Hinge system for inclined door of rolling drum washing machine

A drum washing machine and hinge technology, which can be used in other washing machines, washing devices, textiles and paper making, etc., can solve problems such as complex structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

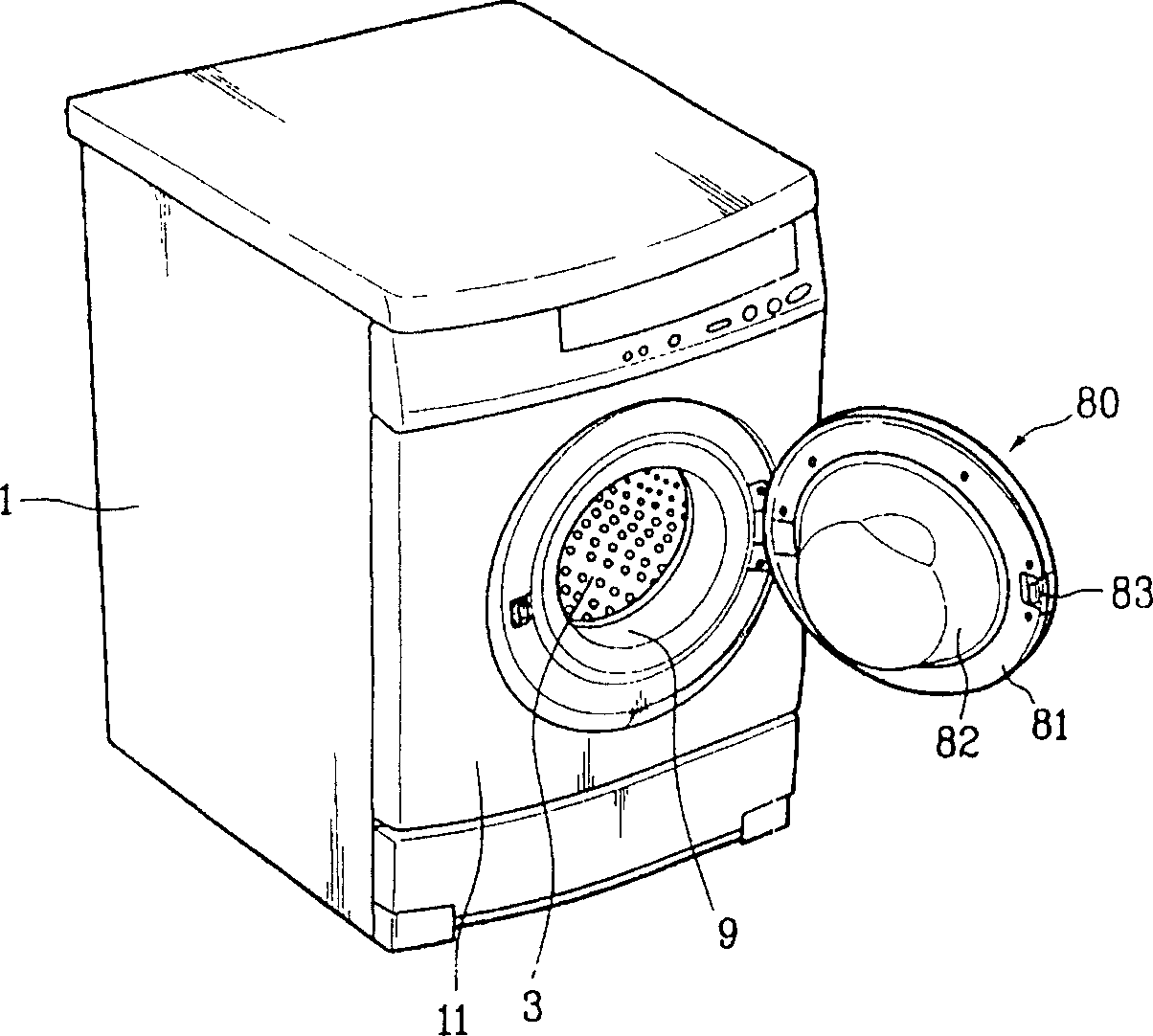

[0030] Hereinafter, it will be described in detail with reference to the drawings of the hinge system of the inclined door of the front-loading washing machine according to the present invention.

