Electroluminescent device and method of manufacturing thereof

A technology of electroluminescent element and manufacturing method, which is applied in the field of light-emitting device and the manufacture of the aforementioned electroluminescent element, and can solve the problems of lack of solubility and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

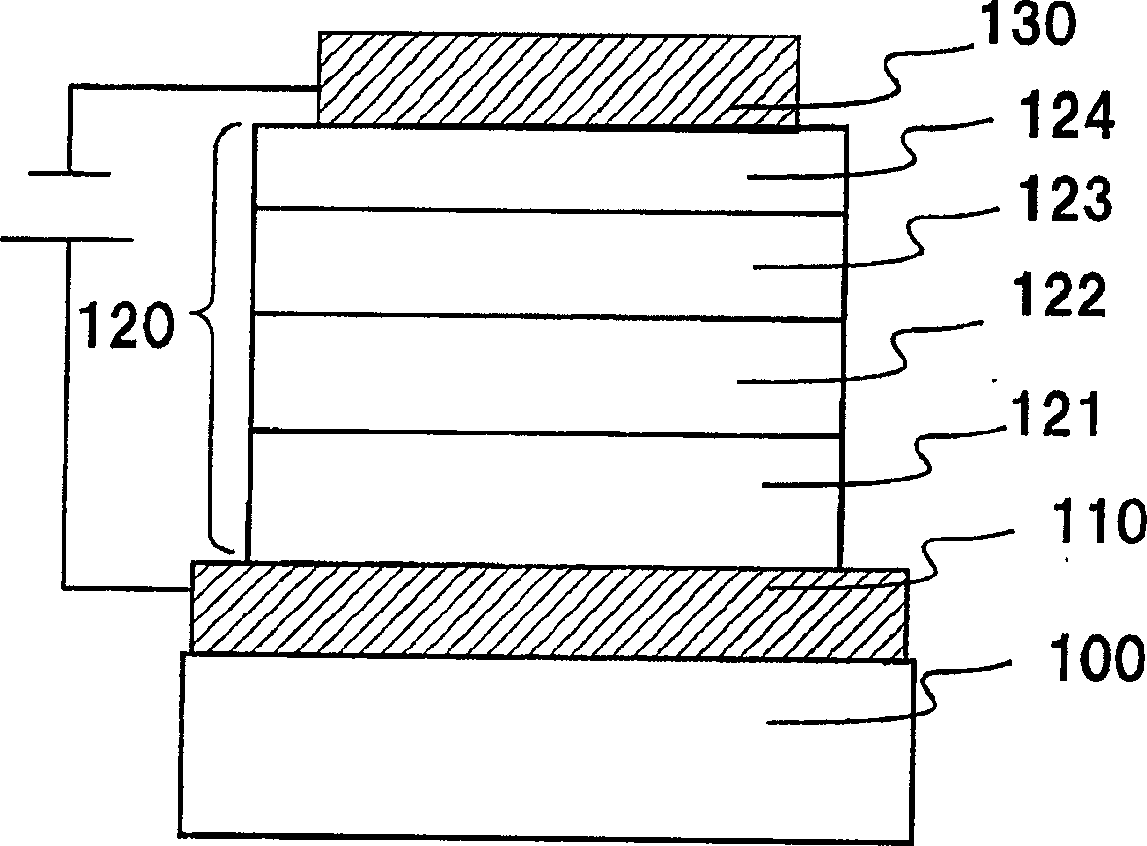

[0109] In Embodiment 1, the above-mentioned organic compound (ligand) and metal salt are co-evaporated and heated, and the structure of the electroluminescent element when the layer thus obtained is formed as a light-emitting layer is defined by figure 1 Be explained.

[0110] figure 1 The structure is as follows: a first electrode 110 is formed on a substrate 100, an electroluminescent layer 120 is formed on the first electrode 110, and a second electrode 130 is formed thereon.

[0111] It should be noted that, here, as the material used for the substrate 100 , as long as it is used for a conventional electroluminescent element, for example, a material made of glass, quartz, transparent plastic, etc. can be used.

[0112] In addition, in Embodiment 1, the first electrode 110 functions as an anode, and the second electrode 130 functions as a cathode.

[0113] That is, the first electrode 110 is formed of an anode material. Here, as an anode material that can be used, metals,...

