Multilayer link plate type highly viscous fluid filtering machine

A filter and fluid technology, which is applied in the fields of filtration and separation, separation methods, chemical instruments and methods, etc., can solve the problems of high price and achieve the effect of cost saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

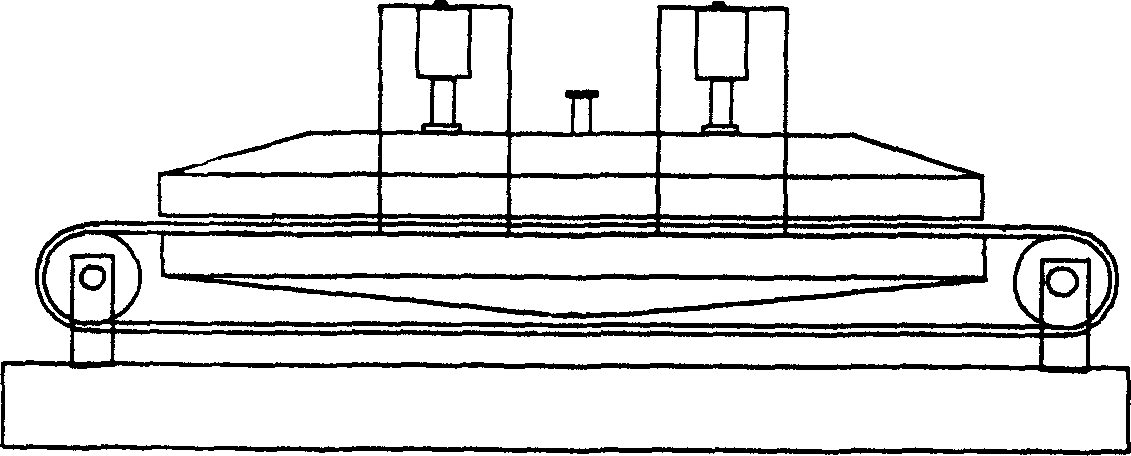

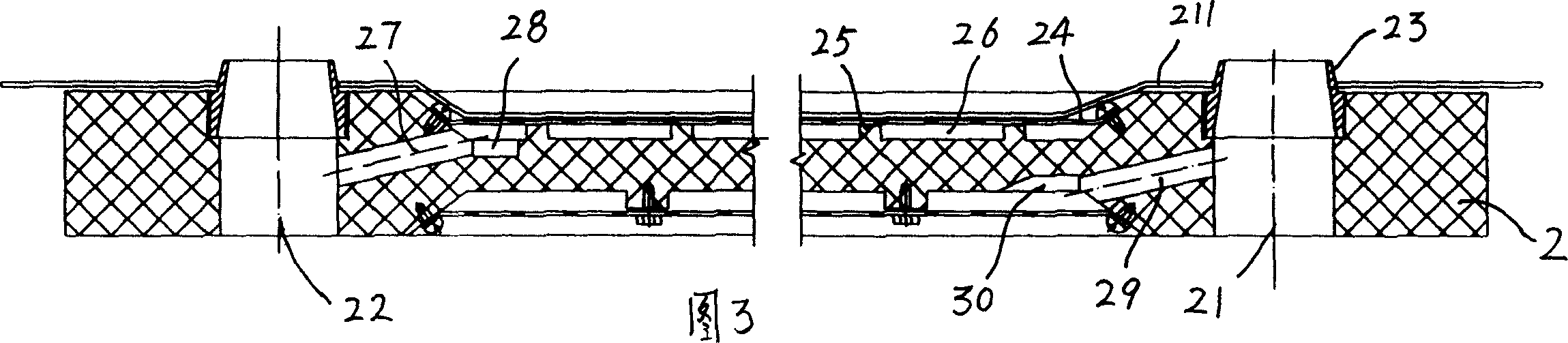

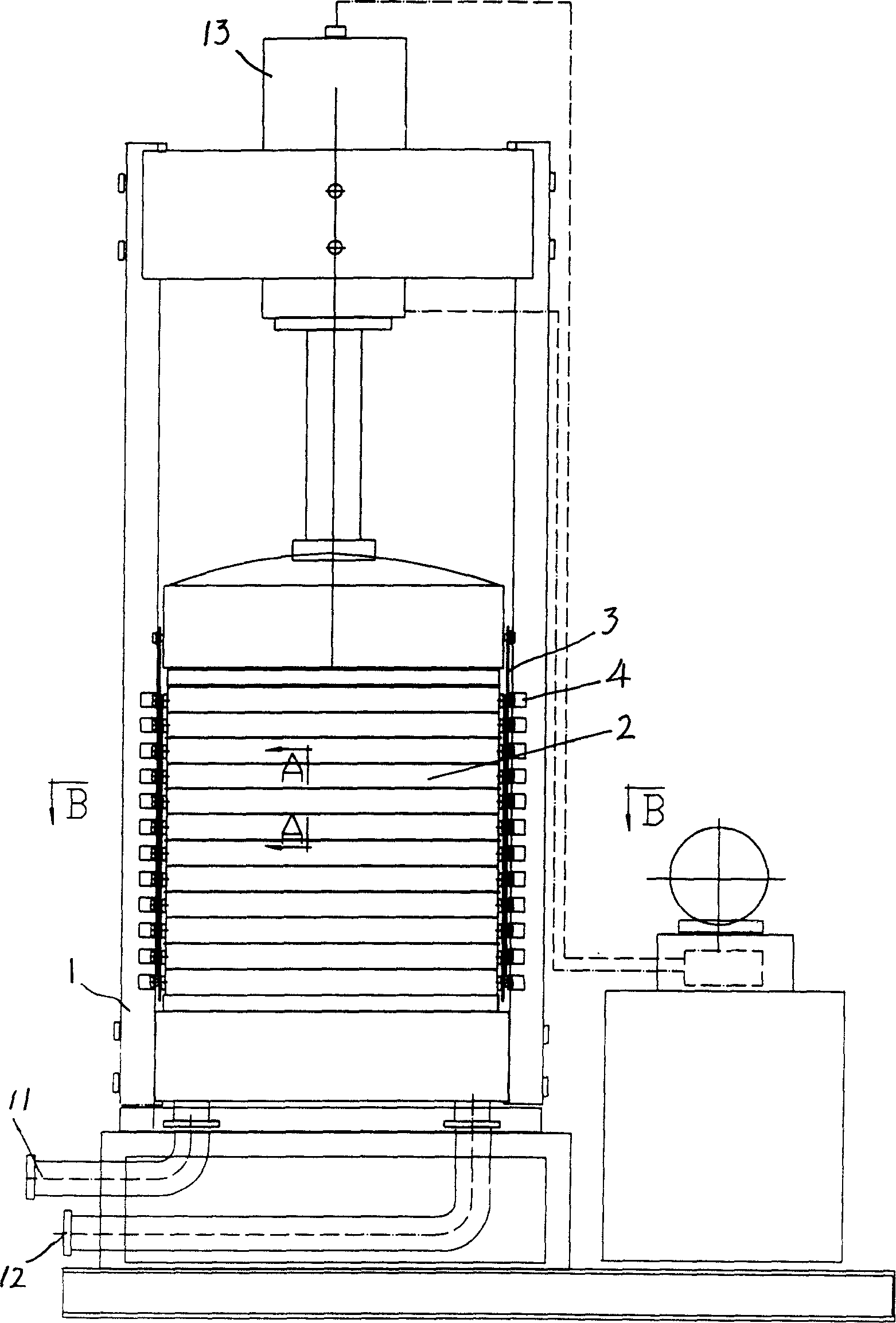

[0019] As shown in the figure, this embodiment includes a bracket 1, the bracket is provided with a liquid inlet 11 and a liquid outlet 12, several layers of filter plates 2 stacked on each other are arranged in the bracket 1, and a pressure cylinder 13 is arranged above the bracket 1 , the filter plate 2 is provided with a liquid inlet channel 21 and a liquid outlet channel 22, there are two liquid inlet channels 21 and two liquid outlet channels 22 on the filter plate 2, and the liquid inlet channel 21 is arranged on the filter plate 2 to form a diagonal line On the two corners of the distribution, the liquid outlet channel 22 is arranged on the other two opposite corners on the filter plate 2, and a guide tapered pipe 23 is provided above the liquid inlet channel 21 and the liquid outlet channel 22, and each filter plate 2 The liquid inlet channels 21 are superimposed on each other and connected to the liquid inlet 11 on the support 1, the liquid outlet channels 22 on each f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com