Paper tube cut type compressor package structure

A technology of packaging structure and compressor, which is applied in the directions of packaging food, transportation and packaging, and types of packaging items, and can solve the problems of reducing the degree of shrinkage of paper tube incisions, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] How to implement the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

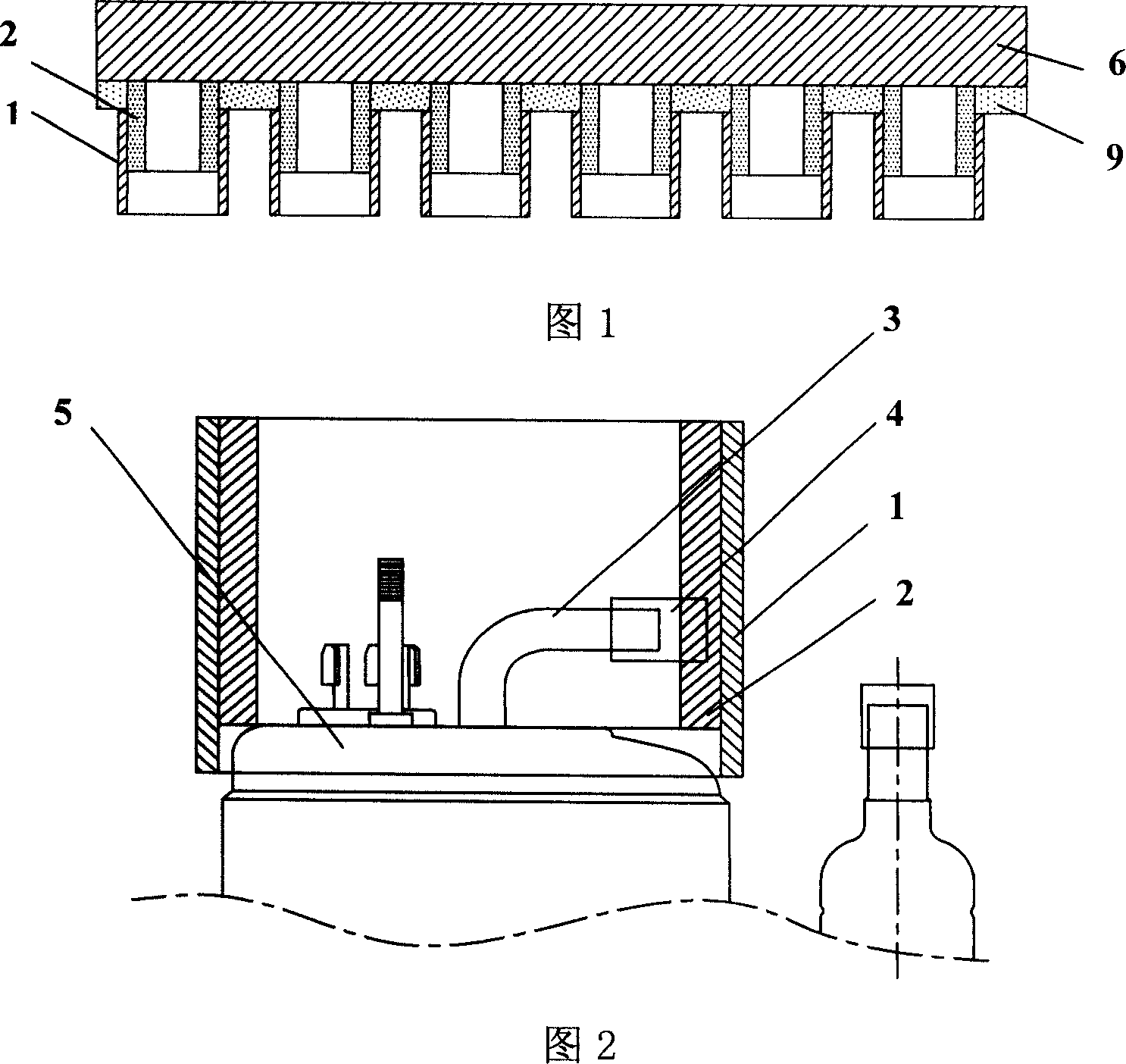

