Load bearing fabric assembly and method of making a load bearing fabric assembly

一种制造方法、组装件的技术,应用在化学仪器和方法、分层产品、家用元件等方向,能够解决粘结失败、织品松开或脱落等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

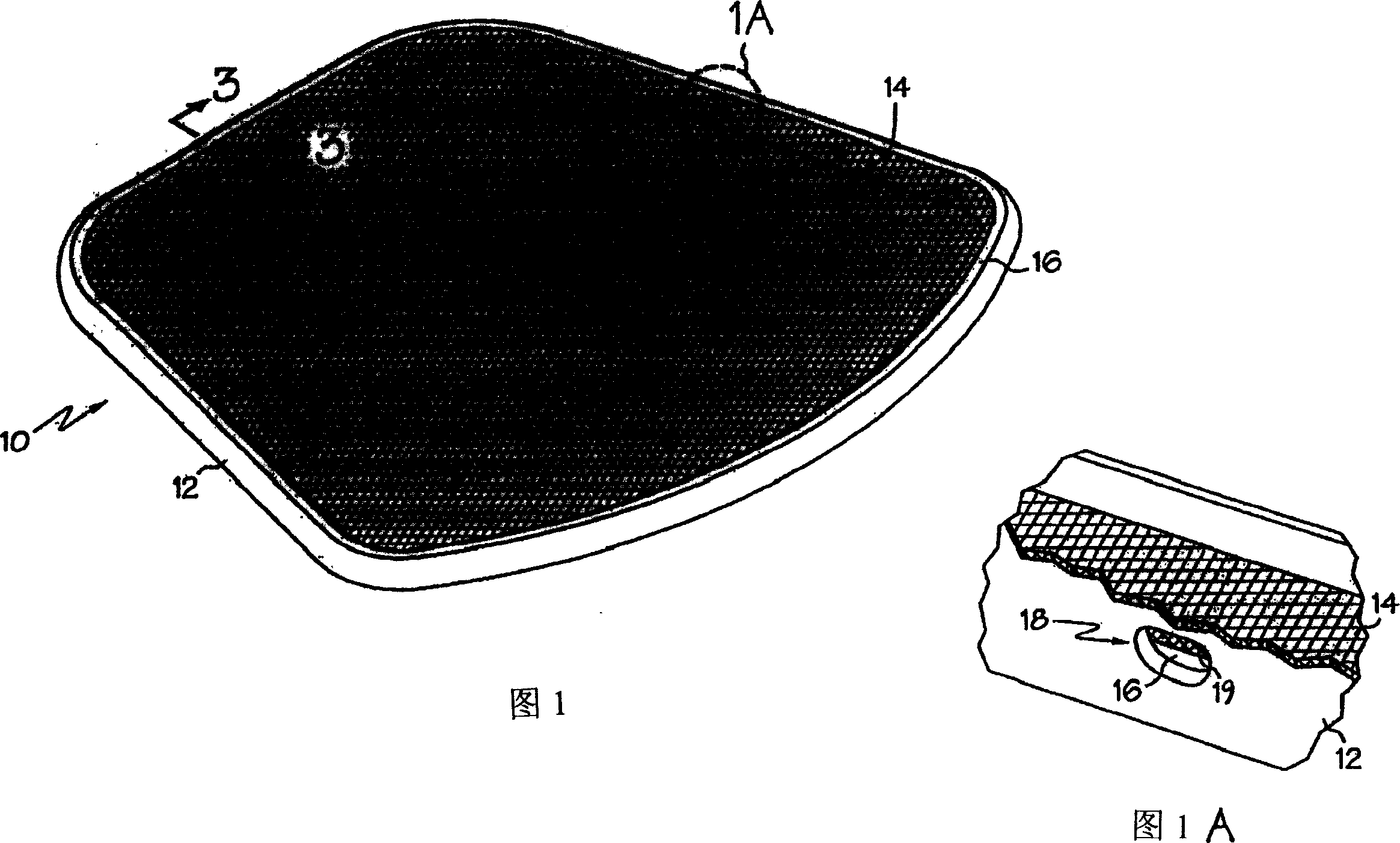

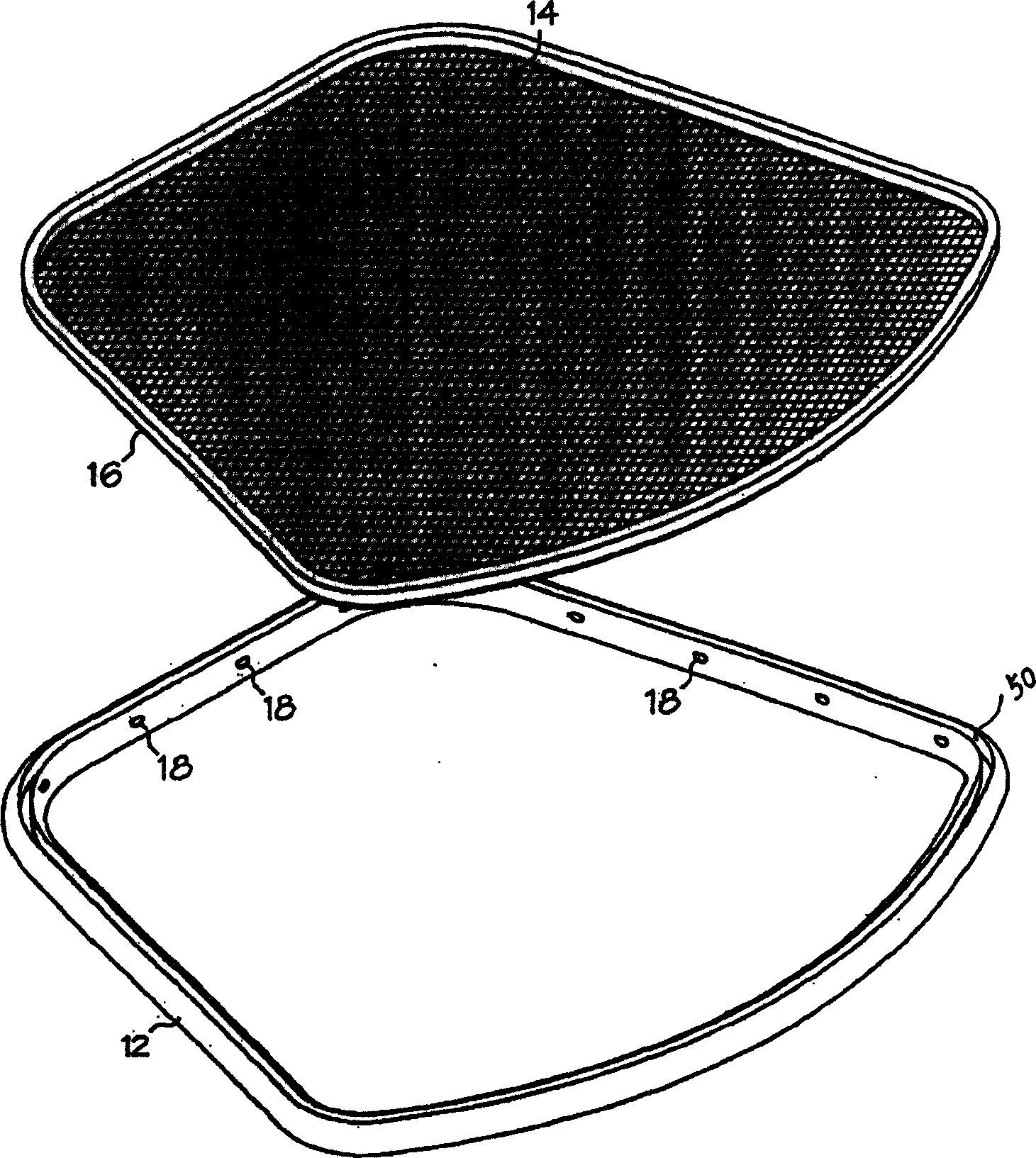

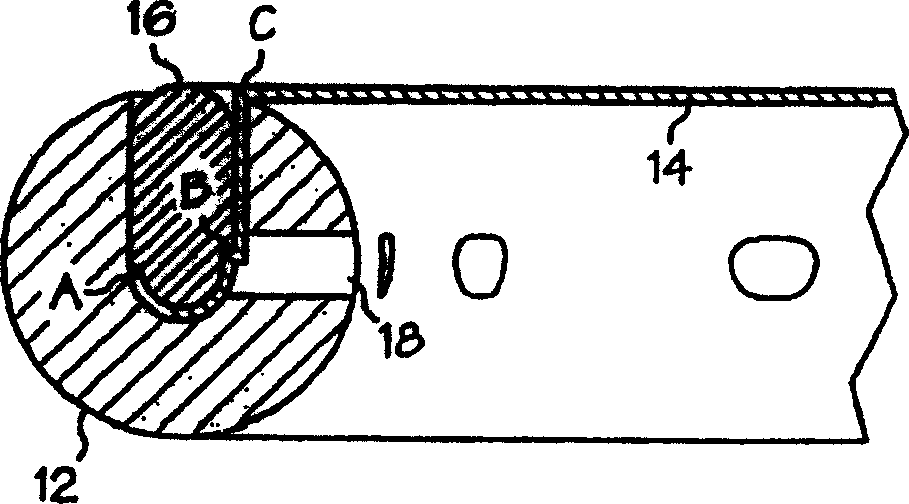

[0021] Figure 1 shows a load-bearing fabric assembly, generally designated 10, for use as a chair seat. The assembly 10 generally includes a carrier assembly 15 mounted to a frame 12 . Carrier assembly 15 includes load-bearing fabric 14 interconnected with a carrier 16 . The frame 12 defines a plurality of viewing windows 18 through which the connection of the carrier 16 and the load-bearing fabric 14 can be observed after the carrier assembly 15 is secured to the frame 12 . Although the invention has been described in connection with a chair seat assembly, the invention is equally applicable in a variety of applications associated with load bearing fabrics. For example, the present invention is applicable to shoe soles, mattresses, cots, wheelchairs, and various other bases.

[0022] As noted above, the load-bearing fabric assembly 10 generally includes a frame 12 , a carrier 16 and a load-bearing fabric 14 . The carrier 16 and the load-bearing fabric 14 are interconnected...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com