Transformer

A technology of transformers and iron cores, which is applied in the direction of transformers, fixed transformers, transformer/inductor cores, etc., and can solve the problems of the difference in length between the inner and outer magnetic circuits of iron core materials, high magnetic flux density, and reduced magnetic flux density.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Hereinafter, preferred embodiments of the present invention will be described with reference to the drawings.

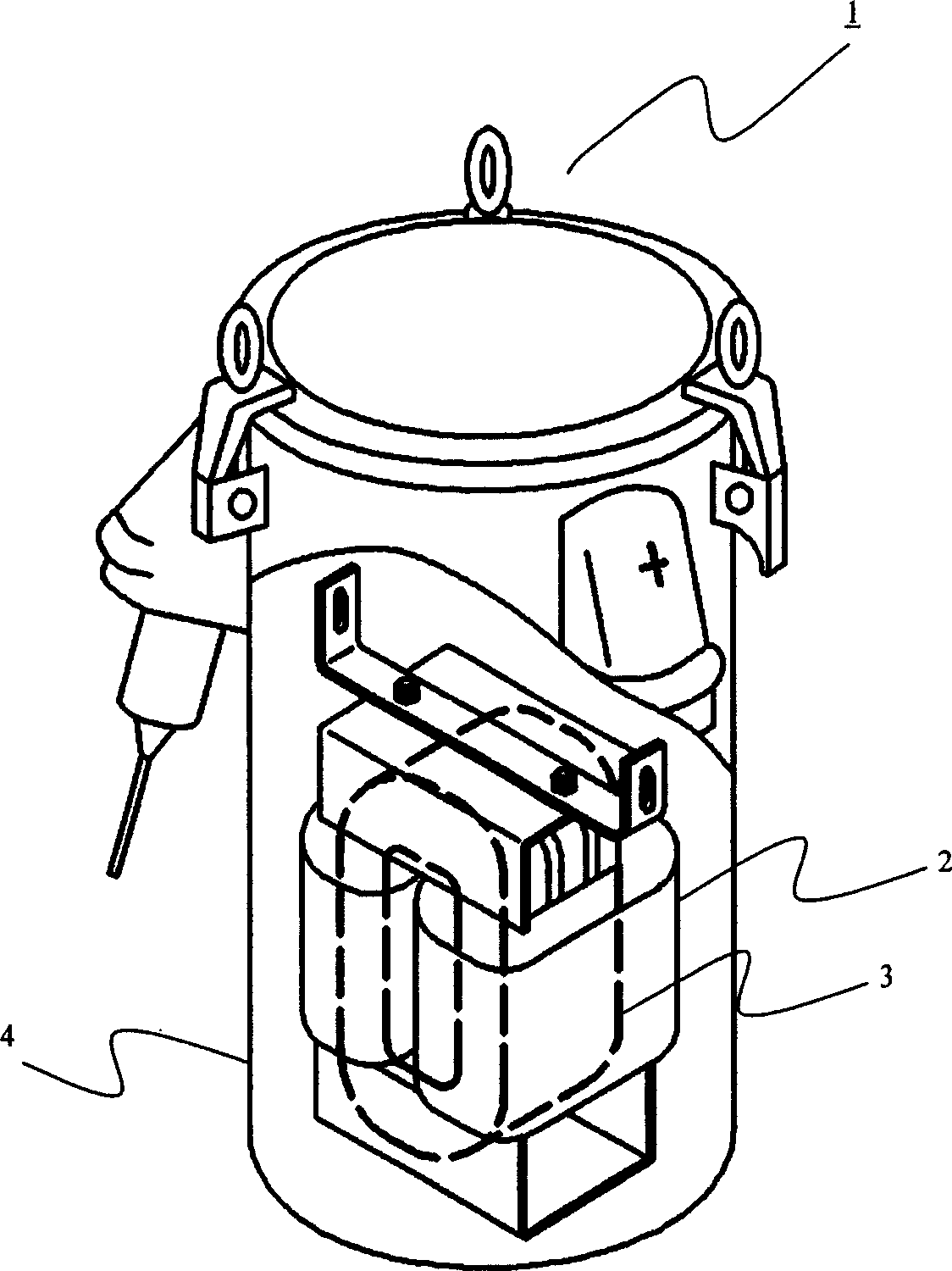

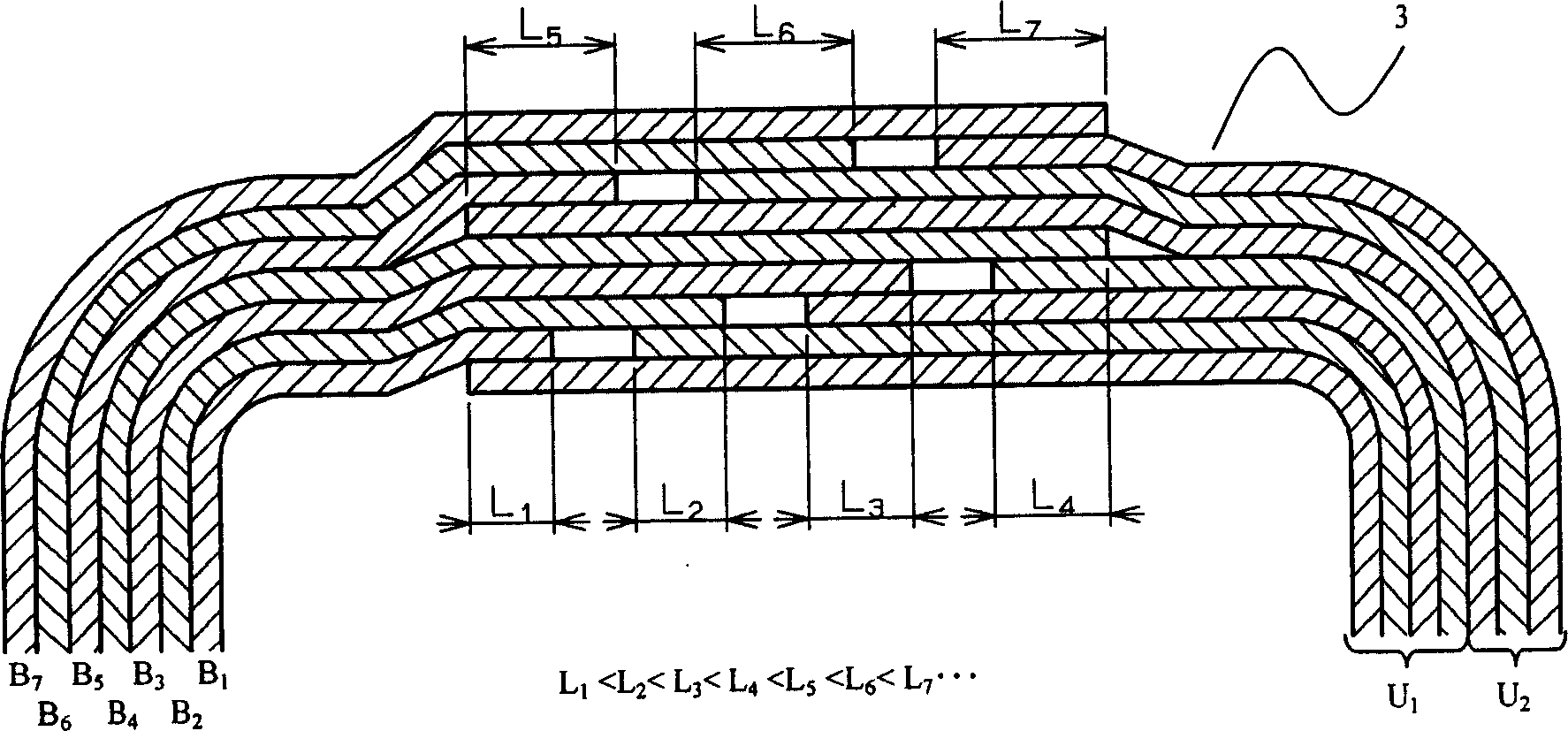

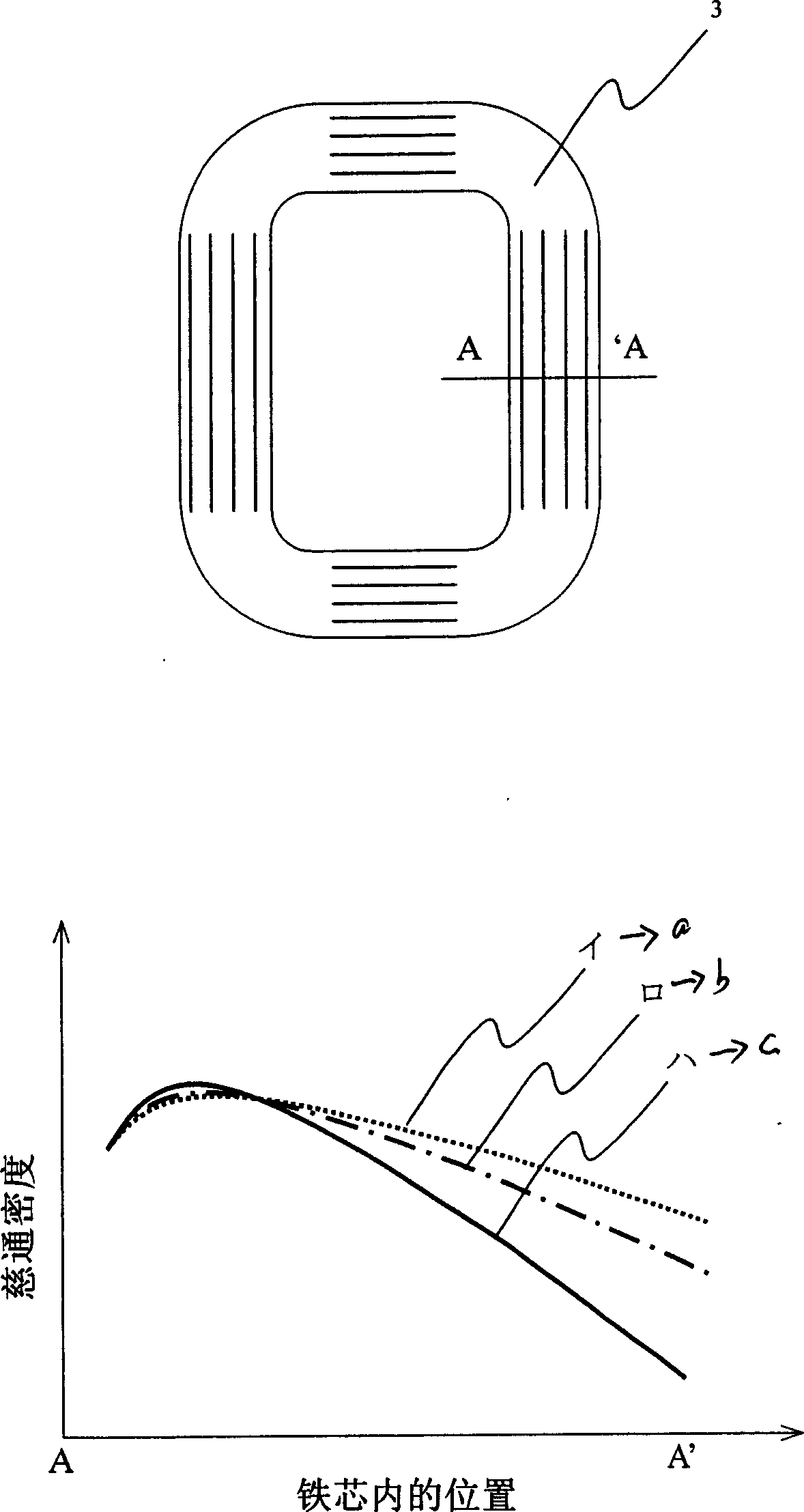

[0023] Figure 1~3 It is an explanatory diagram of the first embodiment of the present invention. figure 1 It is a diagram of a structural example of a transformer as a first embodiment of the present invention. figure 2 for figure 1 Structural diagram of the junction cross-section of the iron core used in the transformer. image 3 It is an explanatory diagram of the magnetic flux distribution in the iron core.

[0024] exist figure 1 Among them, 1 is a transformer, 2 is an excitation coil forming an electric circuit, 3 is a wound core forming a magnetic circuit, and 4 is a container for mechanically protecting the transformer. Iron core 3 is, for example, 0.02×10m -3 ~0.60×10 -3 The plate-shaped magnetic materials of about m are stacked in multiple layers, and are stacked into a ring shape. The two ends of the laminated plate-shaped magnetic material...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com