A linear actuator with self-locking spindle

A technology of an actuator and a rotating shaft, which is applied in the field of furniture and can solve problems such as insufficient space for the actuator

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

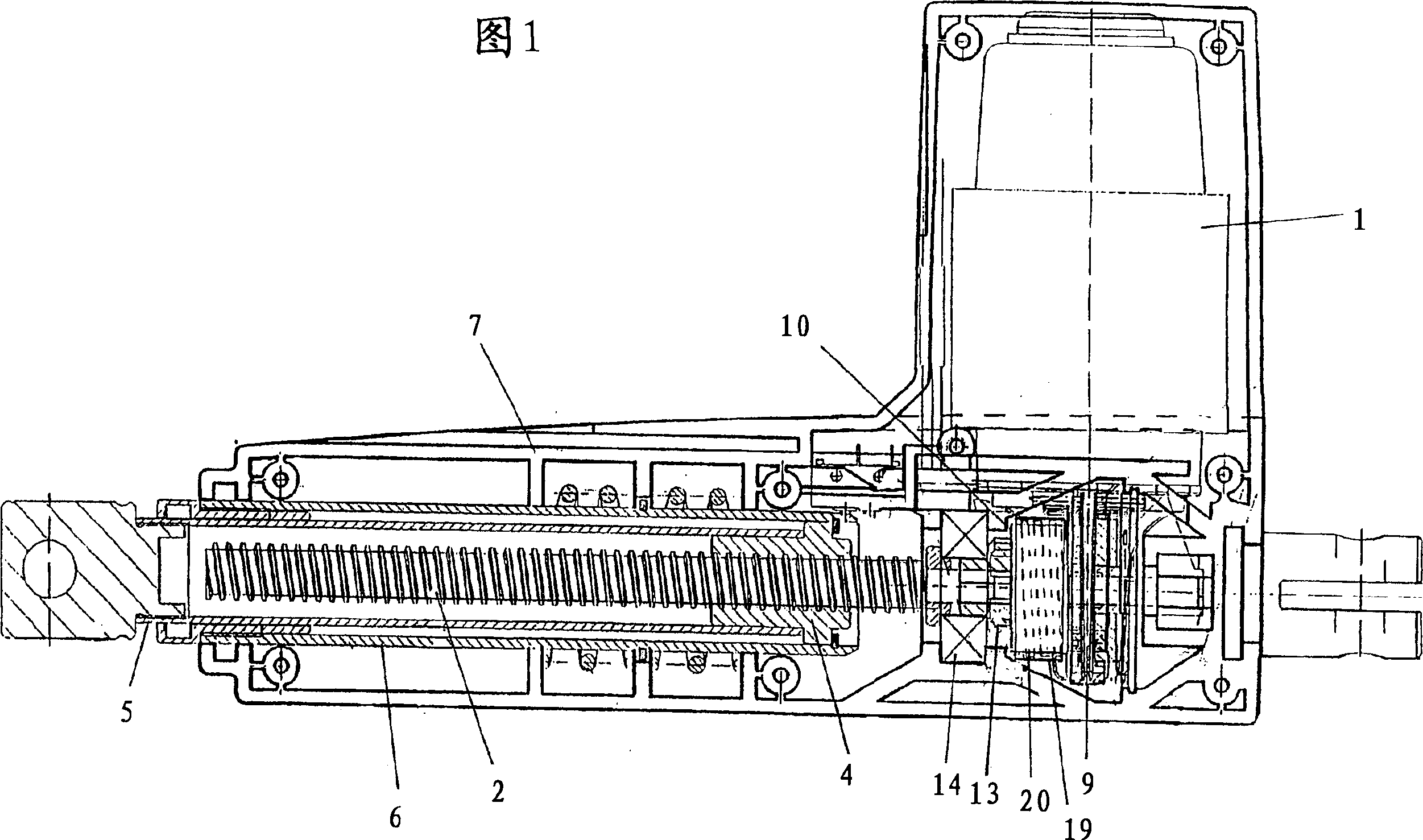

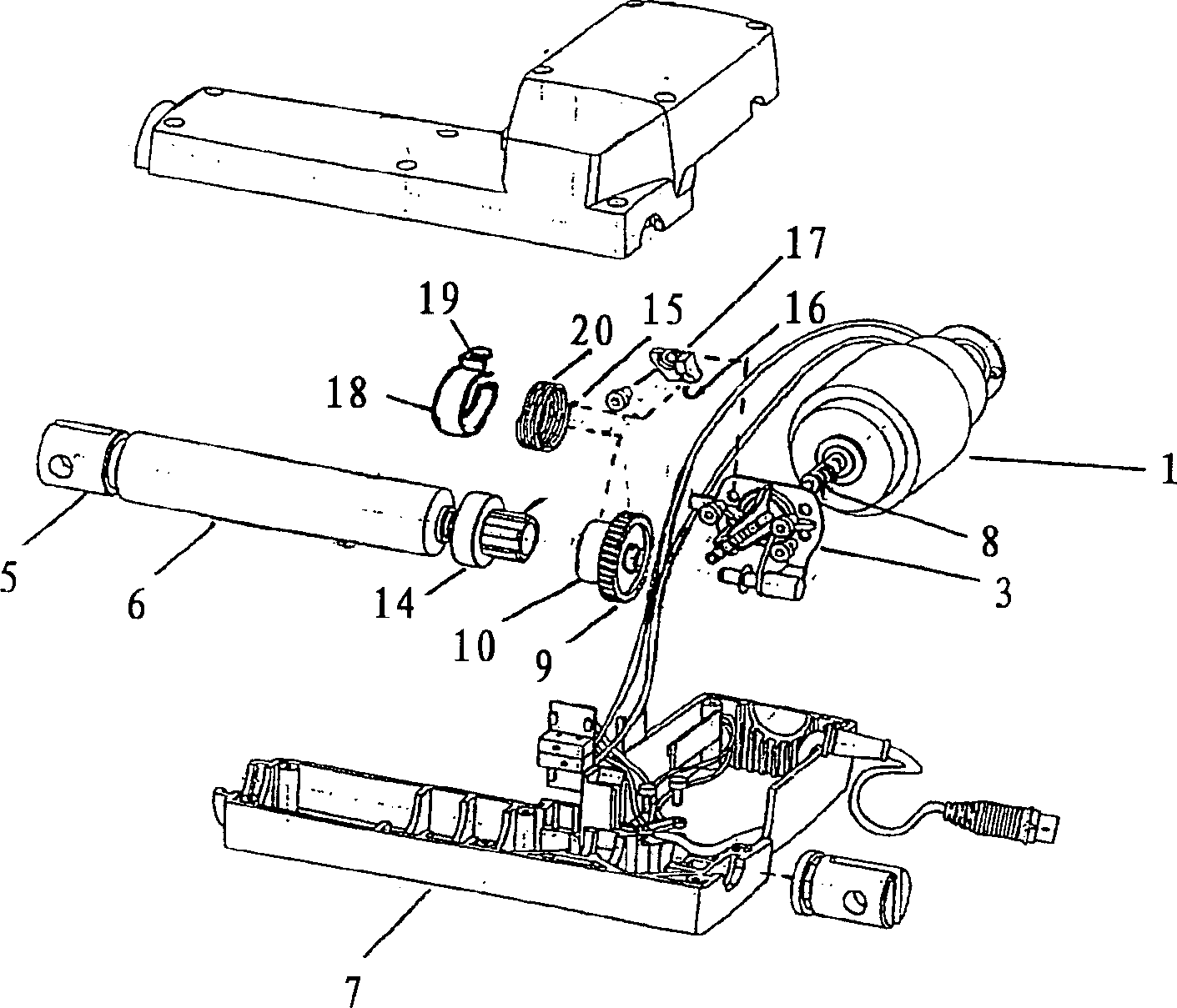

[0014] The linear actuator shown in the figures comprises a reversible low voltage electric motor (DC) 1 which drives a rotating shaft 2 through a worm drive. Reference numeral 3 designates a front part for the motor. A nut 4 is arranged on said shaft and has fixed thereon a drive rod 5 in the form of a tube telescopically arranged in an outer tube 6 embedded in the housing of the actuator 7 in.