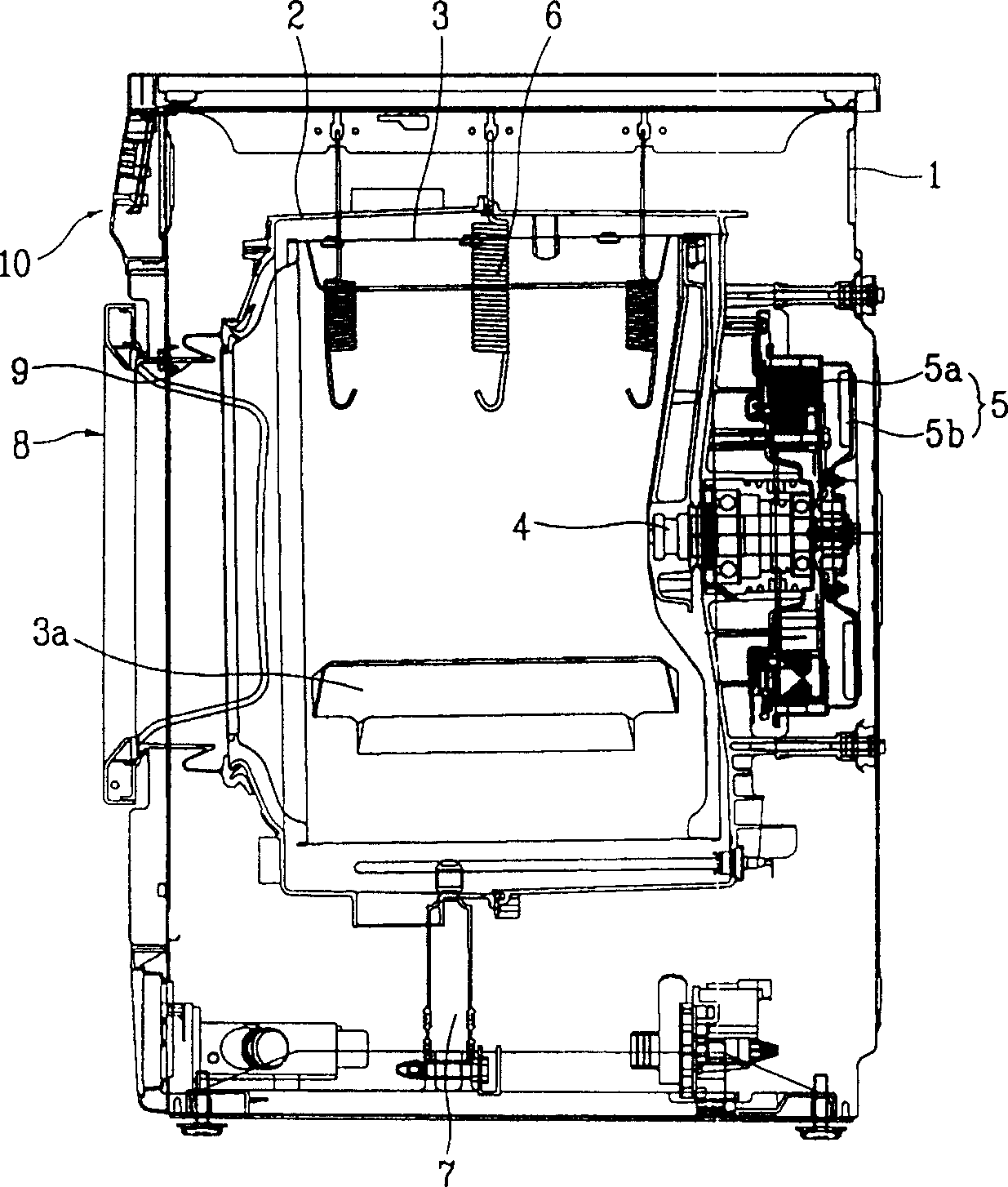

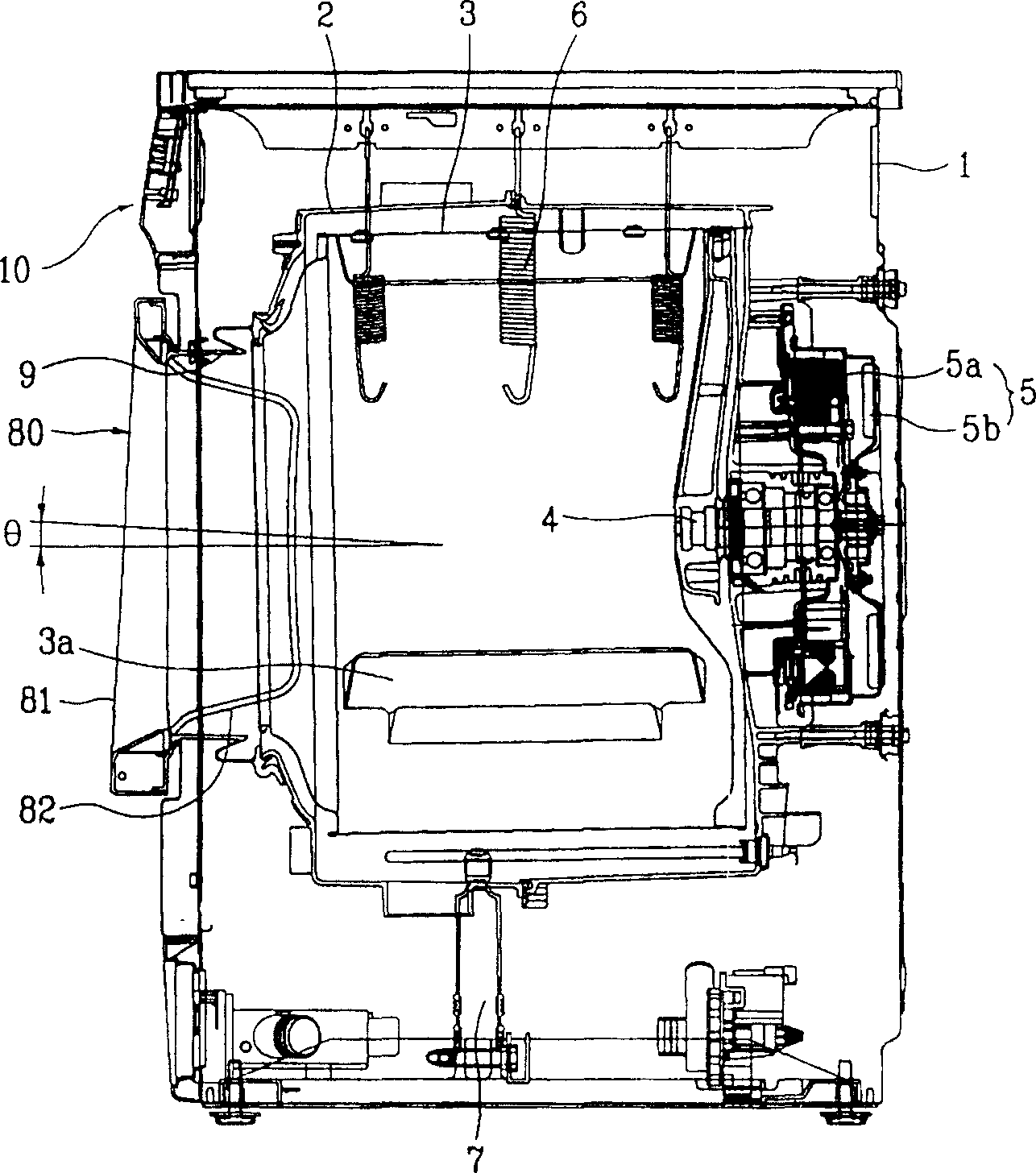

[0031] figure 2 and image 3 It is a structural diagram of a front-loading washing machine of the present invention. A drum-shaped drum (3) rotating around a horizontal axis is installed in the cabinet (1), and a turbine (2) wrapping the outside of the drum (3) is also installed. The above-mentioned turbine (2) is supported by a baffle (7) and a spring (6).

[0032] The drum shaft (4) at the rear of the drum (3) is connected to the drive unit (5), and rotates by the operation of the drive unit. Here, the drive unit (5) is formed by a rotator (5b) and a stator (5a). behind the above-mentioned turbine (2), so as to be able to accept the driving force of the above-mentioned spinner (5b), or to transmit it directly to the drum (3) without a conveyor belt.

[0033] On the chassis cov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com