Iron type golf club head

A technology for golf clubs and hitting heads, which is applied to golf balls, golf clubs, rackets, etc., can solve the problems of reduced rebound performance, and achieve the effect of improving the hitting feeling and having both hitting feeling and rebound performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

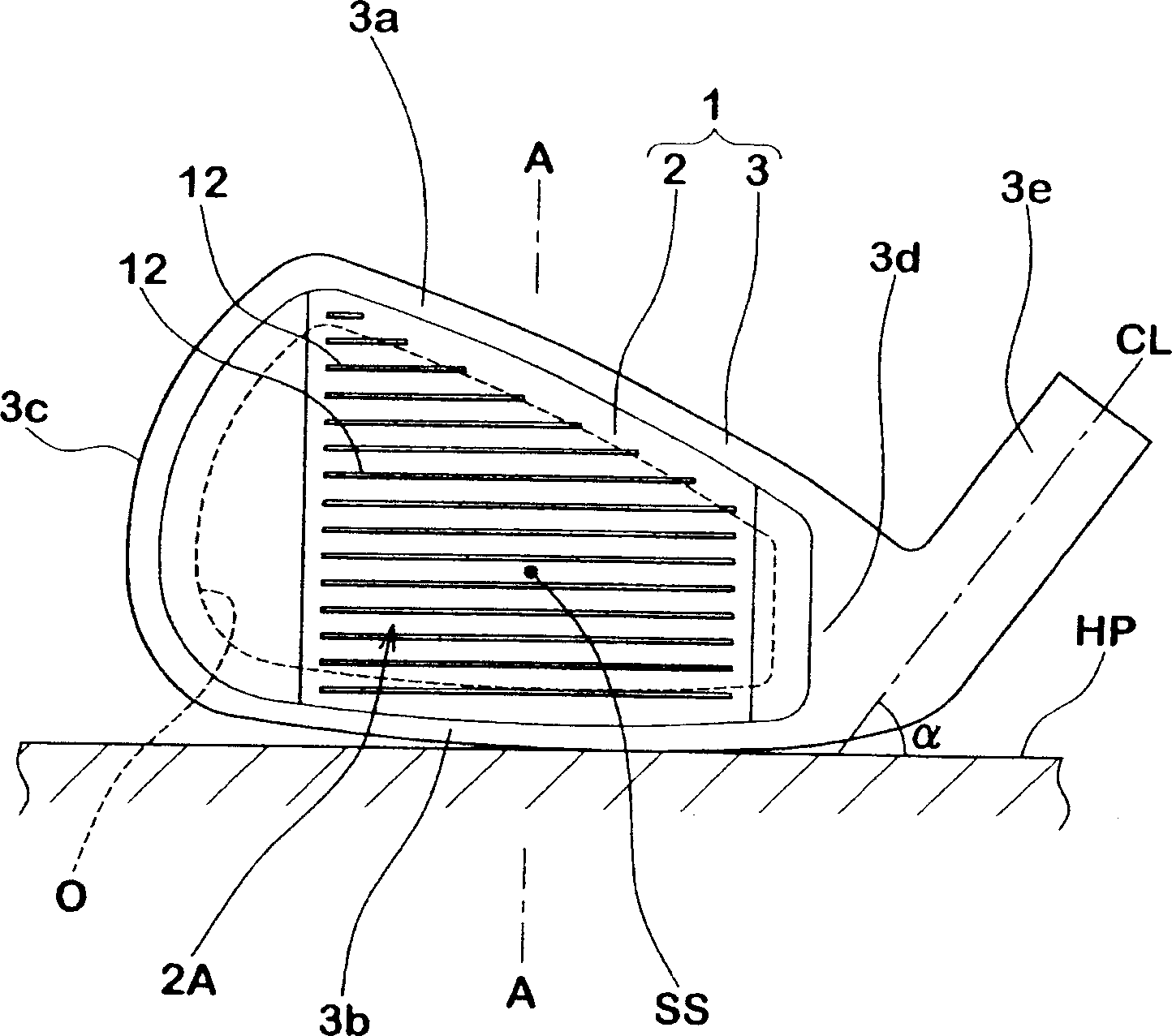

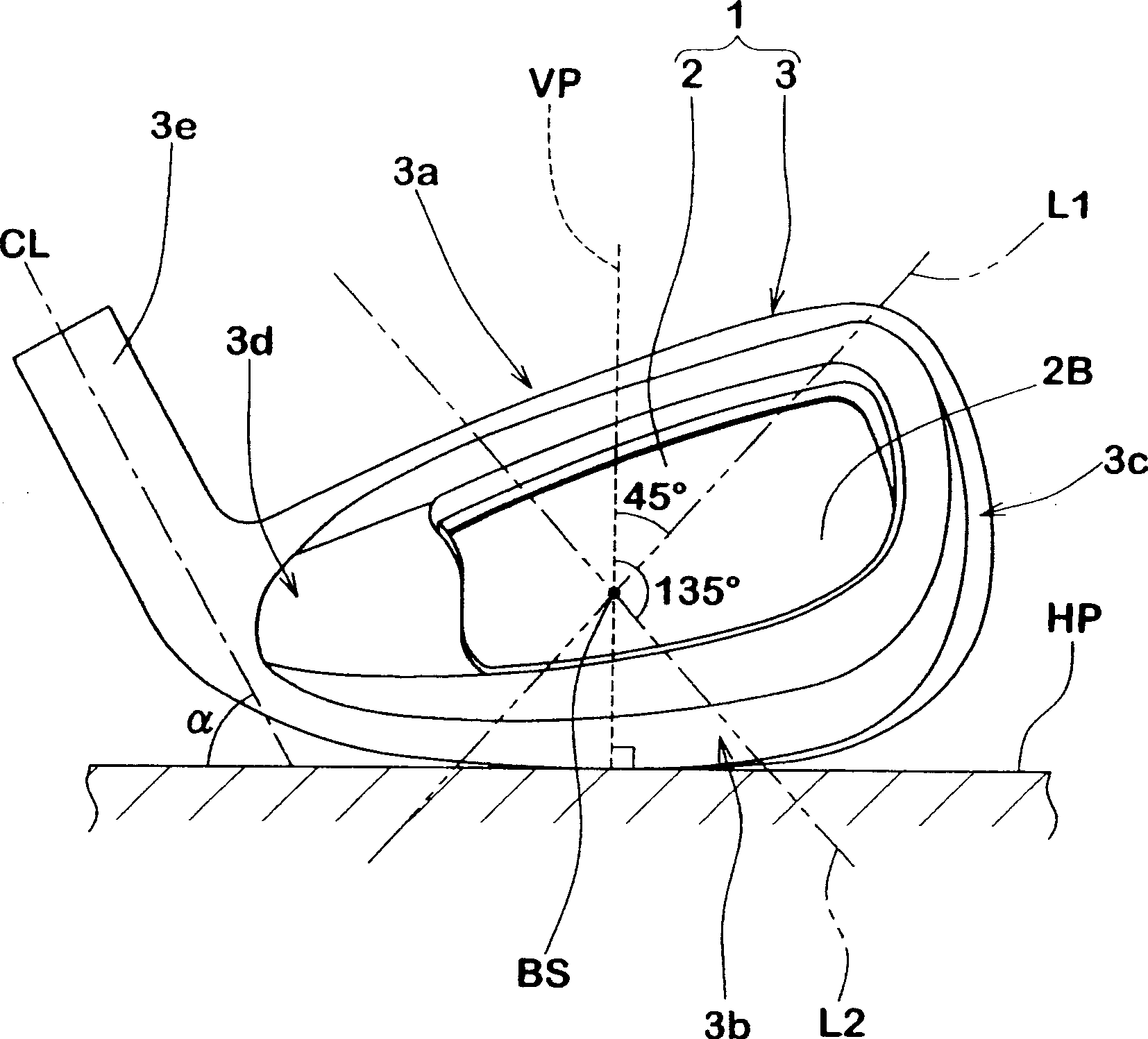

