Air filter for engine

An air filter and engine technology, applied in the direction of combustion air/combustion-air treatment, charging system, machine/engine, etc., can solve the problems of engine flameout, incomplete combustion, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

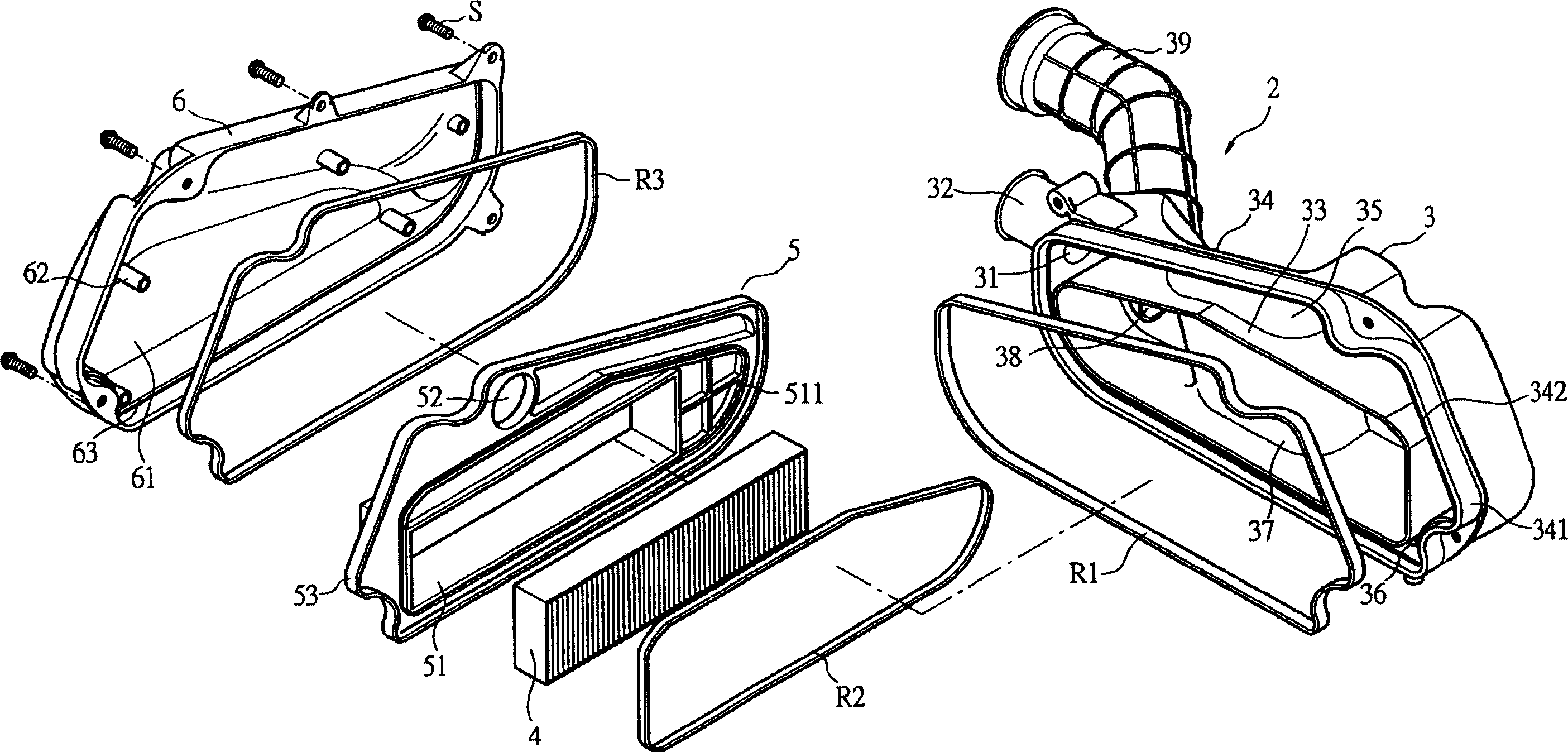

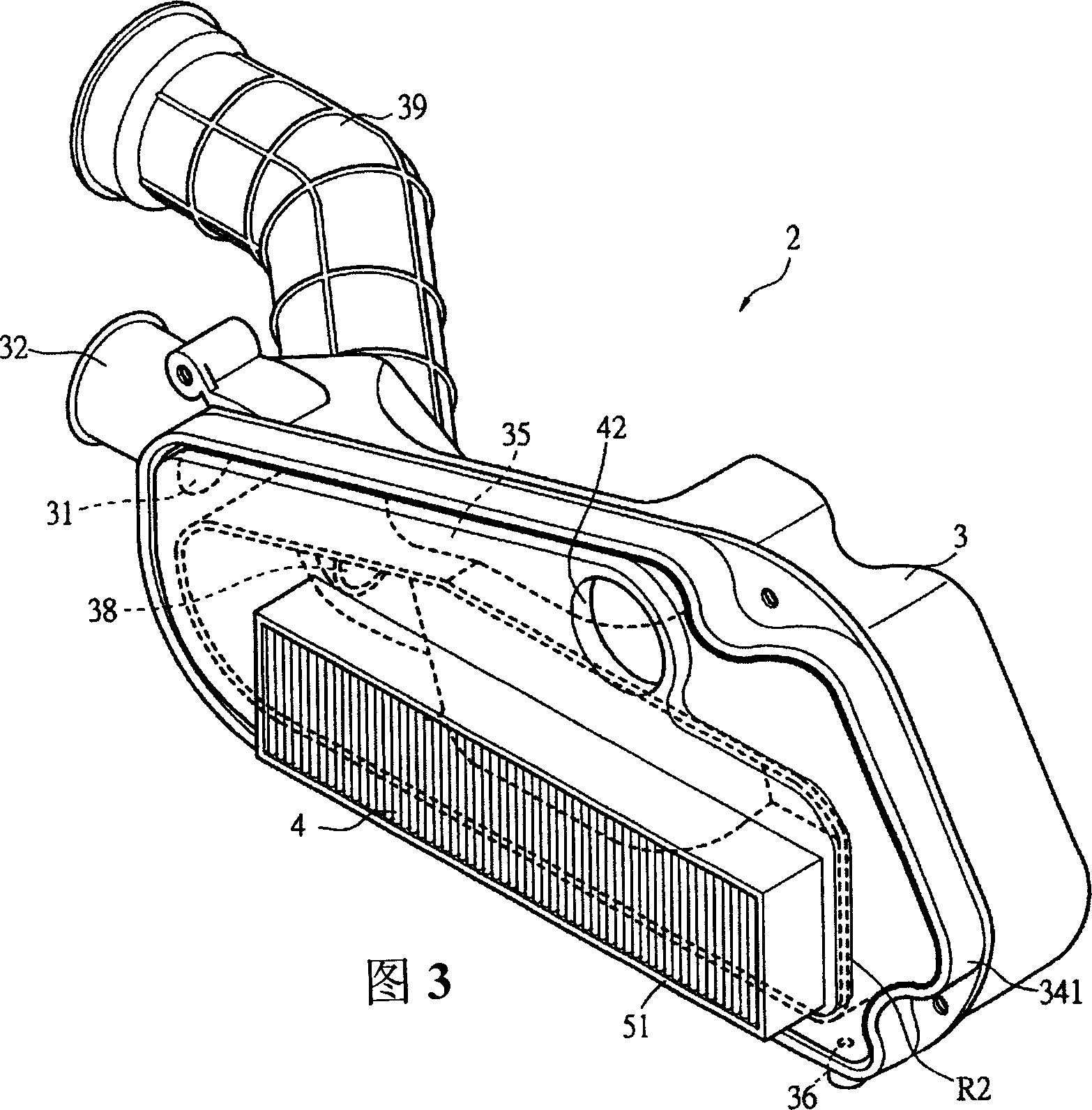

[0028] In order to understand the structure of the present invention and the effects that can be achieved more easily, the illustrations are as follows:

