Refurbishment of a coated chamber component

A component and surface coating technology, applied in the field of cleaning and coating of process chamber components, can solve problems such as unacceptable, long pumping time, and unsatisfactory adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

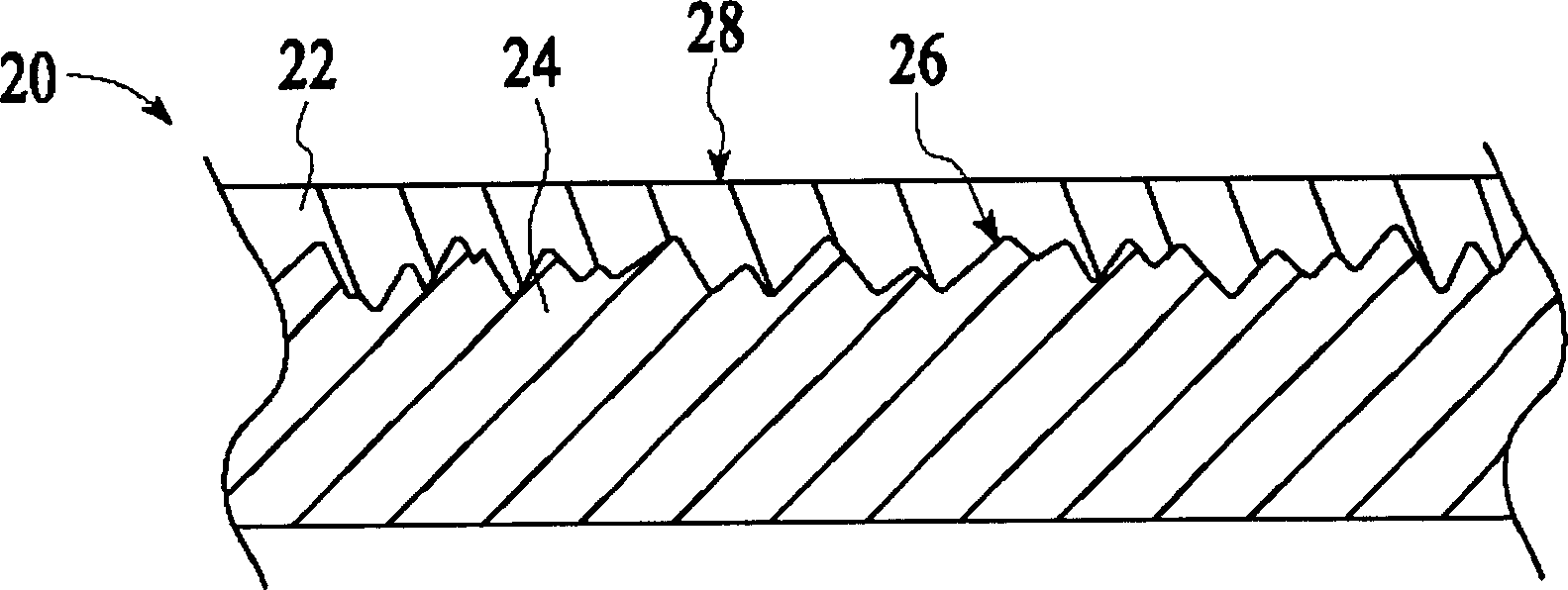

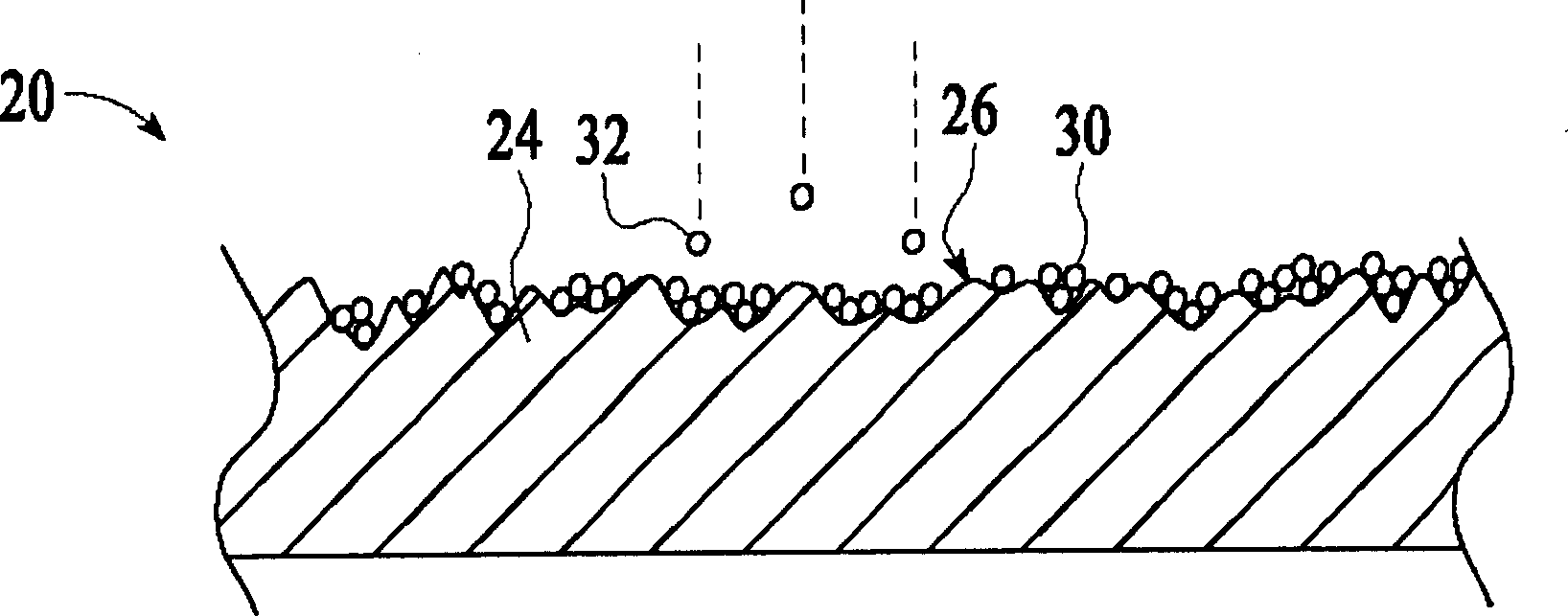

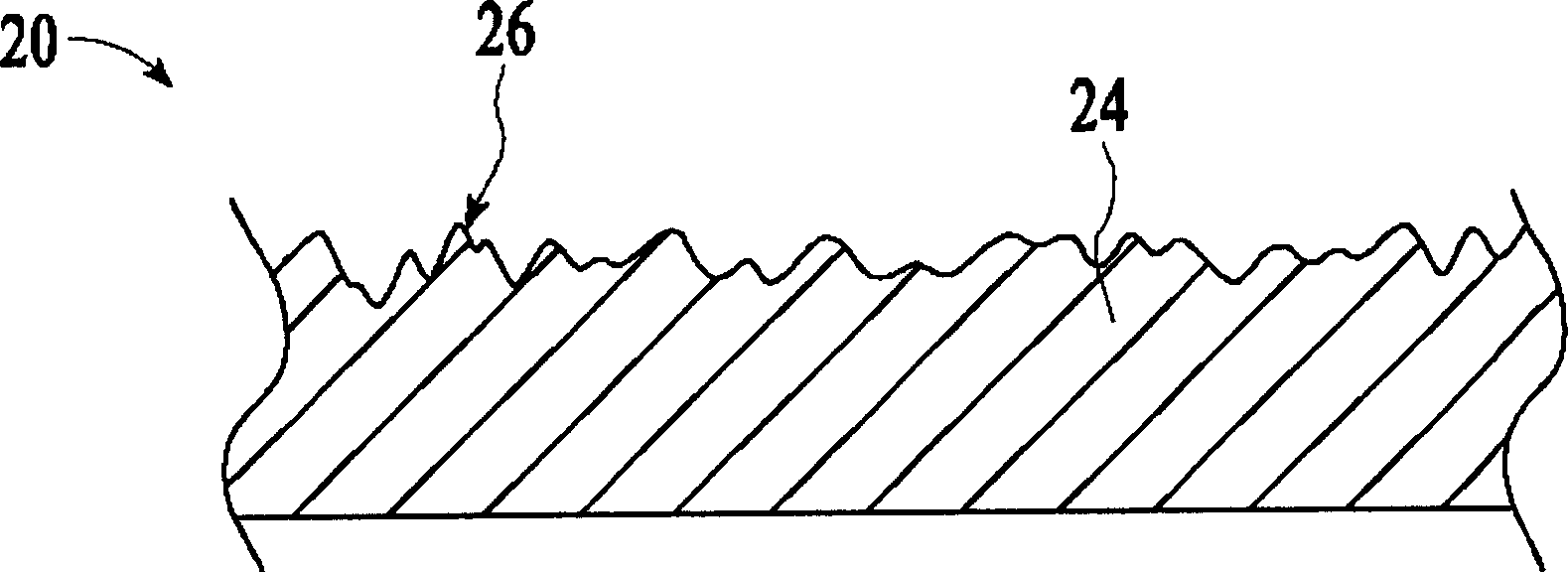

[0016] The treatment method of the present invention is suitable for cleaning and refurbishment of components 20 having a coating 22, as shown for example in FIG. 1 . This treatment method improves the cleaning and refurbishment of the component 20 and also improves the technical effect of removing volatile residues from the component 20 . Removing volatile residues can reduce the overall pumping time to achieve the desired pressure level in the chamber 106 . The processing method may be used to clean and refurbish one or more etch-susceptible components 20 in the chamber 106, including, for example, one or more portions of the gas delivery system 112 that provides the chamber Process gas in 106; substrate support 114 to support substrate 104 in chamber 106; gas energizer 116 to energize process gas; chamber housing wall 118 and shield 122 and an exhaust port 120 for exhausting gas from the chamber 106, an exemplary embodiment of all of which is shown in FIG. 3 . For example...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com