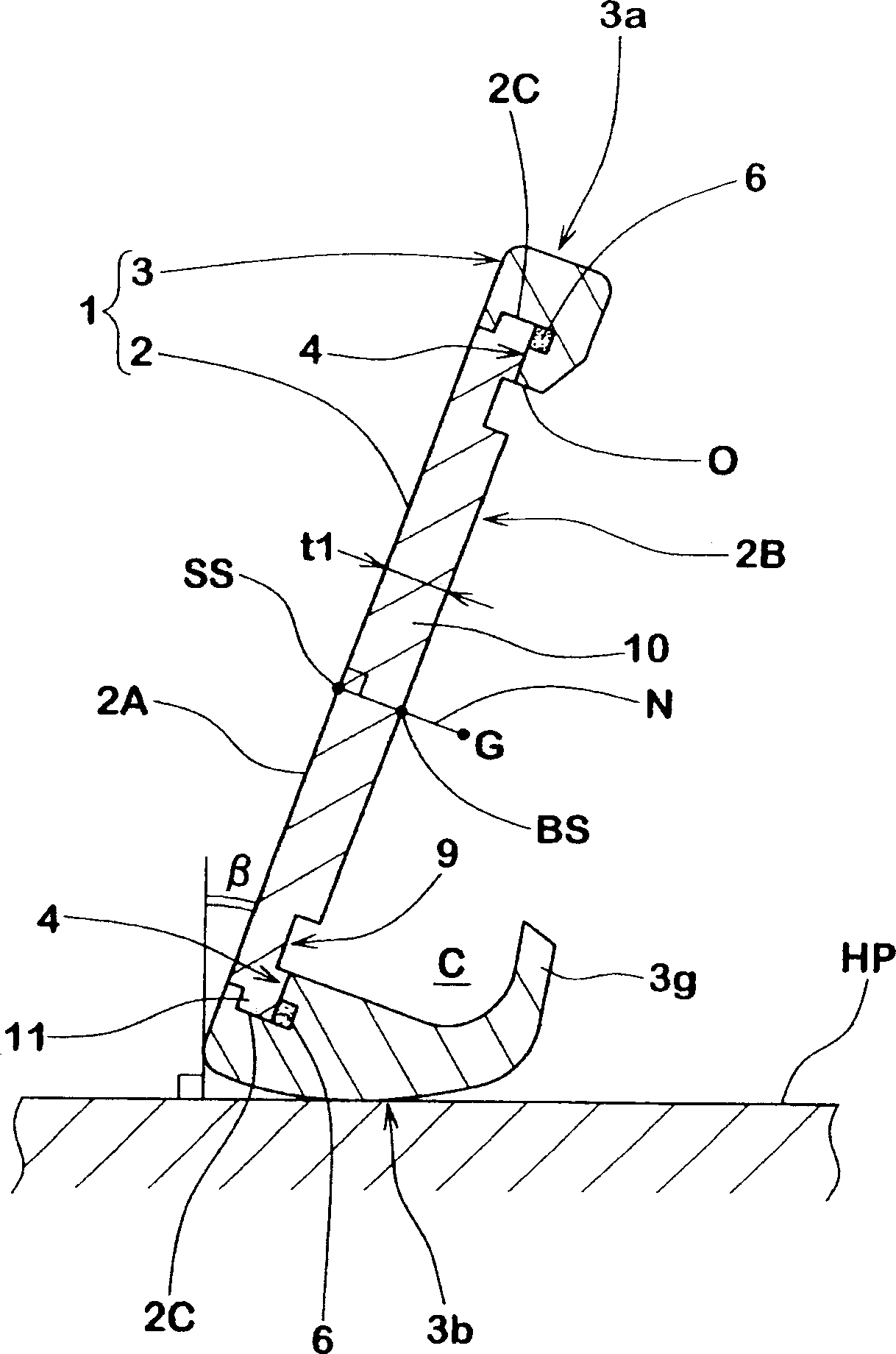

[0061] According to Table 1, an iron type golf club hitting head with a lie angle of 24° was trial-produced. Each head is made of SUS630 head body molded by the lost wax investment casting method and the ball face member made by punching 6Al-4V-Ti plate and then finished by NC. Adhesive is applied simultaneously , by pressing in and as in image 3 shown riveted to form. In addition, the groove provided on the back surface of the face member is formed with a width of 4mm, and is formed by milling with an NC machine. For the impact absorber, an elastomer (polymer mixture) formed by die-casting of a Mitsubishi Chemical Co., Ltd. product name "Wabalong SR04" was used. In addition, each head main body is shown in FIGS. 11 to 16 . while embodiment 9 as Figure 17 As shown, a void is provided on the bottom surface of the recess.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com