Aeration free multi hole hollow type extrusion mould

A technology of hollow tires and extrusion molds, which is applied to tires, household appliances, and other household appliances. It can solve the problems of costly materials, complicated installation, and poor elasticity, and achieve the effects of convenient manufacture, wide application, and simple structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

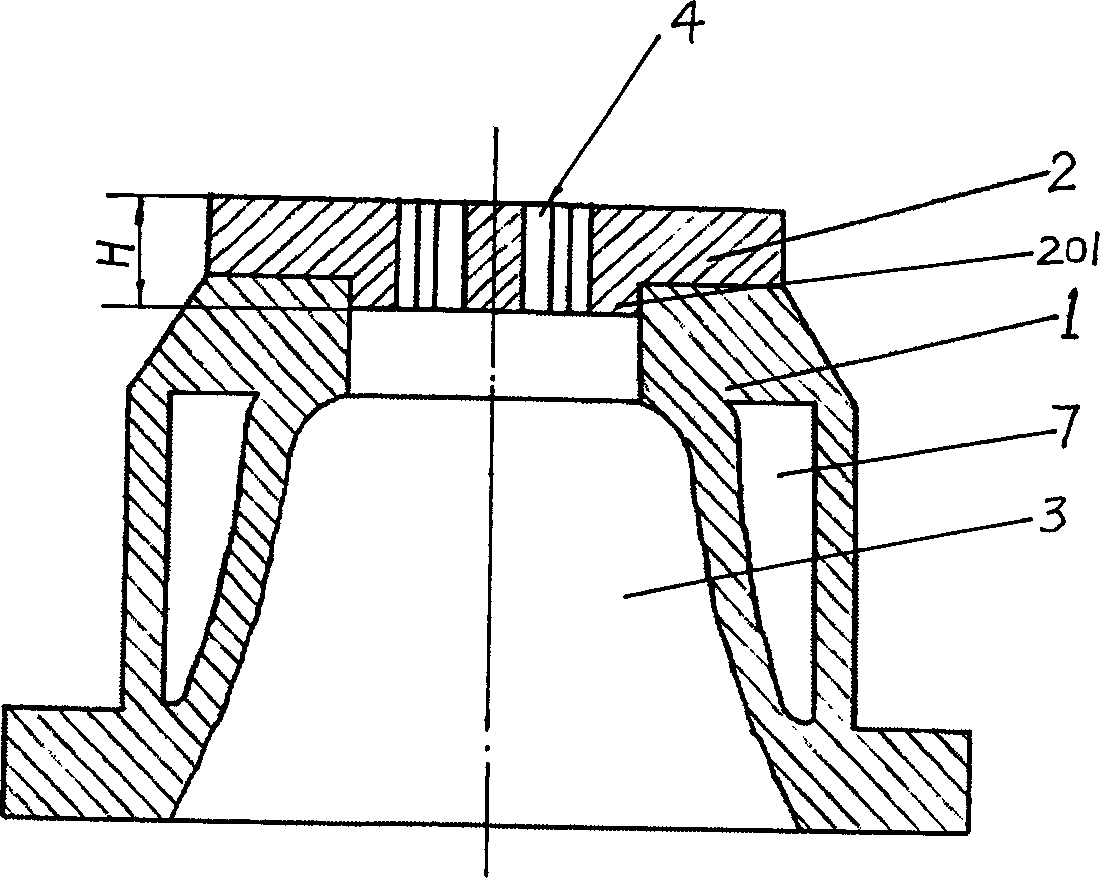

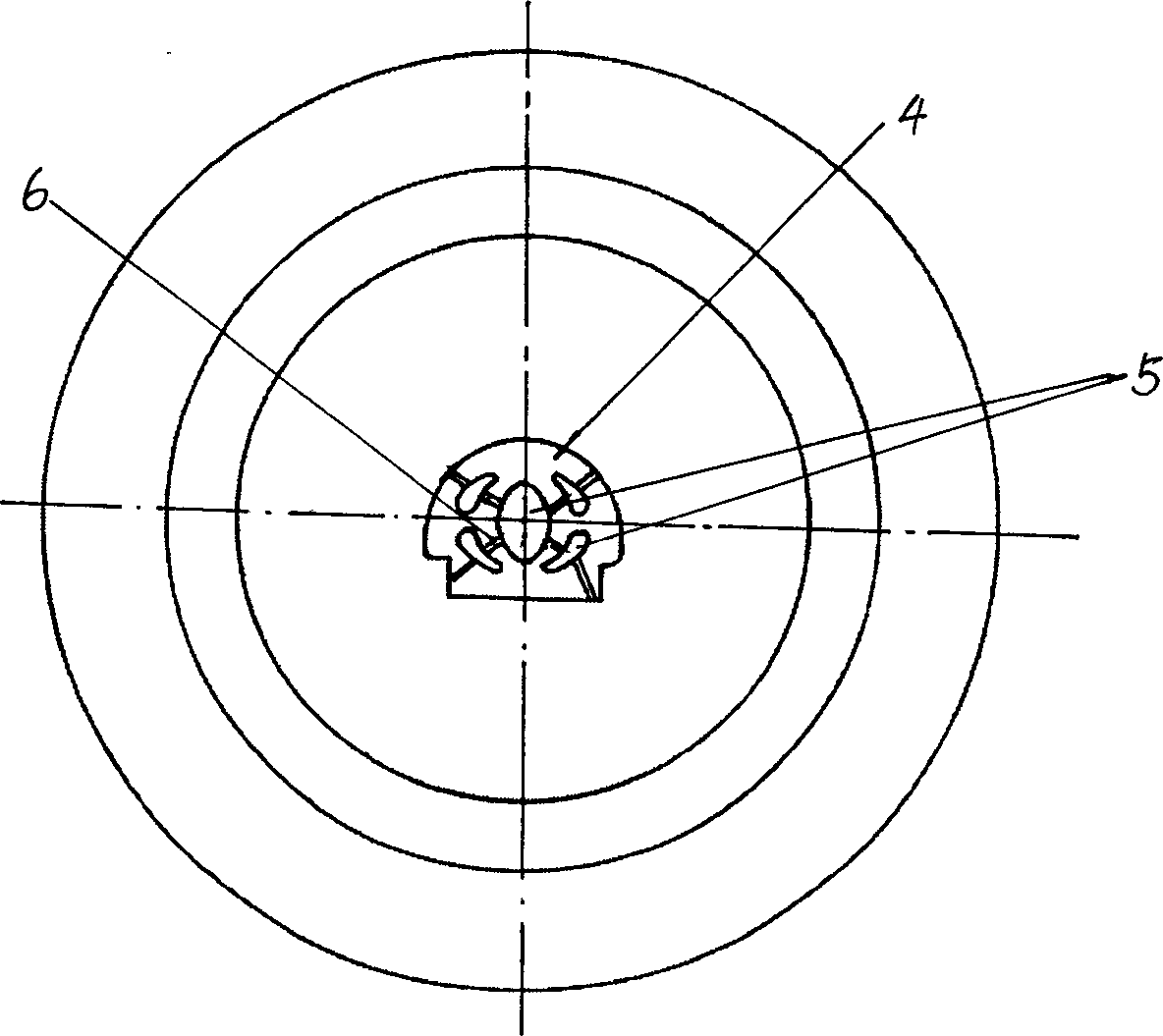

[0020] Such as figure 1 , 2 shown.

[0021] A non-inflatable porous hollow tire extrusion die, which is only composed of two parts: a mold frame 1 and a mold core 2. The mold frame 1 is provided with a feed through hole 3, and the mold core 2 is provided with the rubber to pass through to form the required The discharge hole 4 of the hollow hole, in order to ensure the molding effect, the height of the discharge hole 4 should be greater than or equal to 10 mm, one end of the mold frame 1 is connected with the feeding device of the extruder, and the other end is connected with the mold core 2; The side where the core 2 is connected to the mold frame 1 is provided with a boss 201 (the boss 201 can also be omitted during specific implementation, that is, the side where the mold core 2 is connected to the mold frame 1 is a plane), and the boss 201 is inserted into the mold In the feeding through hole 3 provided inside the frame 1, one end of the feeding through hole 3 communicat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com