Pull disc device for initiating engine

An engine and coil reel technology, applied in the field of puller devices, can solve the problems of manual work, affecting the smoothness of starting the engine 2, small size, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The aforementioned and other technical contents, features and effects of the present invention will be more clearly understood in the following detailed description of a preferred embodiment with reference to the drawings.

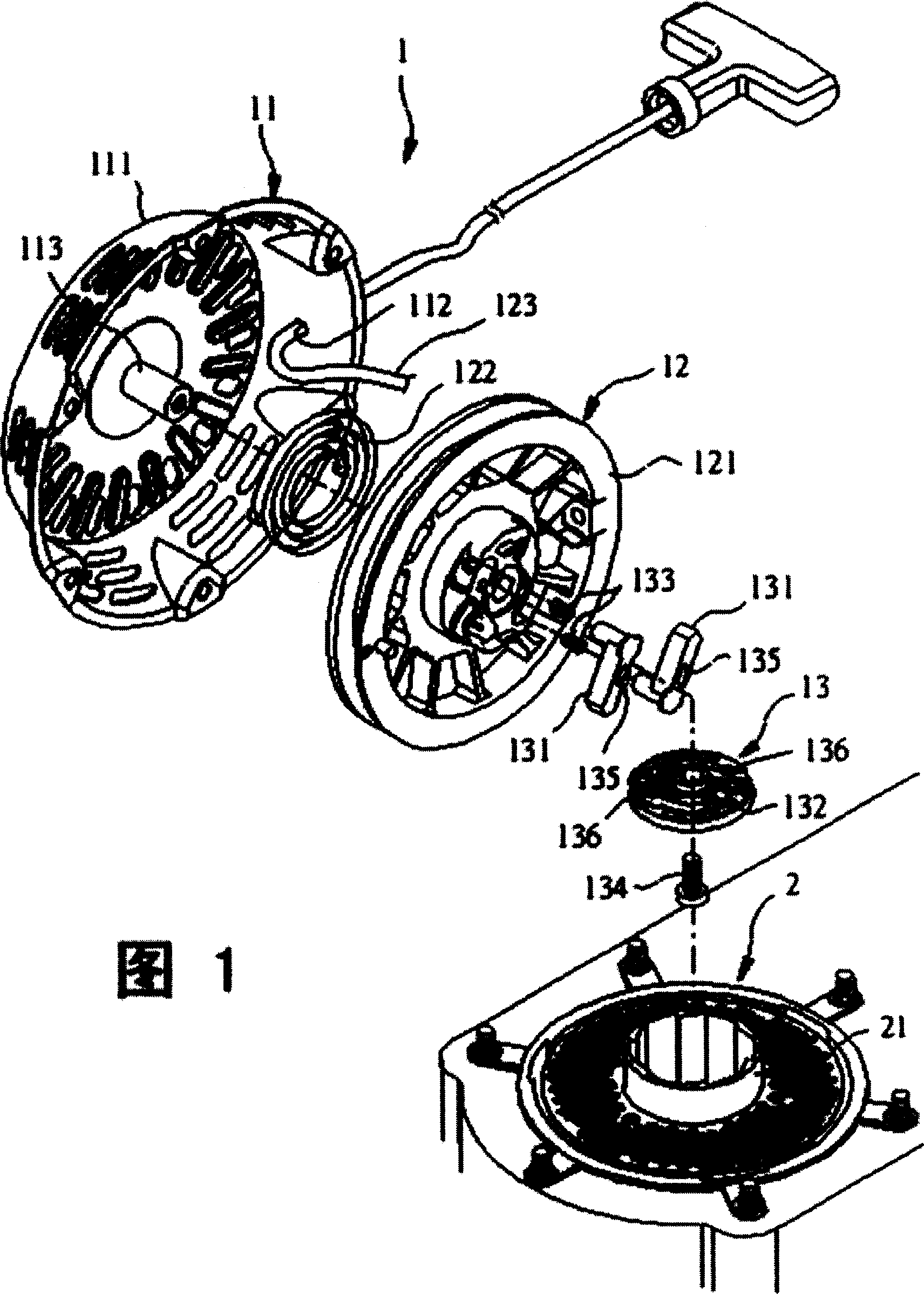

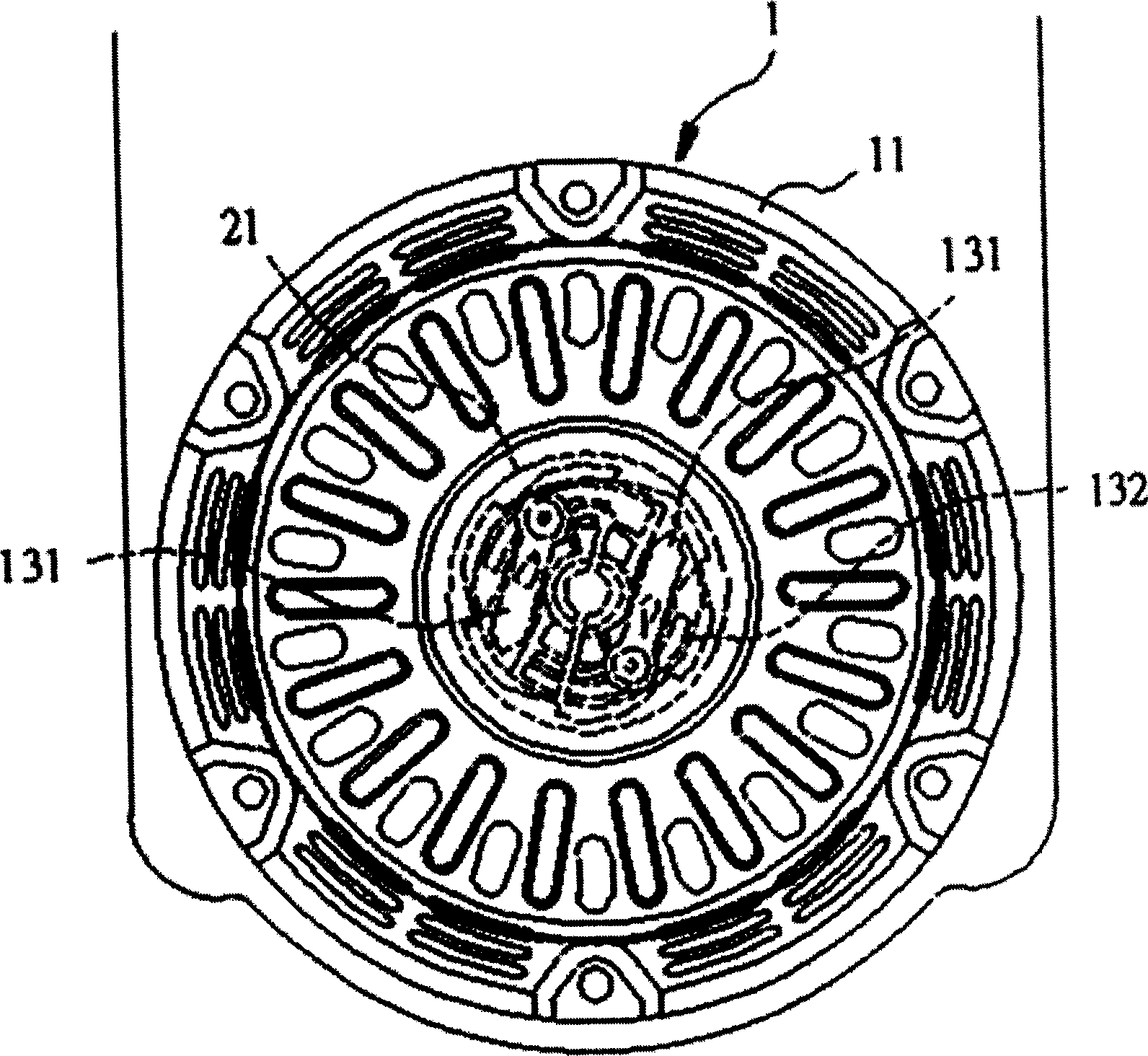

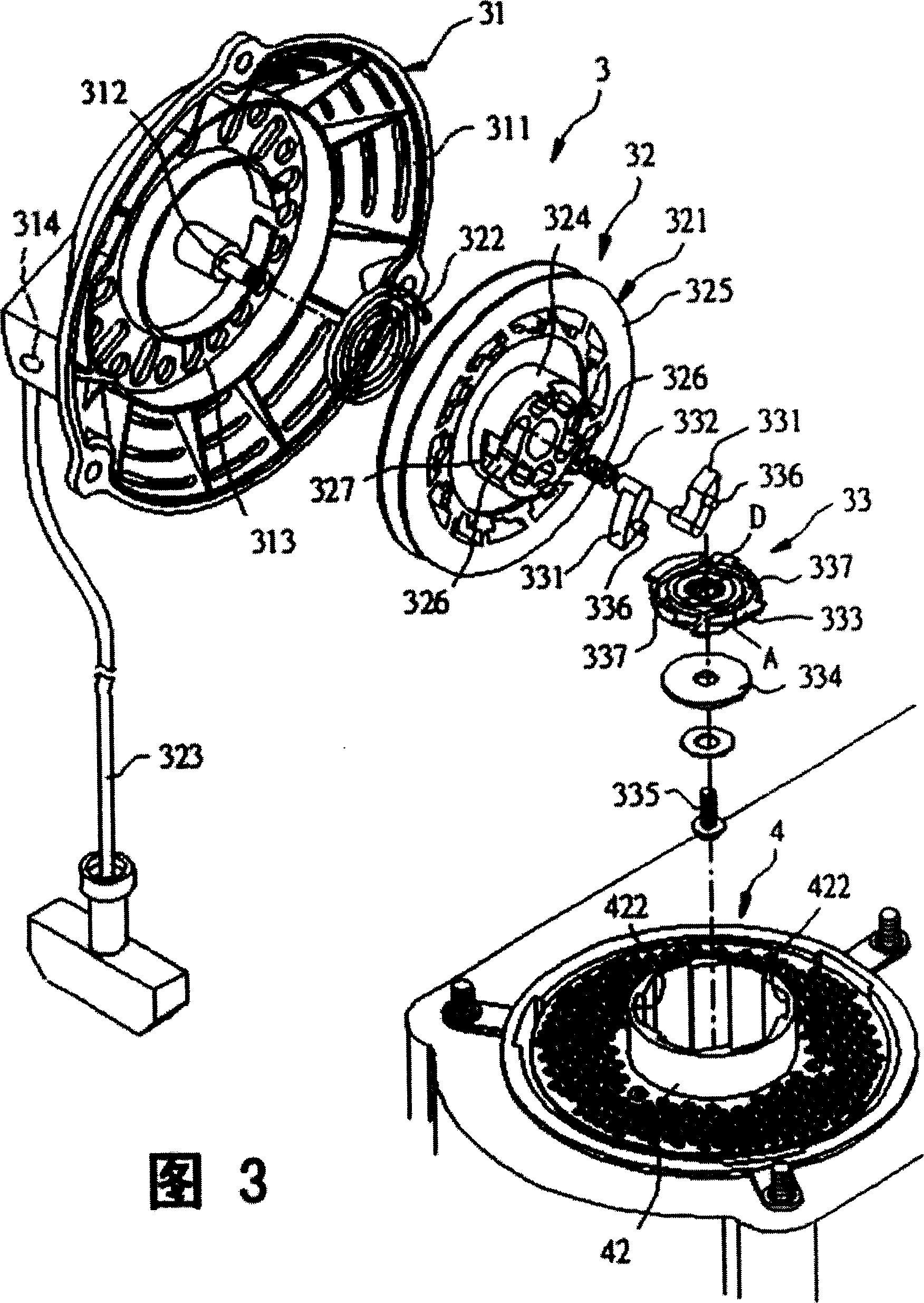

[0033] See Figure 3 with Figure 4, is the preferred embodiment of the pulling device 3 for starting the engine of the present invention. Wherein, the engine 4 includes a starting flywheel 42 , and the inner peripheral surface of the starting flywheel 42 has a plurality of engaging slots 422 spaced apart from each other. The pulling device 3 used for starting the engine comprises an outer cover unit 31 that can be assembled on the starting flywheel 42 of the engine 4, a coil unit 32 that is arranged in the outer cover unit 31, and a coil unit 32 that can receive the coiled wire. The unit 32 drives the driving unit 33 that starts the flywheel 42 to rotate in conjunction with each other. The driving unit 33 is located below the winding unit 32 .

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com