Self contained lubricant dispenser

A technology for dispensing devices, lubricants, applied in the directions of dispensing devices, special dispensing devices, liquid dispensing, conveying or transferring devices, etc., can solve problems such as less choice

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

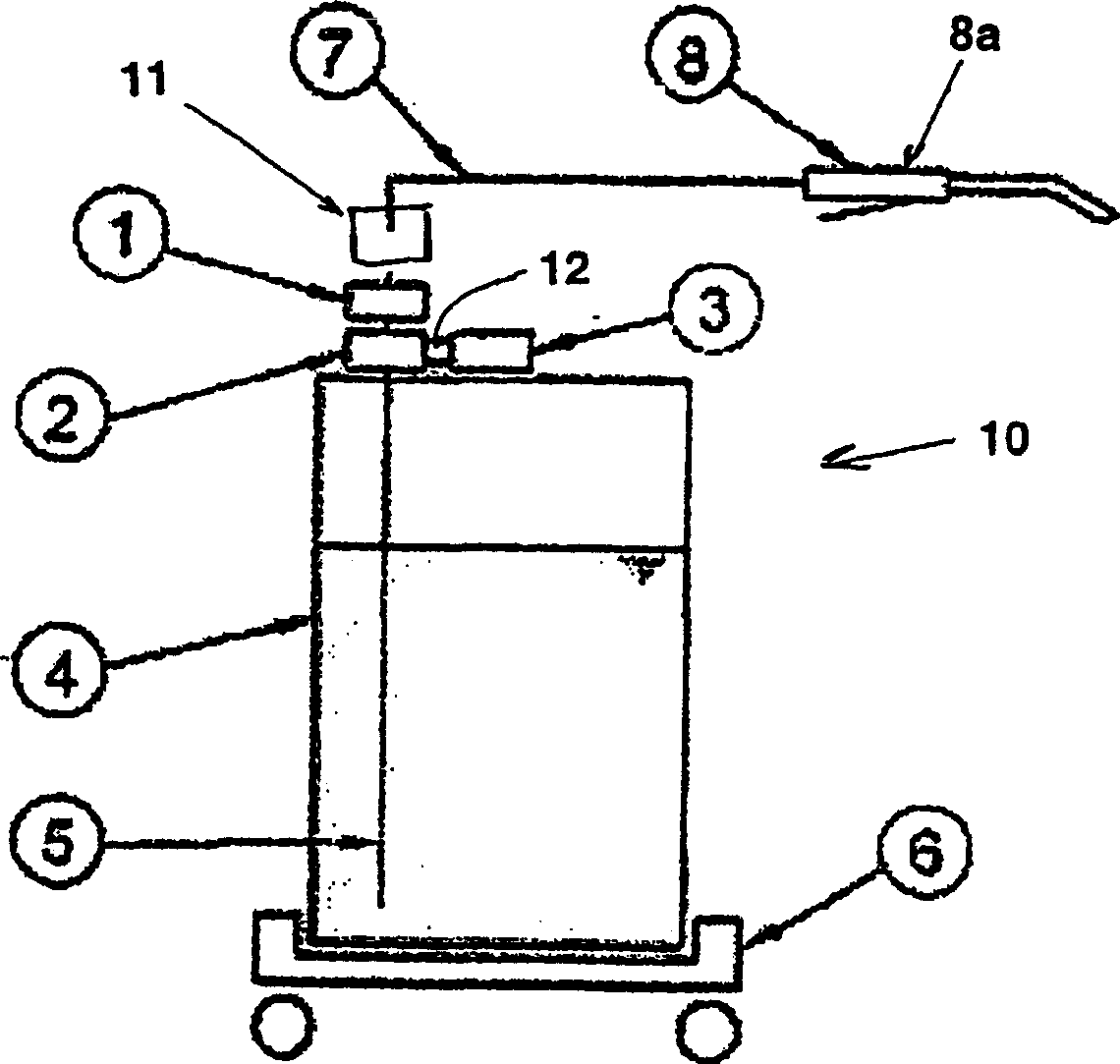

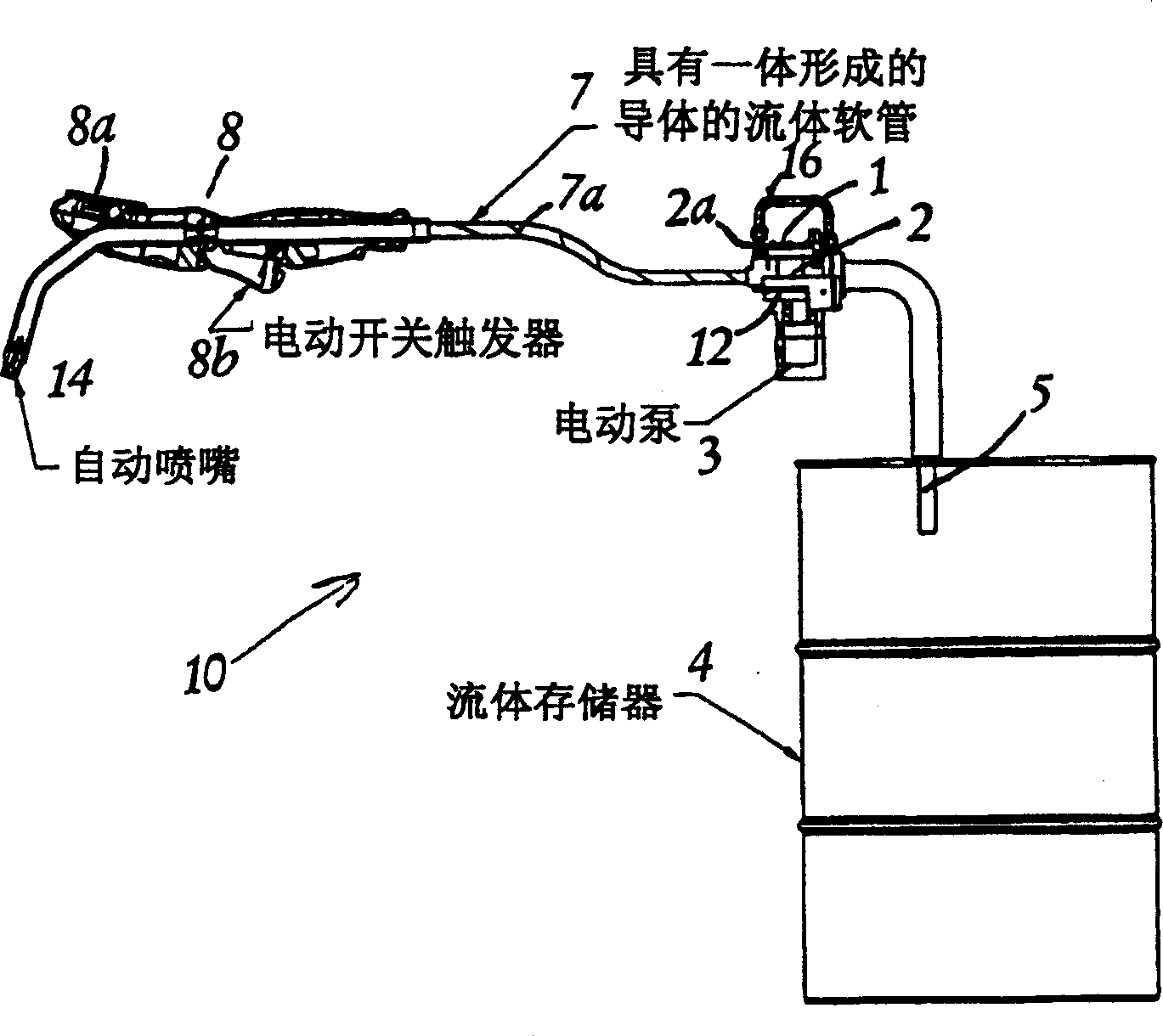

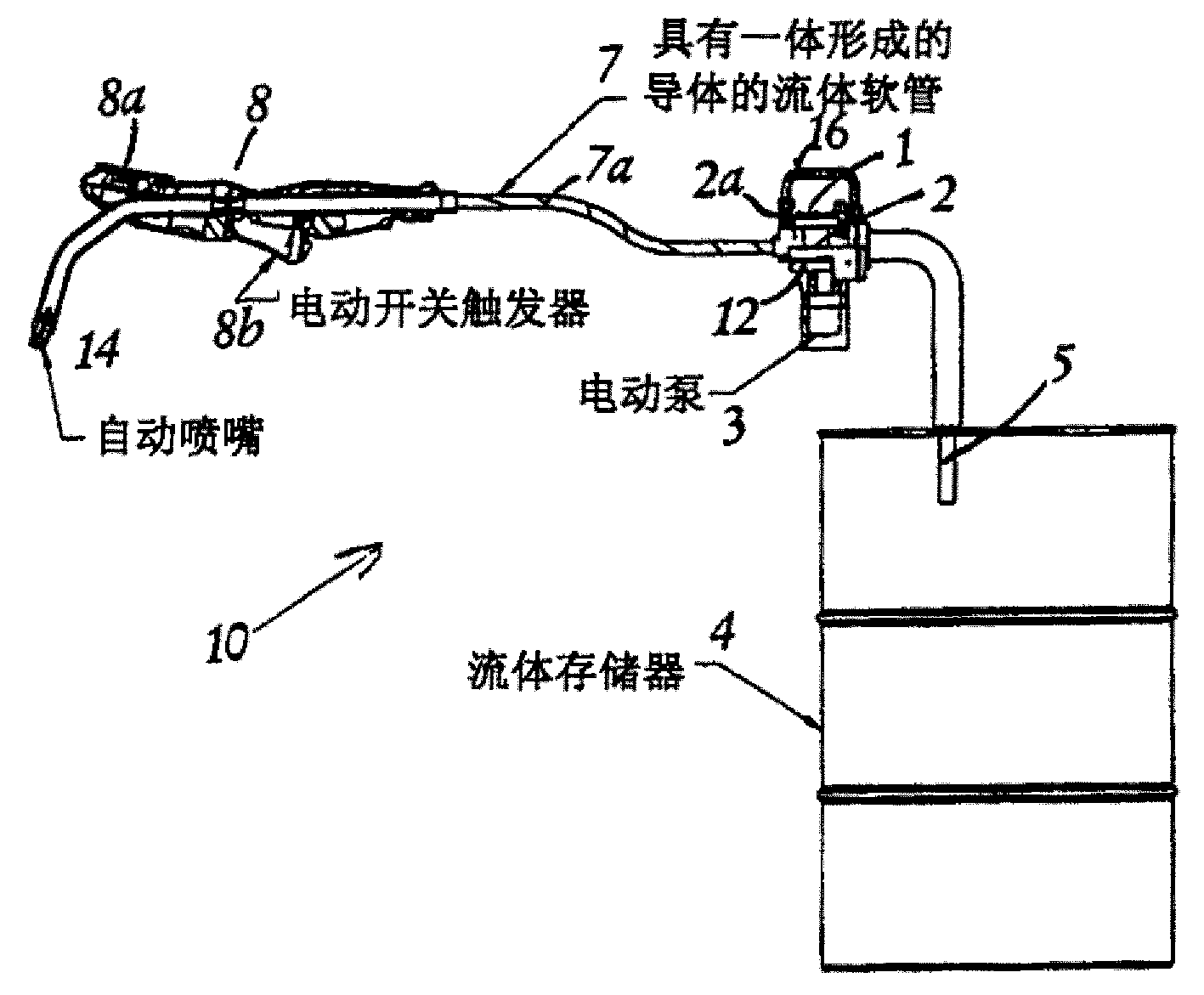

[0008] The invention, generally designated 10, comprises a flow meter 1 and a pump 2 associated therewith. In the preferred embodiment, these two elements are combined, wherein the pump 2 is a gerotor pump type pump, and by placing a Hall effect sensor 2a in the gerotor pump housing to calculate the The pulse generated by the gear teeth displacement of the internal gear oil pump forms the flow meter 1.

[0009] The DC motor 3 drives the pump 2 through a gearbox 12 in order to reduce the rotational speed level. In the preferred embodiment, the motor 3 runs at 20,000 RPM and decelerates to about 600 RPM to produce a flow rate of about 1.5 gallons per minute. The dispensing device 10 is designed to fit over a large volume fluid container 4 and has a suction tube 5 depending downwardly into the container 4 . A portable base 6 can also be provided.

[0010] The dispensing hose 7 leads to a dispensing valve 8, which has a display device 8a indicating the dispensing amount. Dispe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com