Embodiment approach 2

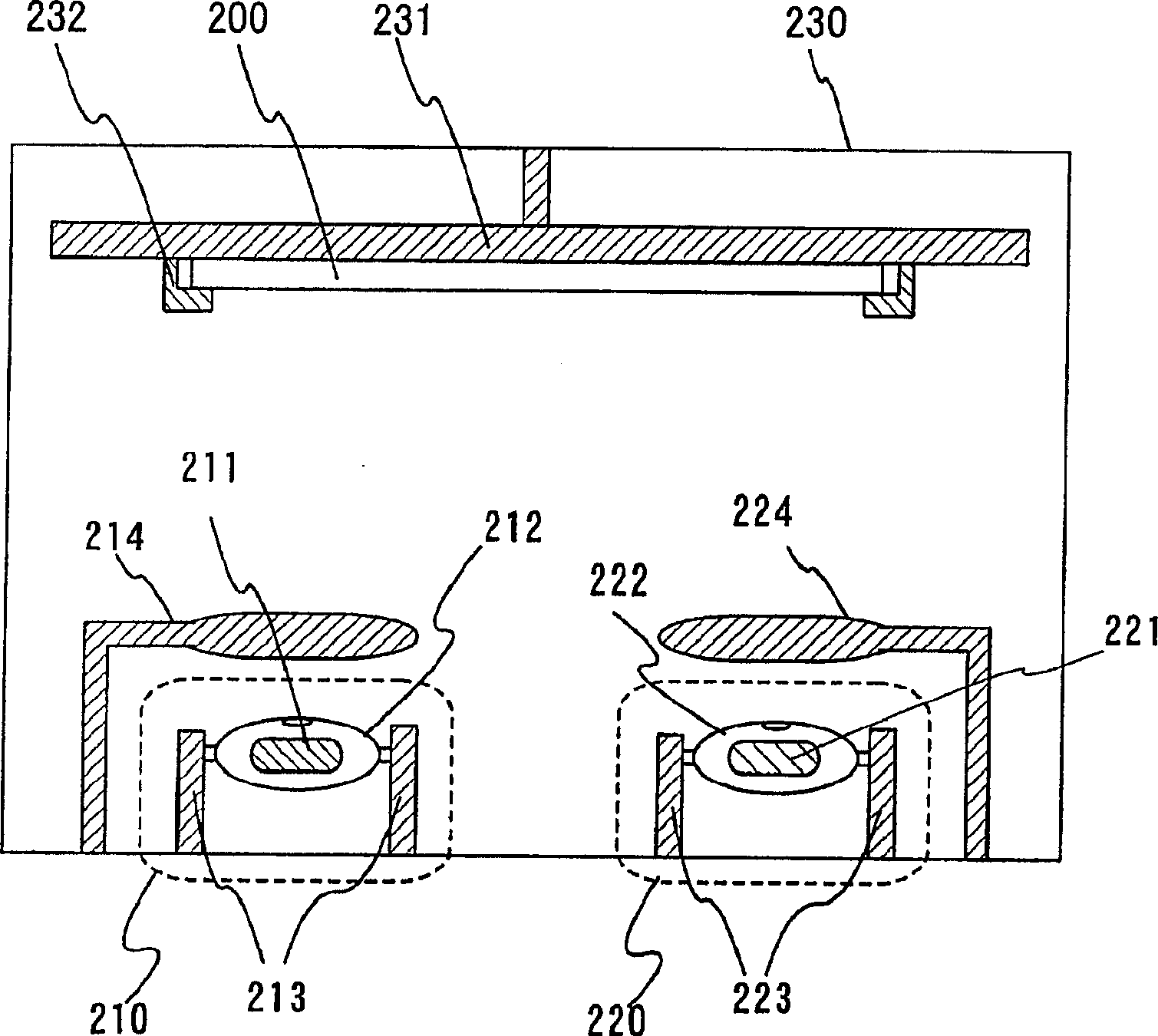

[0131] In Embodiment 2, for the above co-evaporation method, use figure 2 Describe its specific shape. It should be noted, figure 2 A cross-sectional view of the vapor deposition machine. As the shape of the vapor deposition source, there are types using batteries, types using conductive heating elements, etc. figure 2 Shown in is the case where a conductive heating element is used.

[0132] First, the container a212 filled with the aforementioned organic compound 211 is fixed on the electrode a213 located at the bottom of the vapor deposition chamber 230 . Similarly, on the electrode b223, the container b222 filled with the aforementioned metal salt 221 is fixed. In addition, the substrate 200 on which the first electrode of the electroluminescent element and the like are deposited is fixed by the substrate holder 232 on the rotating disk 231 positioned above the vapor deposition chamber 230 so that the first electrode faces downward.

[0133] Then, by applying a volt...

Embodiment 1

[0137] In this example, a method for synthesizing an organic compound used for co-evaporation will be specifically exemplified.

[0138] Mix 20 ml of a methanol solution of 1.72 g of 1-hydroxy-2-naphthaldehyde and 50 ml of a methanol solution of 0.57 g of 1,2-cyclohexanediamine (the molar ratio at this time is 2:1), and stir for 1 to 2 hours. As a result, yellow crystals were precipitated. Utilize vacuum filtration to take out this precipitate, it is dried with vacuum oven, obtains 1,2-bis(2-hydroxyl-1-naphthylene)-cyclohexanediamine (hereinafter referred to as na2-cHex) (such as Shown in structural formula (17), the crystallization temperature is 120°C, the melting point is 205°C, and the decomposition temperature is 305°C.

[0139]

PUM

| Property | Measurement | Unit |

|---|---|---|

| crystallization temperature | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| decomposition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com