Long-effective composite fertilizer with high nitrogen content and production thereof

A compound fertilizer and compound fertilizer technology, applied in fertilizer mixture, fertilization device, application, etc., can solve the problems of fertilizer nutrient loss, increased nitrous oxide pollution, and too late for crops to absorb it

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

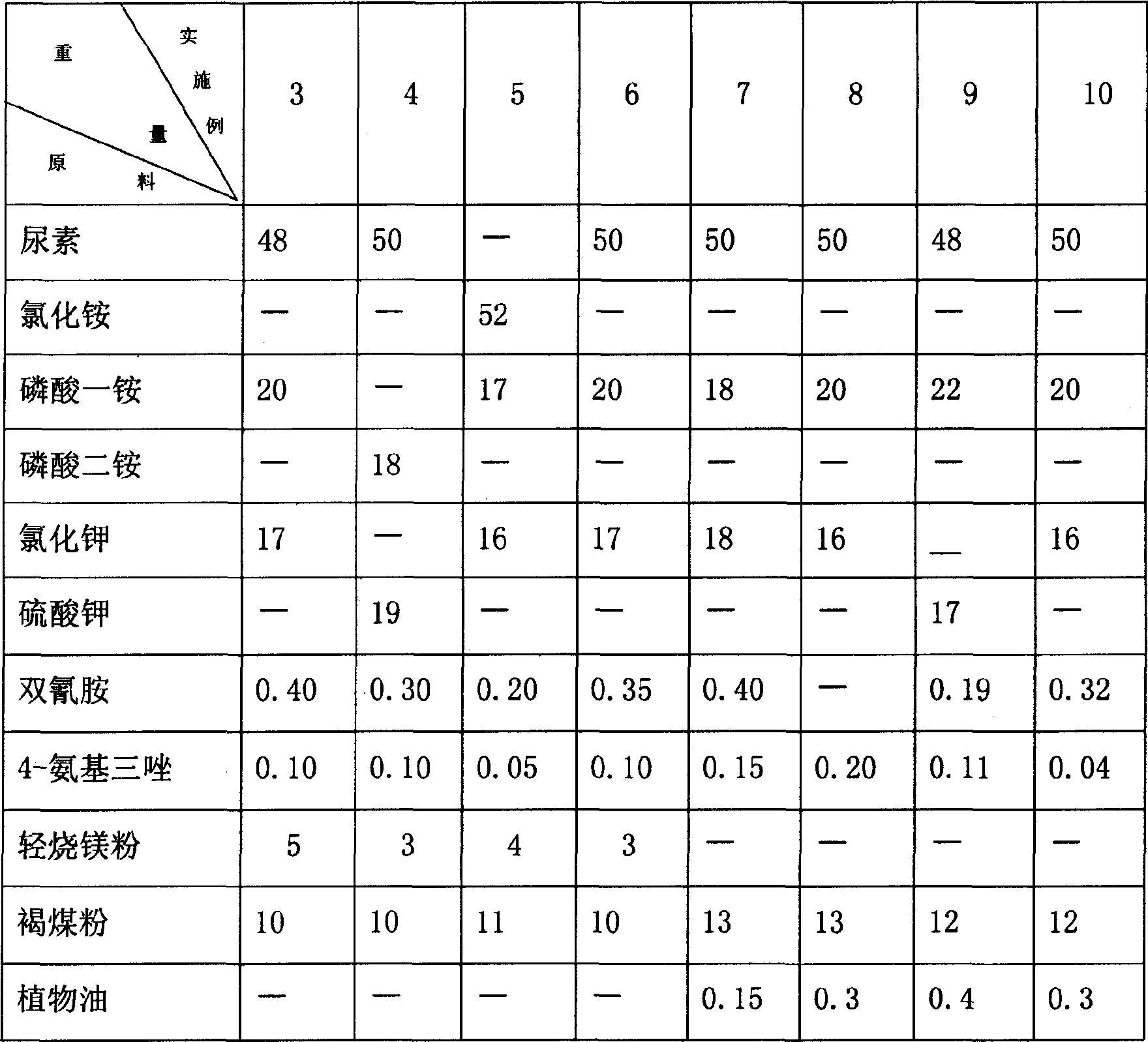

Examples

Example Embodiment

[0033] Example 1:

[0034] Weigh 45kg of urea, 20kg of monoammonium phosphate, 17kg of potassium chloride, 13kg of brown coal powder, 5kg of light burnt magnesium powder, 0.25kg of dicyandiamide, and 0.1kg of 4-aminotriazole by weight. Granulation, drying, sieving, and packaging are carried out in a drum granulator, and the particle size is controlled to 3-5 mm to obtain a long-acting high-nitrogen compound fertilizer with a total nutrient content of 44%.

Example Embodiment

[0035] Example 2:

[0036] Weigh 50 kg of urea with a particle size of 3-5 mm, 20 kg of large particles of monoammonium phosphate, 18 kg of large particles of potassium chloride, 10 kg of large particles of brown coal powder, 0.4 kg of vegetable oil, 0.25 kg of dicyandiamide, and 4-aminotriazole. 0.1kg, firstly mix 0.25kg of dicyandiamide and 0.1kg of 4-aminotriazole to prepare a nitrogen fertilizer long-acting agent for use; coat the urea with vegetable oil evenly and mix it with the nitrogenous fertilizer long-acting agent to obtain the outer surface Evenly adhere to a layer of urea granules of nitrogen fertilizer long-acting agent. Finally, it is conventionally mixed with large-particle phosphate fertilizer, large-particle potash fertilizer and large-particle brown coal powder. After mixing, it is dried, sieved, and packaged according to the conventional process to obtain a long-acting high nitrogen with a total nutrient content of 47%. Compound fertilizer.

[0037] The prepara...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap