Push-on switch

A switch and movable contact technology, applied in the field of push switches, can solve the problems of deterioration of action characteristics, sluggish touch of pressing load, etc., achieve easy positioning, prevent the increase of pressing load, and reduce the number of parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

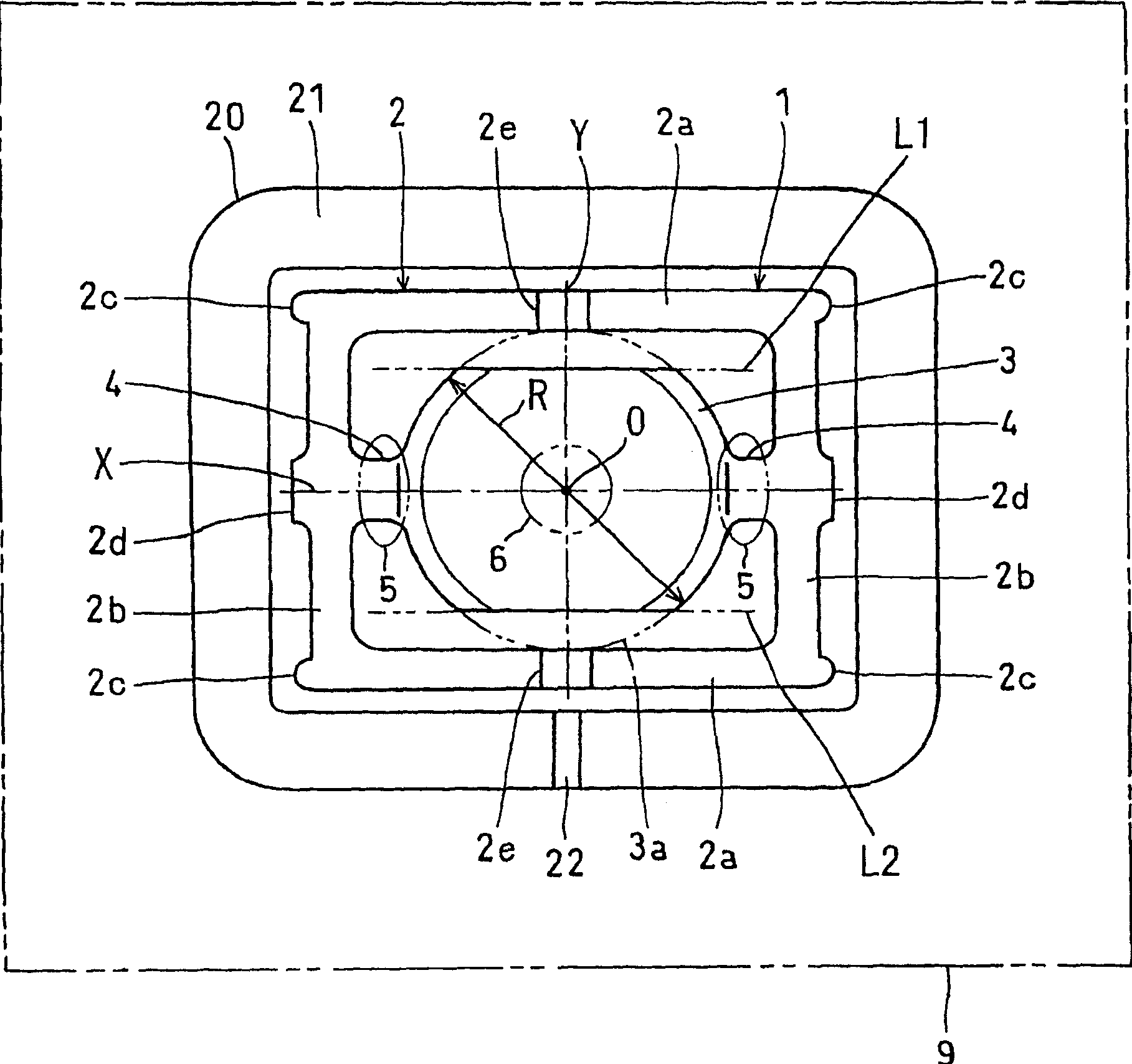

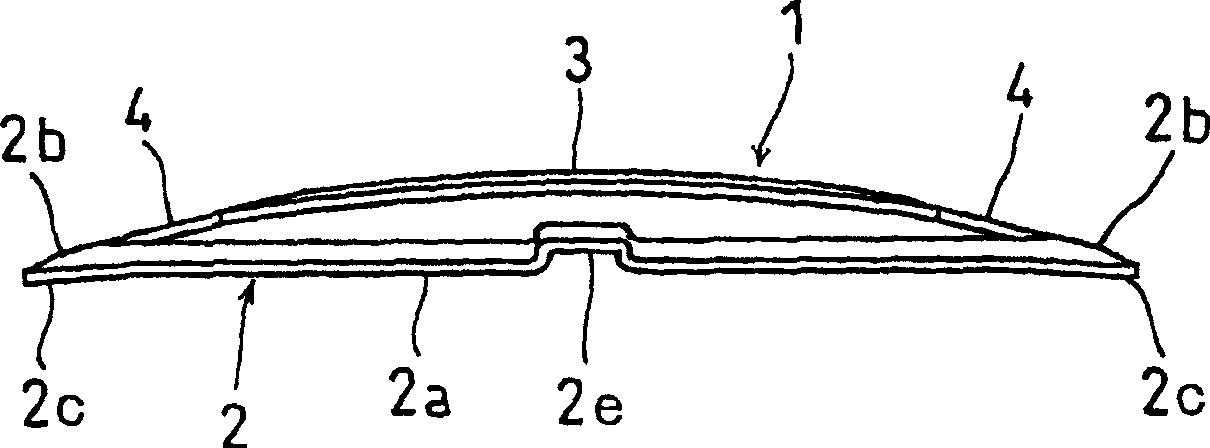

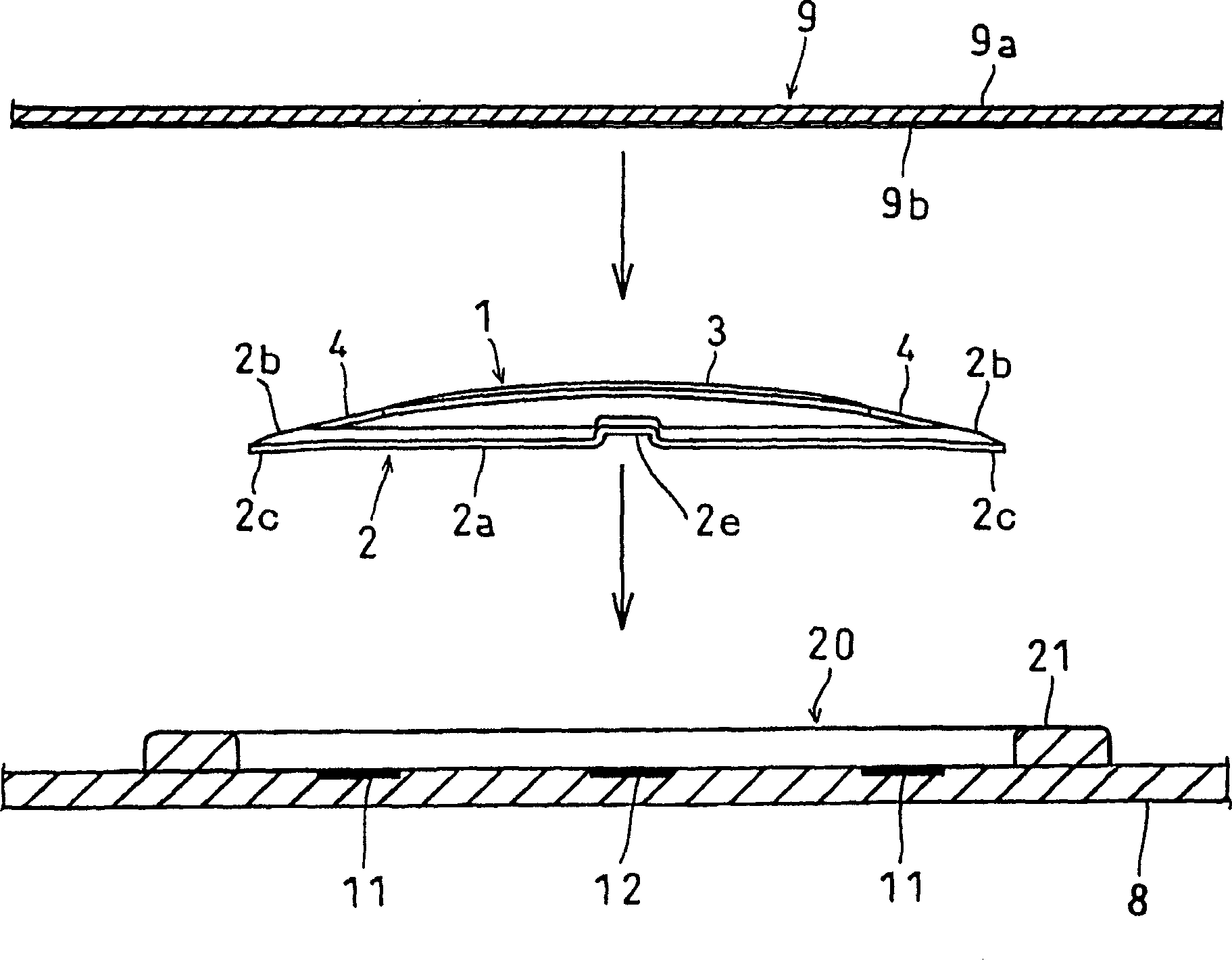

[0030] Embodiments of the present invention will be described below with reference to the drawings. figure 1 It is a plan view showing the push switch of Example 1 of this embodiment, figure 2 It is a side view of the movable contact plate of the push switch of embodiment 1, image 3 It is a side view showing the disassembled state of the push switch of Embodiment 1 before assembly, Figure 4 is a central cross-sectional view showing the assembled state of the push switch of Embodiment 1, Figure 5 It is a central longitudinal sectional view showing the assembled state of the push switch of Embodiment 1, and FIG. 6 is a central cross-sectional view showing the action of the push switch of Embodiment 1.

[0031] The outline of the push switch of the first embodiment will be described. The configuration of this push switch is that first fixed contacts 11, 11 and second fixed contacts 12 are provided on a circuit board 8 such as a printed circuit board (PCB) or a flexible cir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com