Grinding apparatus for buttons on rock drill bit

一种凿岩钻头、设备的技术,应用在钻孔/钻孔设备、磨削/抛光设备、金属加工设备等方向,能够解决产生振动和噪音等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

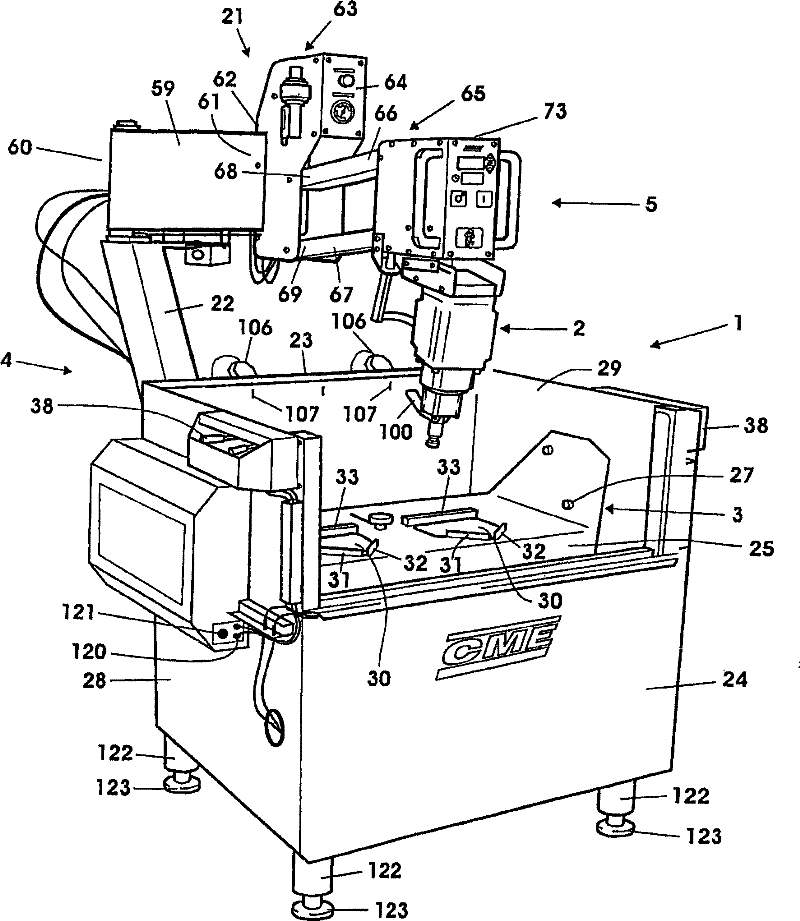

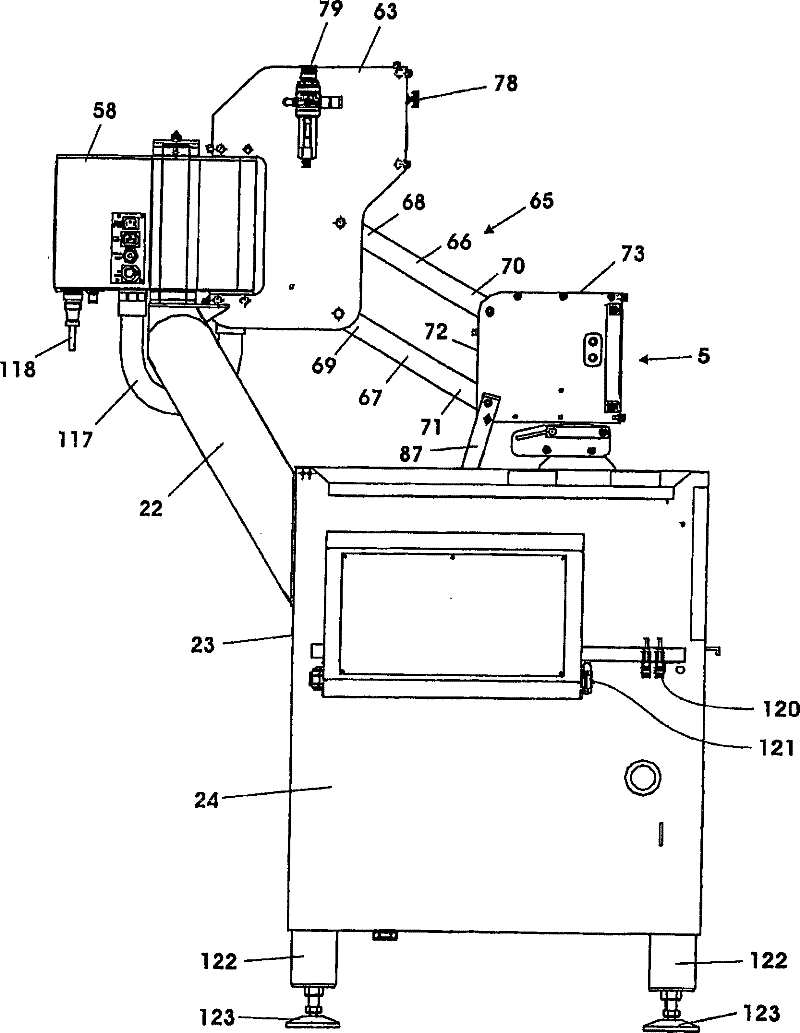

[0038] see figure 1 , 3 , 4, an embodiment of the grinding device according to the invention is generally designated by the reference numeral 1 in these figures. The grinding device 1 comprises: a grinding machine 2; means for holding one or more drill bits to be ground, generally designated by the reference number 3 in the figure; and a support system, generally designated by the reference number 4 . The grinder 2, the means for holding the bit 3, and the support system 4 are arranged to allow relative movement between the grinder 2 and the bit being ground, thereby allowing alignment of the grinder 2 with the longitudinal axis of the button on the bit . Preferably, the grinding apparatus 1 includes a control system having a programmable operator control panel 5 capable of monitoring and adjusting one or more operating parameters. The most concerned working parameters are selected from a set of working parameters, which include feed pressure, rotating speed of the grindin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com