Capped flat end windings in an electrical machine

A technology of end windings and field windings, which is applied in the direction of windings, electric components, manufacturing motor generators, etc., and can solve problems such as the obstruction of cooling medium path discharge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

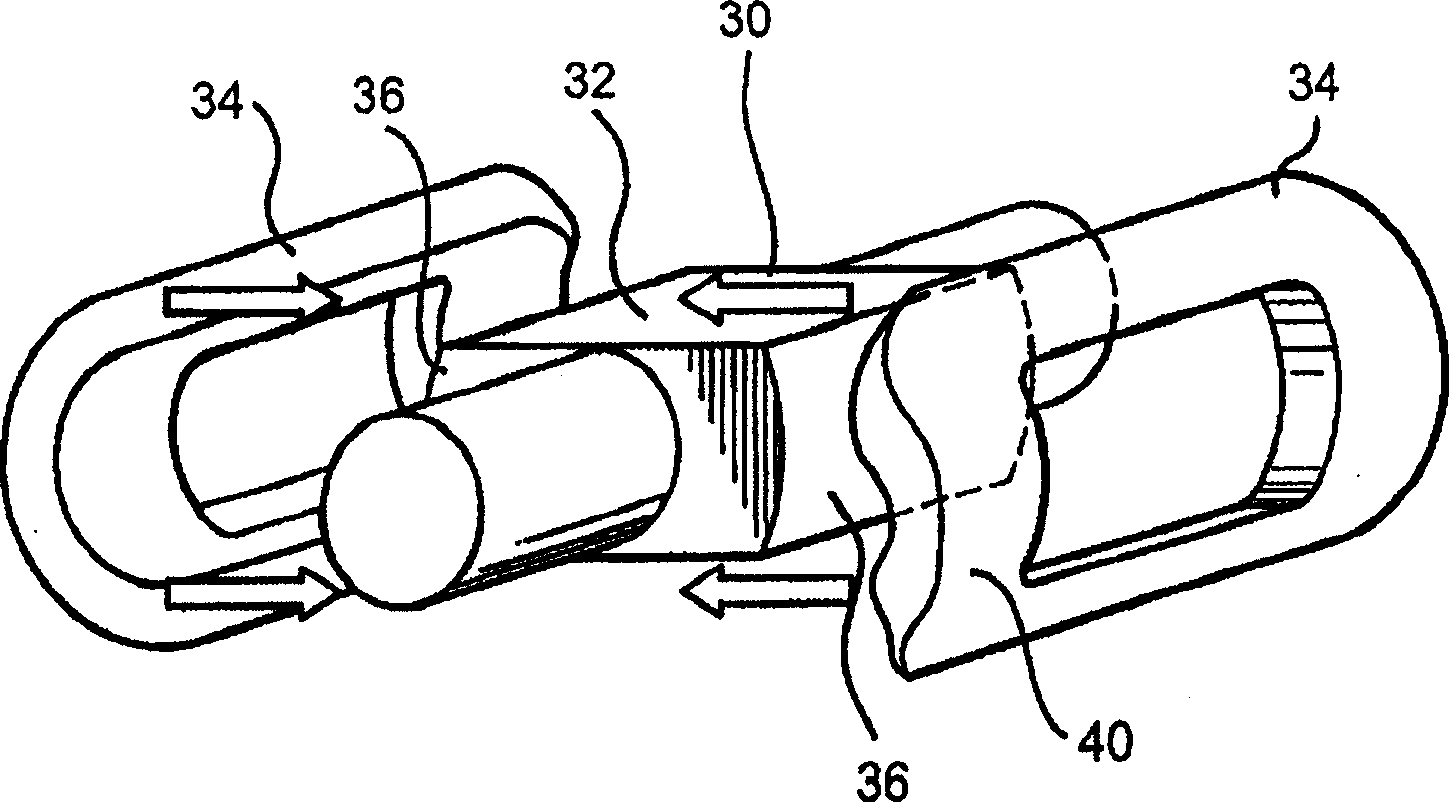

[0014] As depicted in FIG. 1 , generator 30 includes a multi-pole core 32 (a two-pole core is shown) and a plurality of winding assemblies 34 , one for each pole, and corresponding pole surfaces 36 . The construction and materials of the magnetic core 32 and winding assembly 34 are known. The prefabricated winding assembly 34 is disposed over the parallel side forgings forming the rotor body and is bent in an arc generally concentric with the rotor body. Although not shown, it will also be appreciated that the rotor is disposed within the stator, not shown, with an air gap between the inner surface of the stator and the outer surface of the rotor. The generator rotor shown in Figure 1 has end windings 40 extending arcuately over the mandrel at opposite ends of the rotor within the final assembly of the rotor body. The previously described rotor body is a carbon fiber rotor housing (CFRE), which offers several advantages over existing conventional generators which typically ha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com