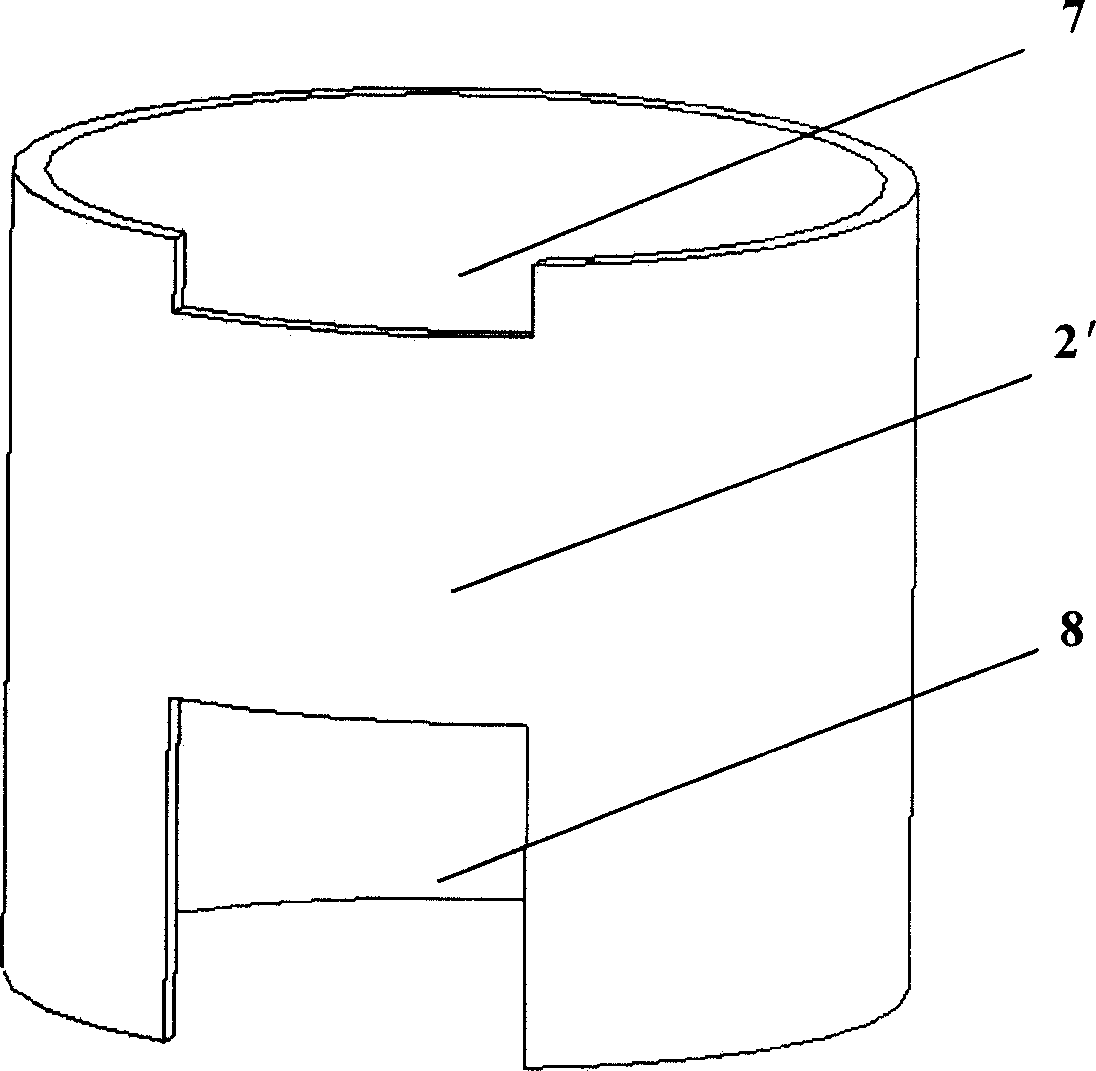

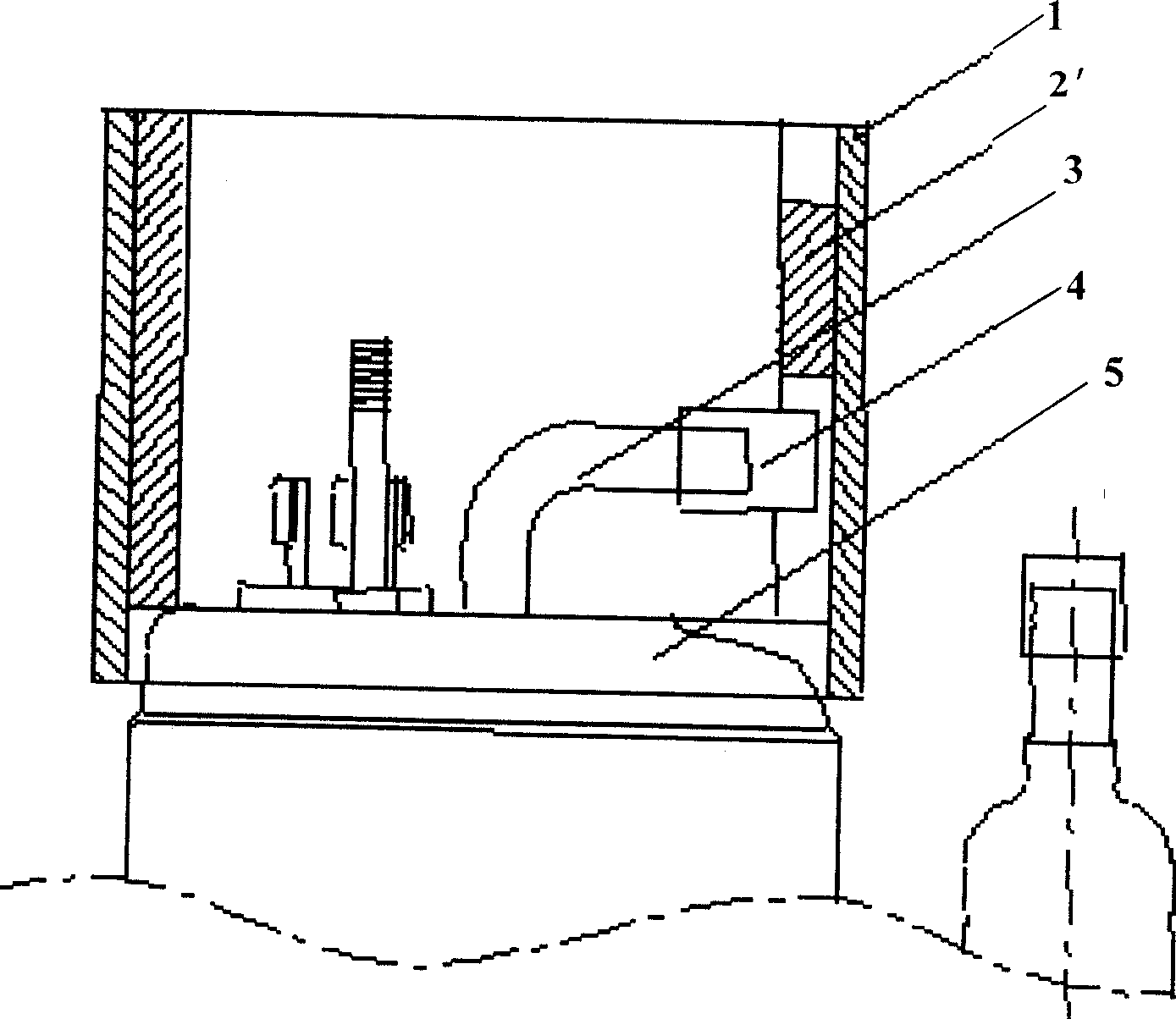

[0019] As shown in Figure 2, image 3 As shown, the packaging structure of the paper tube cut-out type compressor includes a middle layer of cardboard 6 for separating the upper and lower layers of the compressor. The middle layer of cardboard 6 is provided with a die-cut circle 10, and the lower part of the middle layer of cardboard 6 is bonded with a double-layer paper tube. The double-layer paper tubes are the outer paper tube 1 and the inner paper tube 2' that is glued in the outer paper tube 1 to support the upper compressor. One side of the inner paper tube 2' is correspondingly opened with positioning grooves forming an H shape. 7 and elbow groove 8.

[0020] The groove depth of the elbow groove 8 is greater than the groove depth of the positioning groove 7 .

[0021] The present invention digs and cuts an "H" type otch...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap