Design method for push rod of hydraulic support

A design method and technology of hydraulic support, applied in pillars/supports, mining equipment, earthwork drilling and mining, etc., can solve the problems of unsuitable support, hydraulic support design, manufacture, and assembly inconvenience, so as to improve design work efficiency and facilitate maintenance , reduce the effect of the design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

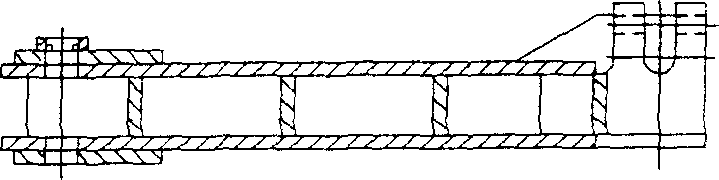

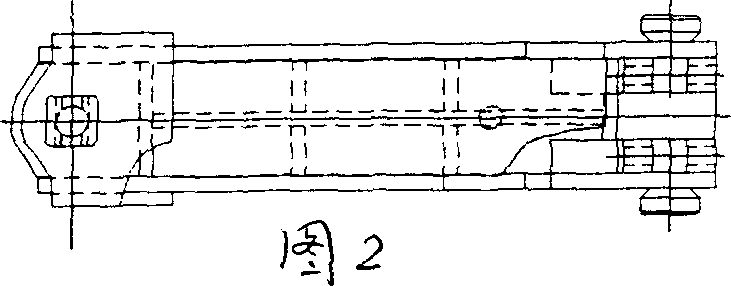

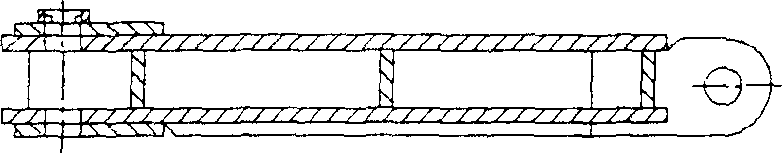

[0019] As shown in the figure, the design method of the hydraulic support push rod of the present invention is to fix the cross-sectional area size of the push rod which is difficult to design through strength calculation, and divide the easy-to-achieve length changes into series, specifically The design steps are as follows:

[0020] The first step is to divide the putter into three structural forms: short putter, integral long putter, and split long putter;

[0021] The second step is to fix the cross-sectional area size of the push rod under the condition of meeting the strength requirements for the short push rod and the overall long push rod according to the bore diameters of the push jacks connected to them; the length is within the specified size range A series is formed within a certain interval; the change in the length of the components corresponding to each length in the series is listed in the component chart one by one in the form of a list; the change size of eac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com