Light guiding plate and manufacturing method thereof

A manufacturing method and technology for light guide plates, which are applied in optics, nonlinear optics, diffusing elements, etc., can solve the problem of low light utilization rate of light guide plates, and achieve the goal of improving light utilization rate, reducing light transmission interface, and improving light rate. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

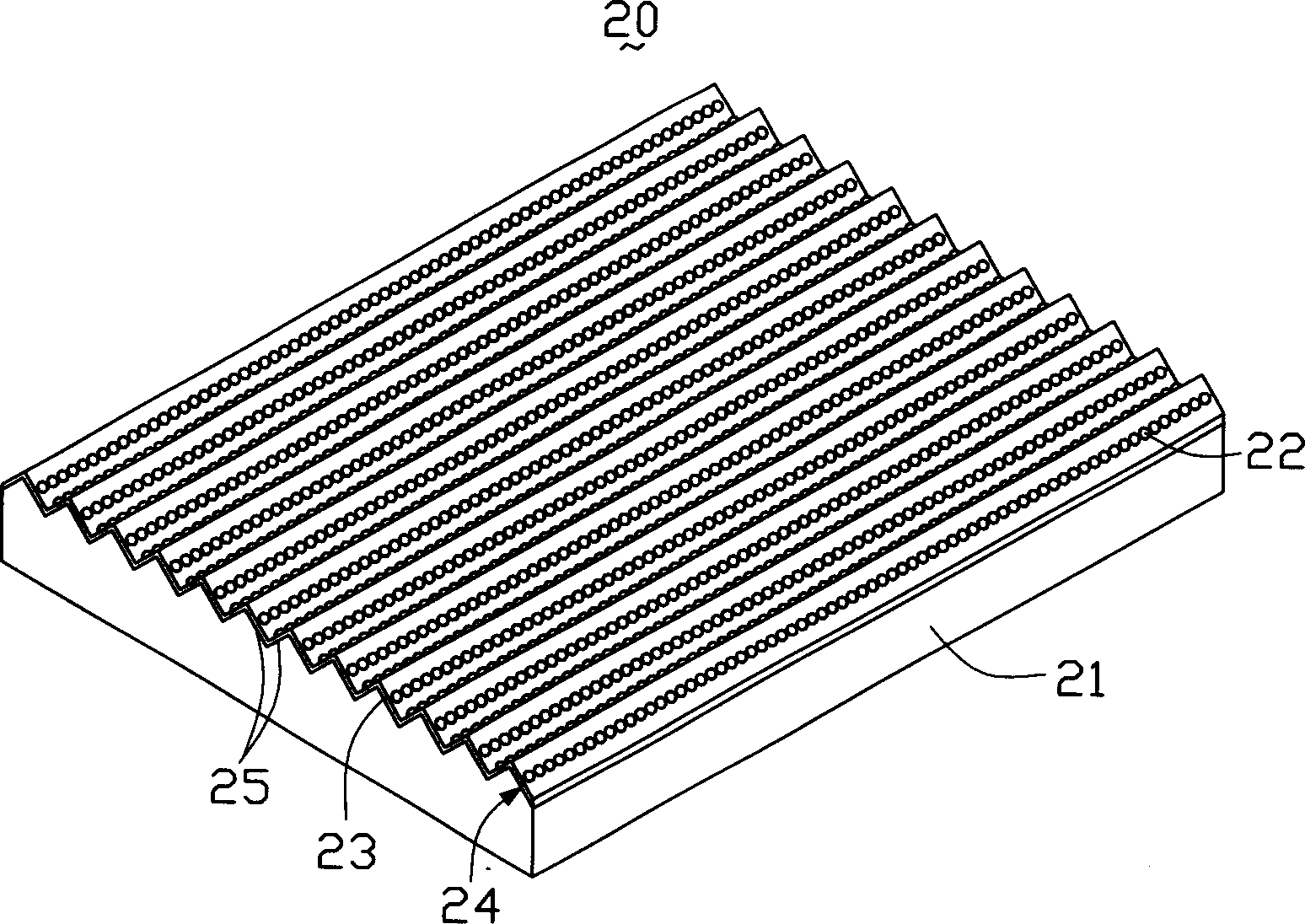

[0018] see figure 2 , is a schematic perspective view of the first embodiment of the light guide plate of the present invention. The light guide plate 20 includes a substrate 21 and a plurality of transparent particles 22 . The substrate 21 is a rectangular transparent substrate. The substrate 21 includes a surface 24 having a groove array 25 , and the groove array 25 is a V-shaped groove array. The size of the plurality of transparent particles 22 is 10 -9 Meter. The plurality of transparent particles 22 are evenly adhered on the surface through a glue layer 23 . The adhesive layer 23 is a transparent adhesive layer.

[0019] The V-shaped groove array shape of the groove array 25 can control the outgoing angle of the light and converge the outgoing light at a certain angle, which can make full use of the outgoing light and improve the light utilization rate. The groove array 25 controls the outgoing angle of the light, and matches with the viewing angle of the liquid cr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com