Pull-out faucet

A faucet and pull-out technology, which is applied in the field of pull-out faucets and faucets with pull-out nozzles, can solve the problems of increasing the production cost of faucets and increasing the weight of product shipments, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

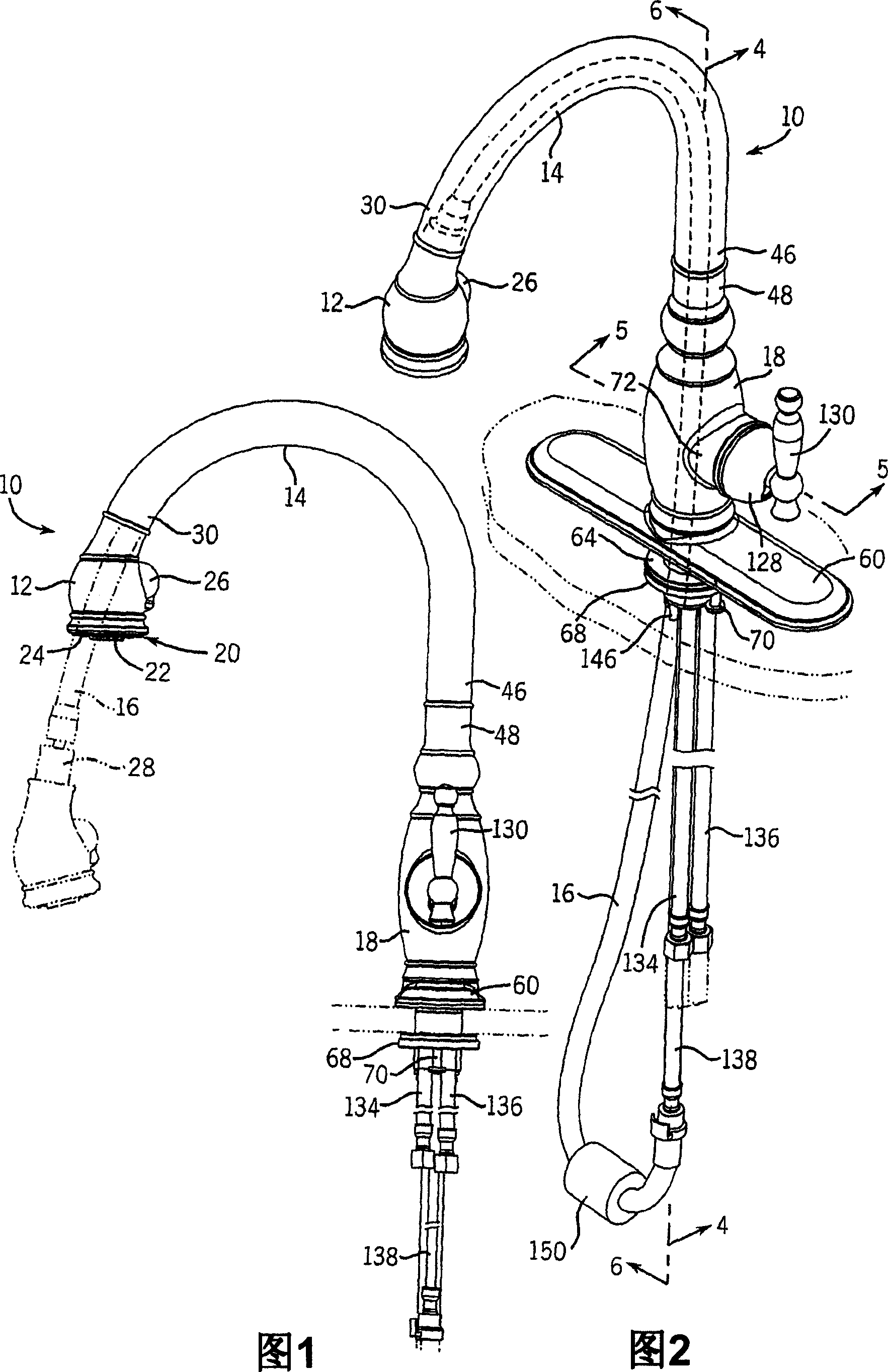

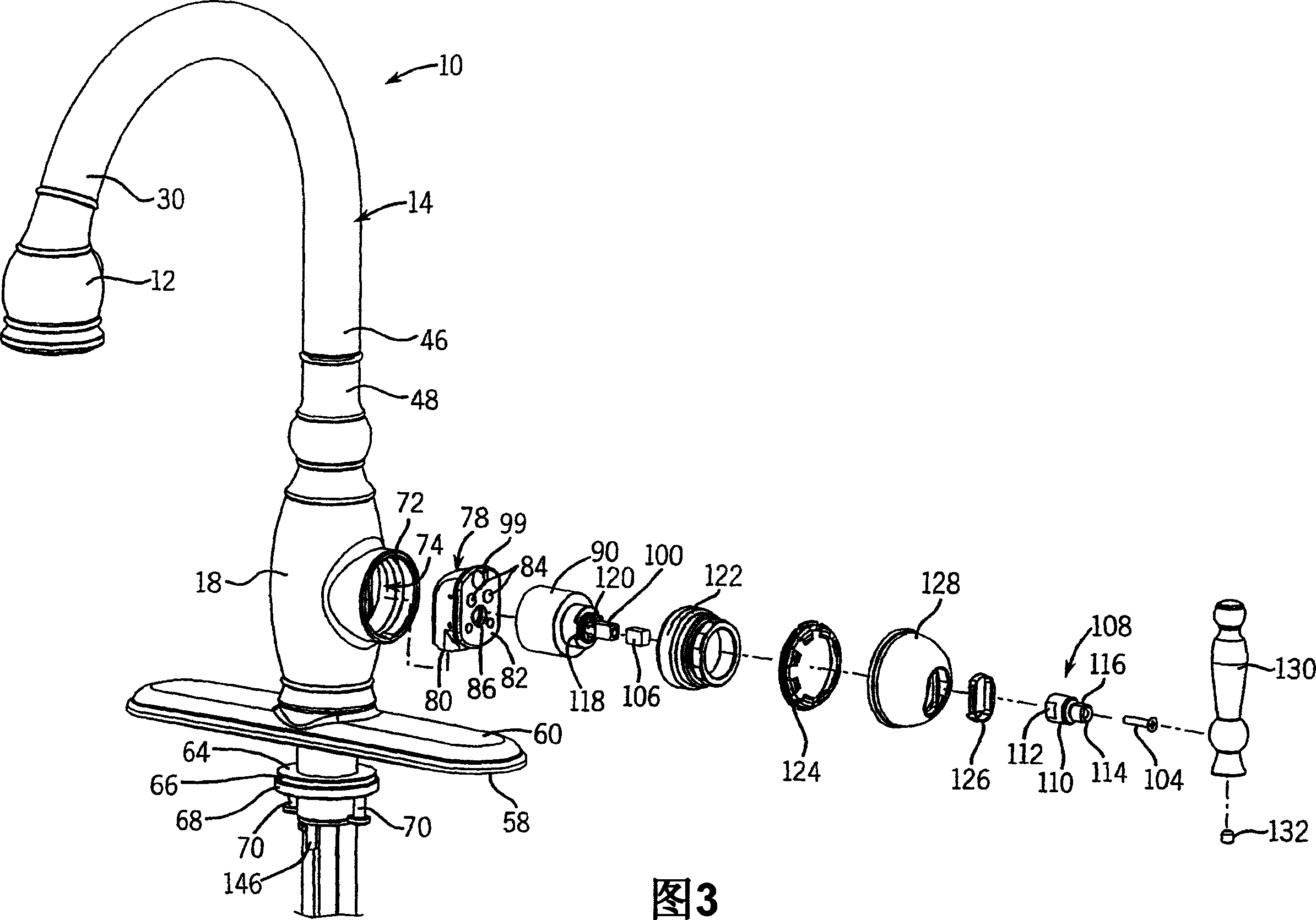

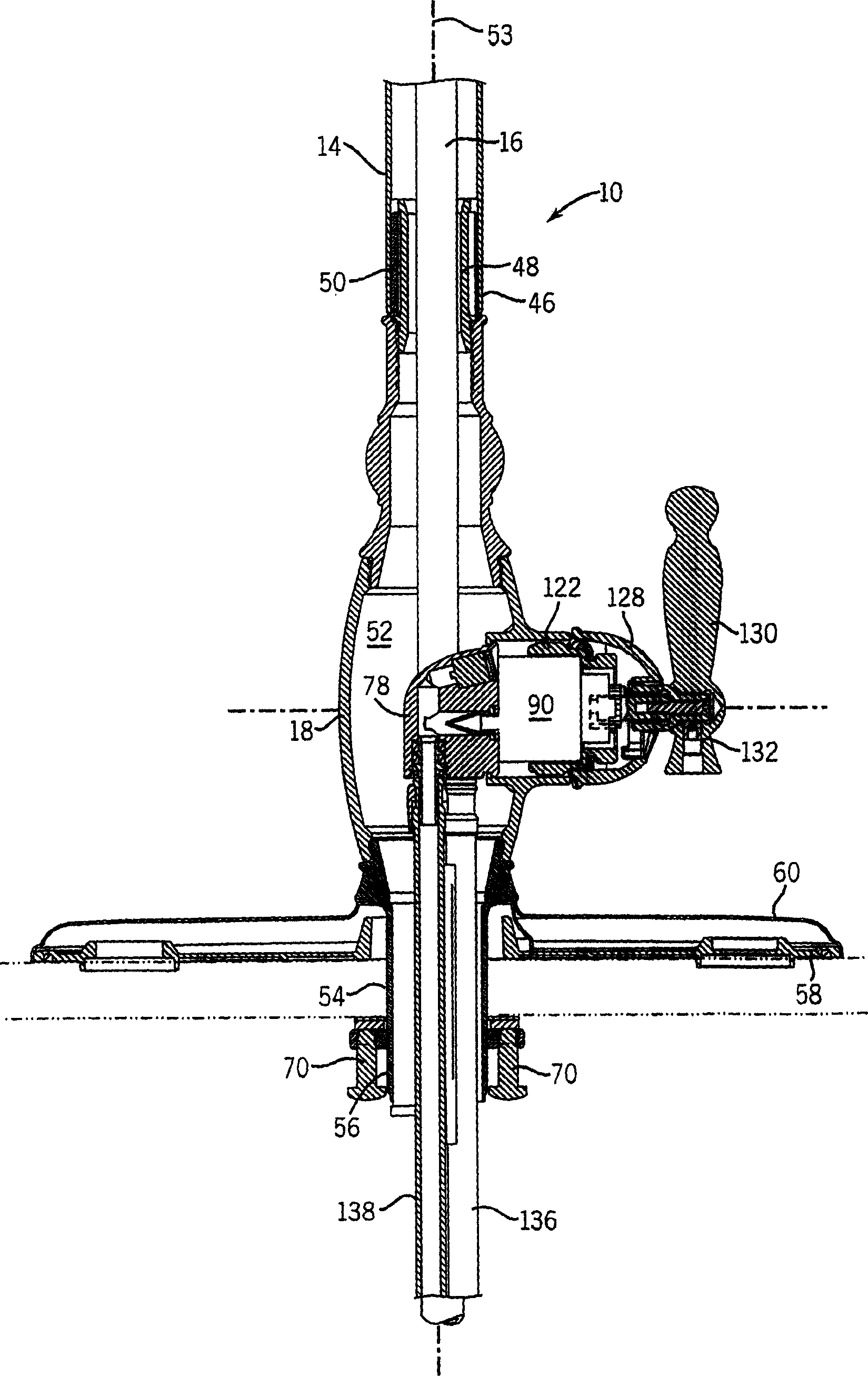

[0028] The main structure of the faucet 10 includes a spout 12 , a spout 14 and a body 18 . Figure 1 shows a preferred version of a pull-out faucet. Figure 2 illustrates that the spout 12 of the tap can be pulled down, in this case first from the (full representation) retracted position down to the (analog representation) extended position. The faucet can thus be used as a conventional faucet with the spray head attached to the spout 14 or detached from the spout for free movement, limited only by the length of the attached spray hose 16 .

[0029] The internal components of the showerhead may be of the type disclosed in US Patent 6,370,713, the entire disclosure of which is incorporated herein by reference, and is commercially available from AMFAG S.p.A. of Castelgoffredo, Italy. Basically, the spray head has a face 20 with a central outlet 22 and a release nozzle ring 24 which provides a shower-like spray when the manual button 26 is depressed to divert the flow of water fr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com