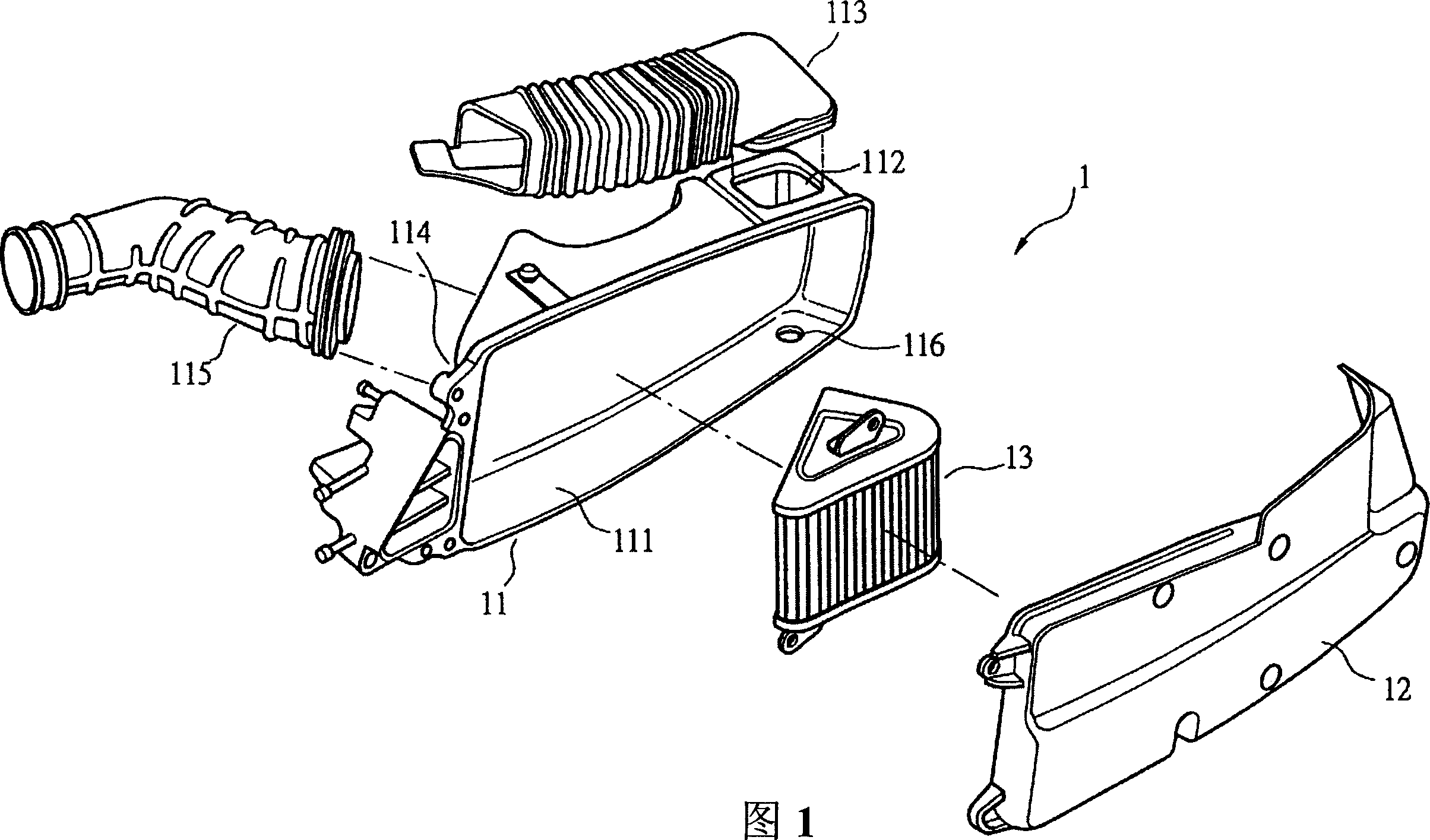

[0029] First, see figure 2 , The air filter 2 of the present invention is mainly composed of a box body 3, a filter element 4, and a cover body 6.

[0030] The box body 3 is a box-shaped body, an air inlet 31 is provided at its front end, an air inlet pipe 32 is connected to the front end of the air inlet 31, and a partition plate surrounding the box body 3 is provided inside the box body 3 33, the partition plate 33 and the ring wall 34 of the box body 3 can just form an air channel 35, and the air channel 35 is an annular channel extending from the air inlet 31 along the box body 3. In addition, on the air passage 35 and at the bottom of the ring wall 34 of the box body 3, a drain hole 36 is provided. An outlet chamber 37 is defined at the center of the box body 3 by a partition 33 , an air outlet 38 is provided on the o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com