0097] Step C: Operate the control switch of the sliding mechanism of the welding room, and slide the welding room to the working state, so that the welding machine system is completely exposed;

[0098] Step E: Put the welding machine down to the center of the track through the retractable device of the welding machine and rotate it left and right, align the rails to be welded at the center of the track, turn on the welding machine, and start the welding operation at the place where the rails are to be welded to realize offline welding;

[0099] Step J: retract the welding machine to the subway rail weldi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com