Radio remote-control movable fully-automatic filling machine

A wireless remote control and mobile technology, applied in packaging, bottle filling, liquid bottling, etc., can solve the problems of poor measurement accuracy and high labor intensity, and achieve the effects of high measurement accuracy, light and flexible movement, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

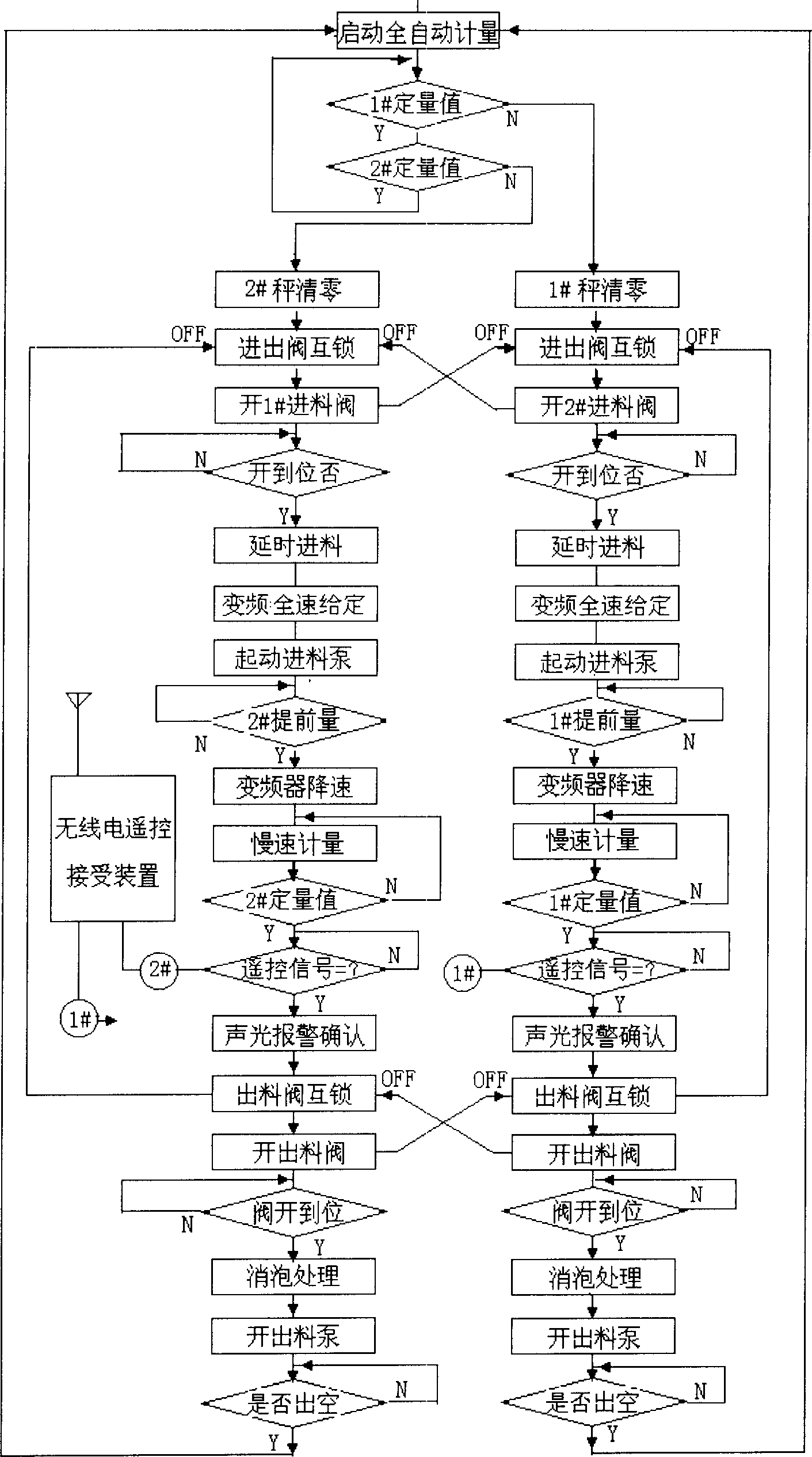

[0017] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

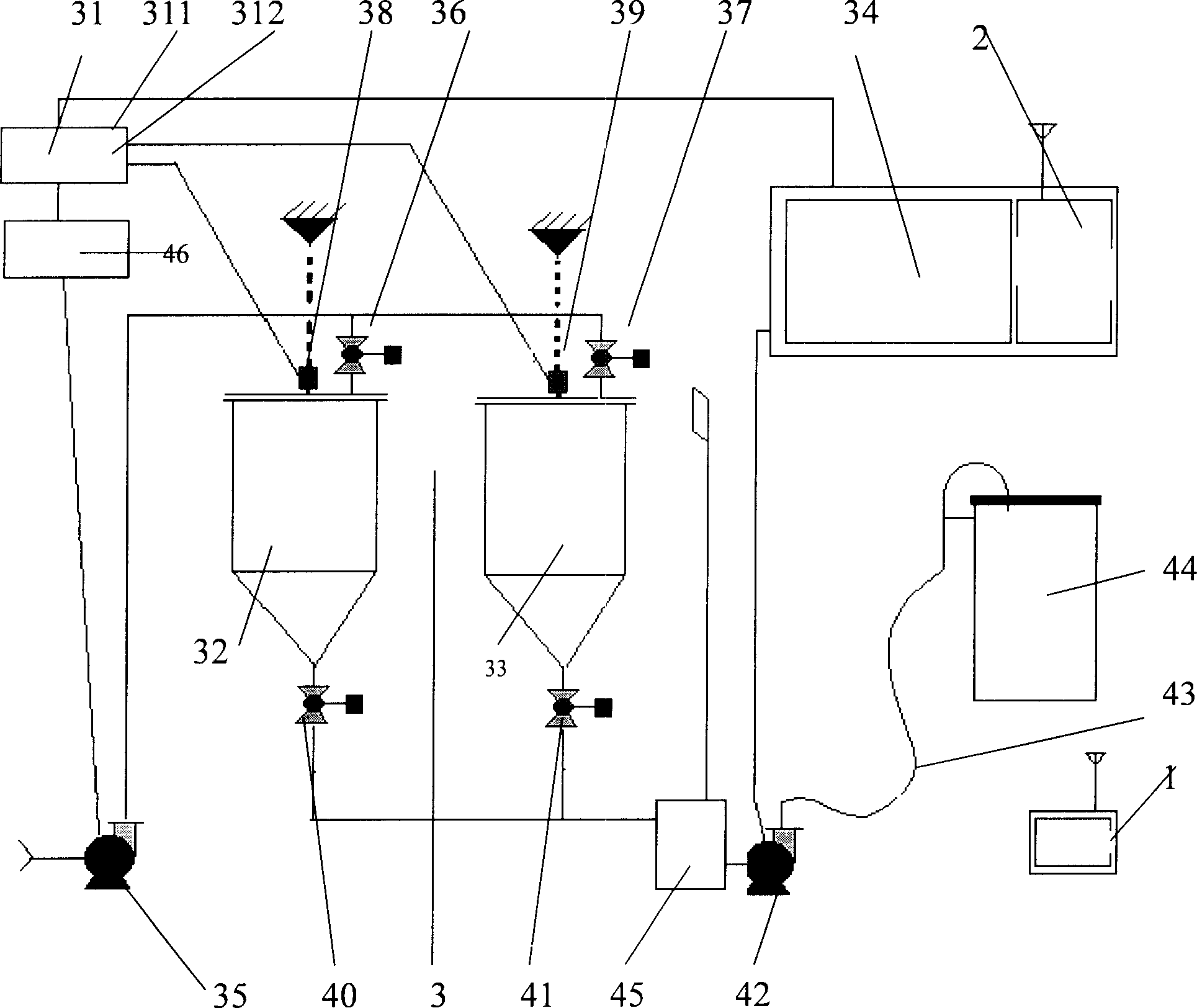

[0018] Depend on figure 1 It can be seen that the wireless remote control mobile automatic filling machine of the present invention includes an automatic metering device 3, a wireless remote control receiving device 2, and a wireless remote control sending device 1; the wireless remote control sending device 1 sends signals to the wireless remote control receiving device Device 2, controlling the automatic metering device 3 to output the required filling raw materials;

[0019] The automatic metering device 3 includes: a control electronic scale 31 including a first electronic scale 311 and a second electronic scale 312, the raw materials required for filling are input into the first metering barrel 32 or the second metering barrel 33, and The PLC controller 34 output from the first metering barrel 32 or the second metering barrel 33;

[0020]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com