Low Nox left-right swing type direct flow coal powder burner with adjustable coal powder gradient field

A pulverized coal burner, left and right swing technology, applied in the direction of burning powder fuel burners, burners, block fuel and powder fuel combustion, etc., can solve the problem that the burner cannot swing left and right, and the jet angle of the burner cannot be adjusted And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

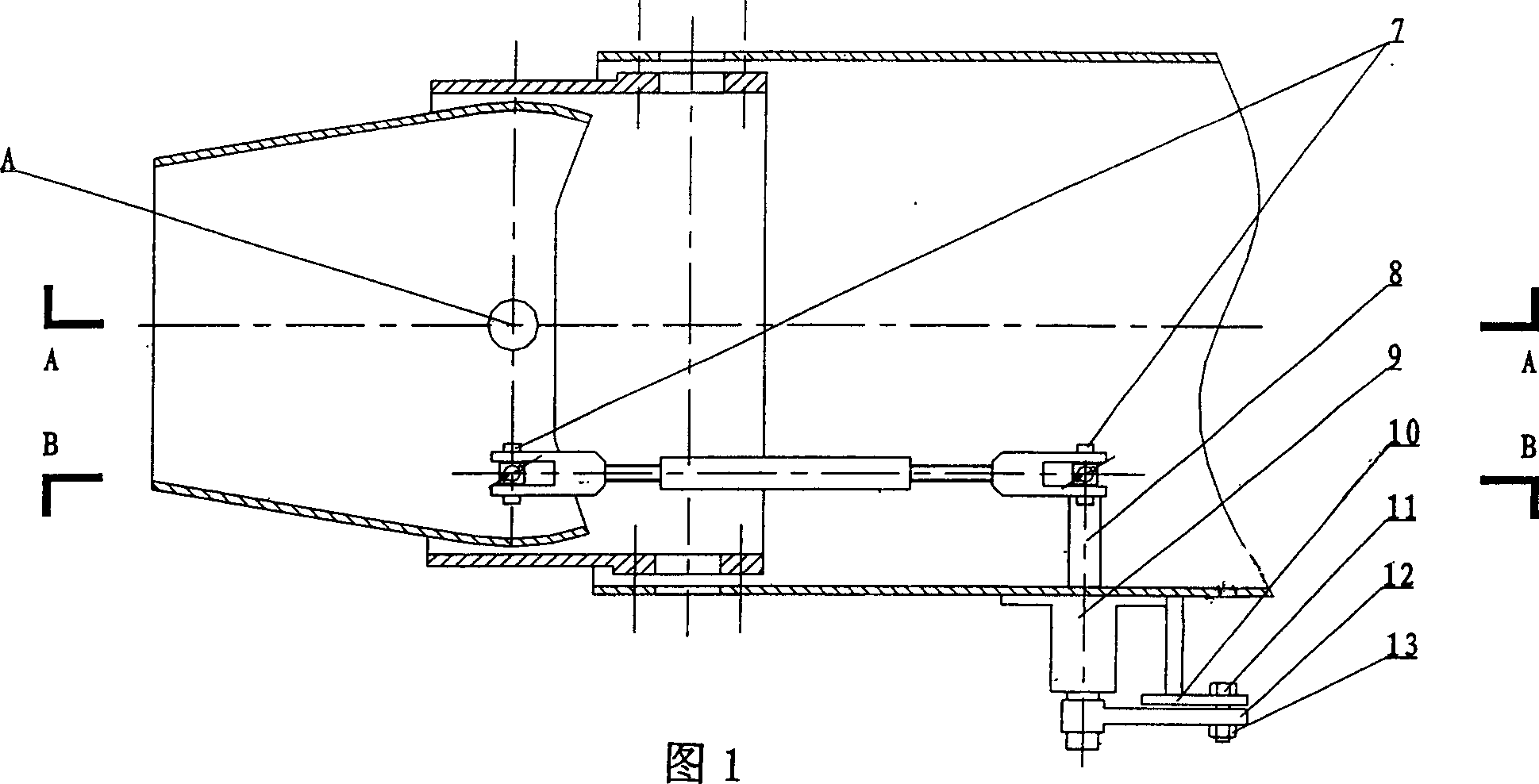

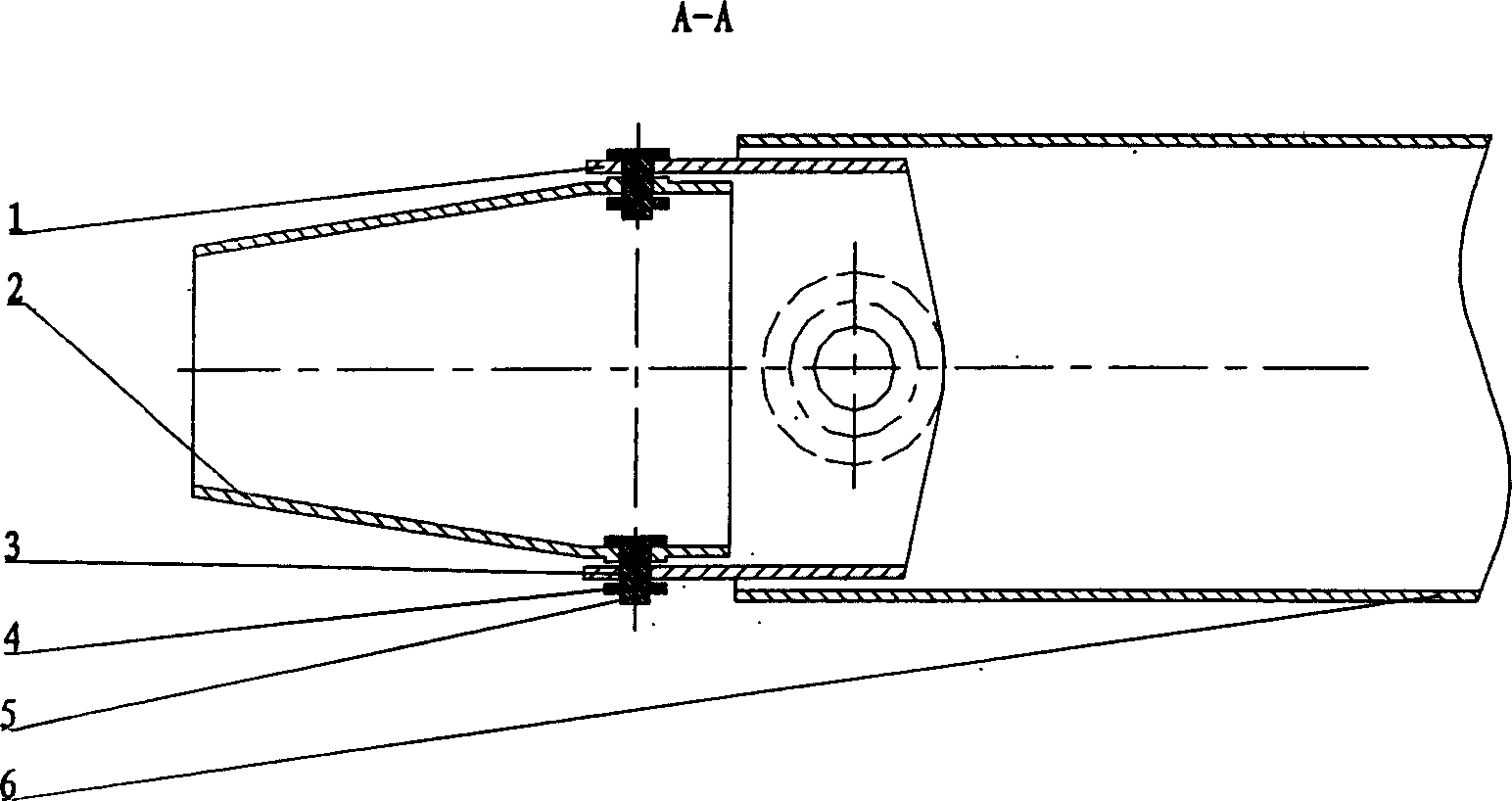

