Conveyor chain

A conveyor chain and chain link technology, applied in the field of conveyor chains, can solve the problems of time-consuming, increased number of parts, etc., and achieve the effects of suppressing wear, prolonging life, and reducing the number of parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

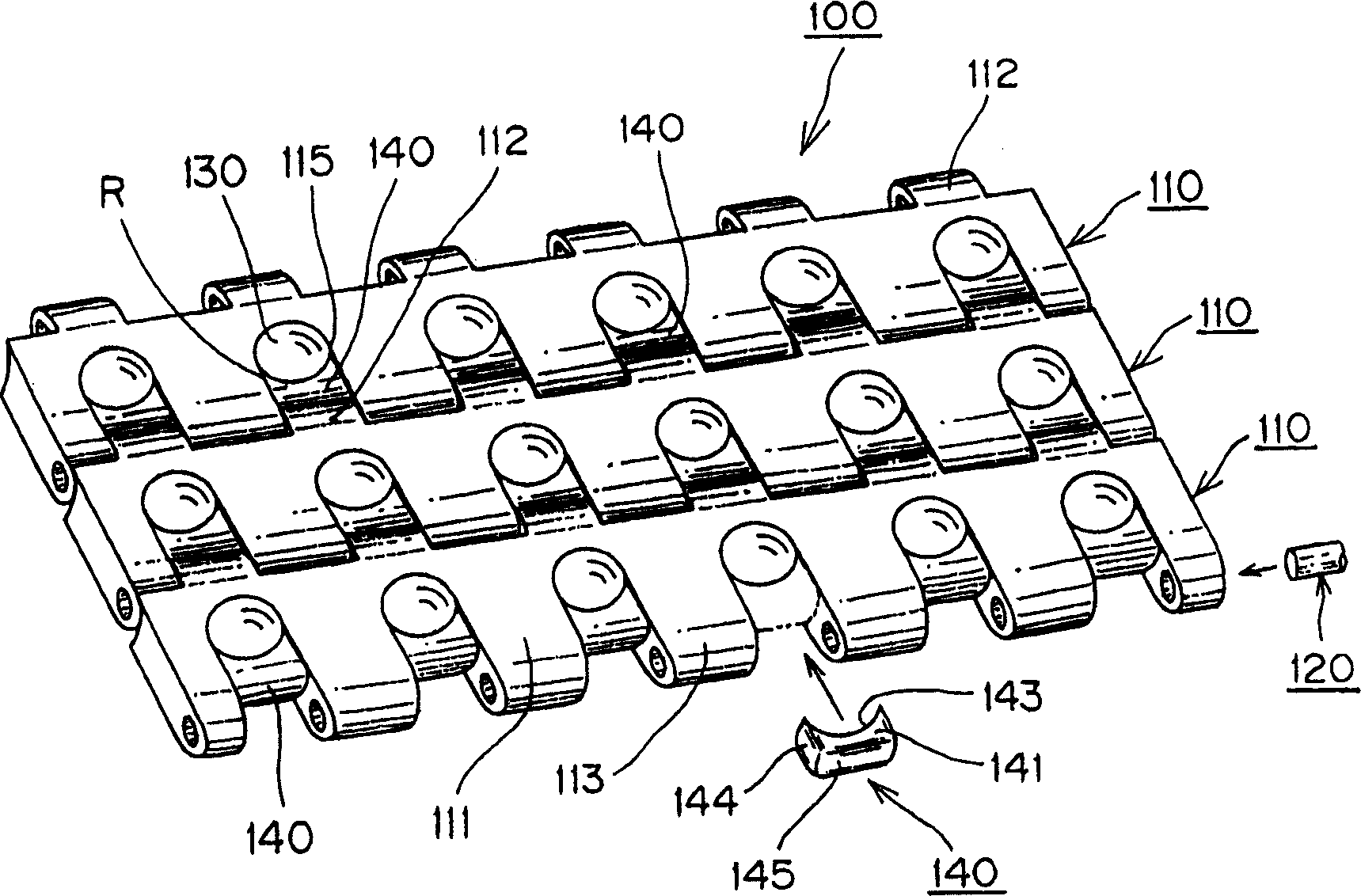

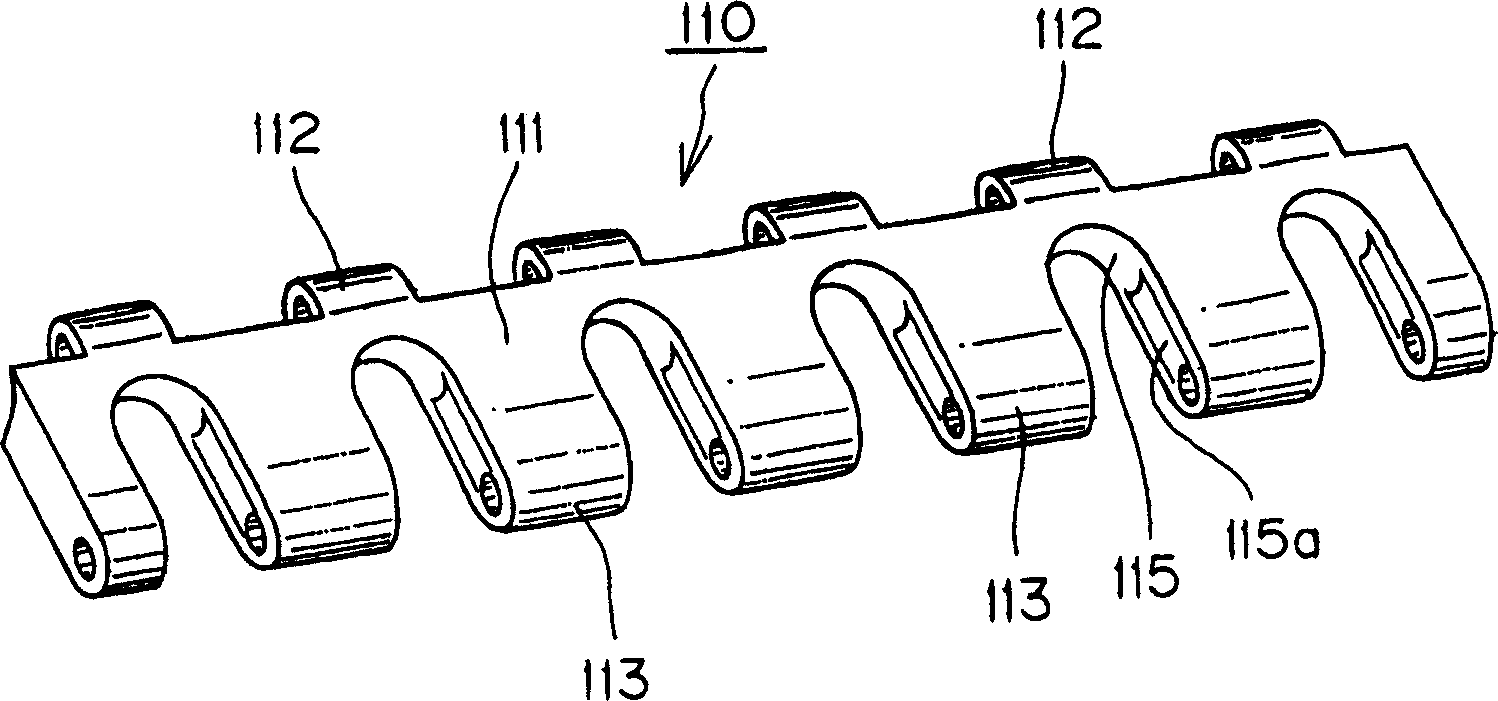

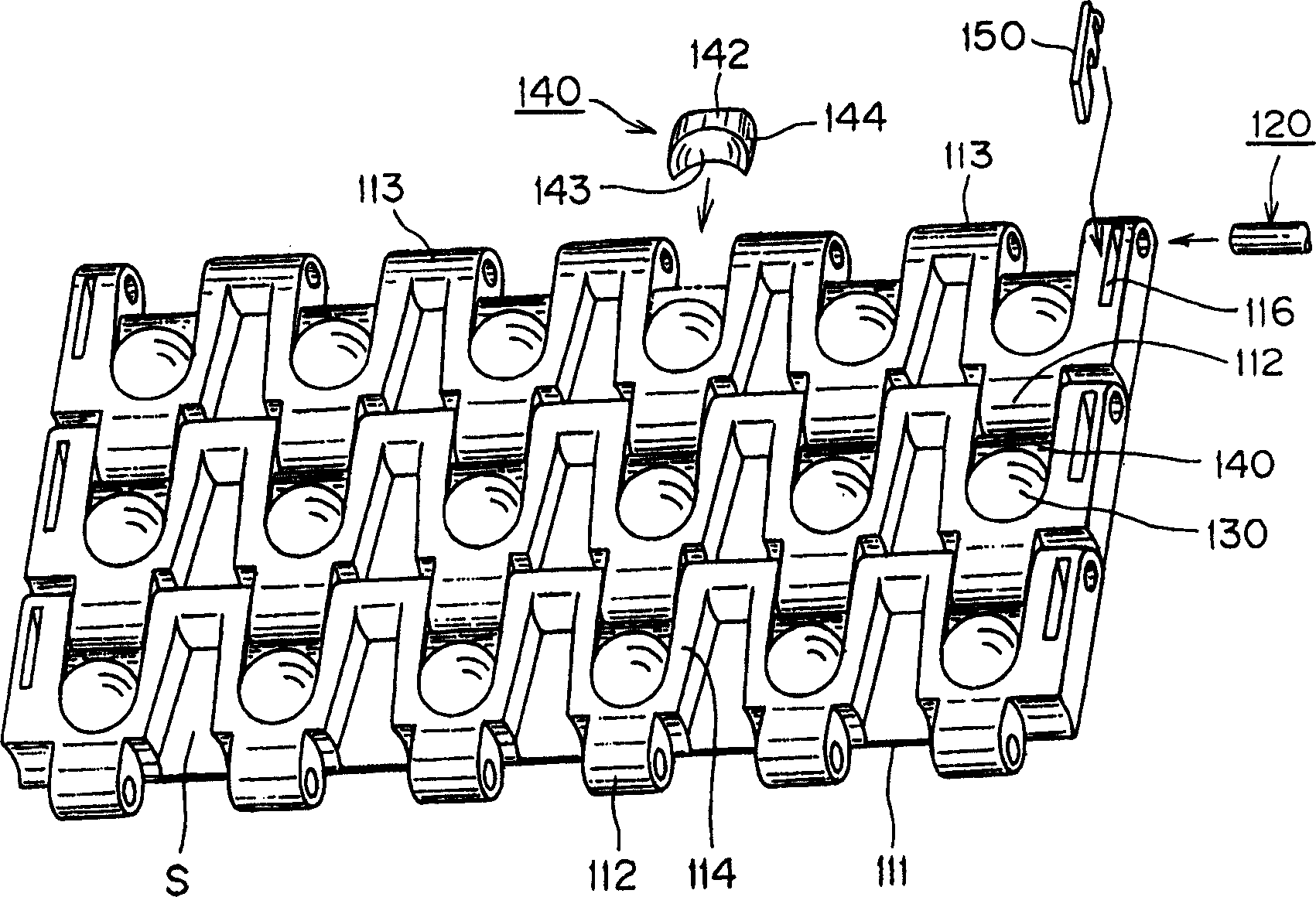

[0018] based on Figure 1 to Figure 7 Examples of the present invention will be described. figure 1 It is a perspective view of a part of the conveyor chain viewed from the surface side, figure 2 It is a perspective view of the link viewed from the surface (conveying surface) side, image 3 It is a perspective view of a part of the conveyor chain viewed from the back side, Figure 4 It is a perspective view of the link viewed from the back side, Figure 5 It is an expanded view of the chain link, (A) is a top view from the side of the conveying surface, (B) is a front view from the arrow X direction of the drawing (A), (C) is a top view from the back side, and (D) is a top view from the drawing (C) The front view of the arrow Y direction, Image 6 It is an explanatory diagram showing an example of the arrangement state of the links constituting the conveyor chain, Figure 7 It is an explanatory diagram showing the operation state of the conveyor chain.

[0019] like fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com