Staple gun with light source

A nailing machine and light source technology, applied in the field of nailing machines, can solve problems such as insufficient light, insufficient use of nailing machines, and inability of users to use nailing machines accurately, so as to achieve reliable and accurate nailing Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

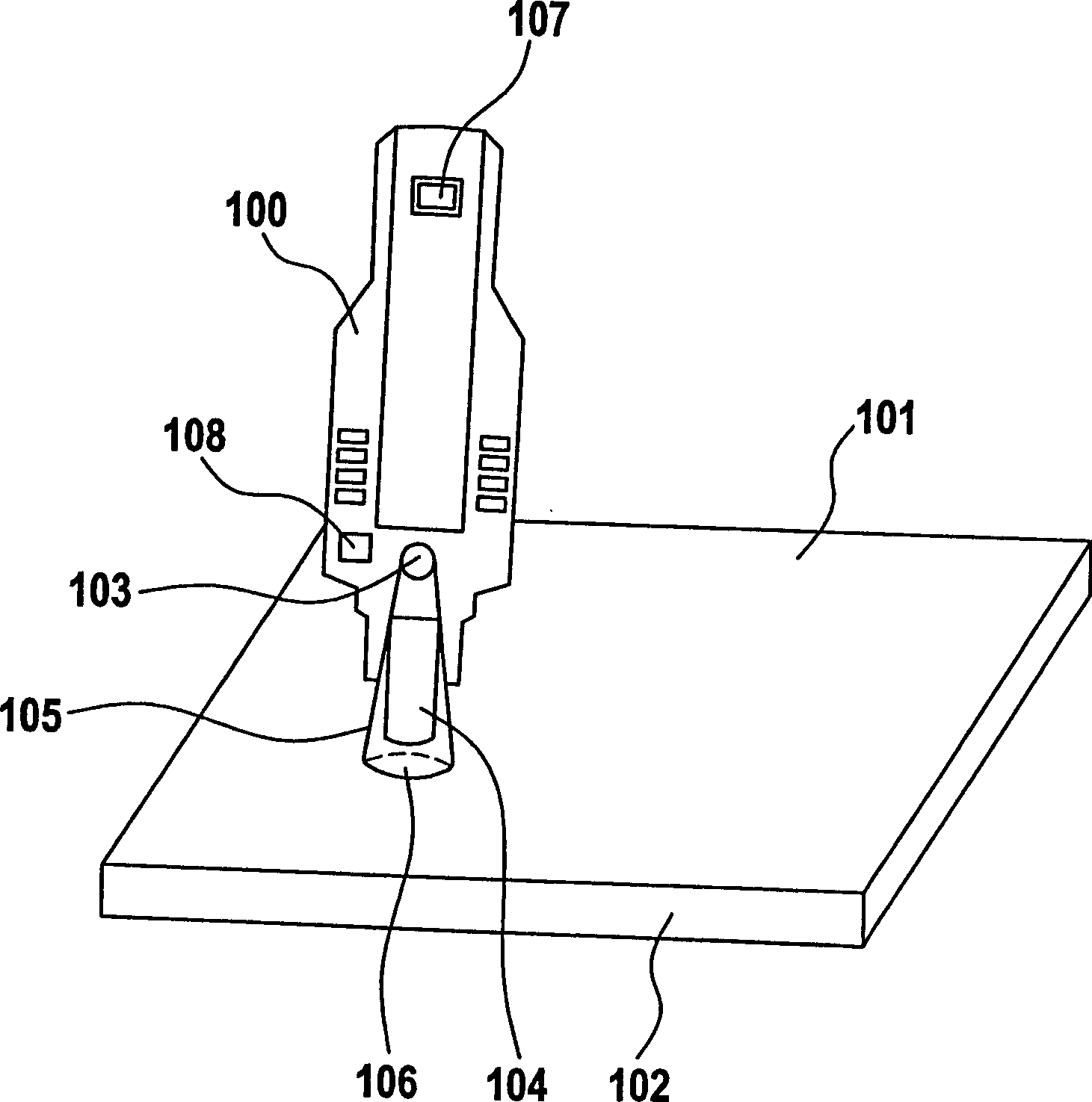

[0014] the only attached figure 1 A nailing machine 100 is shown which is placed on a surface 101 of a material 102 to be stapled. The stapler 100 has a light source 103 designed as a light emitting diode (LED). Underneath the LEDs 103 is a stapler boss 104 of the stapler 100 which is placed on the surface 101 .

[0015] Light-emitting diode 103 is arranged such that it emits a light cone 105 in the direction of surface 101 . In this case, the light cone 105 not only illuminates the nailer boss 104 but also illuminates the region 106 of the surface 101 to be stapled.

[0016] In addition, the nailing machine 100 also has a manual switch 107 and a photoelectric sensor 108 .

[0017] will be described below figure 1 The working mode of nailing machine 100 shown in.

[0018] Let us assume that the user is in a dark attic room nailing up planks. Once the user guides the nailing machine 100 into the dark area where the surface 101 to be nailed is located, the photoelectric se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com