Mixed nozzle measuring device

A technology for testing devices and mixing nozzles, which is applied in measuring devices, testing of machines/structural components, instruments, etc. It can solve problems such as excessive sticky material, influence of feeding effect, and poor atomization effect, so as to ensure atomization effect, The effect of improving product quality and reducing blindness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

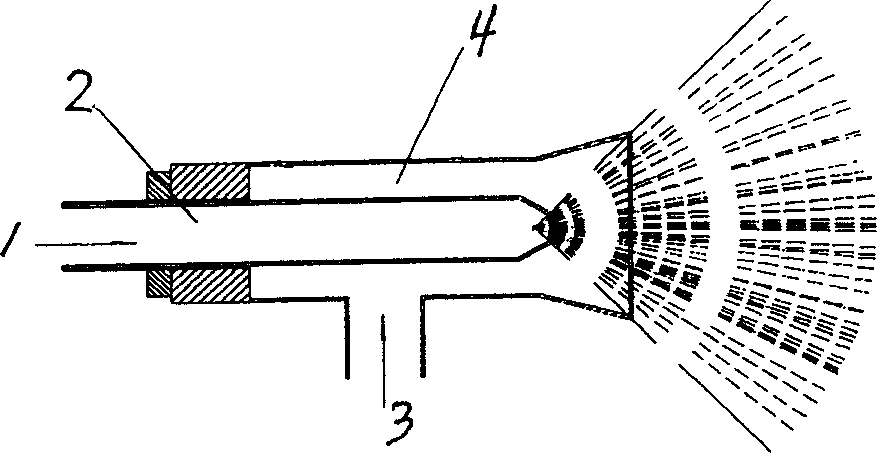

[0013] figure 1 A schematic diagram of the working principle of the existing mixing nozzle is given. Medium 1 such as water and feed liquid enters the inner cavity 2 of the nozzle, medium 3 such as steam and compressed air with a certain pressure and flow rate enters the outer cavity 4 of the nozzle, and the medium 3 atomizes the medium 1 and sprays it out from the nozzle.

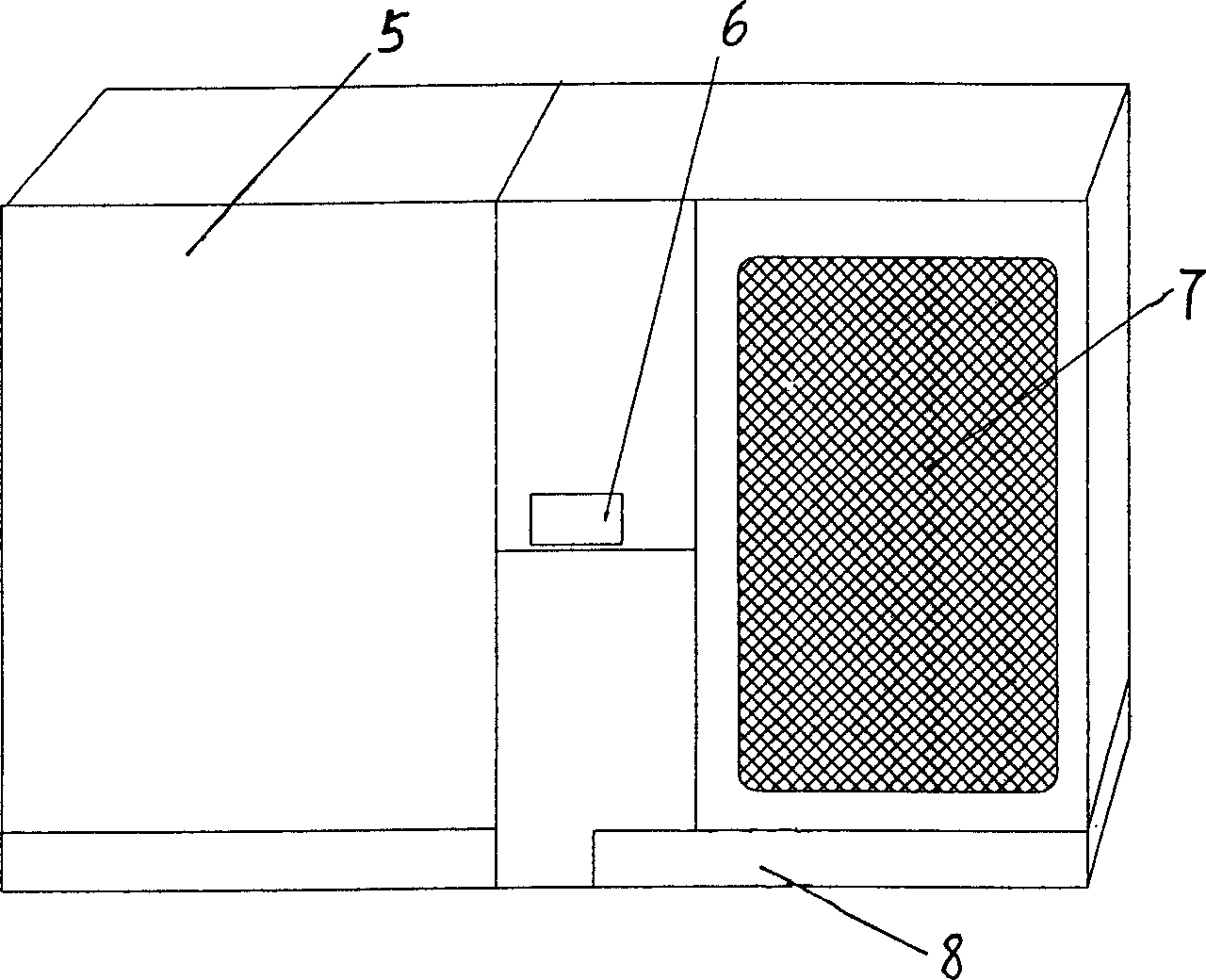

[0014] figure 2 A schematic diagram of the appearance of the nozzle testing device of the present invention is given. The mixing nozzle testing device is composed of a water vapor cabinet 5, a nozzle test bench 6 and an observation room 7. The water vapor cabinet 5 is on one side of the nozzle test bench 6, and the observation chamber 7 is on the other side of the nozzle test bench 6. Both sides of the observation chamber 7 are inlaid with plexiglass, which is convenient for observing the atomization effect of the nozzle, and a water receiving box 8 is provided at the bottom thereof to collect and disch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com