Device for detecting delivered paper position in paper folding machine

A folding machine, sheet technology, applied in the direction of sending objects, folding thin materials, container manufacturing machinery, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

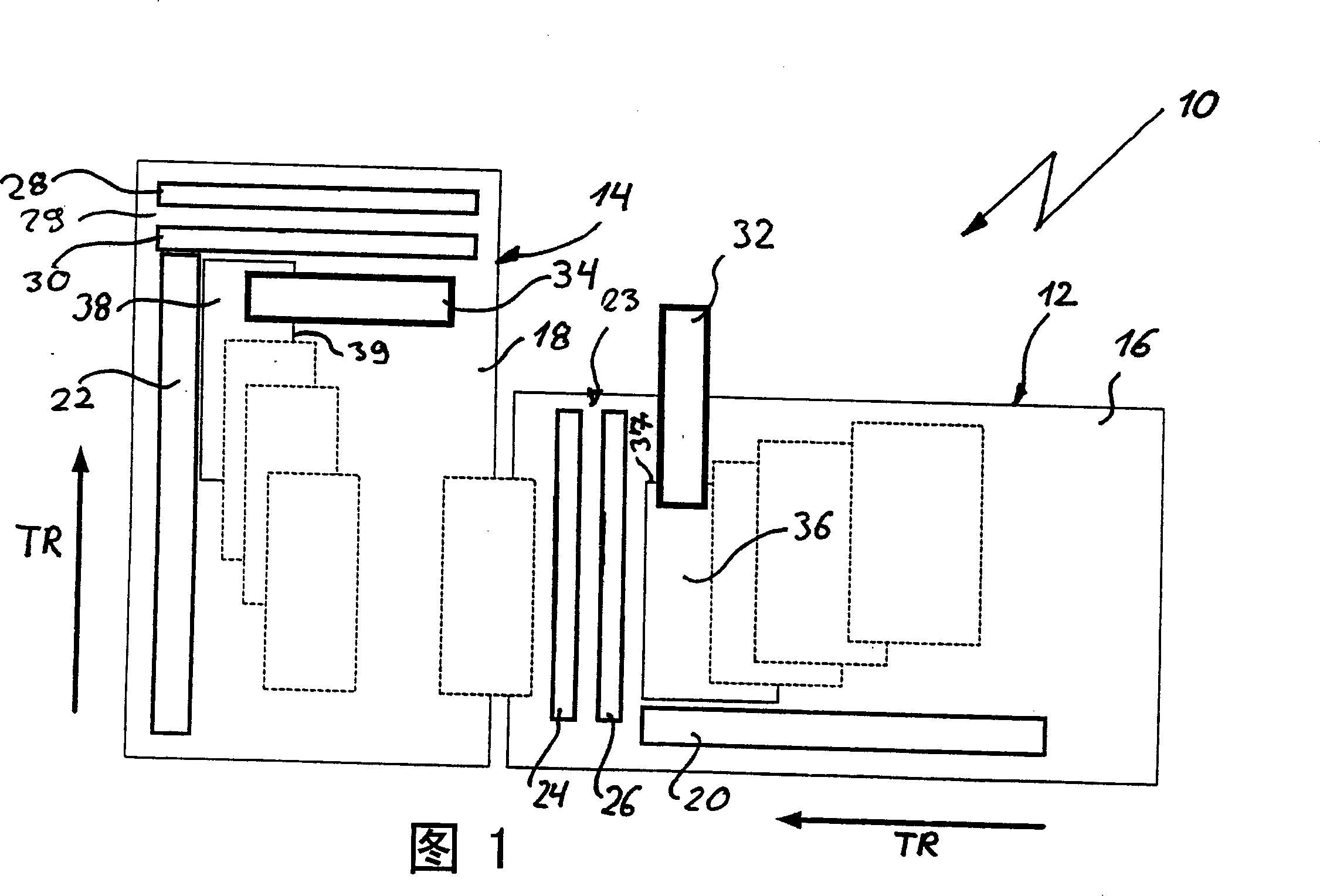

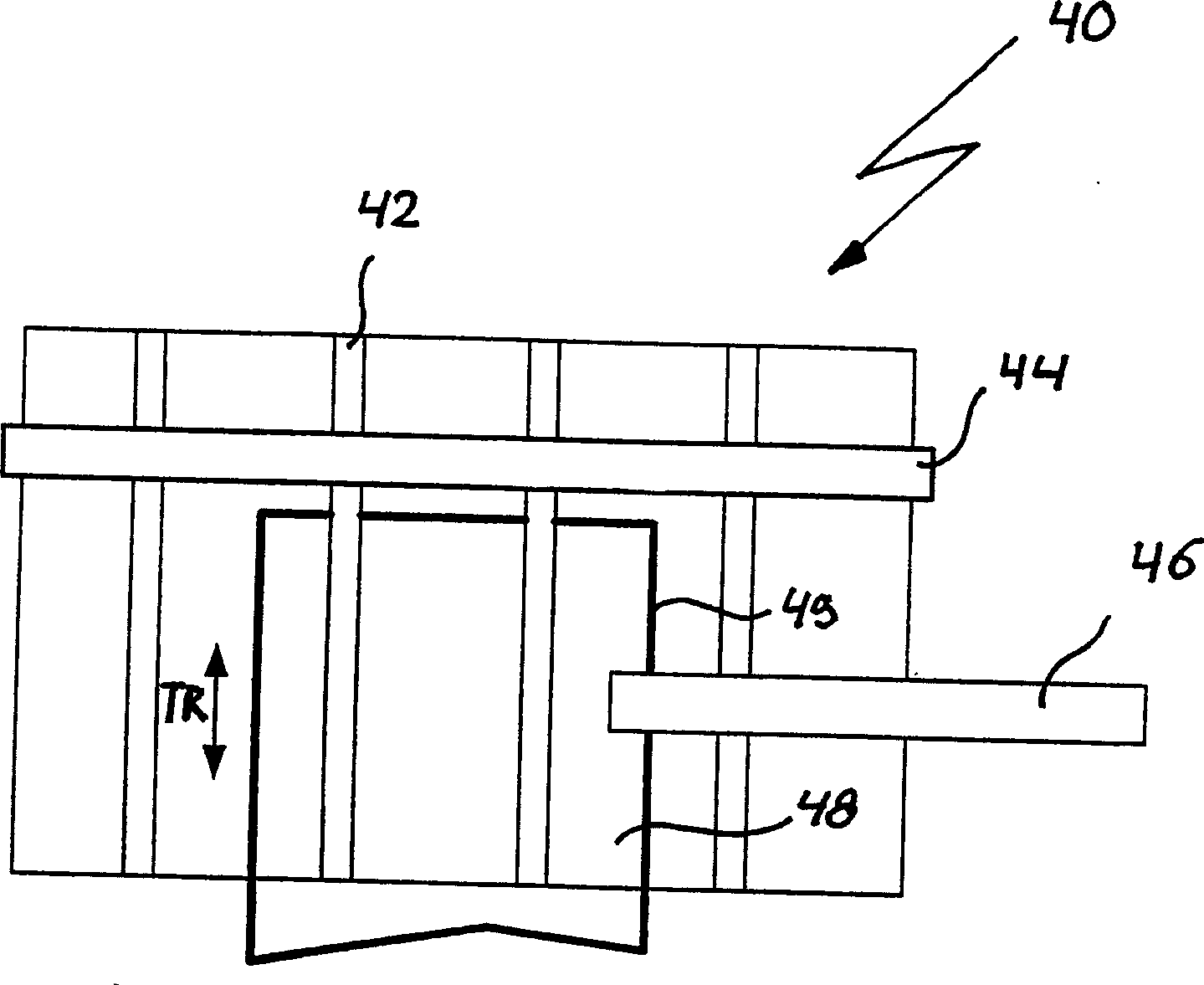

[0024] The folding machine shown in Fig. 1 comprises a first folding device 23 with two folding rollers 24,26 and a second folding roller 28,30 connected behind the first folding device 23 Two folding device 29. Arranged upstream of the first folding unit 23 is a first skewed roller table 16 which, in a known manner, has a positioning side rule 20 which extends in the transport direction TR1 of the sheets 36 . Ideally, the sheet 36 touches the positioning side rail 20 via the first inclined roller table 16 and is then guided in the transport direction TR1 between the folding rollers 24 , 26 and folded by them. After passing the folding rollers 24 , 26 , the folded sheet 39 is conveyed onto the second skewed roller table 18 , whose conveying direction TR2 runs perpendicular to the conveying direction TR1 of the first skewed roller table 16 . The sheet 39 will come into contact with the positioning side rails 22 via this skewed roller table and is then guided between the foldin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com