Partition plate structure of hermetic compressor

A compressor and isolation plate technology, which is applied in mechanical equipment, machines/engines, liquid fuel engines, etc., can solve problems such as impact noise, scratches, fluid leakage, etc., and achieve the effect of preventing impact noise and scratches

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

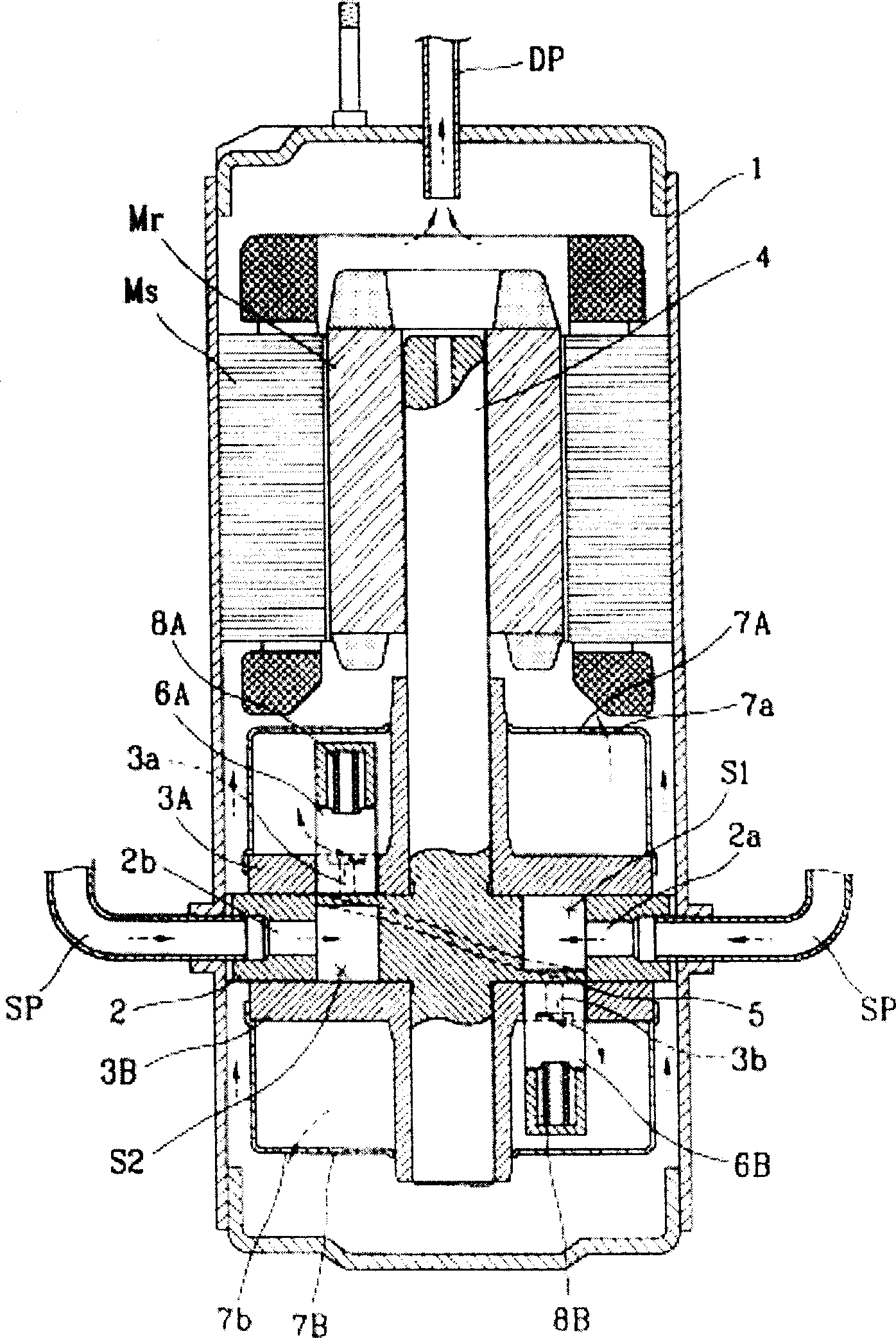

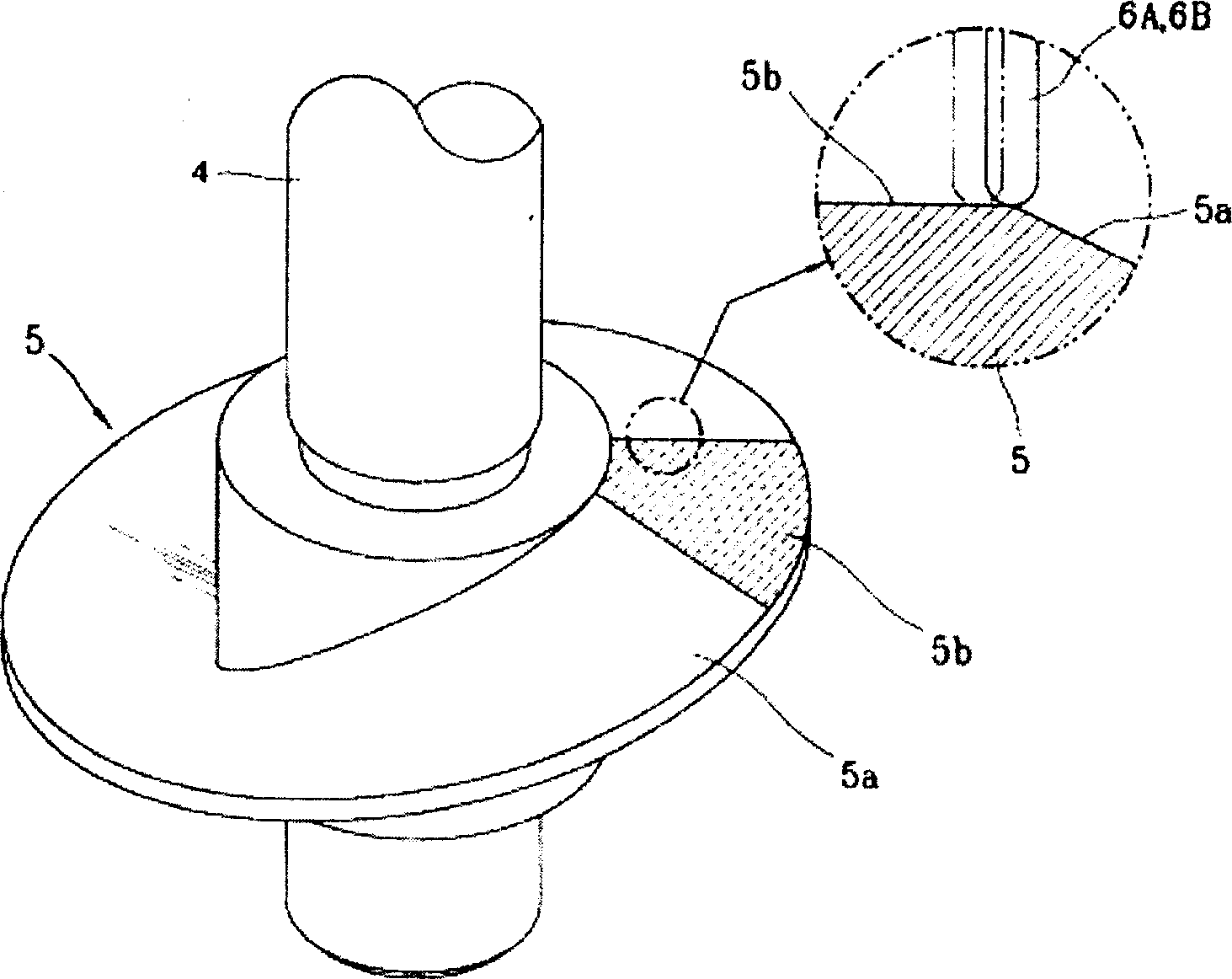

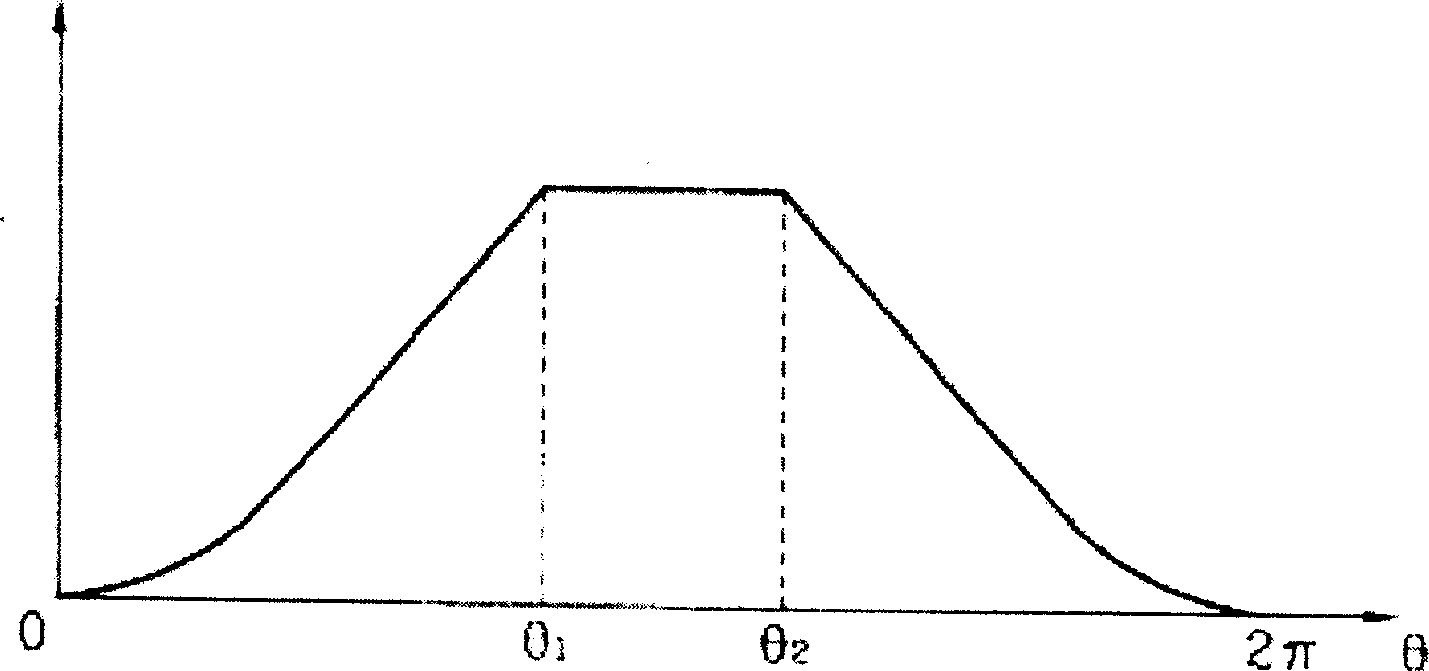

[0025] Hereinafter, the separator plate structure of the hermetic compressor of the present invention will be described in detail using the drawings, Figure 4 It is an oblique view showing the isolation plate of the hermetic compressor of the present invention, Figure 5 It is a schematic diagram showing the coordinate development of the cam surface of the separator plate of the hermetic compressor of the present invention.

[0026] As shown in the figure, the hermetic compressor equipped with the separator plate according to the present invention includes, fixed on the shell ( figure 1 Shown in) (1) The lower half of the cylinder ( figure 1 shown in) (2); the first bearing bracket ( figure 1 shown in )(3A) and the 2nd bearing bracket ( figure 1 shown in) (3B); connected with the rotor (Mr) of the motor mechanism part and connected with each bearing bracket (3A, 3B) at the same time, the rotating shaft (4) that transmits the power of the motor mechanism part to the compres...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com