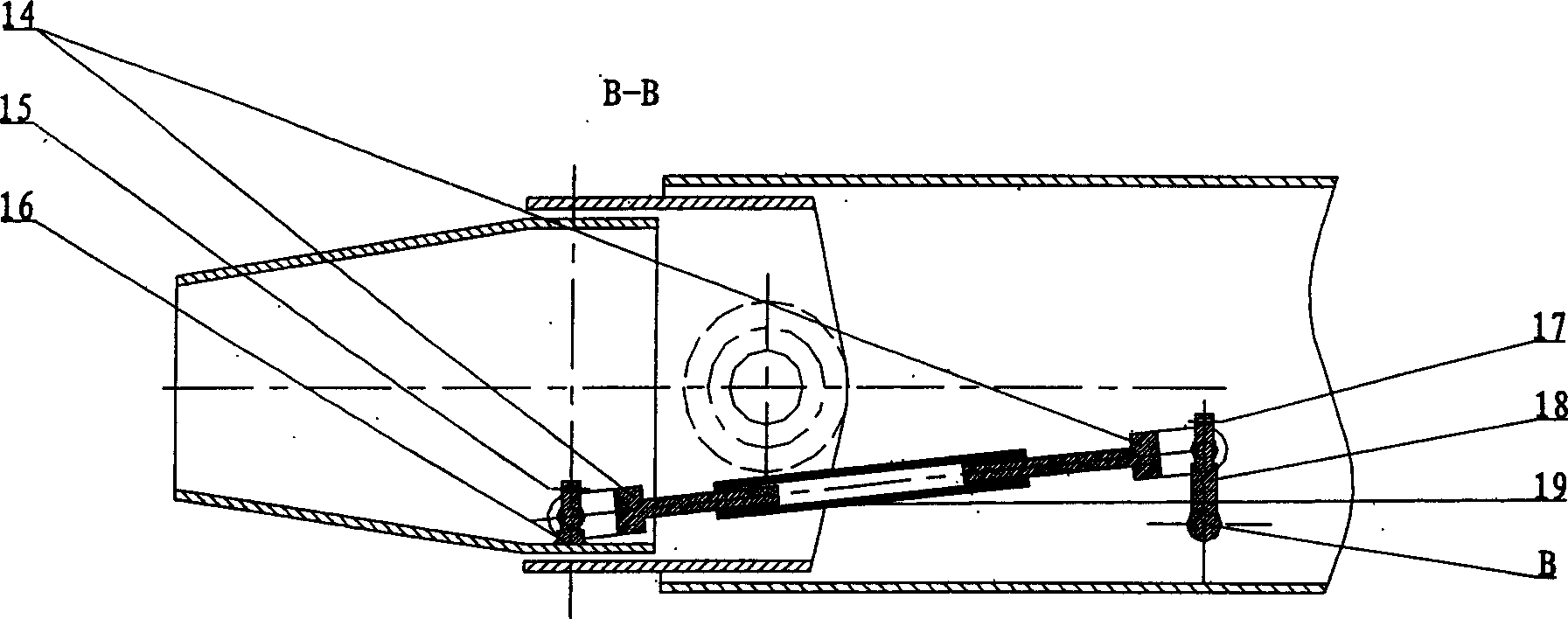

[0011] The present invention will be further described below in conjunction with drawings and embodiments.

[0012] Figure 1, figure 2 , image 3 As shown, the present invention includes a nozzle base 1, a nozzle body 2 and a nozzle body transmission device. The tail of the nozzle body 2 is inserted into the head of the nozzle seat 1, and the two are connected by two cylindrical pins 3, and are respectively positioned with the gasket 4 and the cotter pin 5. The tail of the nozzle body 2 is an arc-shaped structure, which can make the nozzle body 2 Swing around the cylindrical pin 3, the tail of the nozzle seat 1 is connected to the bellows 6; one end of the nozzle body transmission device includes a transmission pin 16, a universal joint 7 and a clamp iron 14, and one end of the transmission pin 16 is fixed on the lower wall of the nozzle body 2, The other end is inserted into the center hole of a universal joint 7, and is positioned with a cotter pin 15, and a universal join...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com