Hydraulic buffer of complex vibration with mechanism in six degree of freedom based on parallel connection

A technology of hydraulic buffer and compound vibration, applied in the field of hydraulic buffer system, can solve the problems such as inability to track the continuous motion of the controlled object, inability to meet the requirements, and achieve the effect of good test effect, good mechanism rigidity and good buffer performance index.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

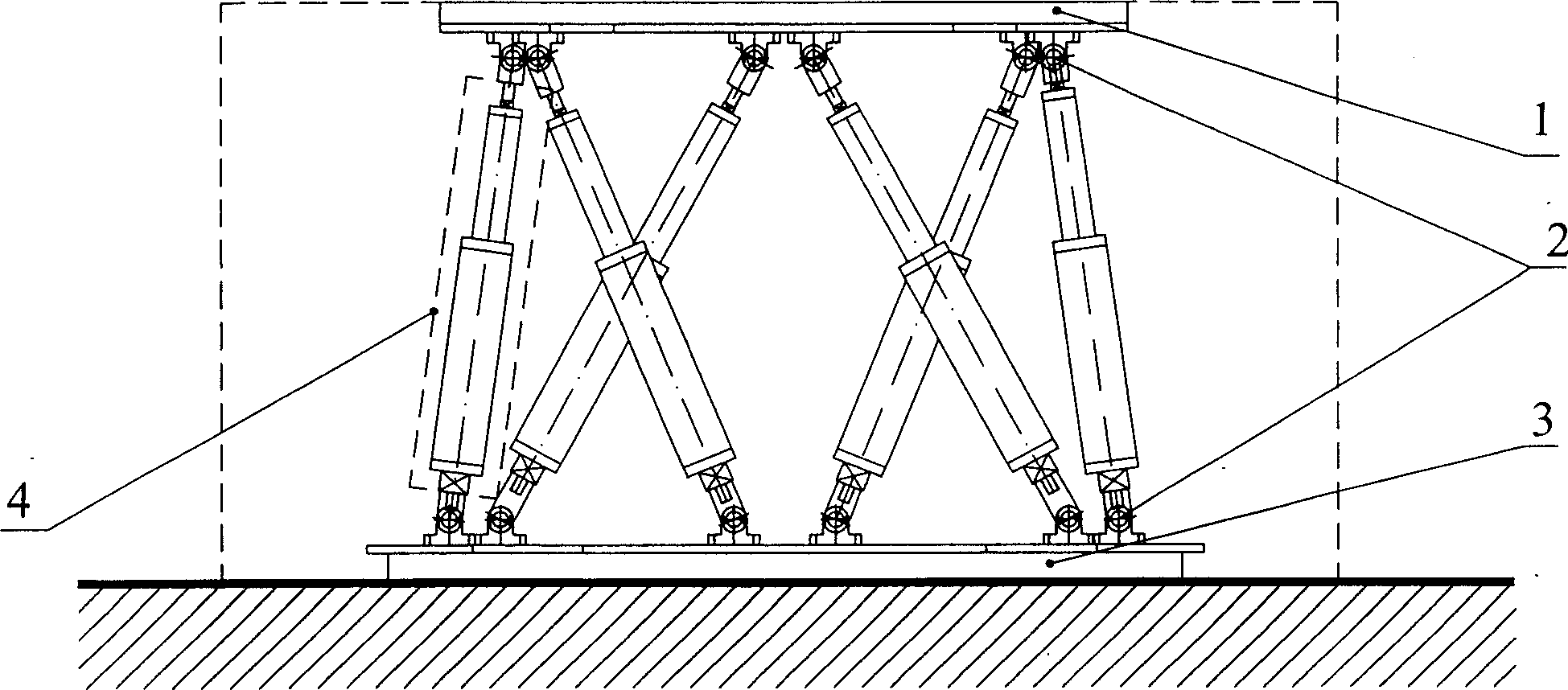

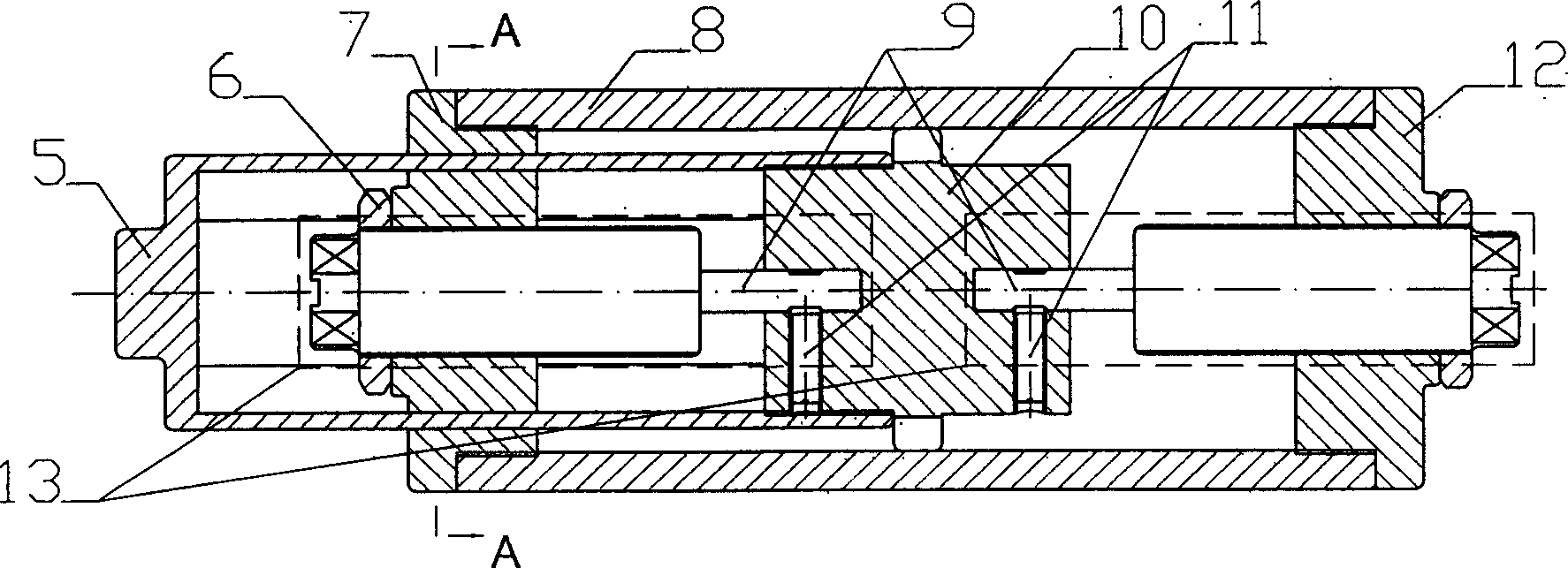

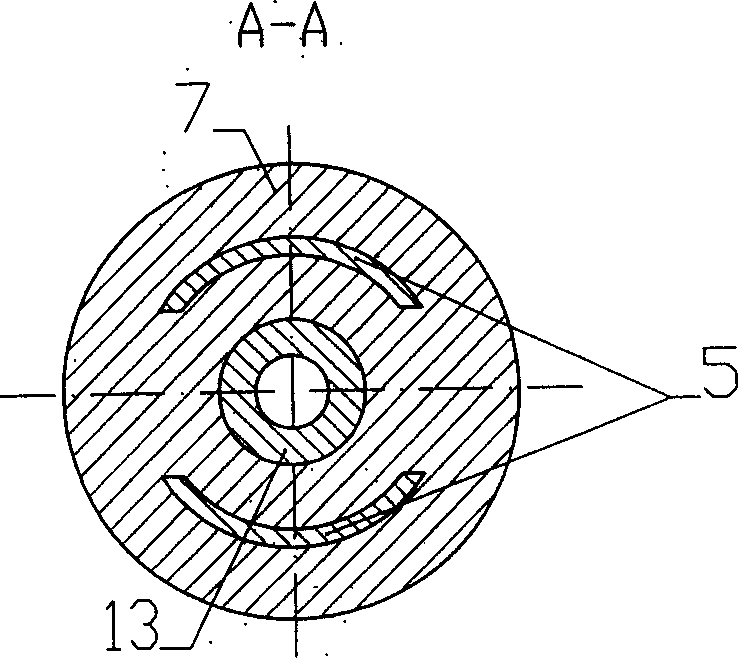

[0015] Buffer movable platform 1, twelve connecting hinges 2, buffer fixed platform 3 and six double-acting single-degree-of-freedom hydraulic buffers 4. The bottom of the buffer movable platform 1 and the top of the buffer fixed platform 3 are respectively equipped with six connecting hinges 2, and the six connecting hinges on the buffer movable platform 1 are respectively connected with the activities of the six double-acting single-degree-of-freedom hydraulic buffers 4. Cylinder connection, the other six connection hinges 2 on the buffer fixed platform 3 are respectively connected with the fixed end caps 12 of the six double-acting single-degree-of-freedom hydraulic buffers 4, and the connection hinges 2 are connected between the buffer movable platform 1 and the buffer fixed platform The arrangement shape on 3 is a semi-symmetrical hexagon.

[0016...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com