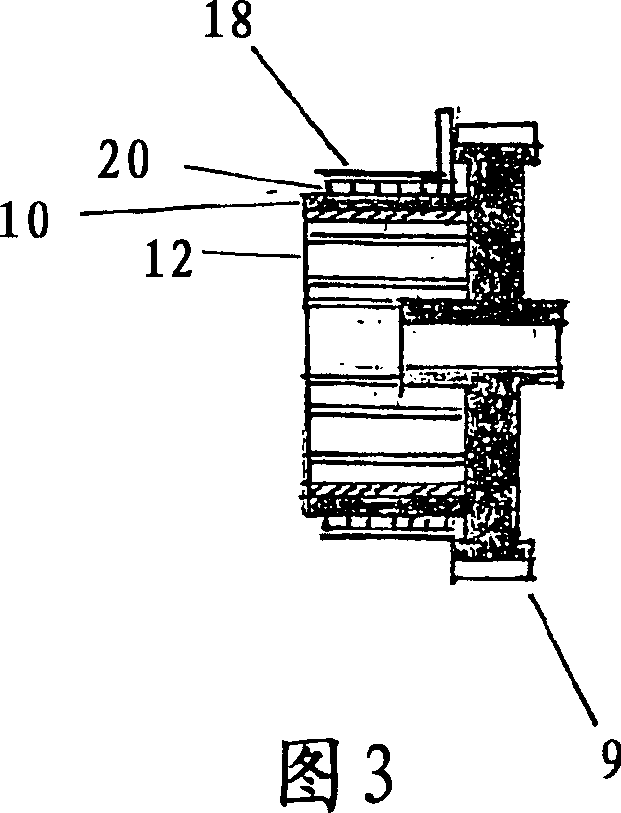

[0015] The worm drive comprises a steel worm 8 formed in the extension of the motor shaft, and a worm wheel 9 with a cylindrical element 10 integrally formed on the side, which houses an insert 12 . The worm gear is made of plastic (POM) fixedly molded on an insert made of light metal (Aluminum Zinc).

[0016] The worm wheel 9 is secured to said shaft by means of a splined coupling where part of the spline is in the insert 12 and the other part is formed by an element 13 fixed on the end of the shaft. The shaft is mounted in a bearing 14 in front of the worm wheel.

[0017] On th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com